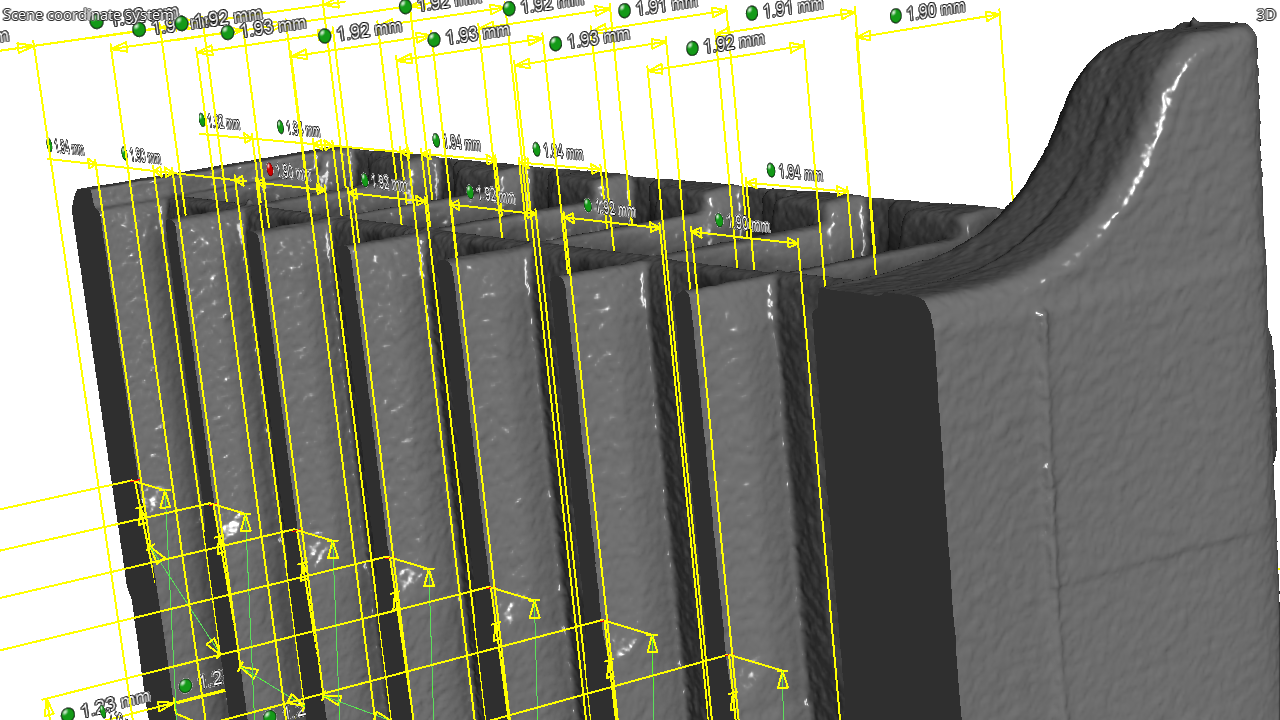

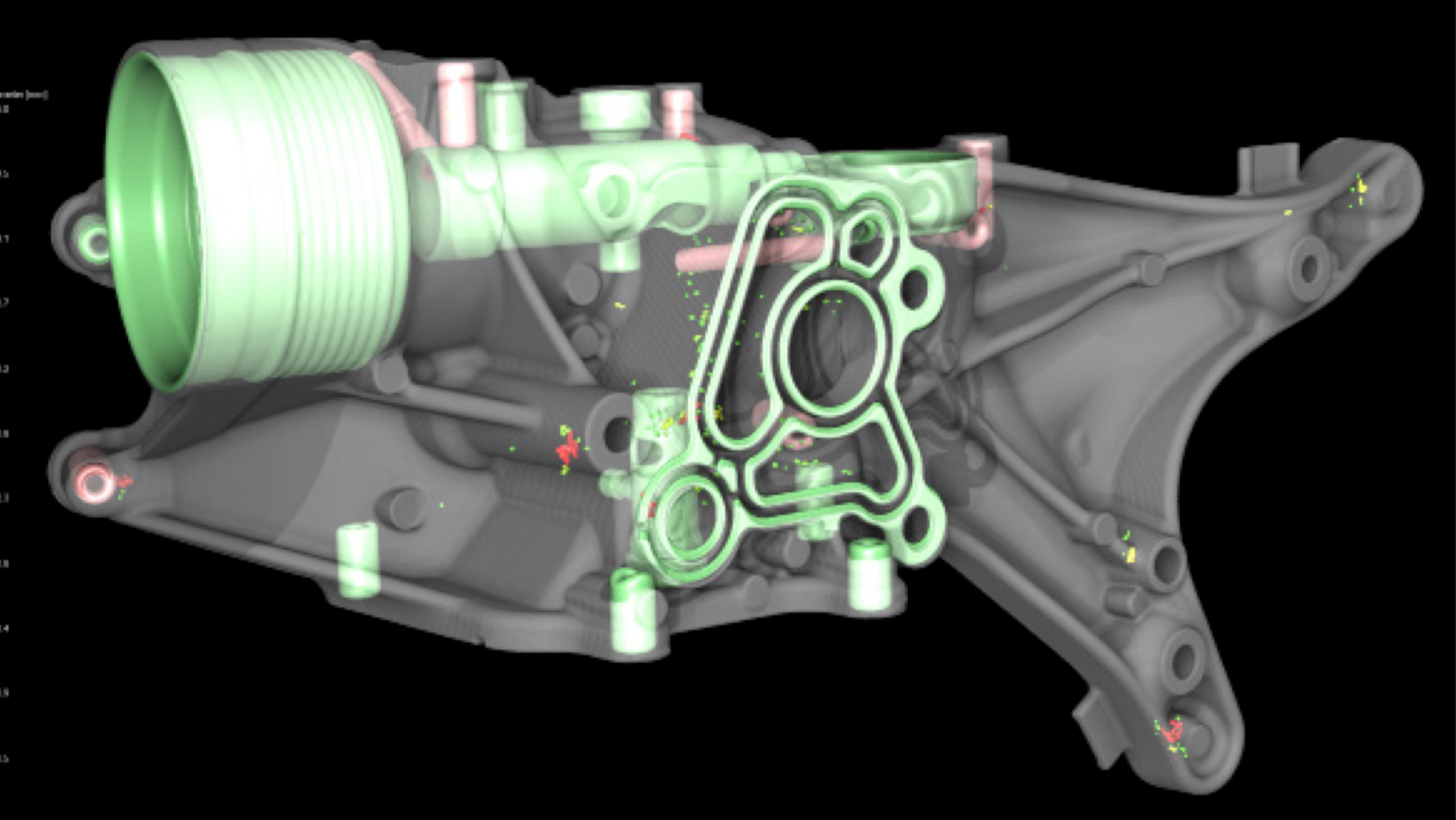

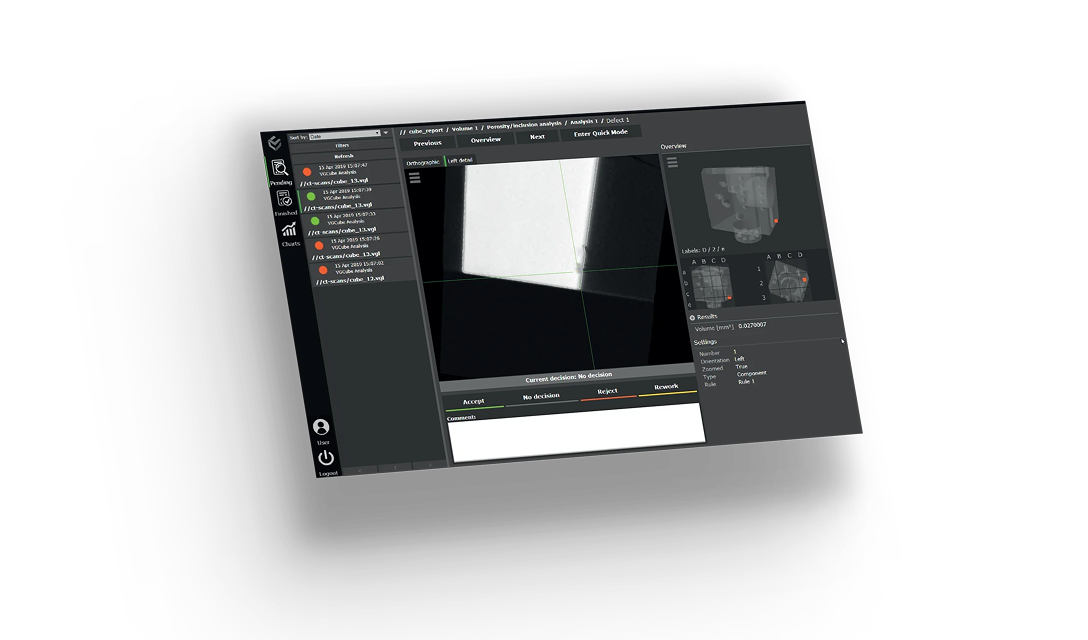

“For the kind of advanced data processing software that would deliver the metrology results our customers were asking for, we found our way to Hexagon’s VGSTUDIO MAX and VGinLINE. Everyone was aware of VG software; it was, and is, the standard in CT software.”

Achieve comprehensive quality assurance

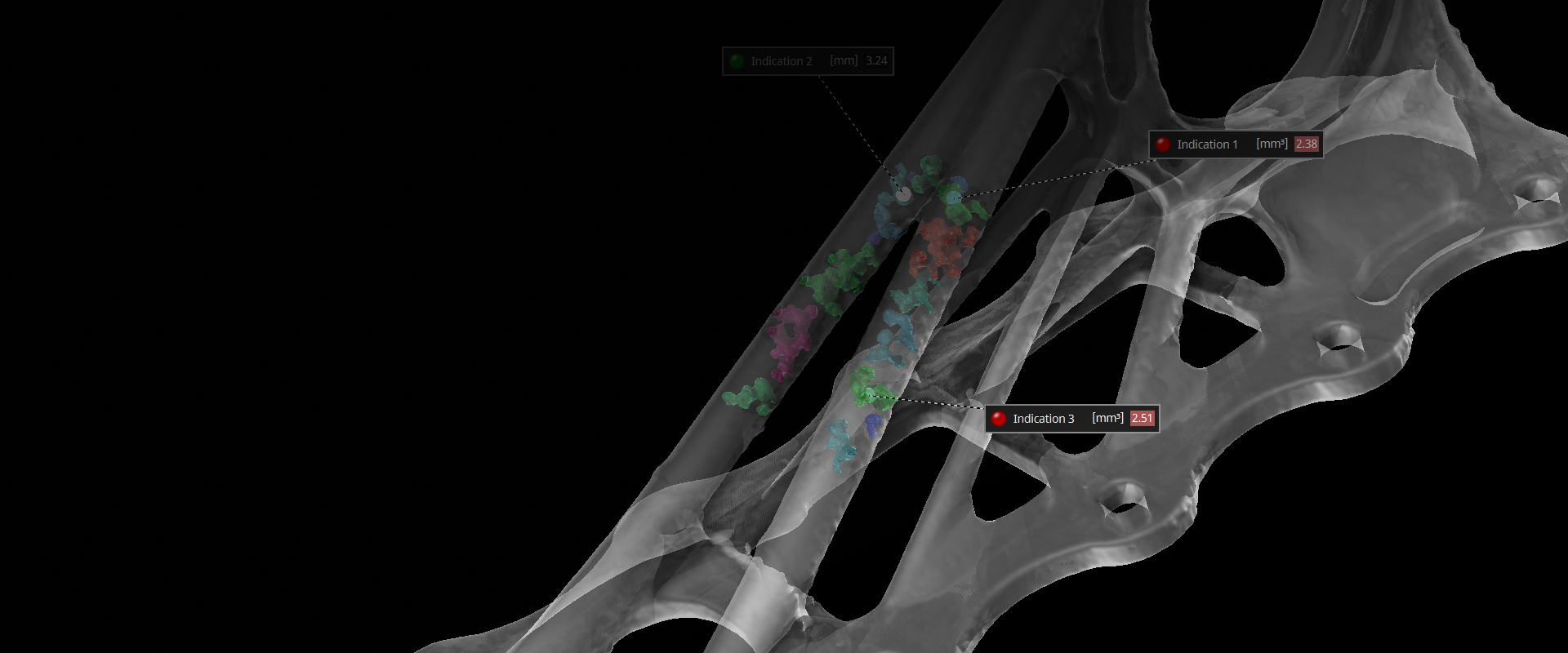

Utilise advanced inspection and analysis tools to detect potential safety issues early in the design and manufacturing process.

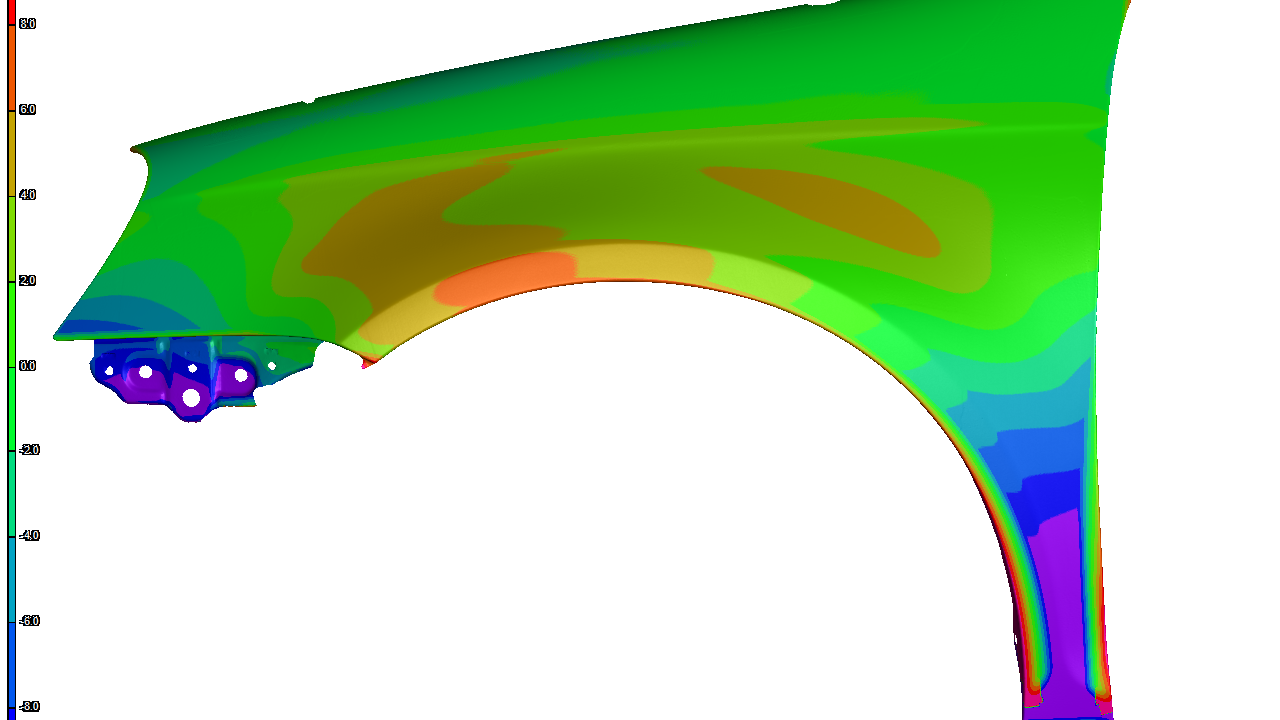

Optimise part design

Implement simulation and testing technologies to develop lightweight, efficient components that reduce emissions and fuel consumption.

Streamline production processes

Leverage digital twins and virtual prototyping to speed up product development cycles and reduce time-to-market.

Lead confidently, ensuring quality, minimising waste, and accelerating production. These are some of the typical inspection tasks you can complete with our software solutions.

Get your free, 4-week trial license and see why we're the industry’s first and longest-trusted CT analysis software.

Request free trial