CT 스캔에 직접적인 기계적 시뮬레이션

복셀 데이터에서 직접 작업하여 쉽게 처리할 수 있는 유한 요소(FE)시뮬레이션:

- 유향 힘,토크 및 압력 사이를 선택하여 정적 기계적 로딩에 적용하는 데 사용할 수 있습니다

- 선형 탄성 재질 속성을 지닌 단일 및 다중 재질 모두에 대해 재질 프로브뿐만 아니라 구성요소를 시뮬레이션하는 데 사용할 수 있습니다

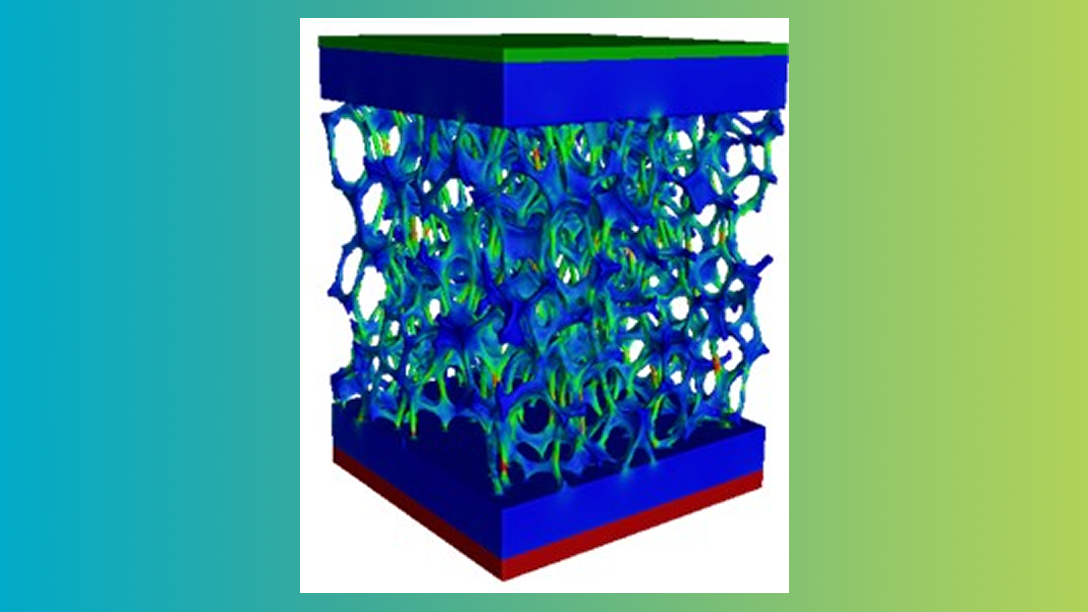

- 마이크로 공극률의 폼 또는 구성요소뿐만 아니라 생체역학적 구조와 같은 매우 복잡한 구조에서도 시뮬레이션 모델을 구축하는 것이 매우 간단해집니다

- 서브복셀 정확도,로컬 적응형 표면 결정을 활용합니다

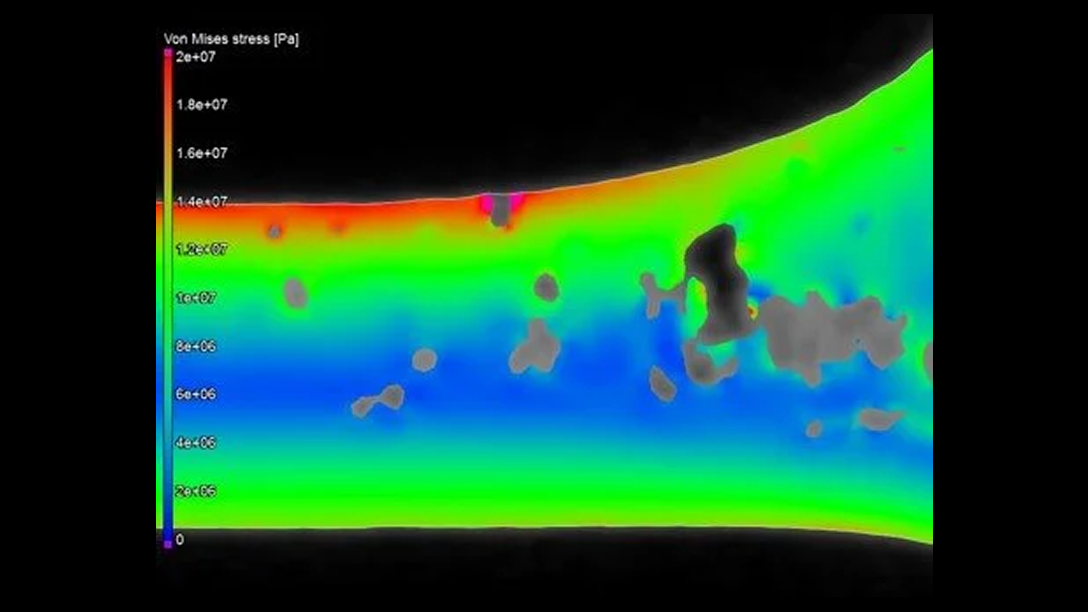

- 한 번의 클릭으로 VGSTUDIO MAX의 모든 알고리즘을 사용해서 공극률 분석 실행 결과를 통합하여 마이크로결함 주변의 응력 농도를 계산합니다

- 분할부터 단일 소프트웨어 내의 구조적인 시뮬레이션까지의 원활한 작업 흐름을 제공합니다

결과

실제 구성요소 스캔에서 직접 결과 보기:

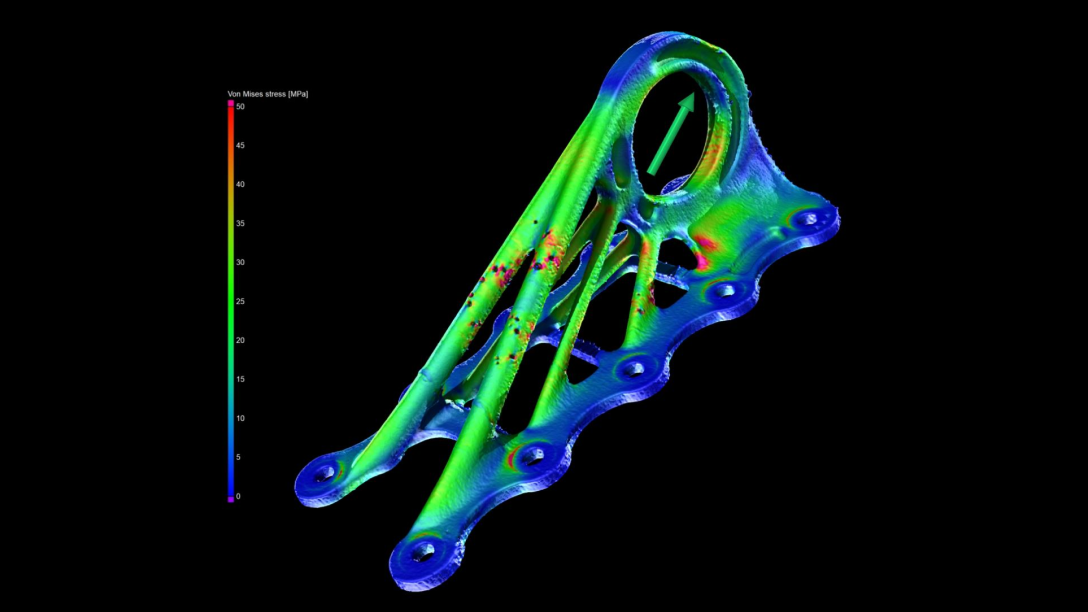

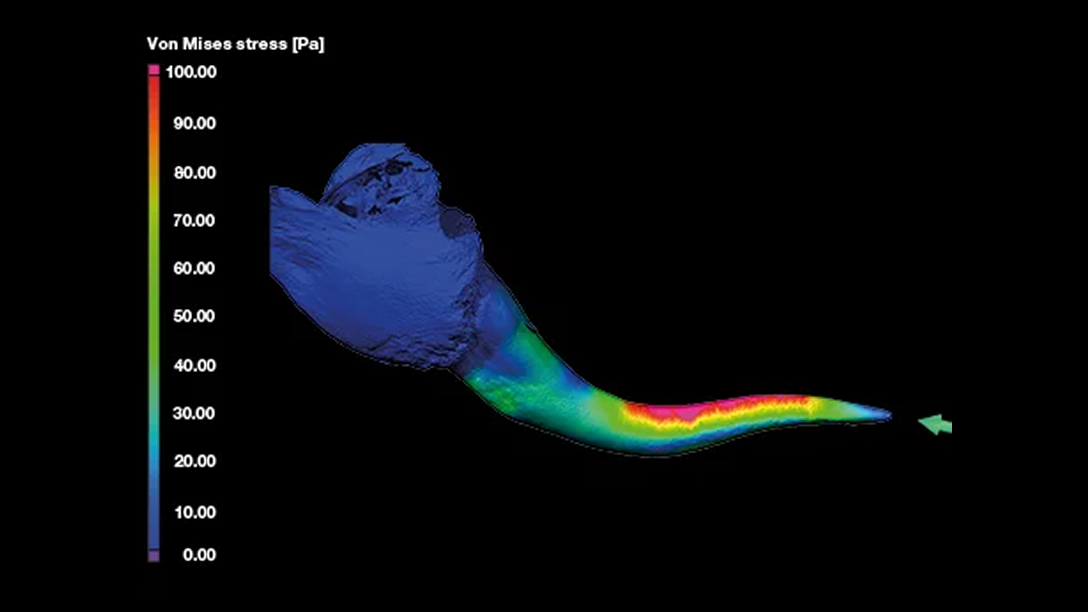

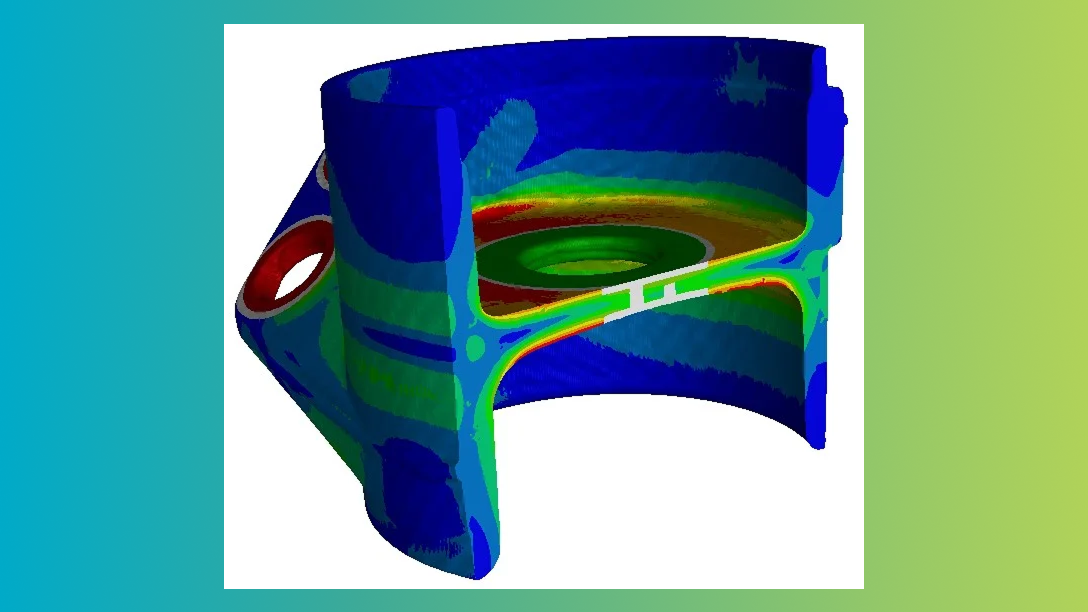

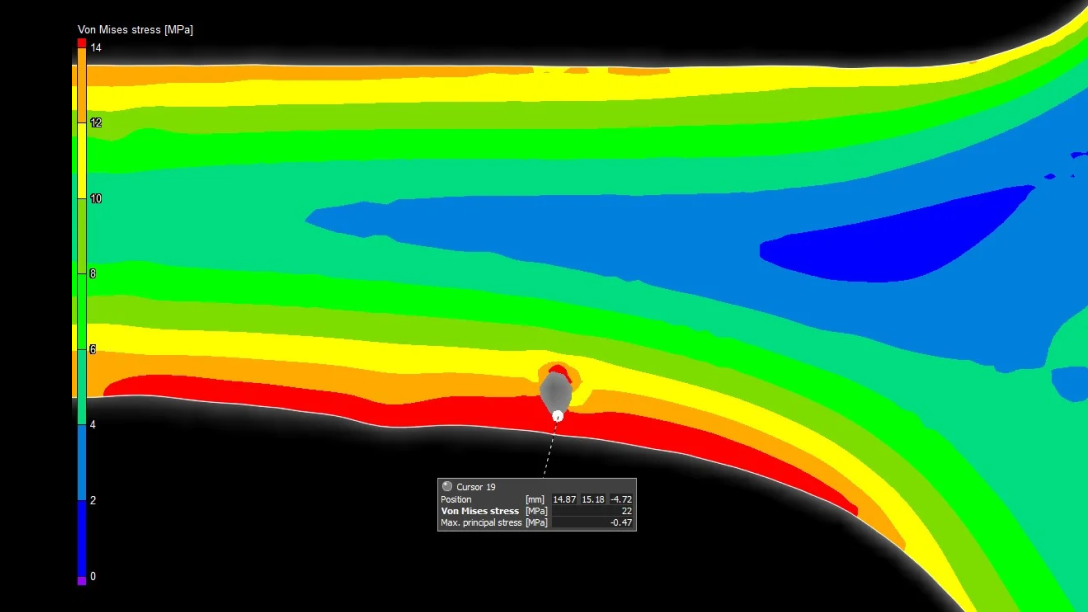

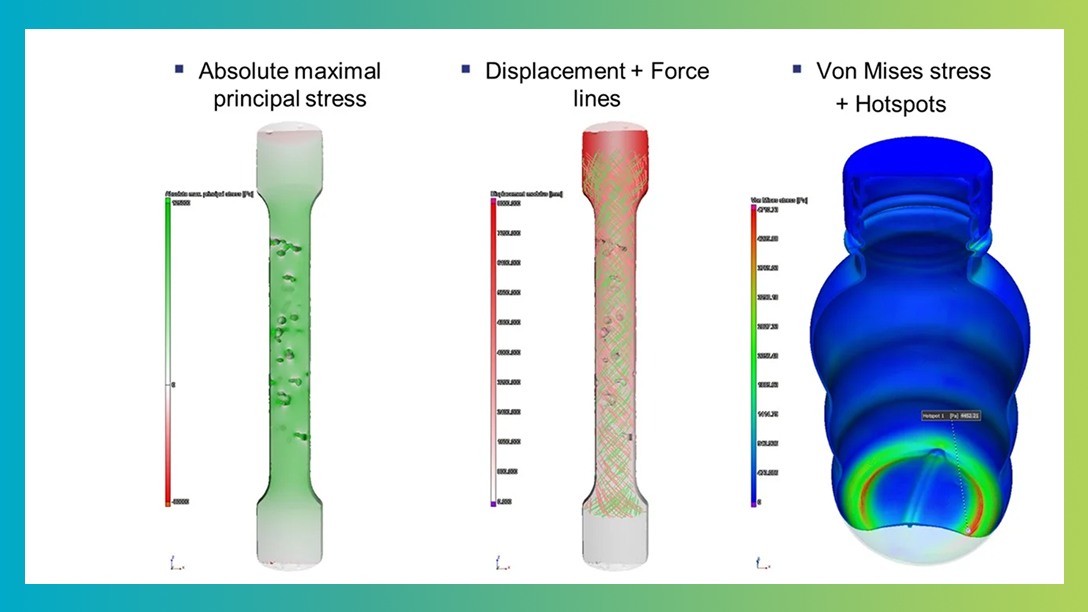

- 플라스틱 수율 한계 평가 또는 파열 위험 추정을 위해 폰 미제스 응력 및 변형율뿐만 아니라 최대 주요 응력을 계산하고 시각화합니다.

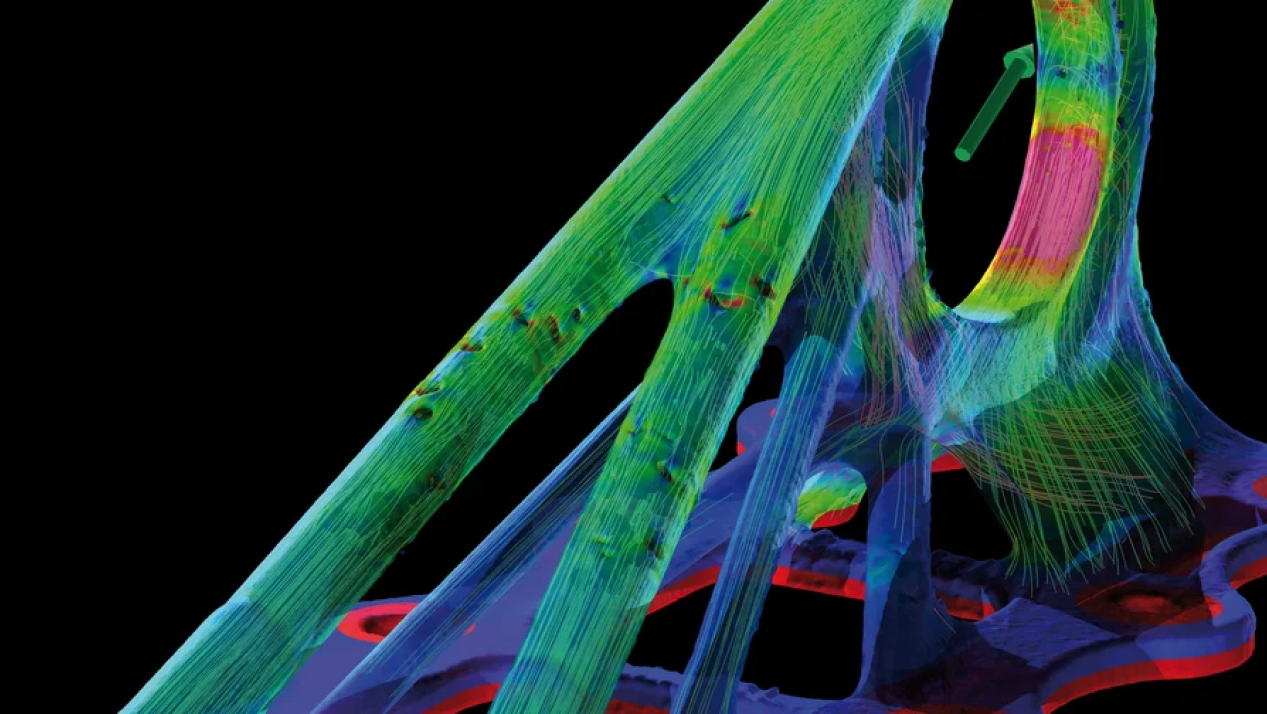

- 해당 고유 백터의 크기에 해당하는 길이로 응력 텐서의 고유 벡터 방향을 설명하는 힘선으로서의 응력 텐서 필드를 시각화합니다.

- 계산된 볼륨에서 각 점의 변위 크기와 색상 코드를 표시하여 계산된 변형을 시각화합니다.

핫스팟에서의 응력 농도

부품에서 중요하게 로드된 영억 식별:

- 폰 미제스 응력의 로컬 최대값,최대 전단 응력 및 최대 주요 응력을 검출하고 시각화하고 변위의 크기를 검출합니다.

- 선택된 응력 구성요소 또는 변위가 특정 임계값을 초과하는 연결 영역을 식별하고 시각화합니다.

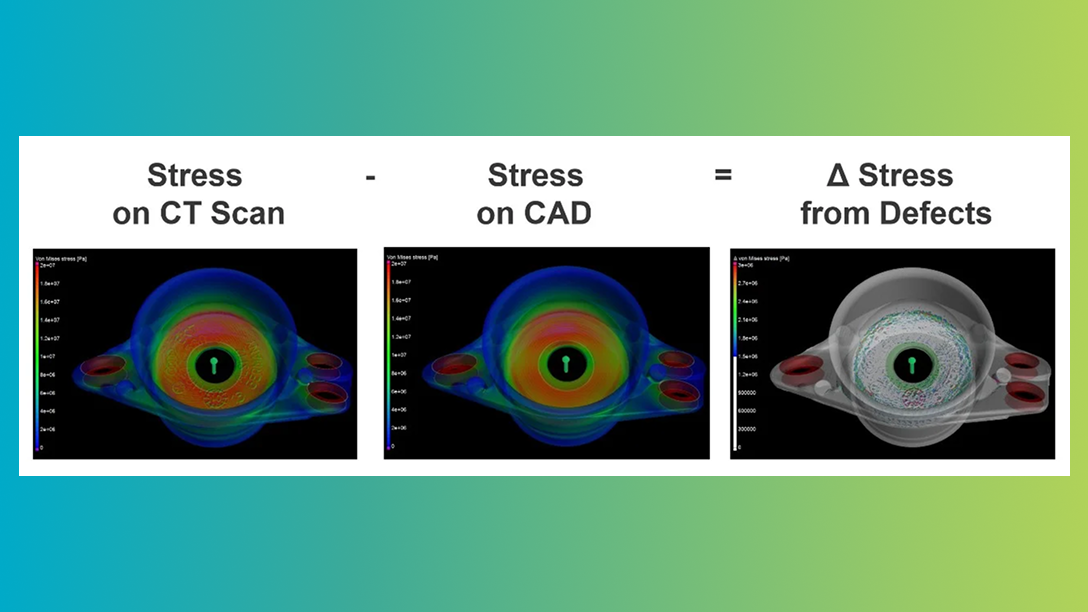

CAD 기반 시뮬레이션과의 비교

해당 CAD 모델에서 시뮬레이션이 있는 실제 부품의 CT 데이터를 기반으로 시뮬레이션 결과 비교:

- 불연속성 및 형태 편차가 있는 CAD 모델과 실제 부품을 둘 다 시뮬레이션합니다.

- 폰 미제스 응력,최대 주요 응력,최대 전단 응력 또는 변위의 크기를 포함한 동일하거나 유사한 객체에 대해 두 가지 시뮬레이션 결과를 자동으로 비교합니다.

- 각 구조 점에 대한 값의 차이를 계산하고 부품의 색상 코드 결과를 시각화합니다.

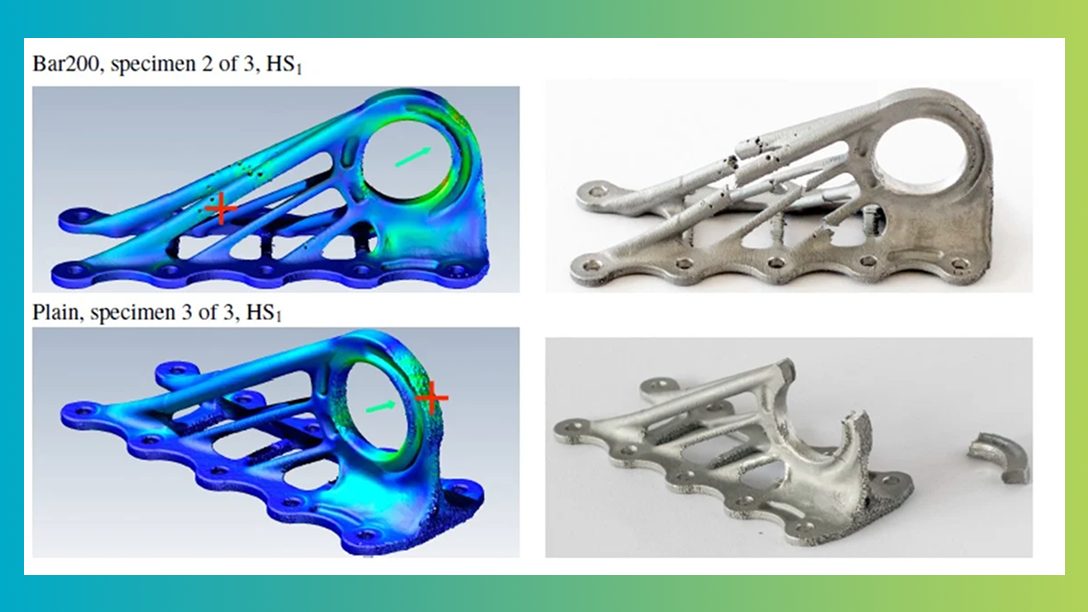

검증된 결과

구조 역학 시뮬레이션 모듈 내 시뮬레이션 방법은 기존의 유한 요소 분석 결과가 수치적으로 검증되어 좋은 일치도를 보였습니다.또한 구조적 구성요소에서 오류가 발생할 가능성이 가장 높은 위치를 식별할 수 있는 능력이 있는 것으로 나타난 물리적 테스트에서 실험적으로 검증되었습니다.(Predicting Failure in Additively Manufactured Parts Using X-Ray Computed Tomography and Simulation, Peer Reviewed Paper, 7th International Conference on Fatigue Design 2017)