“We can meet today’s challenges successfully because we have the competence and the right tools. VG products allow us to tackle all of them.”

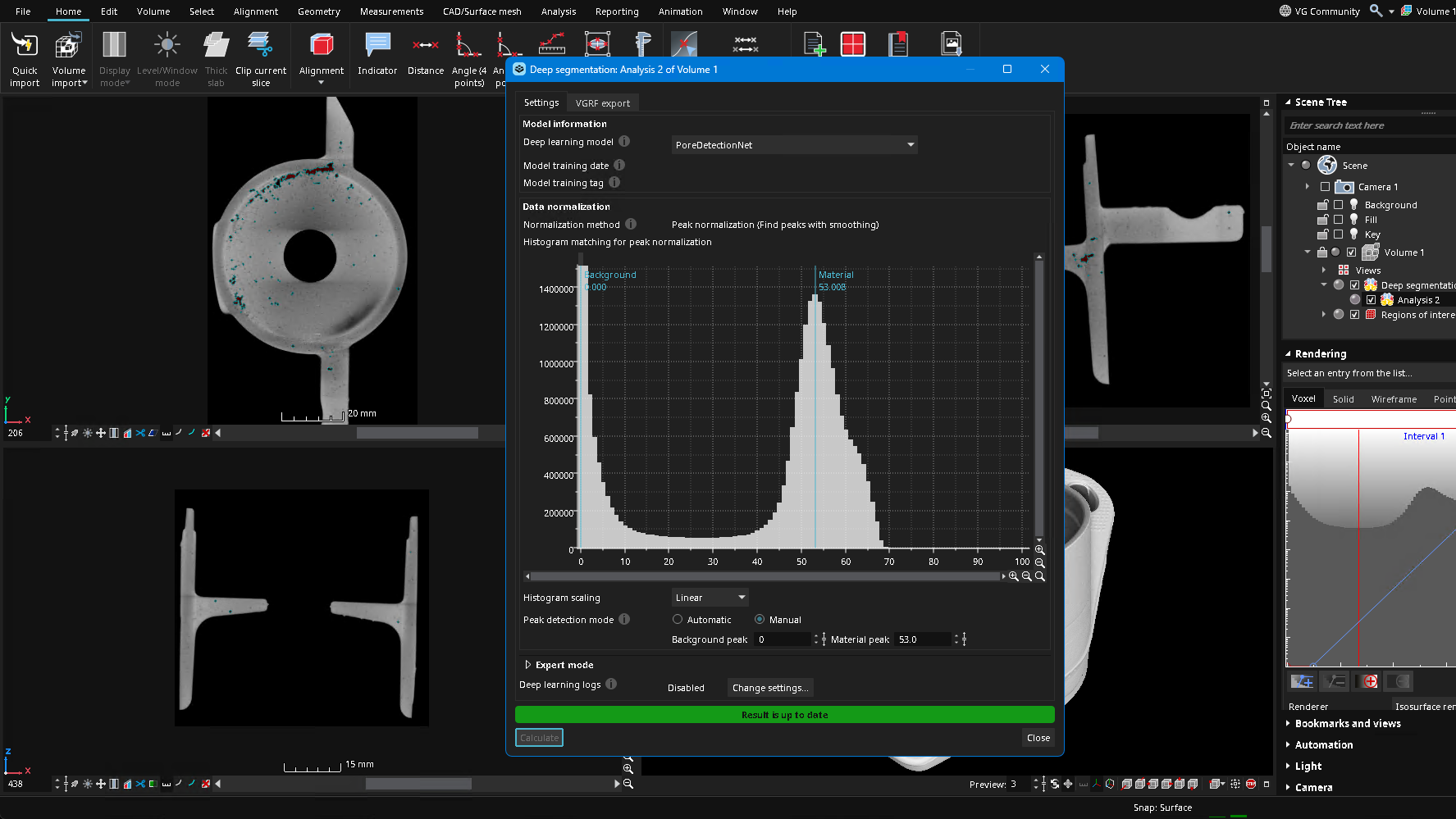

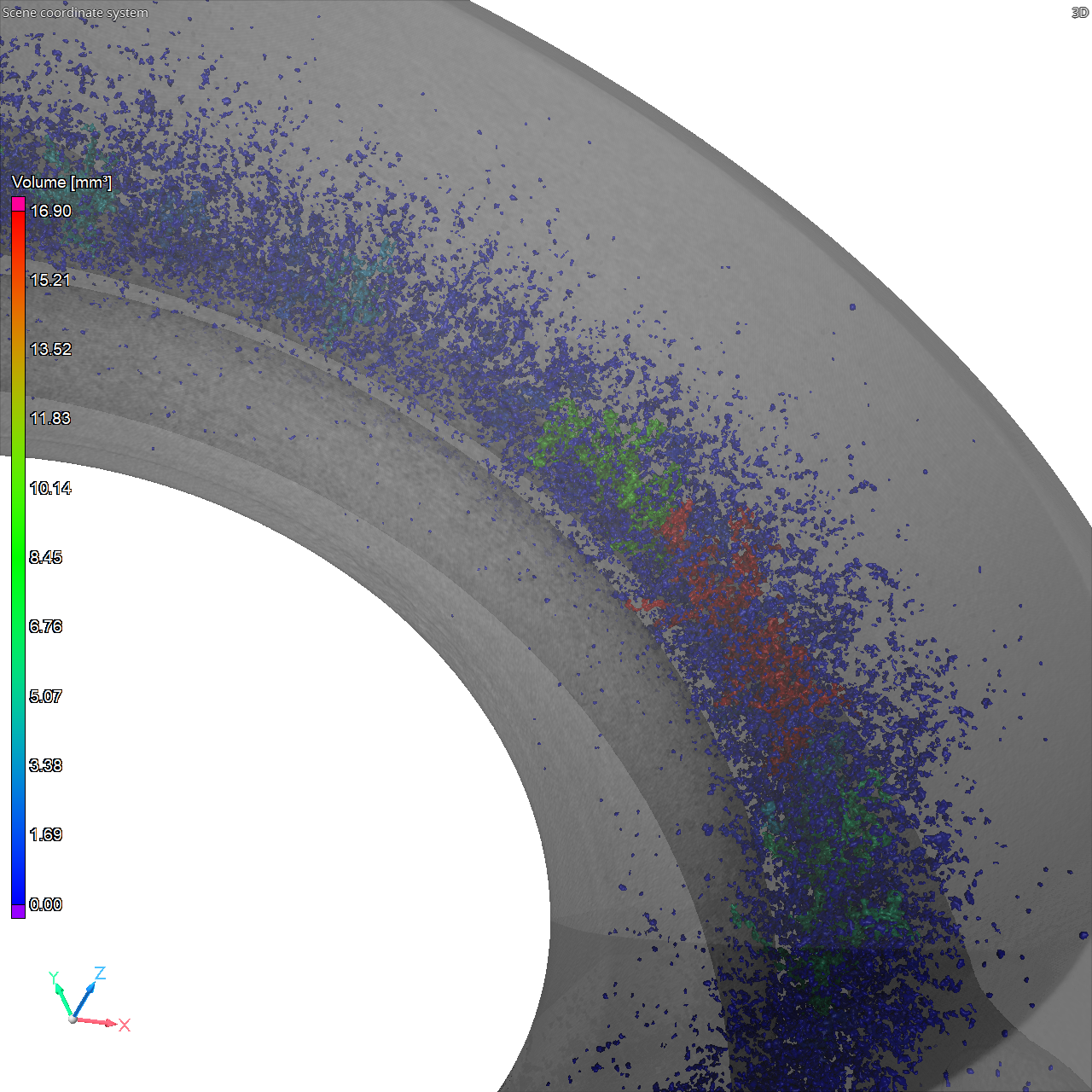

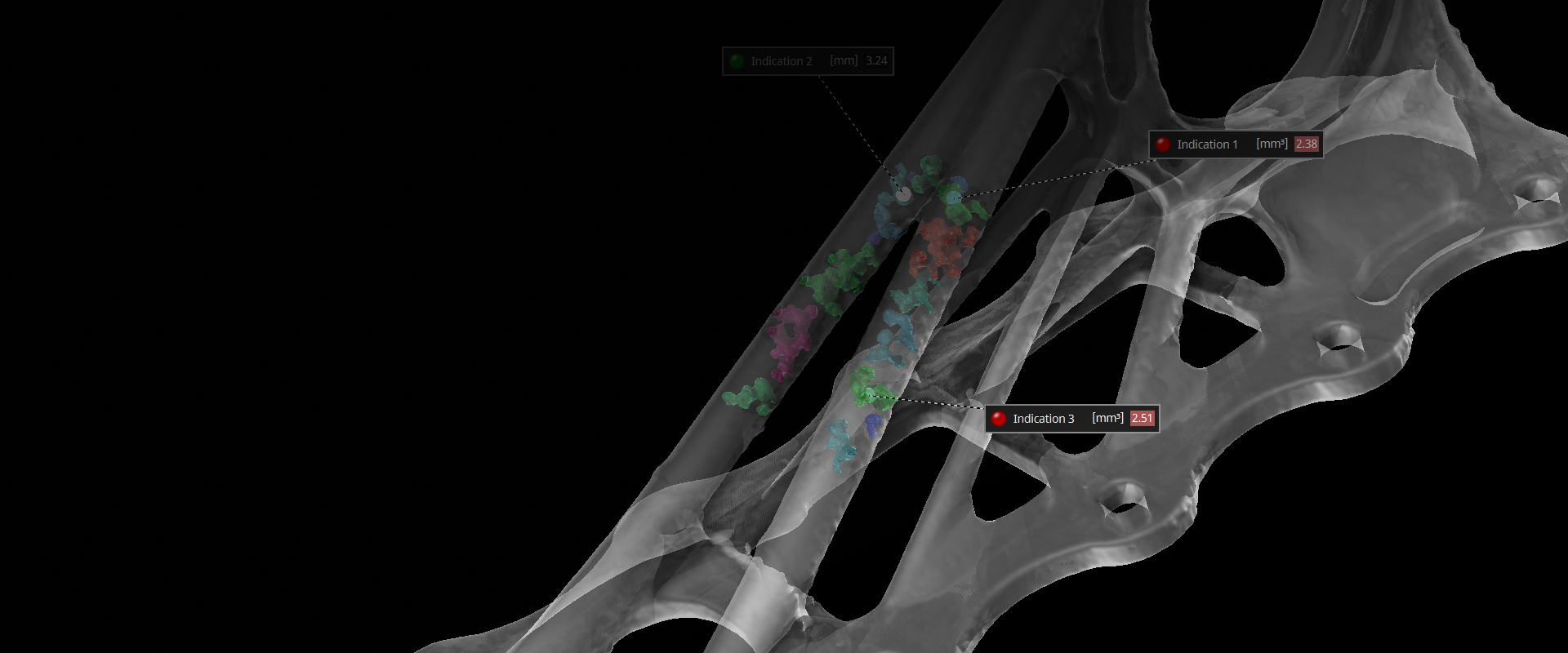

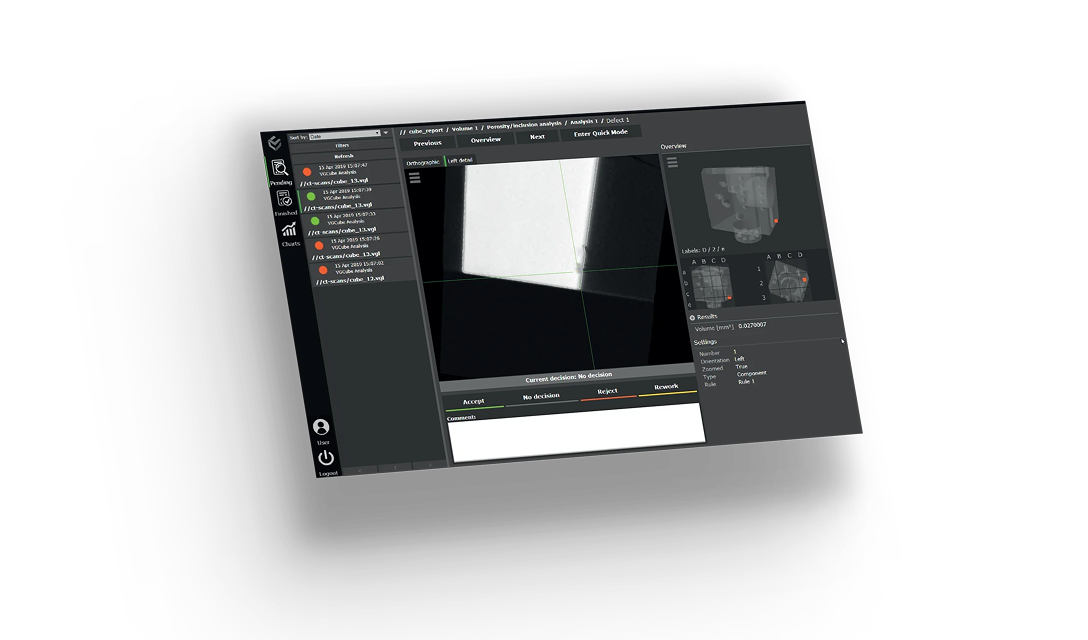

Detect hidden flaws

Detect hidden indications such as porosity, shrinkage cavities, and inclusions before they lead to production issues.

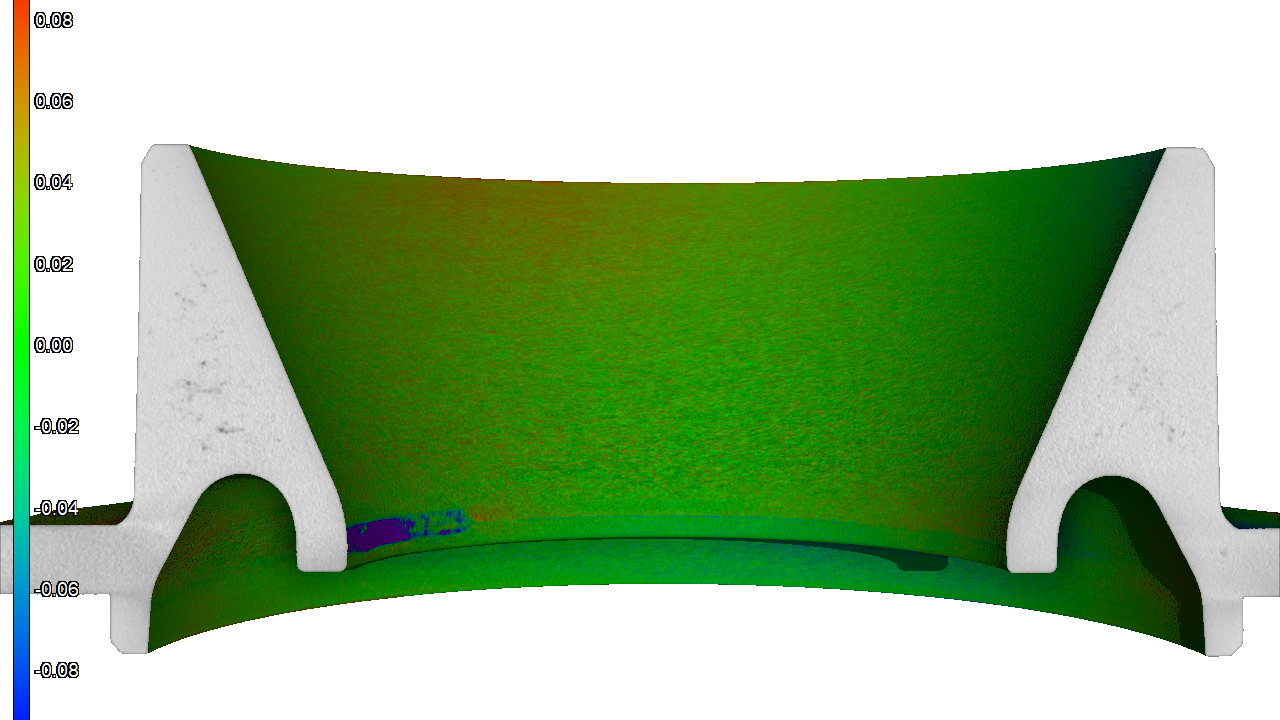

Ensure dimensional accuracy

Achieve superior accuracy in fewer iterations by validating tooling and accounting for material shrinkage and deformation. Analyse part defects to enhance and optimise the entire production process.

Meet customer demands

Extend the lifespan of moulds and tools by optimising designs to minimize wear and ensure uniformity across production batches. Deliver consistent product quality to meet industry standards and fulfill customer expectations.

Produce higher-quality parts with less waste and greater efficiency. These are some of the typical inspection tasks you can complete with our software solutions.

Get your free, 4-week trial license and see why we're the industry’s first and longest-trusted CT analysis software.

Request free trial