“We use many modules from VG and examine nearly our entire portfolio with them. The VG products simplify my daily work by providing a wide range of analysis methods, all conveniently available in a single software package.”

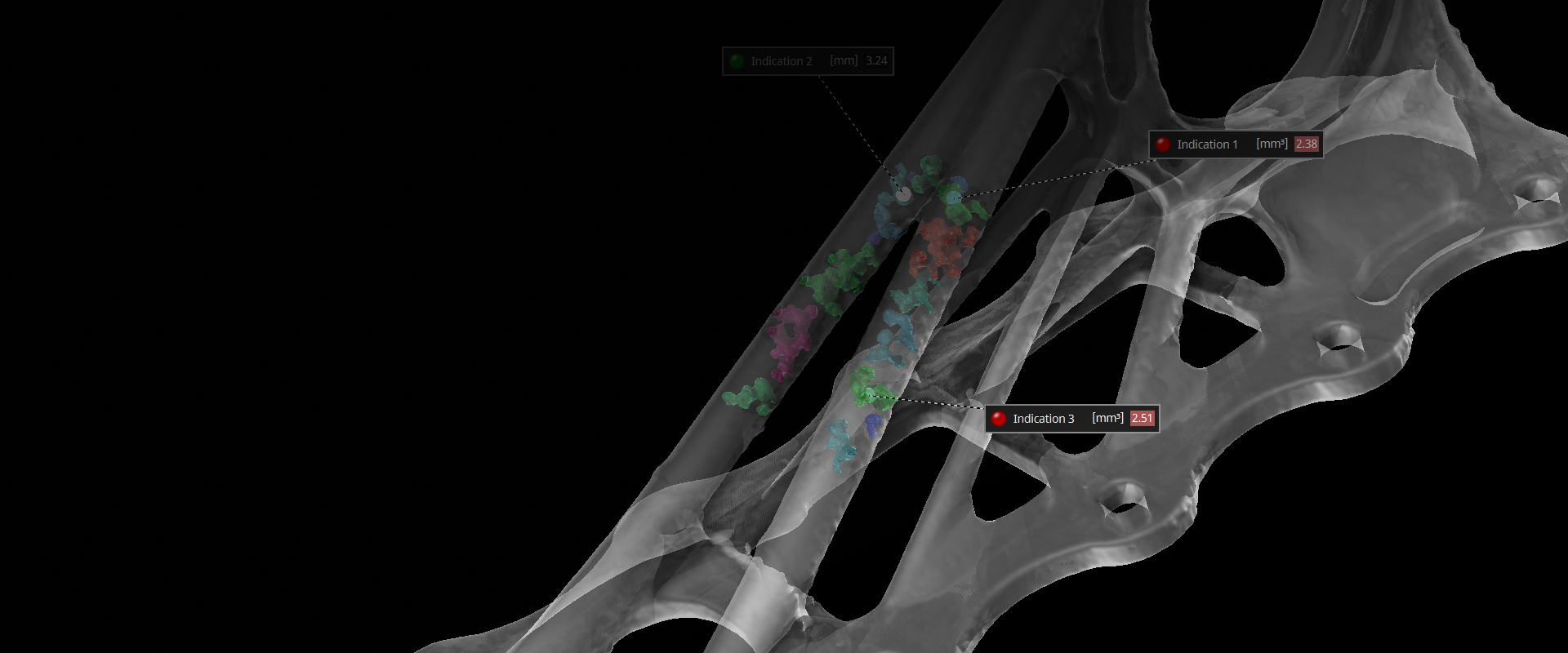

Ensure unmatched quality

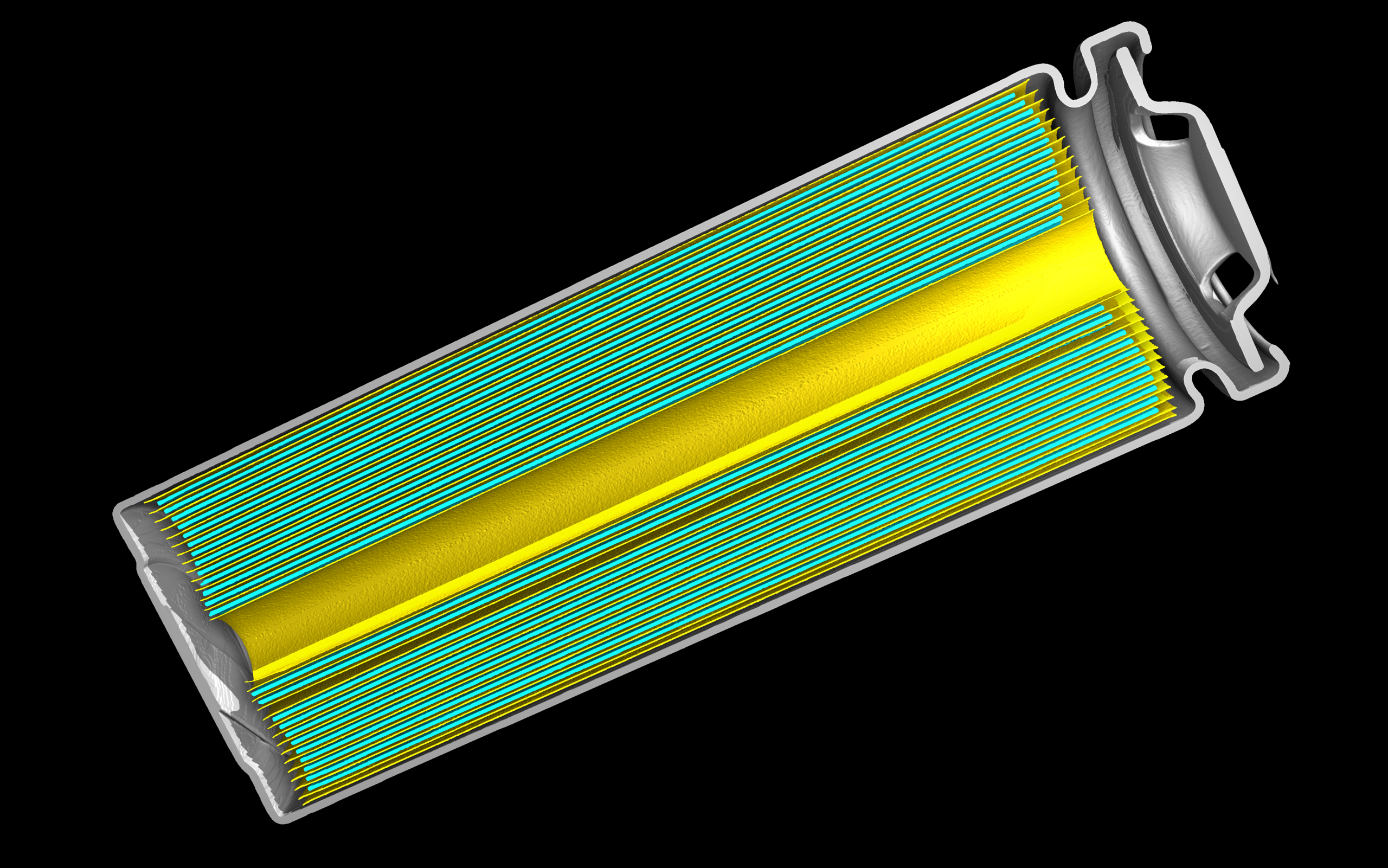

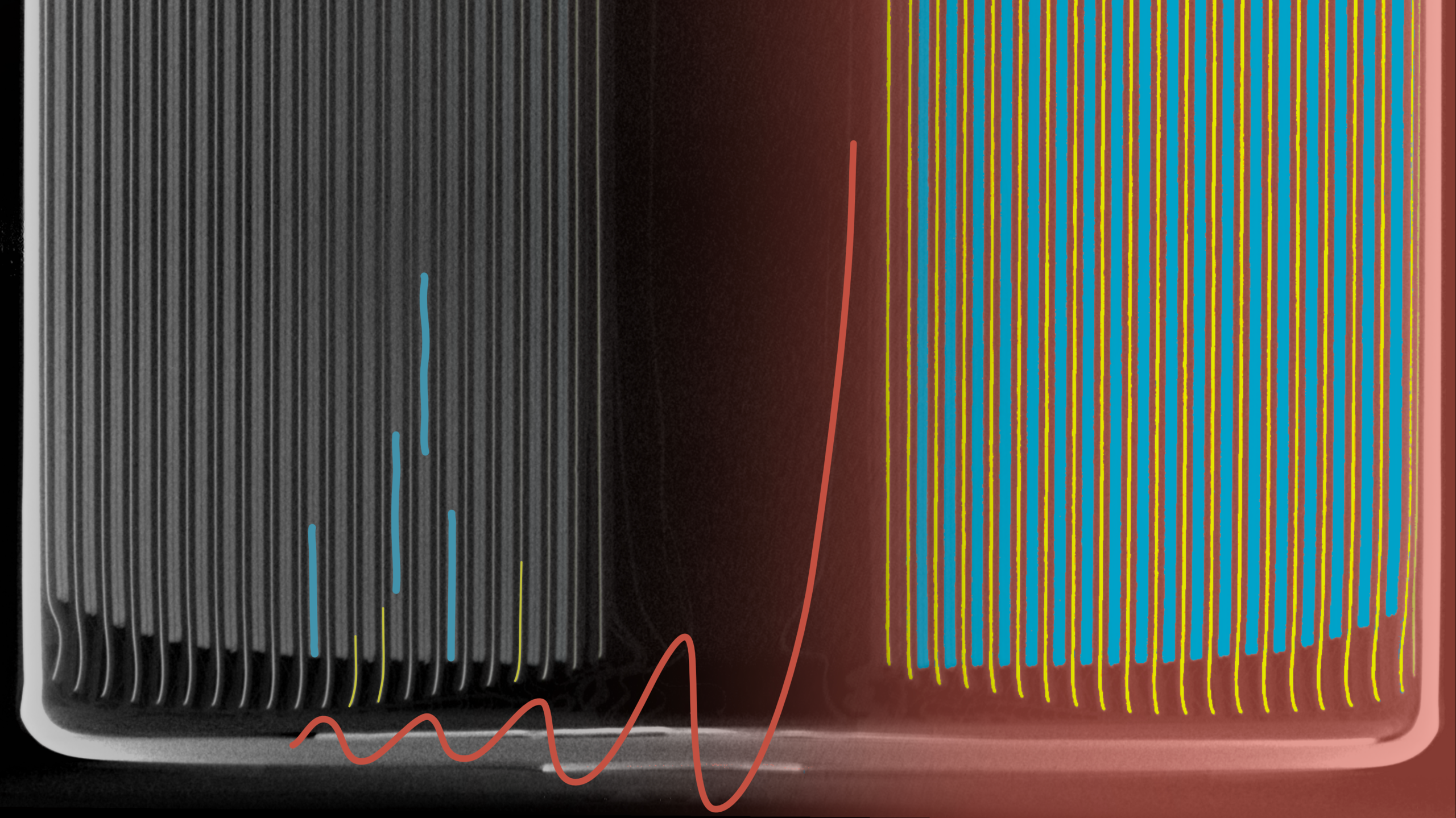

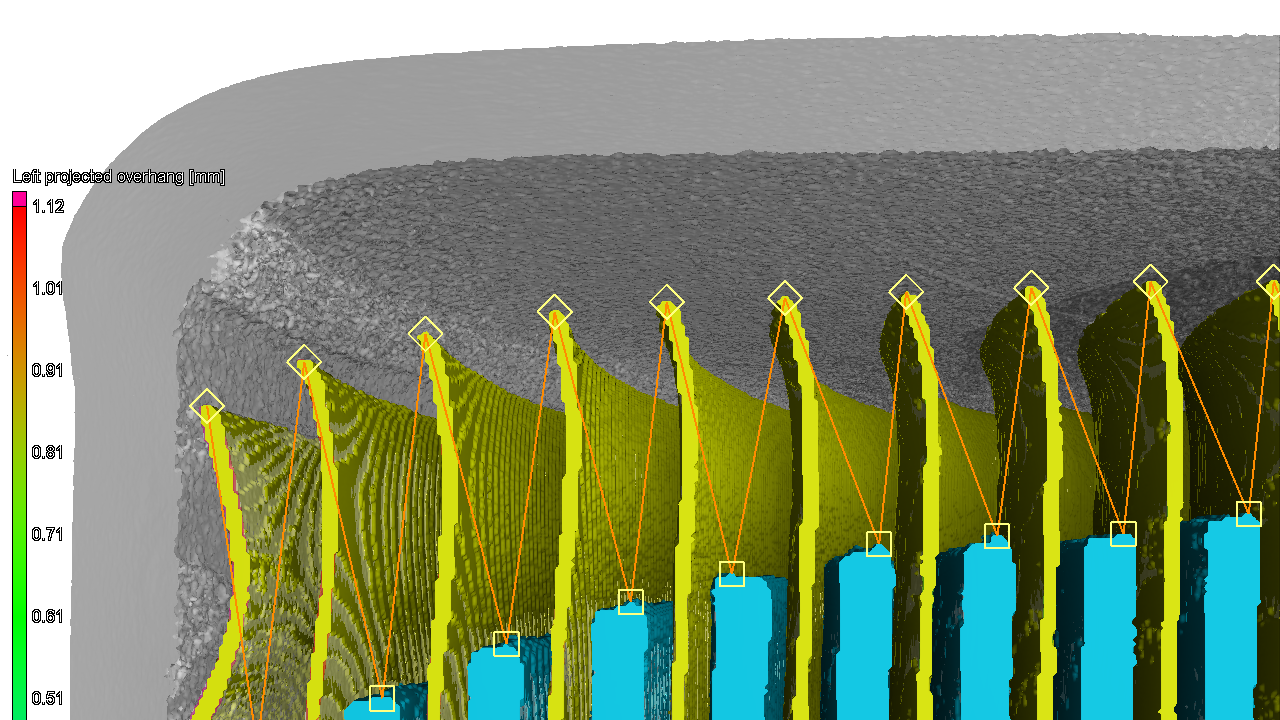

Implement rigorous testing protocols to identify and mitigate potential battery design and manufacturing failure points. Detect anode overhang and electrode misalignment affecting battery performance.

Accelerate development and efficiency

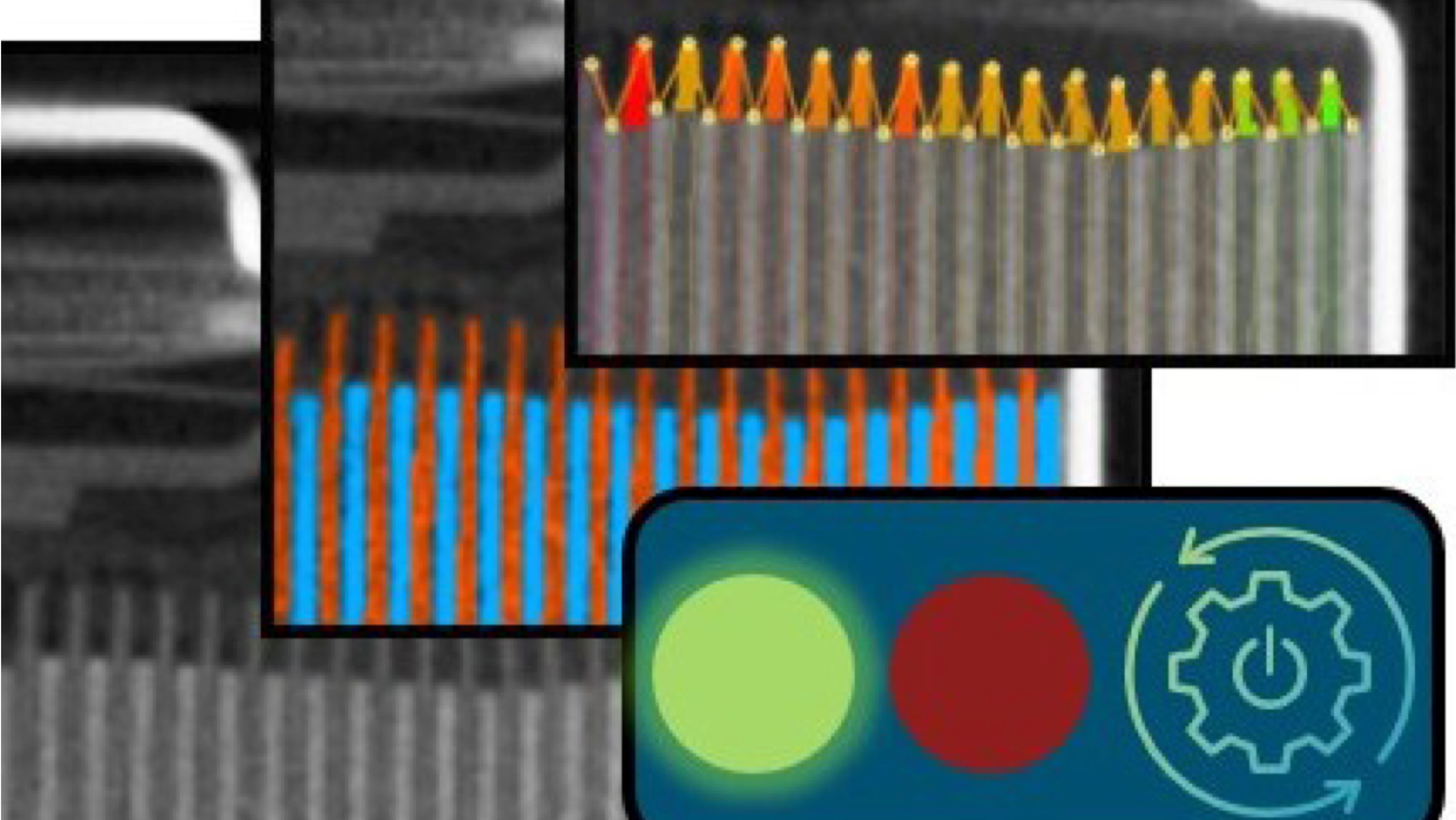

Employ cutting-edge segmentation techniques to explore new materials and designs that improve energy density and longevity. Make progress in battery design and component microstructure characterisation.

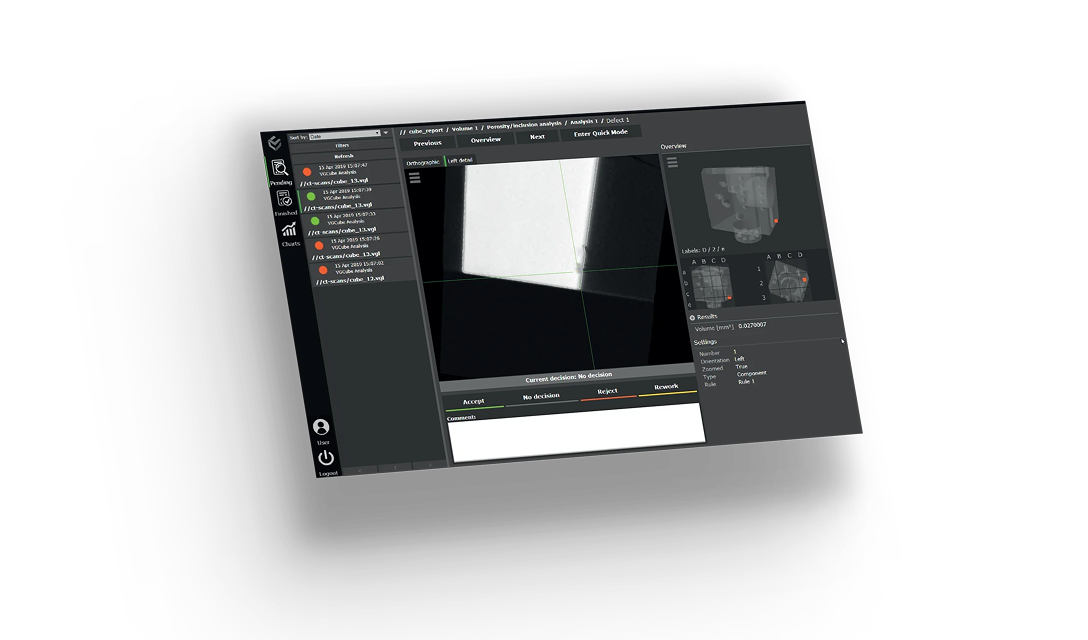

Transform production operations

Identify production defects early to reduce waste and improve yield. Train deep-learning-based segmentation models in-house, keeping your data safe and enabling quality inspection that keeps up with production without sacrificing accuracy.

Push the limits of performance, reliability, and safety. These are some of the typical inspection tasks you can complete with our software solutions.

Get your free, 4-week trial license and see why we're the industry’s first and longest-trusted CT analysis software.

Request free trial