“The main advantage is the visualisation and the rapid evaluation of the scans. VGSTUDIO MAX is very easy to learn, and after a short training period, every user is fully ready to use it.”

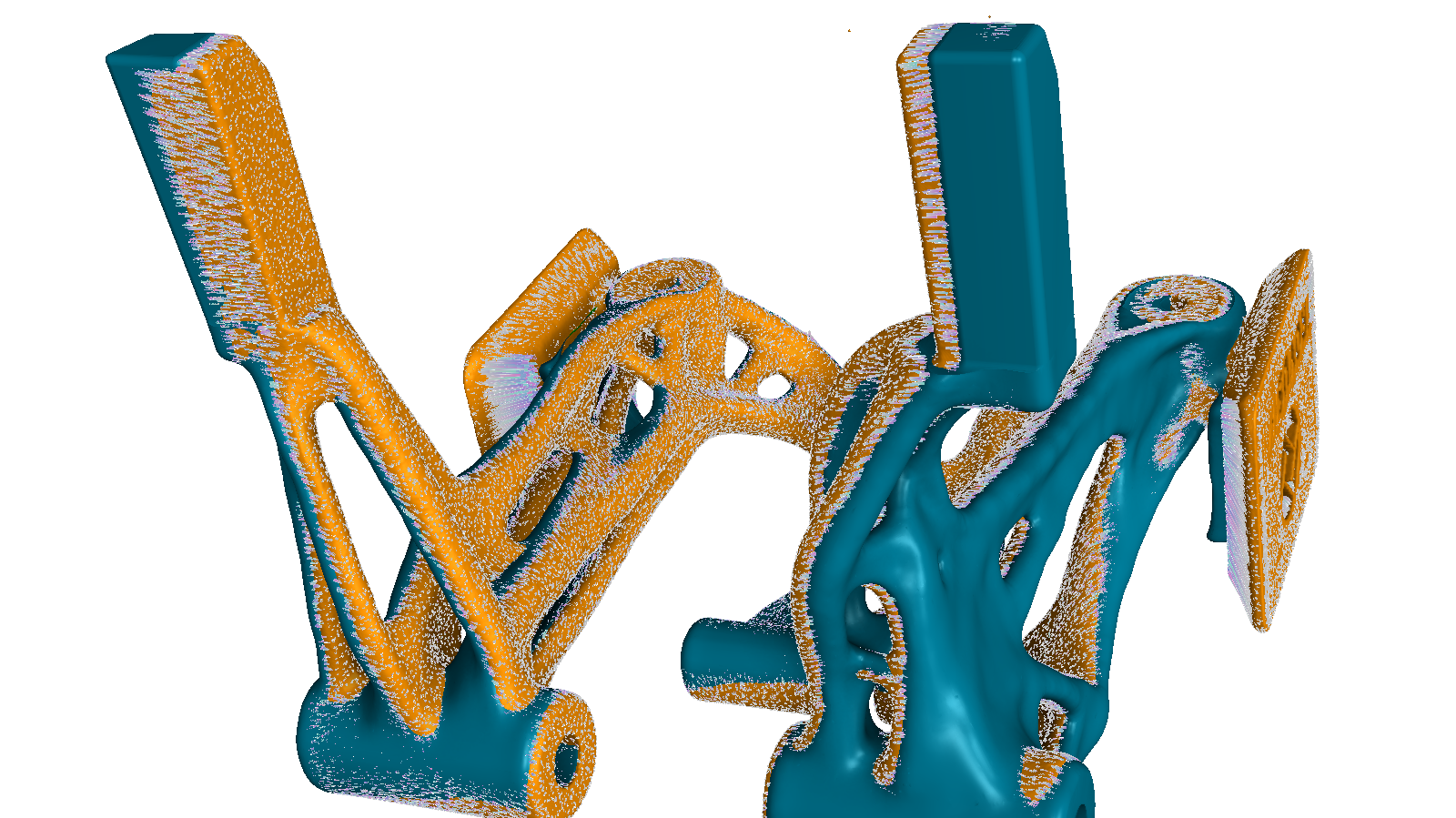

Verify complex geometries

Compare printed parts against CAD models to detect deviations. Iteratively optimise your additively manufactured part’s shape to make sure even complex, thin-walled parts fit together perfectly.

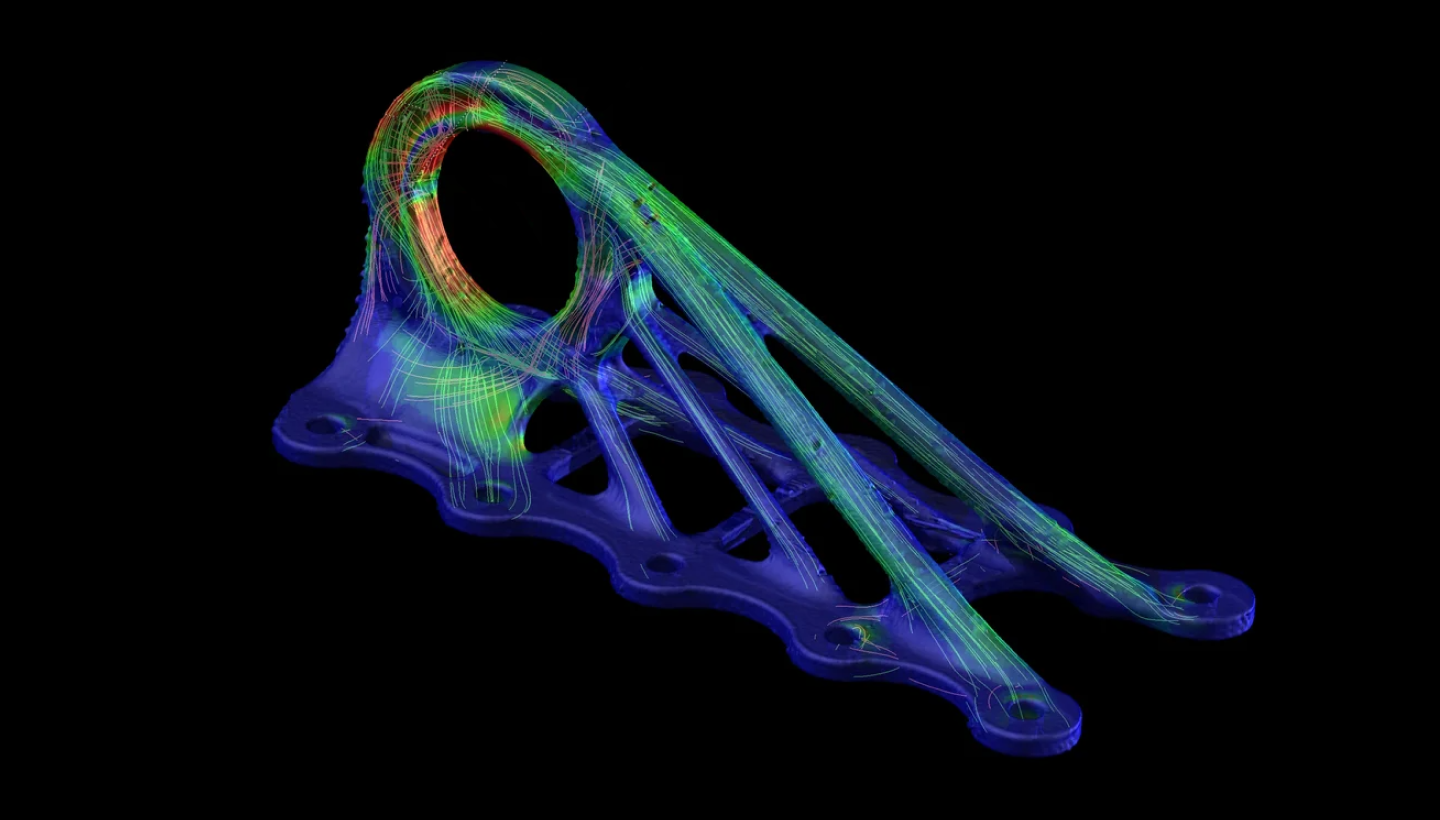

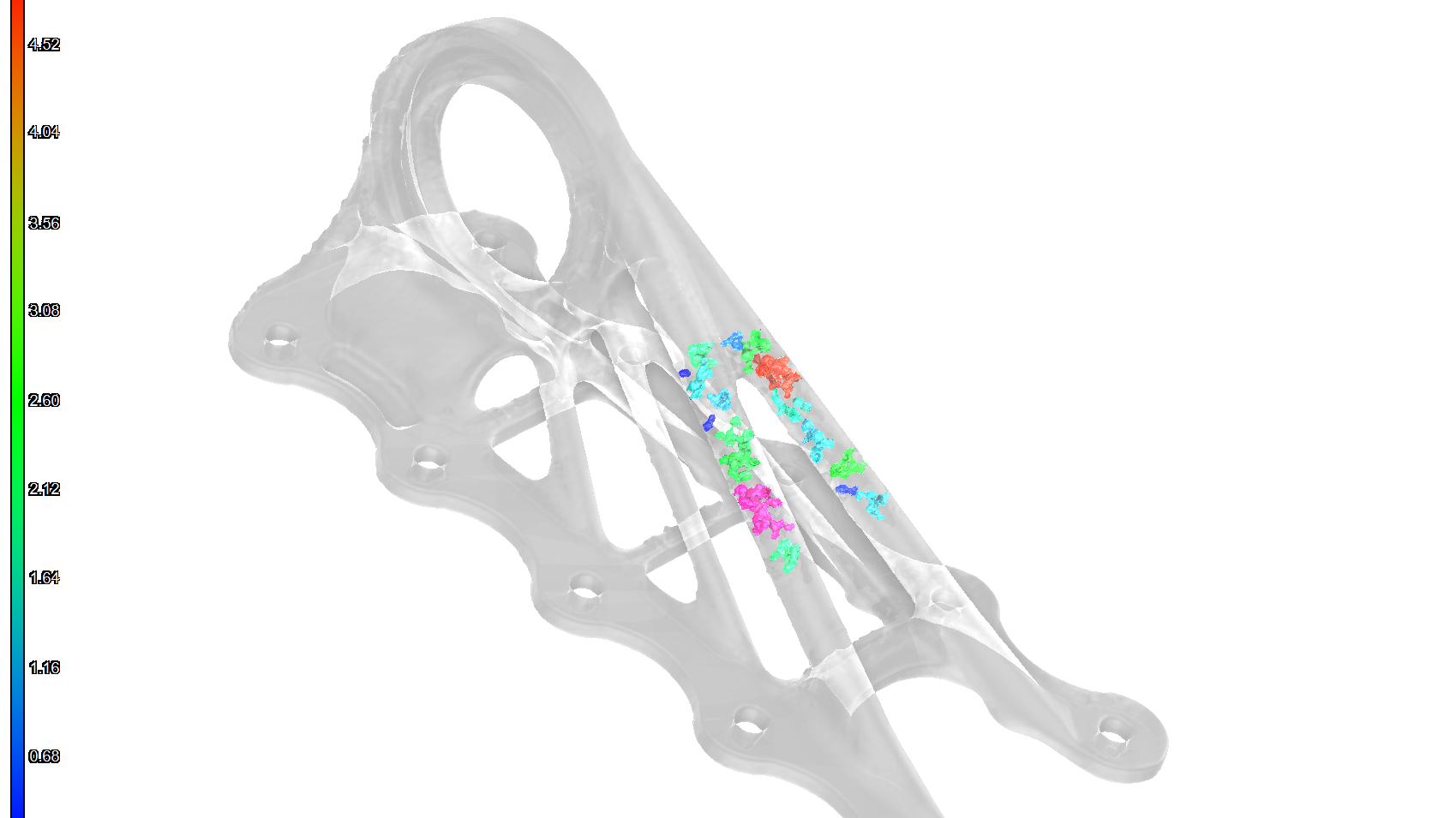

Ensure your parts perform

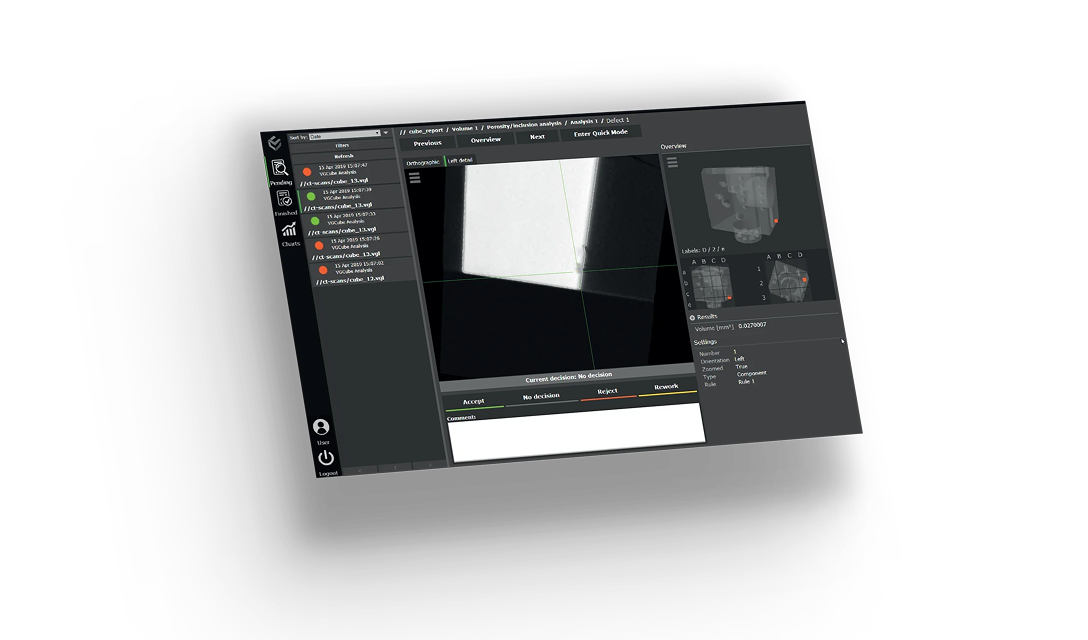

Identify porosity, inclusions, and internal inconsistencies affecting mechanical integrity to ensure your AM parts meet performance criteria. Use these insights to refine printing techniques and improve part consistency.

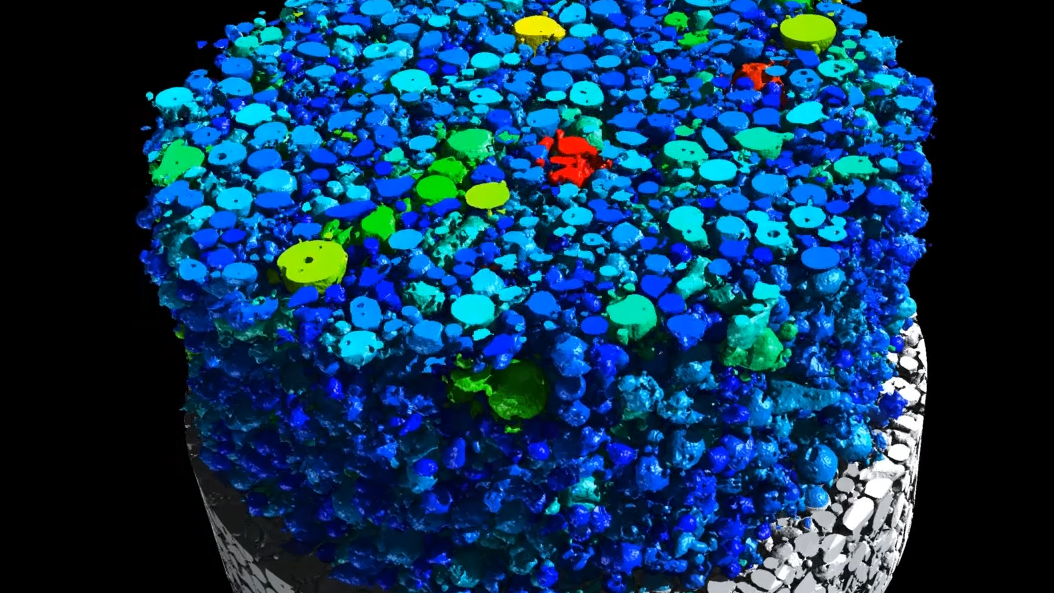

Optimise process parameters

Leverage our specialised powder analysis to identify potential quality issues before the first print. With our range of material analysis options, easily explore new materials and their properties for AM applications.

Move from prototype to production with confidence. These are some of the typical inspection tasks you can complete with our software solutions.

Get your free, 4-week trial license and see why we're the industry’s first and longest-trusted CT analysis software.

Request free trial