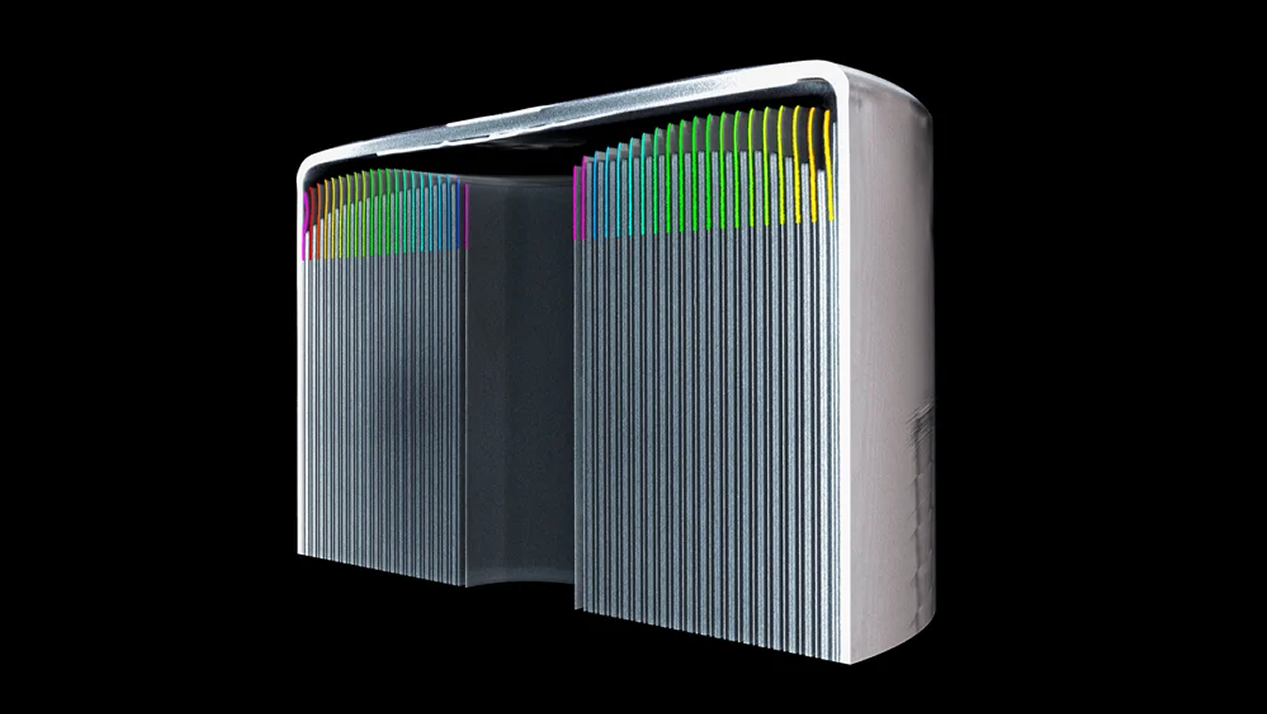

Learn how CT can be utilised to evaluate battery cells non-destructively. Our Battery Analysis Module offers advanced, precise measurements of the anode overhang, accurate tolerancing of electrode shape and ordering, and seamless automation of all functions.

Analyse anode overhang

Ensuring an optimal anode overhang is key for the performance and lifespan of lithium batteries. Our Battery Anode Overhang Analysis allows you to measure the anode overhang in an easy and intuitive way.

- Measure the anode overhang for each electrode with unparalleled accuracy.

- Visualize a color overlay or display numeric results in a table.

- Assess the anode overhang for the adjacent cathode on the right or left.

- Measure the overhang along the anode contour or a straight projection.

- Evaluate global measures, such as the distance from the highest cathode to the lowest anode.

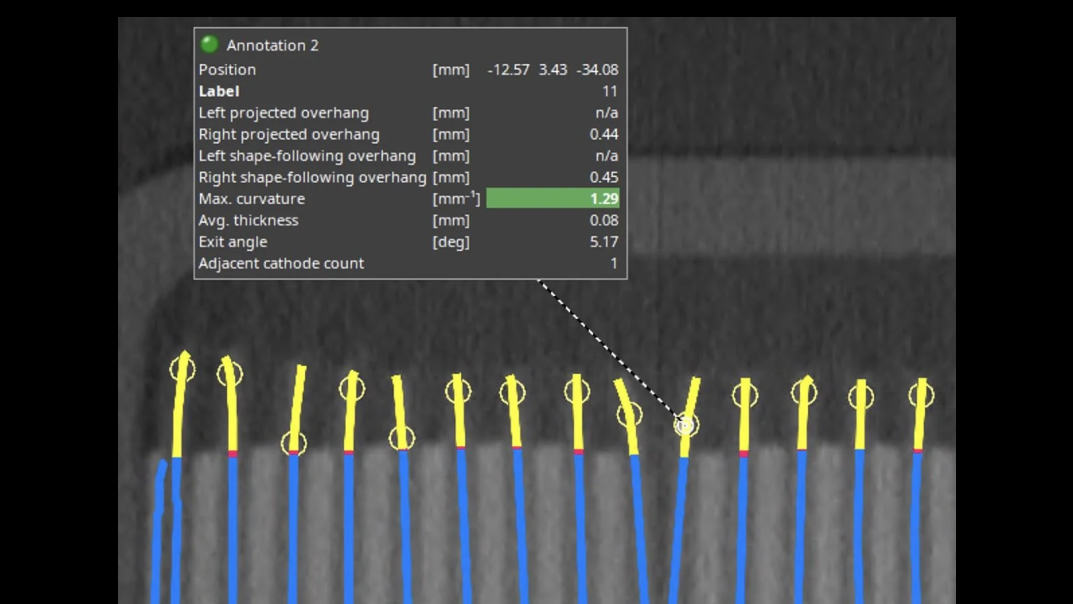

Analyse anode shape

Extreme bending of the anode sheets can cause delamination or cracks in the active material. The Battery Analysis module offers practical tools to analyse anode shape.

- Visualise the shape of the anode as a spline curve.

- Locate the point of maximum curvature for each anode separately.

- Measure the exit angle for each anode.

- Visualise the level of local curvature as a color overlay.

- Set a tolerance for the curvature to detect sharp bends.

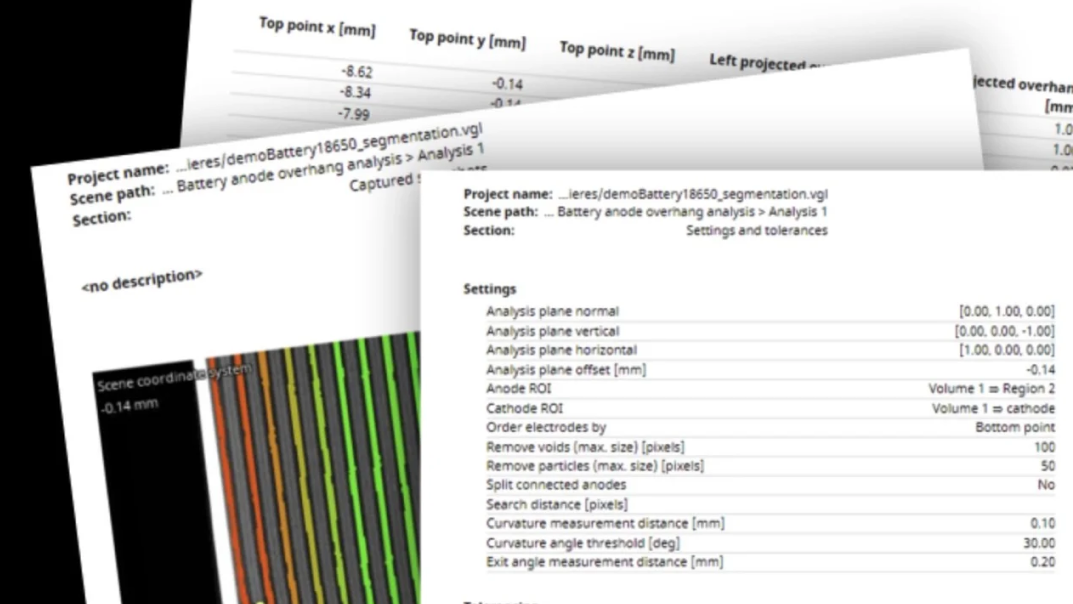

Automation and reporting

The Battery Anode Overhang Analysis integrates seamlessly with the powerful automation framework and reporting capabilities of VGSTUDIO MAX.

- Record your battery analysis as a macro and apply it to new data sets without any manual interaction.

- Create meaningful, concise reports for presenting and archiving the analysis results.

- The Battery Analysis module is compatible with our fully automatic VGinLINE solution.

Tolerancing and annotations

Streamline your analysis with precise evaluation and visualization features:

- All analysis results can be assigned a tolerance to automatically make a pass/fail decision.

- Use the evaluation capabilities of VGSTUDIO MAX to combine tolerances of several analysis results into a global decision.

- Place visual annotations in the scene to highlight specific findings.

- Automatically create annotations based on conditions you define.

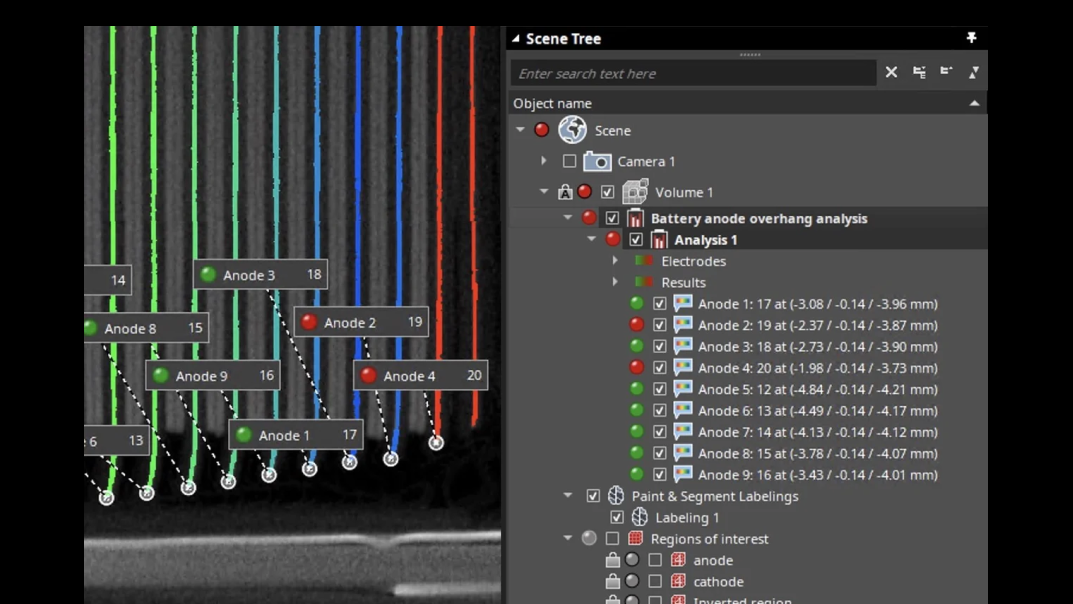

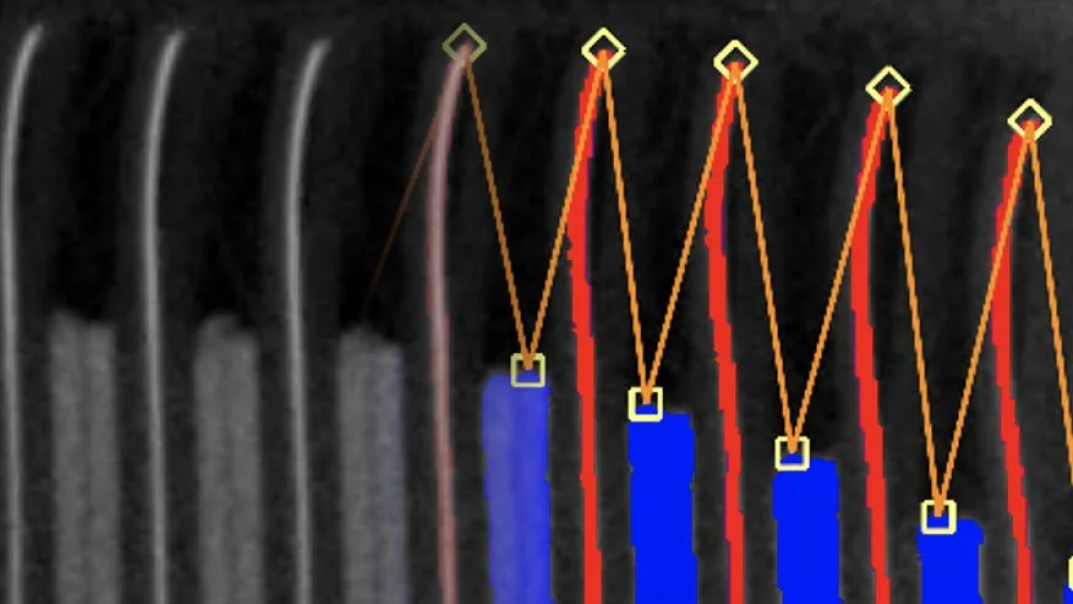

Verify segmentation and correct electrode sequence

The Battery Anode Overhang Analysis relies on a user-provided segmentation of the anodes and cathodes. Try out our machine learning-based Paint & Segment tool or use your preferred method to create the segmentation. The Battery Anode Overhang Analysis offers a range of functions to detect segmentation failures, either through visual inspection or by automated plausibility checks.

- Verify that the total number of electrodes matches the expected value.

- Perform other plausibility checks, such as whether two cathodes neighbor most anodes.

- Use "zig-zag" line visualisation to verify the correct segmentation of the electrode tips at a single glance.

- Supports state-of-the-art segmentation methods like Paint & Segment

- Handles all battery types

- Covers a wide range of scan qualities

- Produces myriad results ranging from classic anode overhang to curvature and bending detection

- Checks and modifies the segmentation if needed

- Integrates seamlessly in an inline system

- Creates results you can easily check using reports and VGinLINE APPROVER

Contact us today—our team is ready to assist!

Request a quote