“VG is really the best on the market. What I love most about VG is the versatility, from failure analysis and metrology to defect analysis and stress strain analysis. Awesome, versatile, incredibly efficient, and well-engineered.”

Ensure quality in every production run

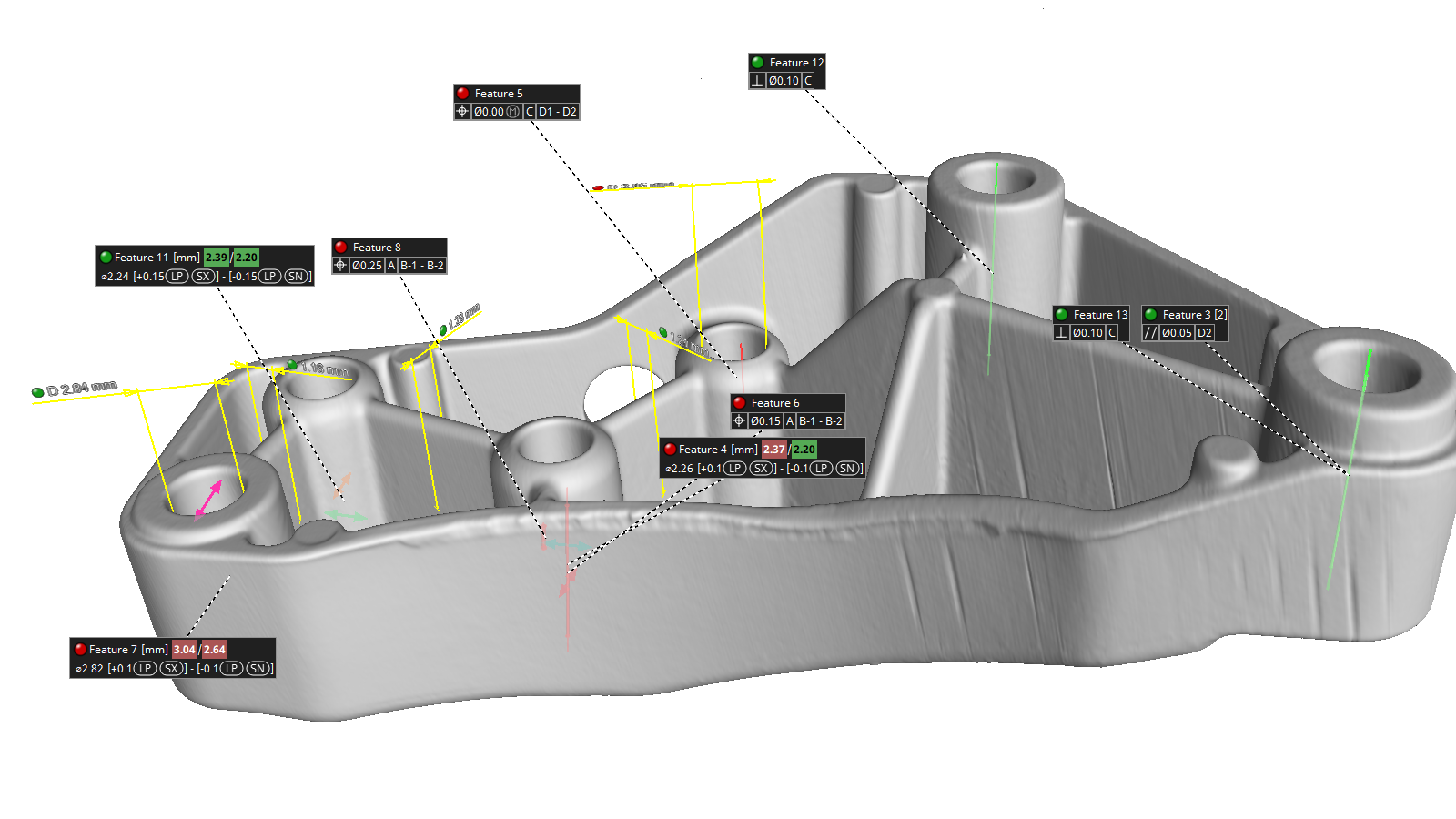

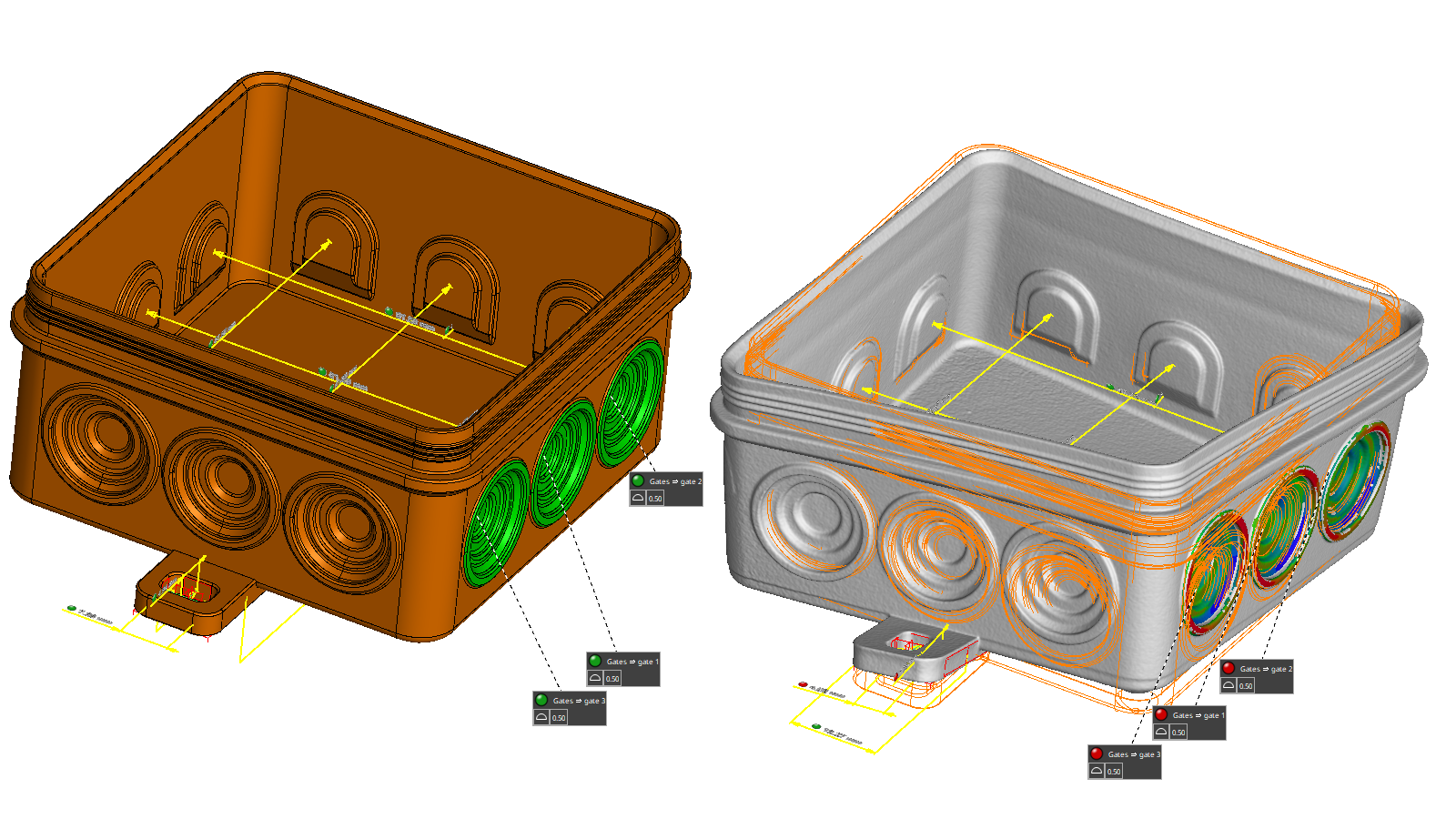

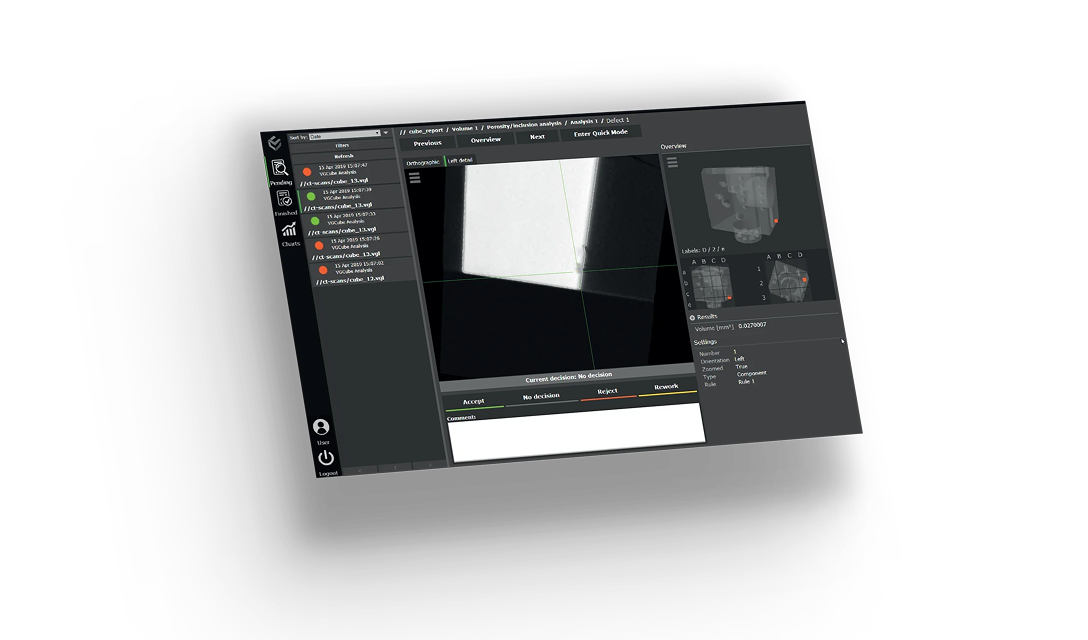

Utilise advanced analyses to maintain high precision and quality. Identify porosity, fibre misalignment, sink marks, and warpage before production failures occur.

Invest in quality at the right stage

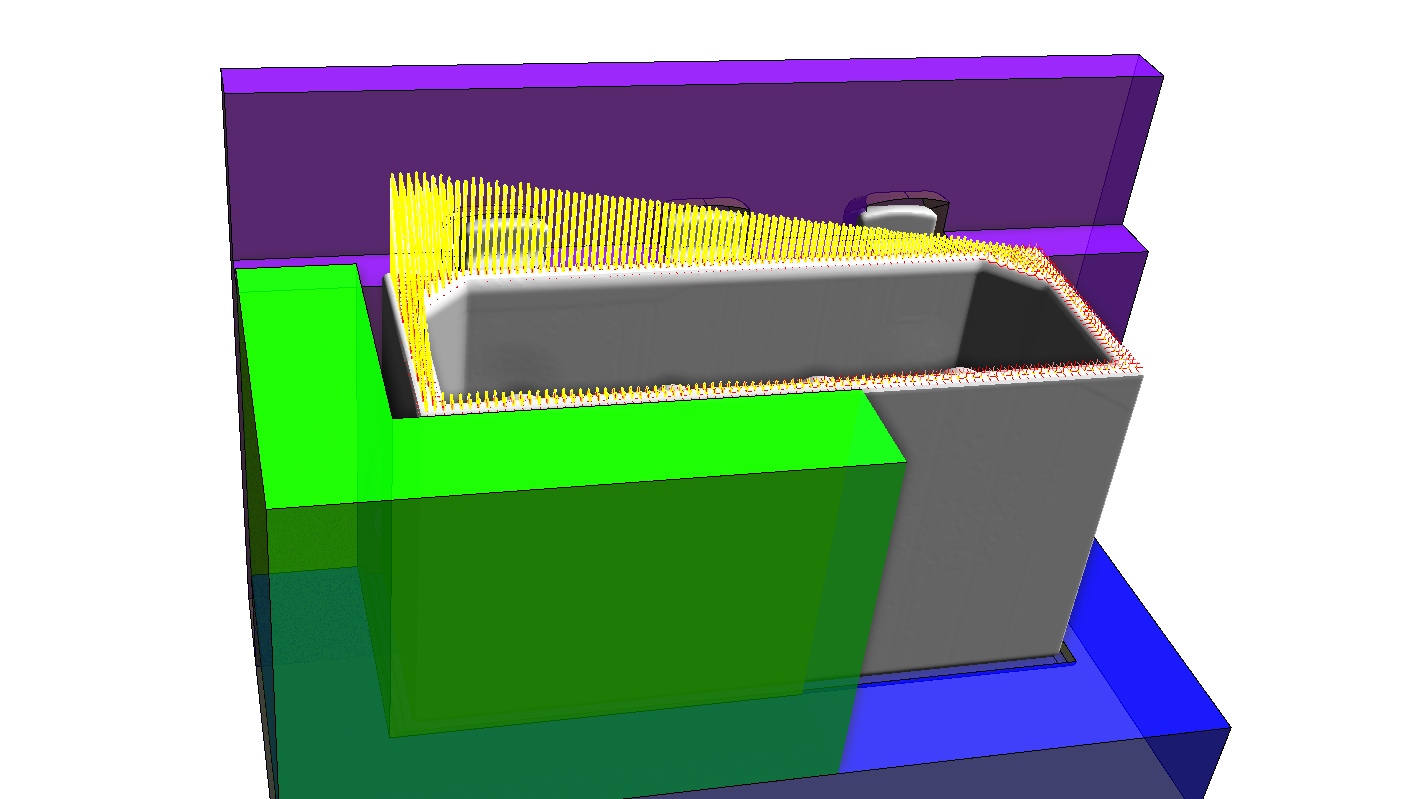

Lower your running costs on fixtures and their qualification by applying VG’s Fixture Simulation module in R&D and quality control.

Make multiple iterations a thing of the past

Advanced software capabilities enable you to use scan data of manufactured parts to optimise your mould designs. Validate tooling and compensate for shrinkage, warpage, and material flow inconsistencies.

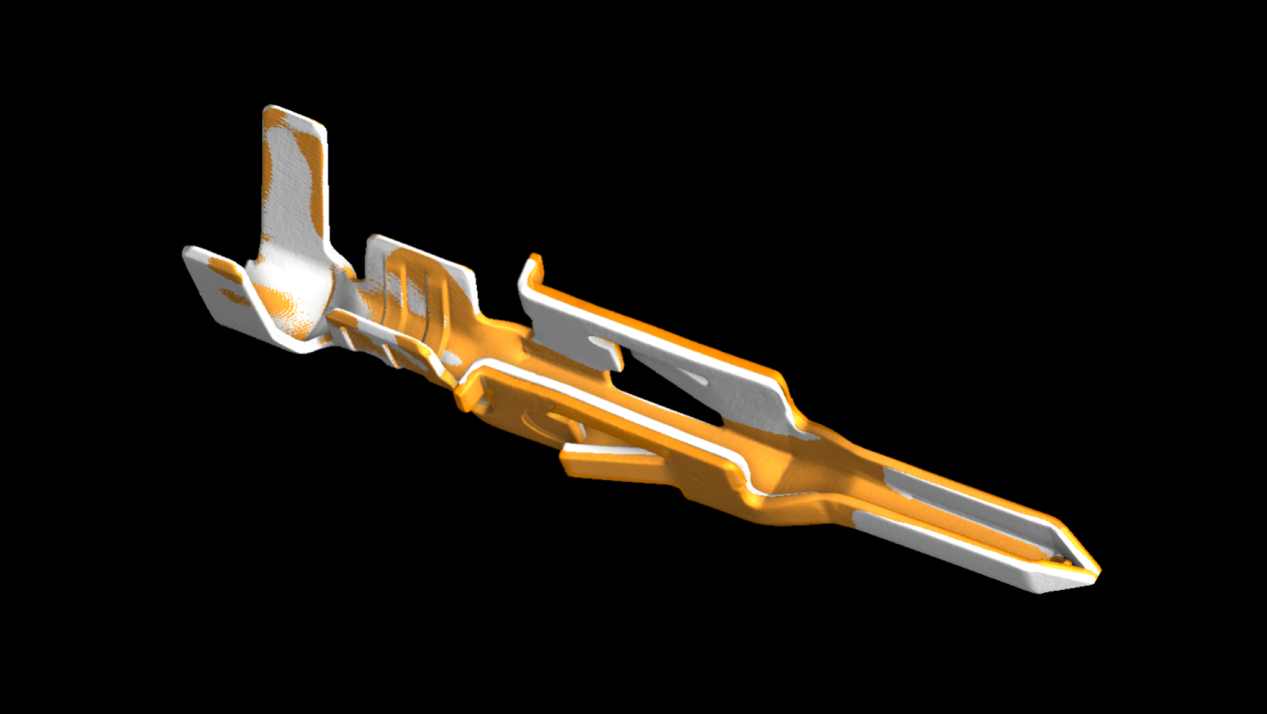

Conquer increased complexity, tight tolerances, and zero-defect production. These are some of the typical inspection tasks you can complete with our software solutions.

Get your free, 4-week trial license and see why we're the industry’s first and longest-trusted CT analysis software.

Request free trial