“We are already users of VG software for analysing and visualising CT data. With the Volume Meshing module, we can now quickly create high-quality volume meshes from CT data. It's easy to use and delivers convincing results in no time.”

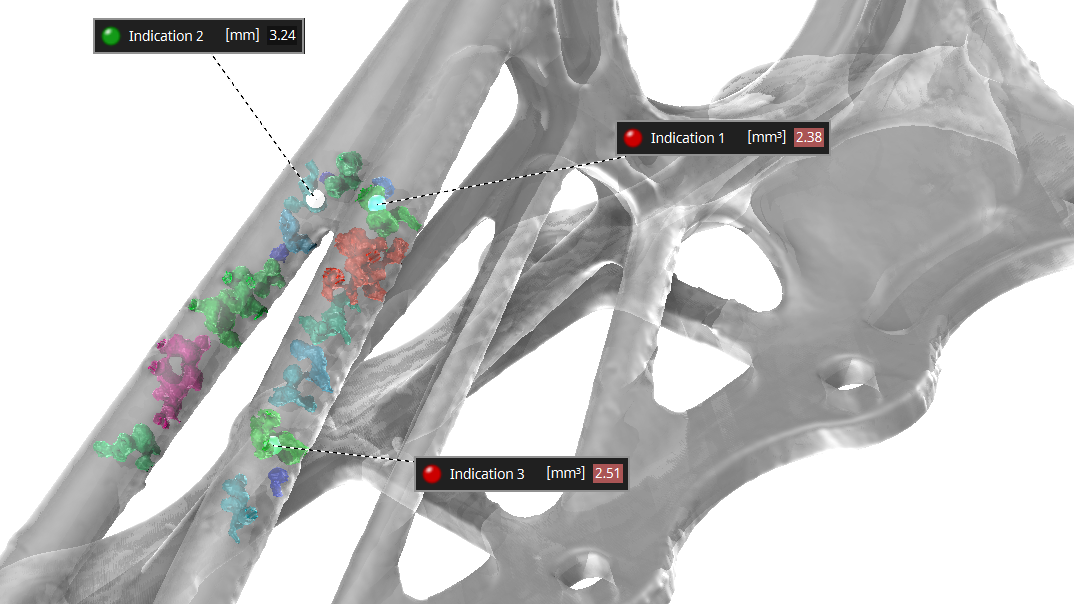

Meet "zero-defect" standards

Safety-critical requirements leave no room for error. VG software delivers precise and reliable inspection data, featuring automation features that minimise risk and reduce human error.

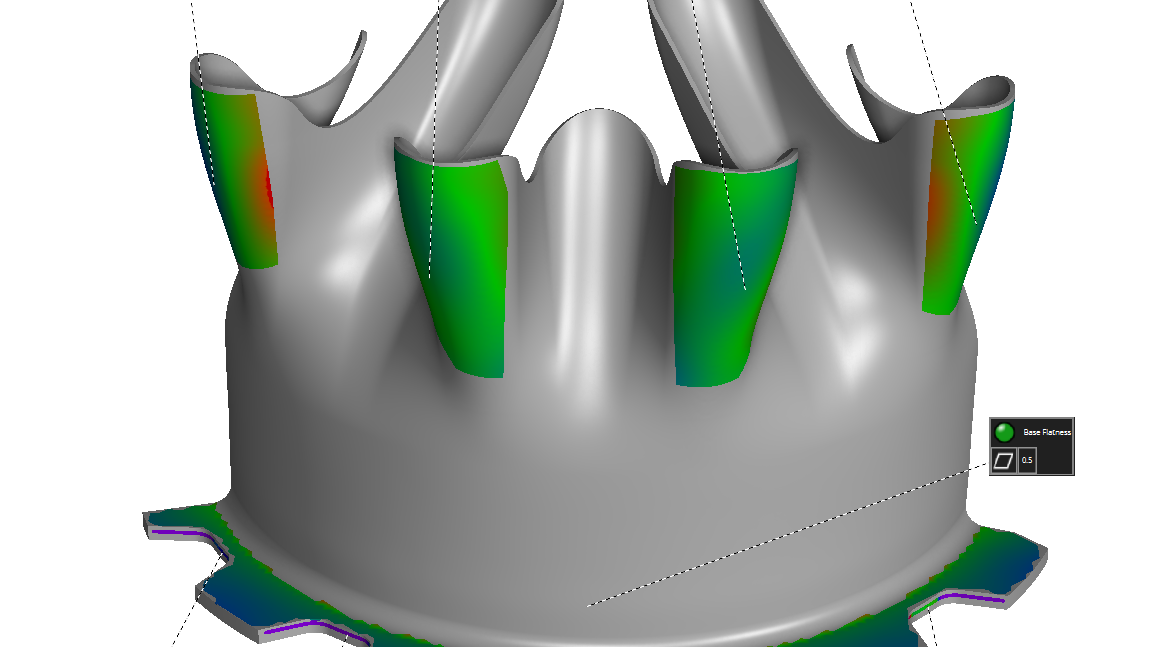

Achieve precision metrology

Gain a holistic view of part quality, reduce iterations, and get it right the first time with holistic inspection insights and automation, maximising output while cutting costs.

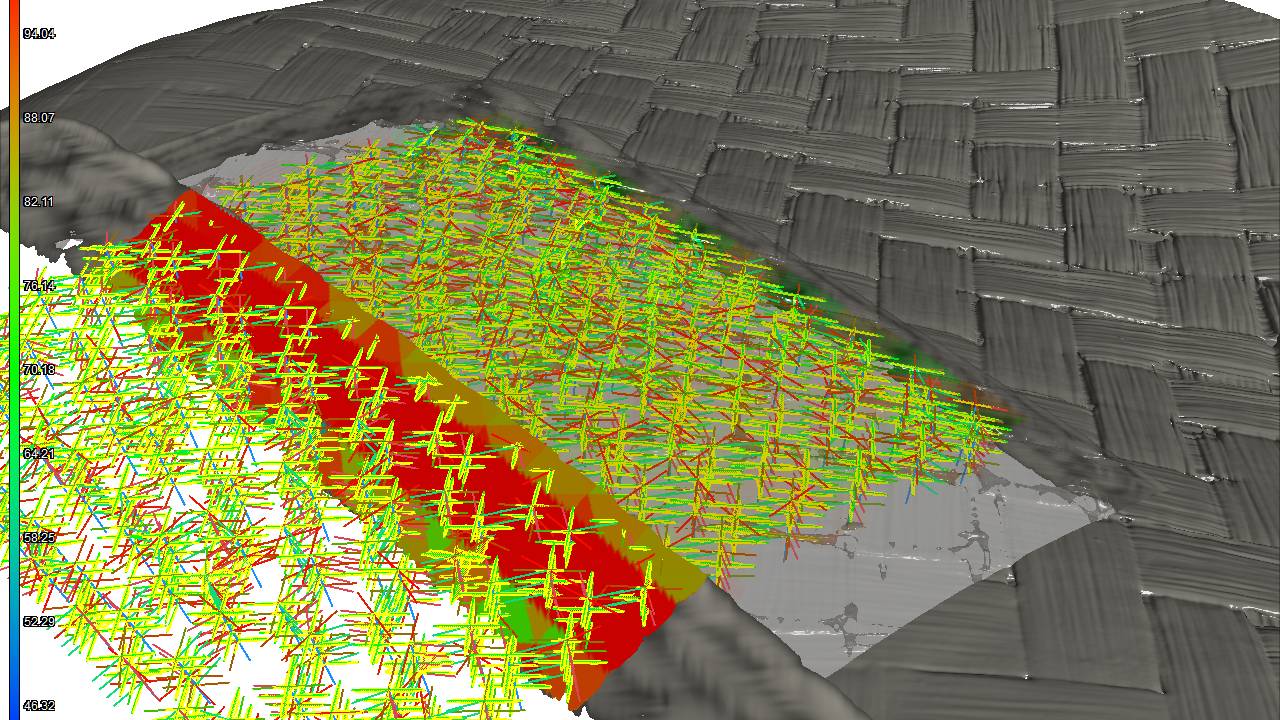

Validate performance

Merge reliable insights into real-world parts with powerful simulation capabilities to drive innovation in aircraft design and production, resulting in weight savings, reduced noise pollution, and decreased fuel consumption.

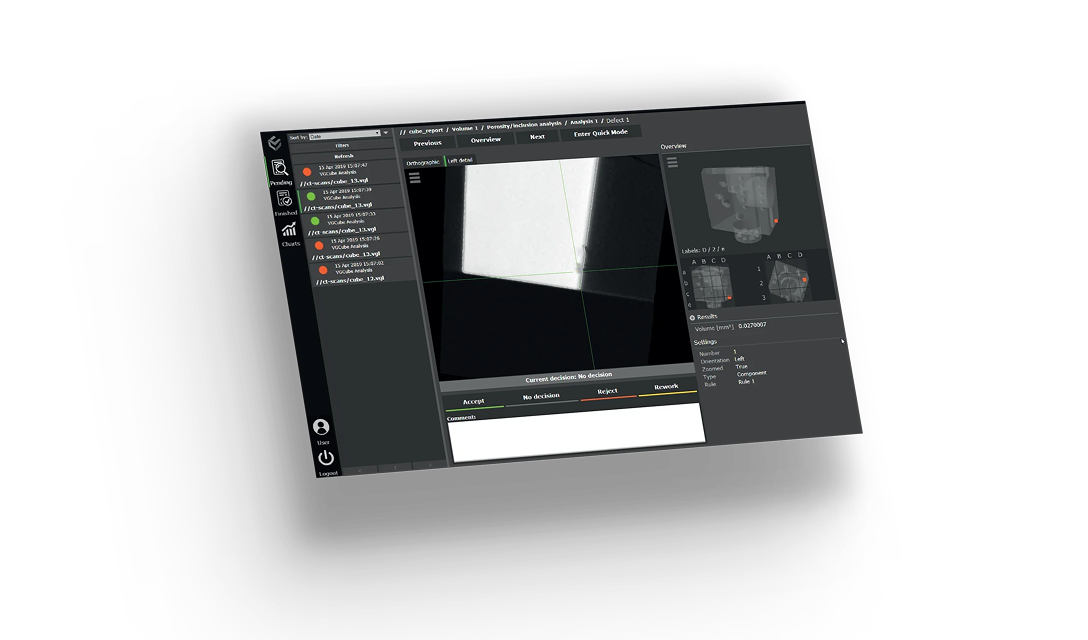

Keep your parts safe, efficient, and ahead of the competition. These are some of the typical inspection tasks you can complete with our software solutions.

Get your free, 4-week trial license and see why we're the industry’s first and longest-trusted CT analysis software.

Request free trial