VGSTUDIO MAX offers analysis modes for each class of fibre composite material and manufacturing process. Whether you work with short-fibre-reinforced materials in an injection moulding process, long-fibre compression-moulded parts, or even woven fabrics of unidirectional fibers, the software has an analysis mode for it all.

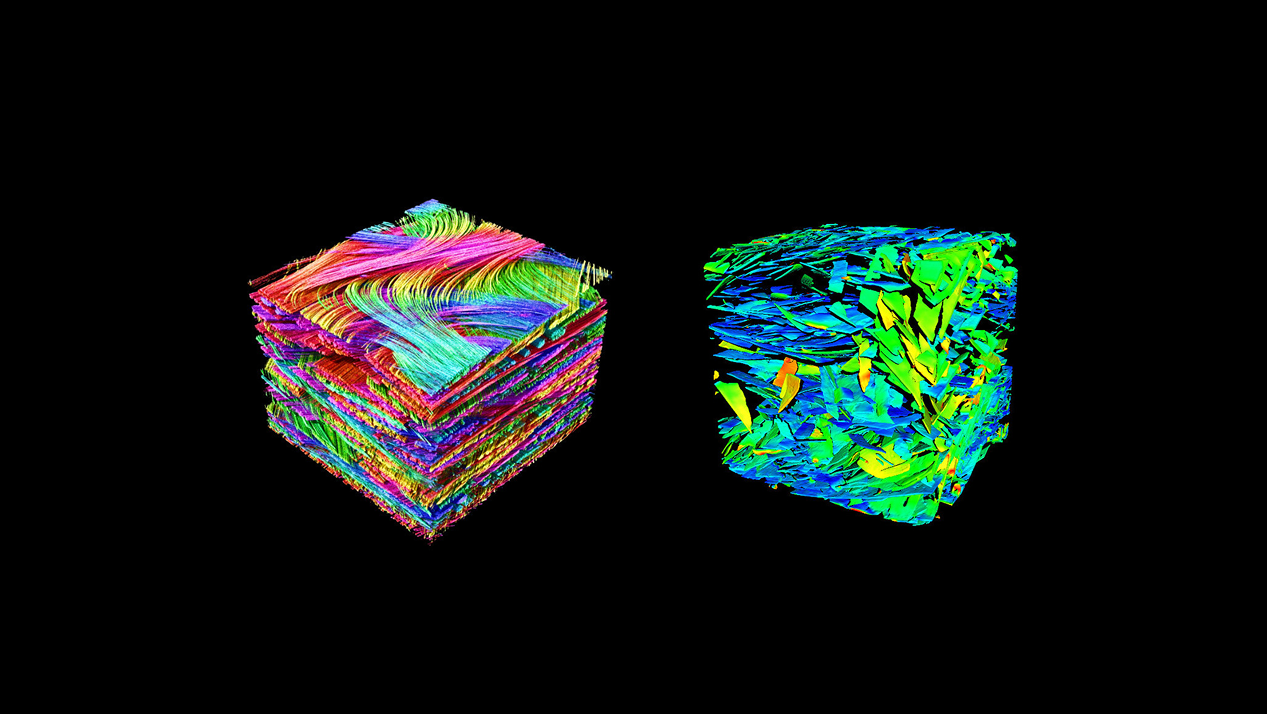

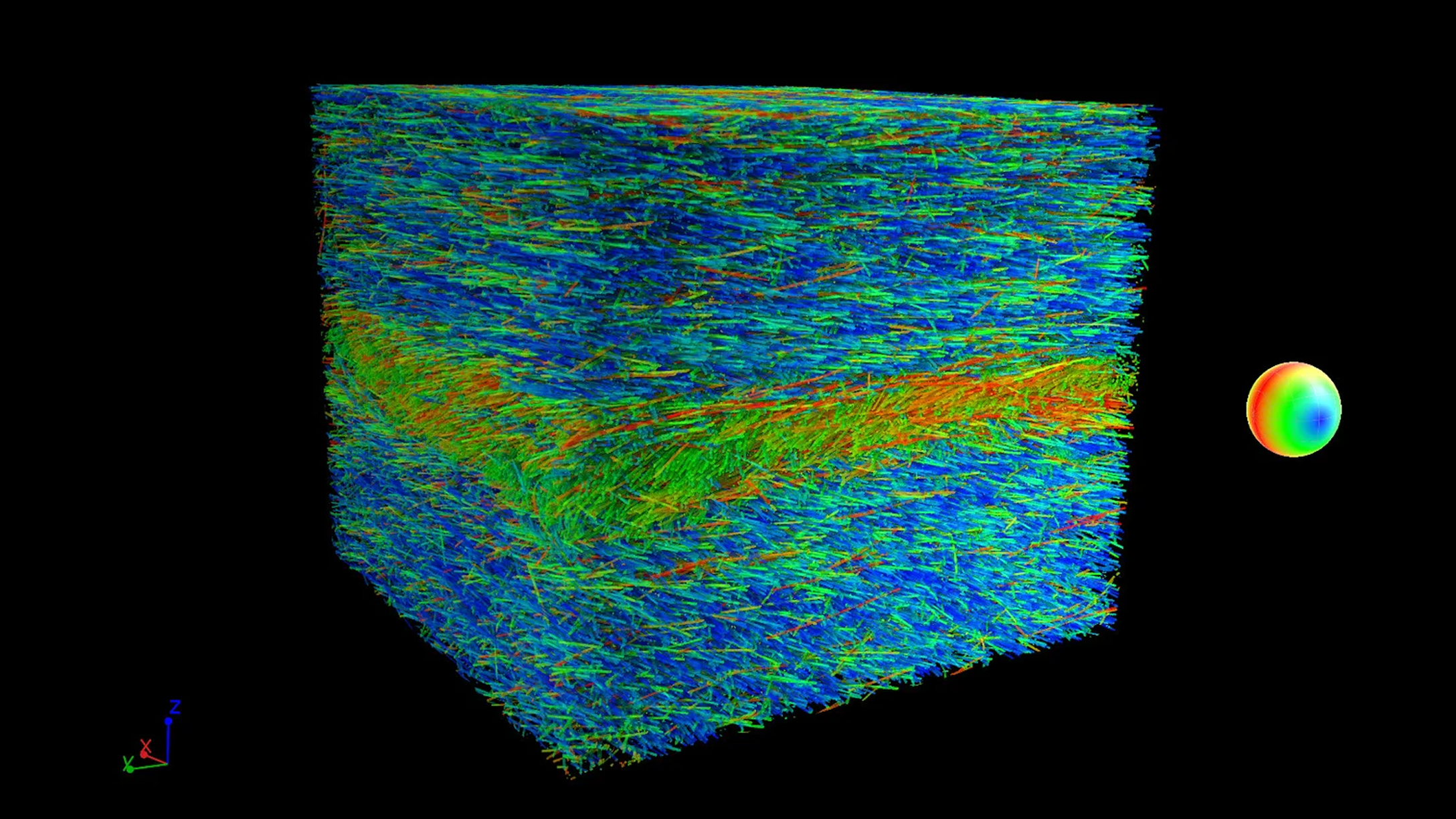

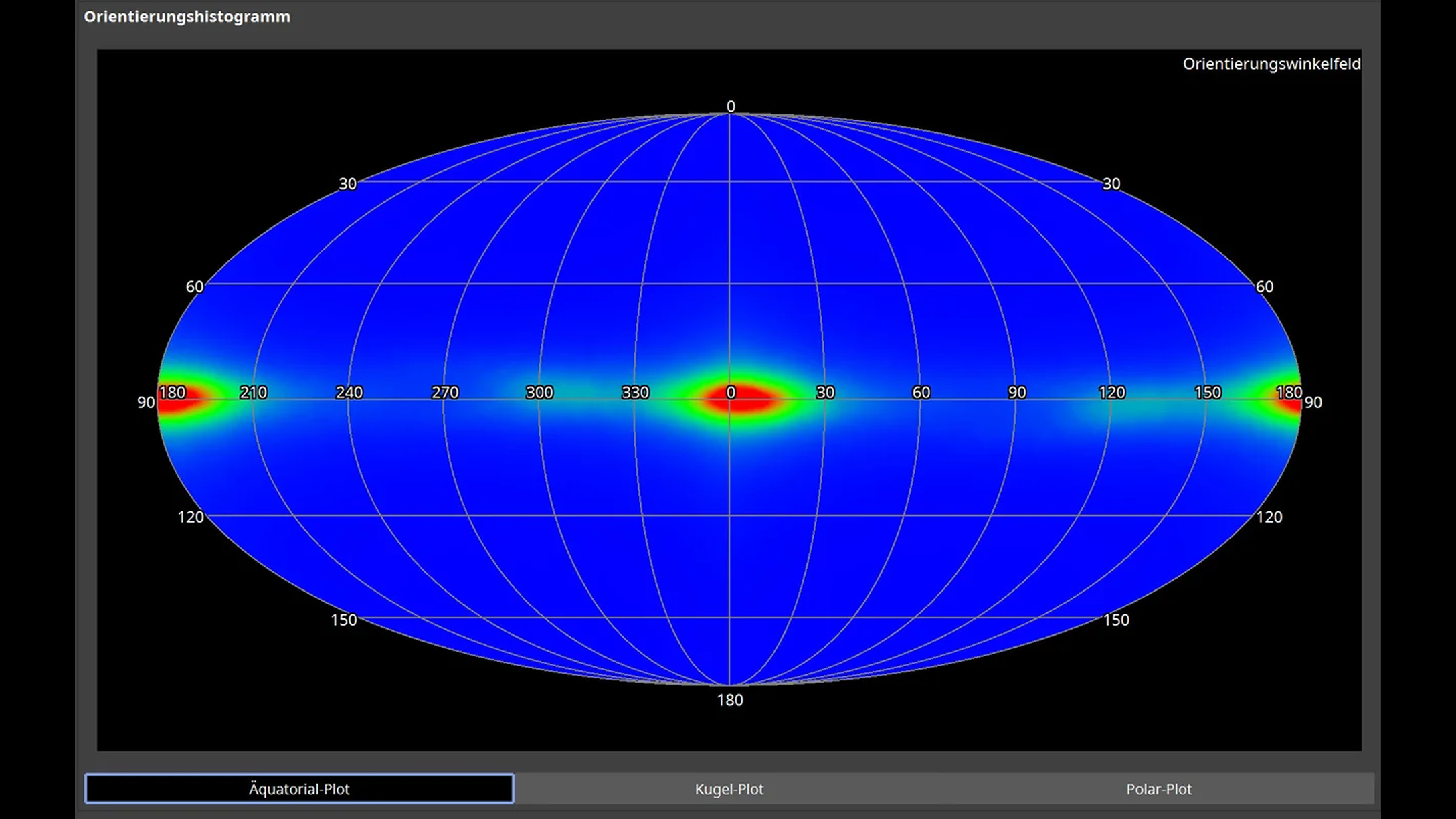

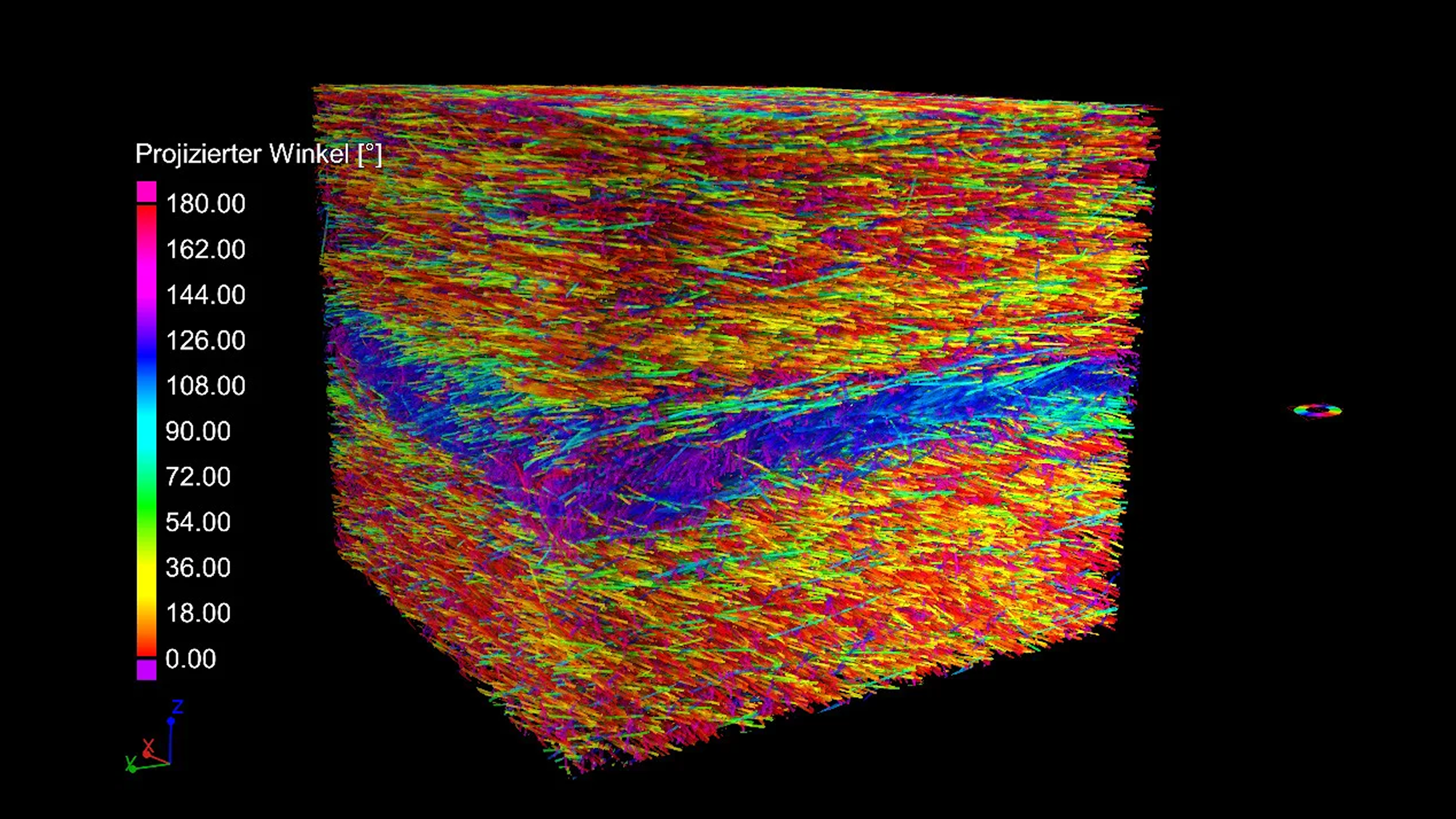

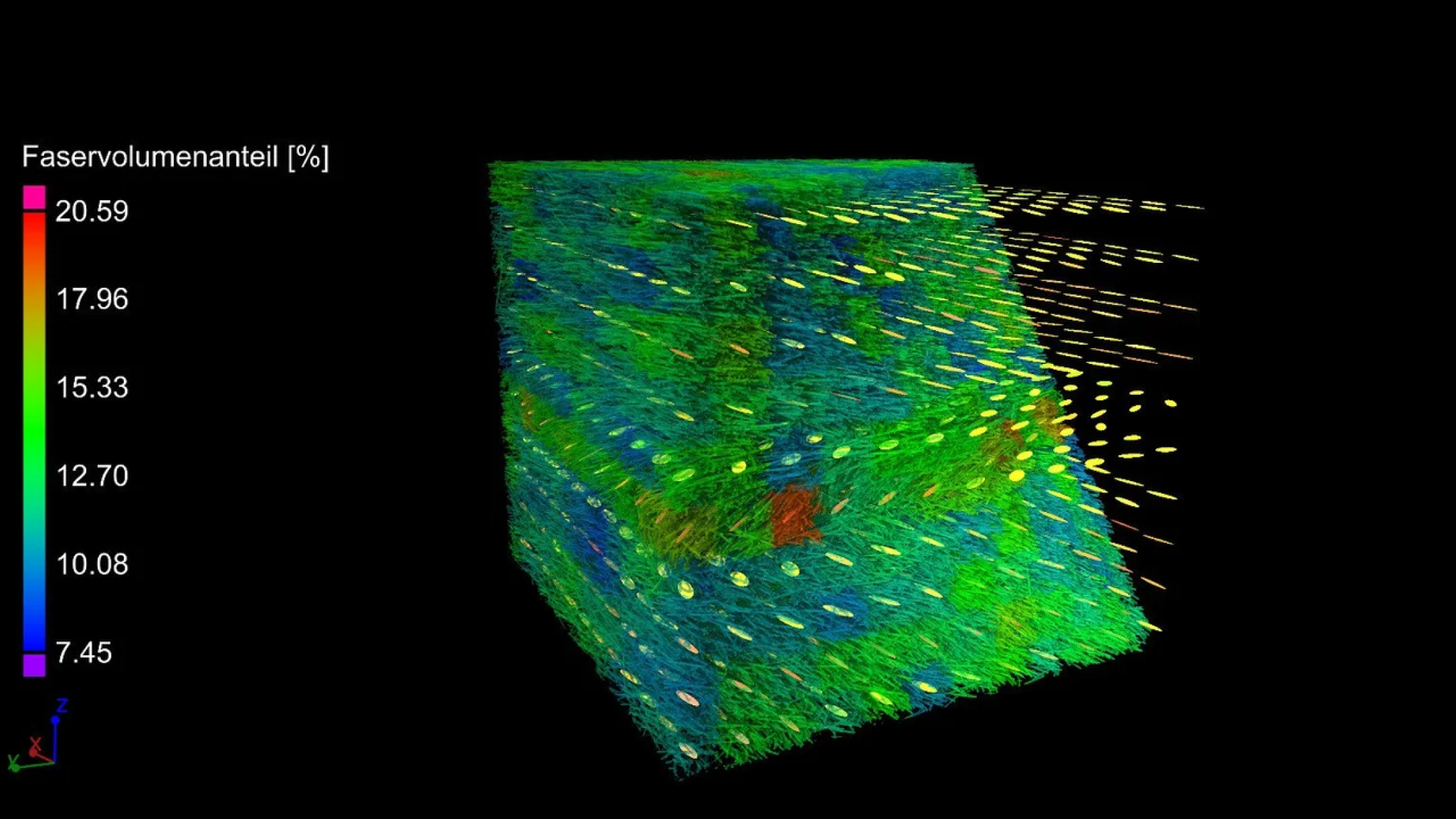

Spatial orientation mode

Our standard mode is very flexible with respect to the visualisation of local orientations in 3D. Use it to take a first look into your fibre-reinforced material and get an idea of the orientation distribution.

In this mode, you can:

- Calculate the local orientation

- Visualise local orientations either with a colour overlay or with three-dimensional needles to gain a qualitative understanding of the fibre orientation inside your sample or component

- Investigate the global orientation distribution in 3D as a heatmap on an equatorial, sphere, or polar plot

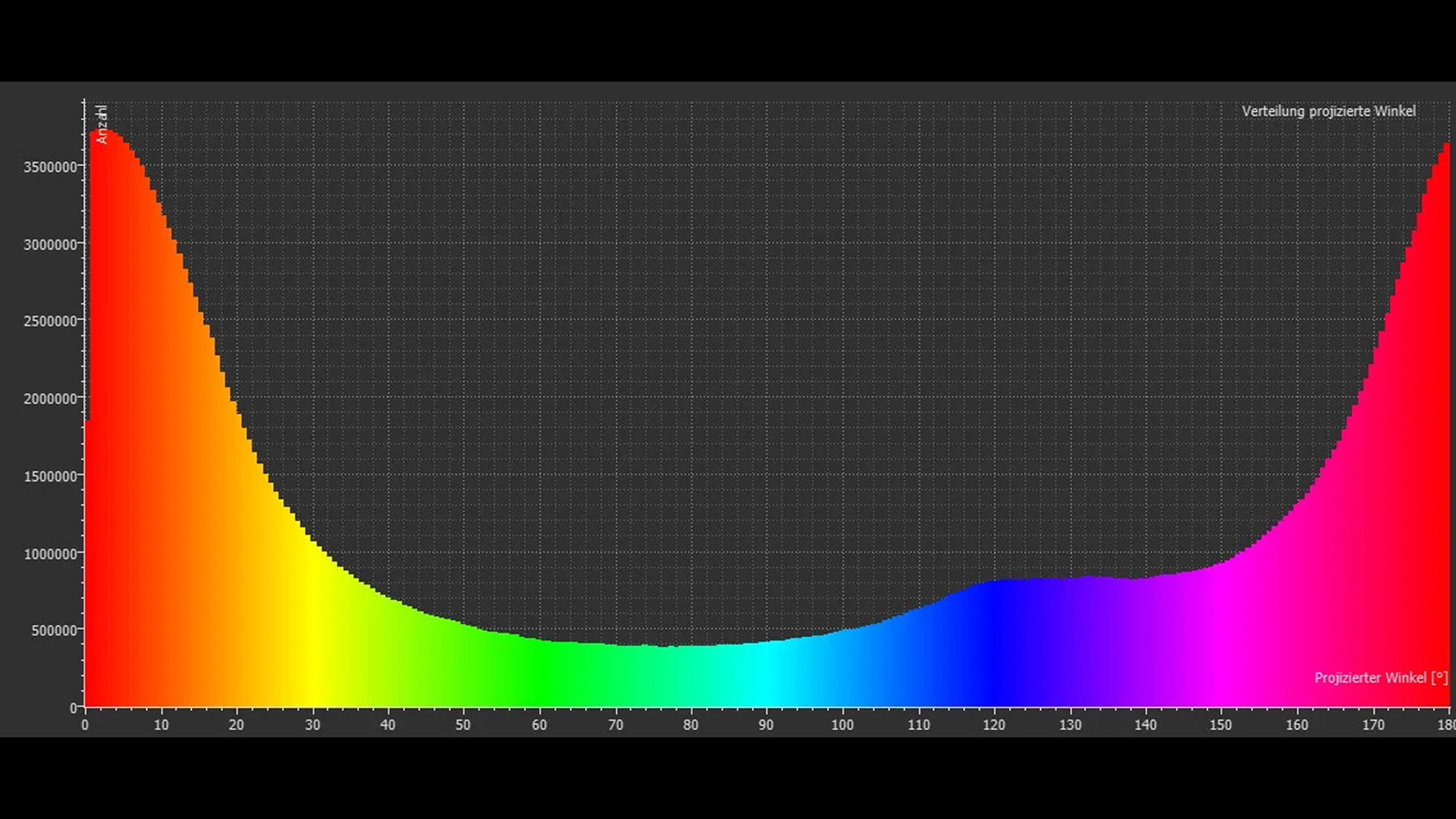

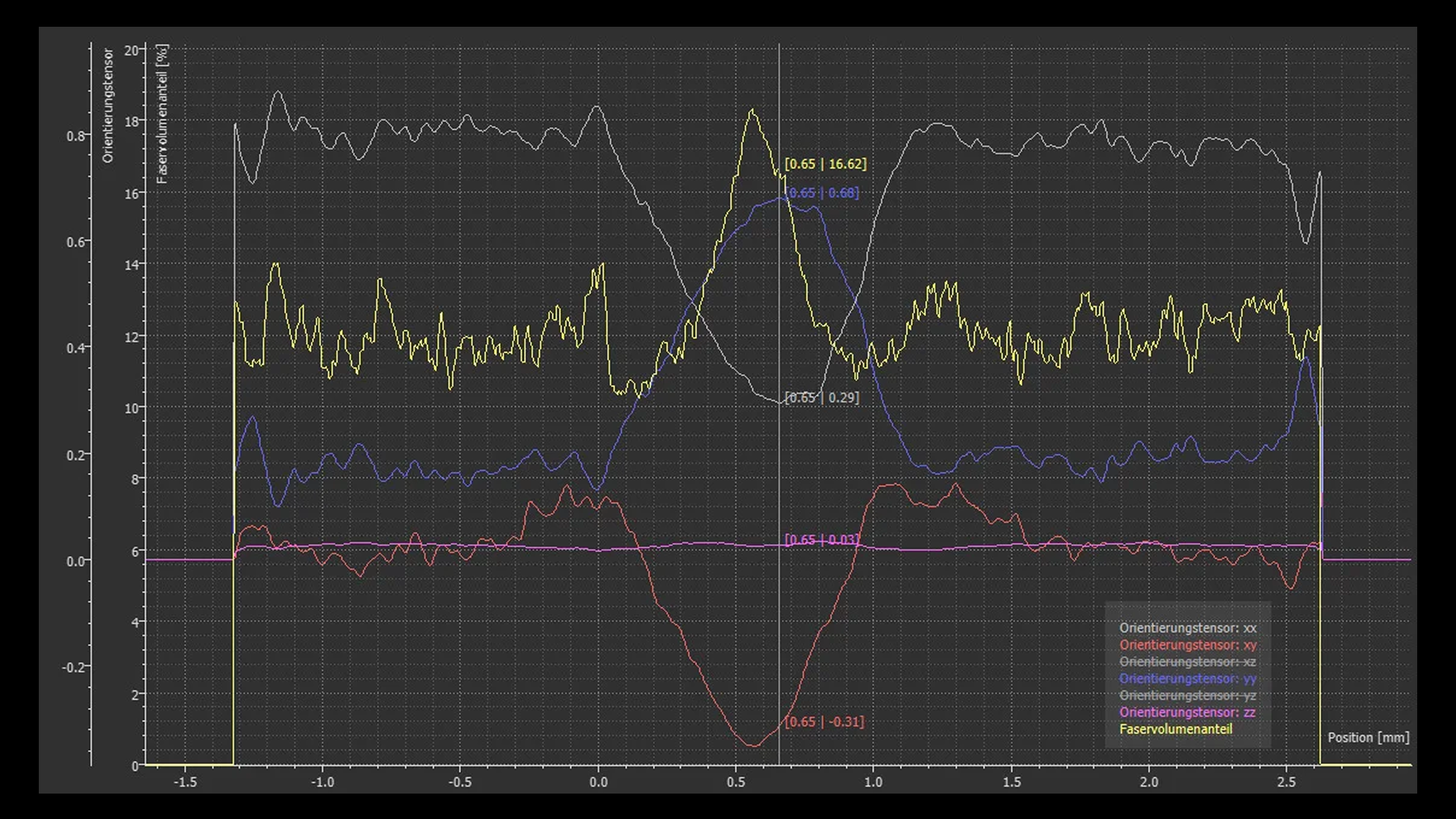

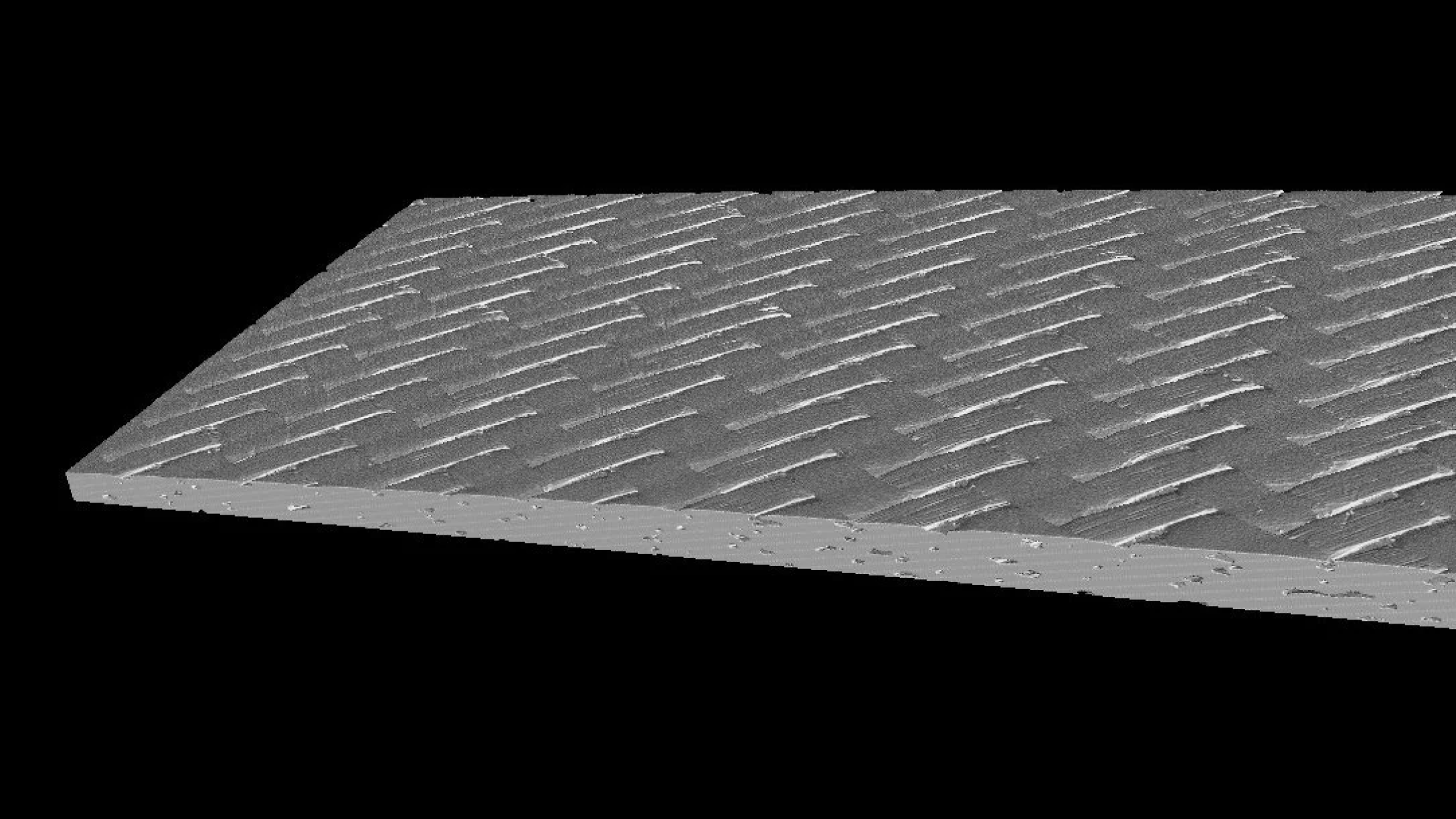

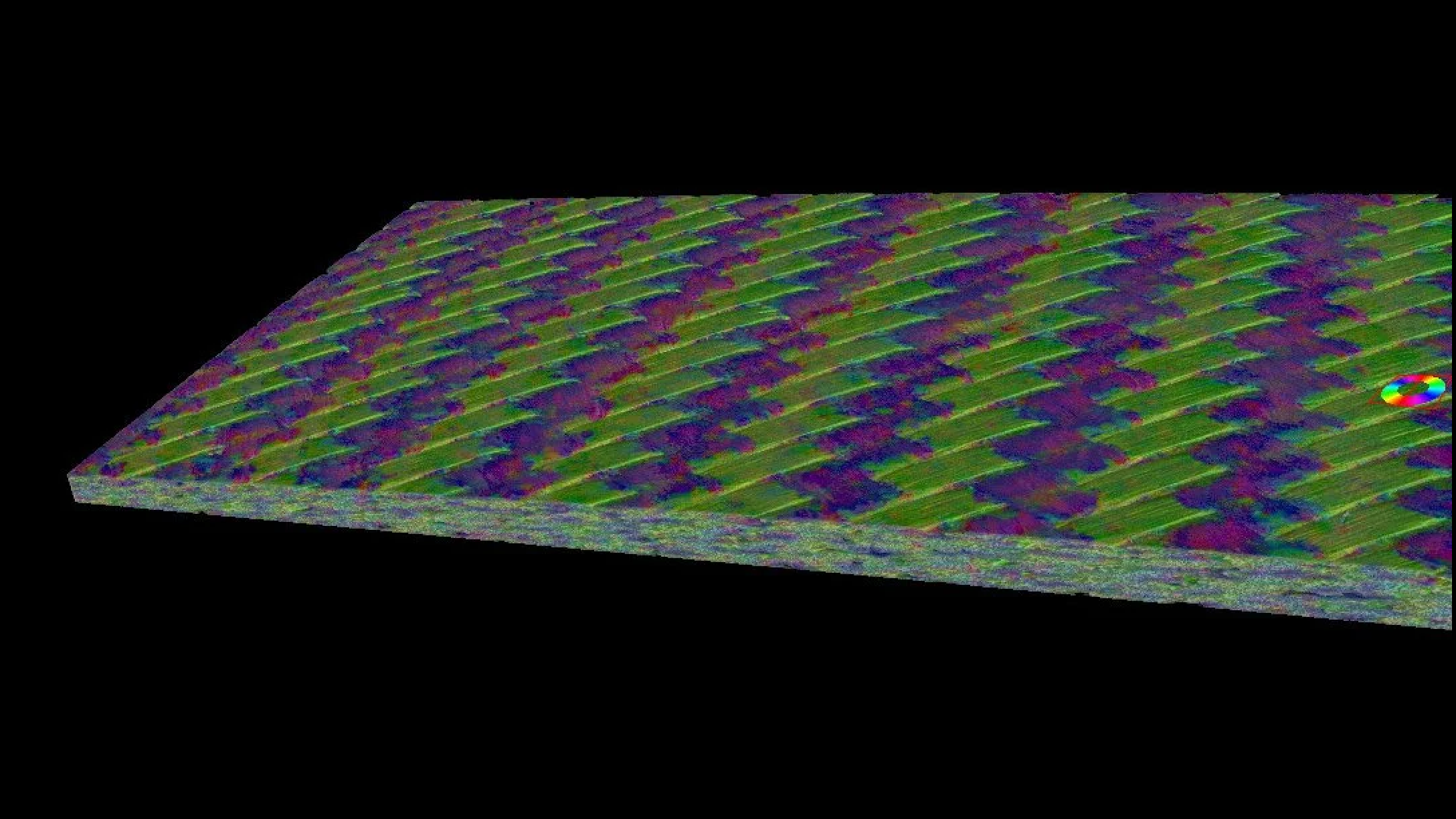

Planar projection mode

Use planar projection mode for planar parts in which the orientation changes over thickness. This is the mode of choice for injection-moulded, short-fibre-reinforced materials, but also for long-fibre, compression-moulded parts where different flow conditions lead to skin-core effects resulting in different orientation states over thickness.

In this mode, you can:

- Visualise the planar orientation distribution on an RGB colour wheel specifying a unique orientation within the analysis plane

- Derive global orientation histograms projected to the analysis plane

- Plot 3D orientation tensor components and fibre volume fraction over thickness perpendicular to the analysis plane

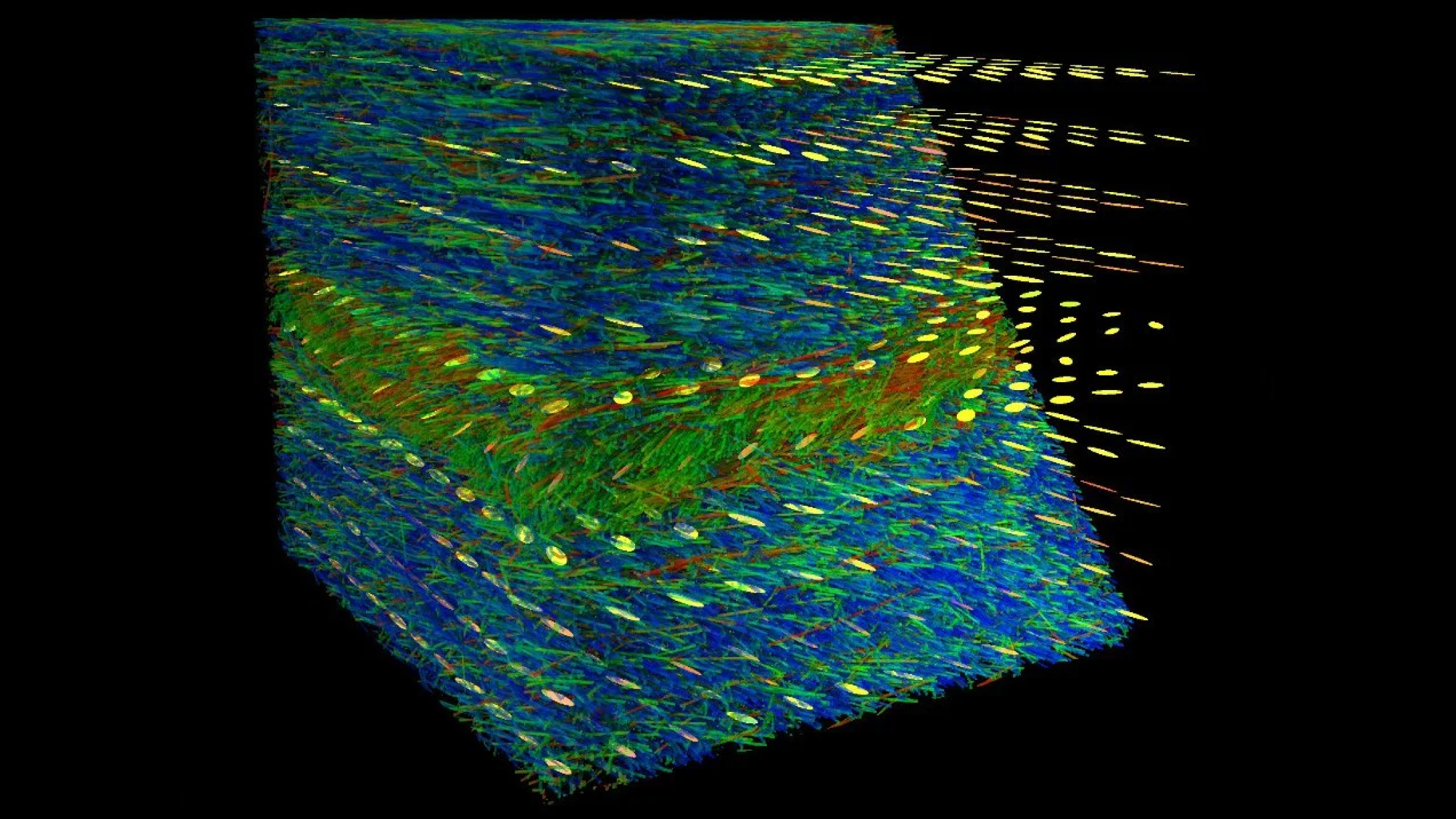

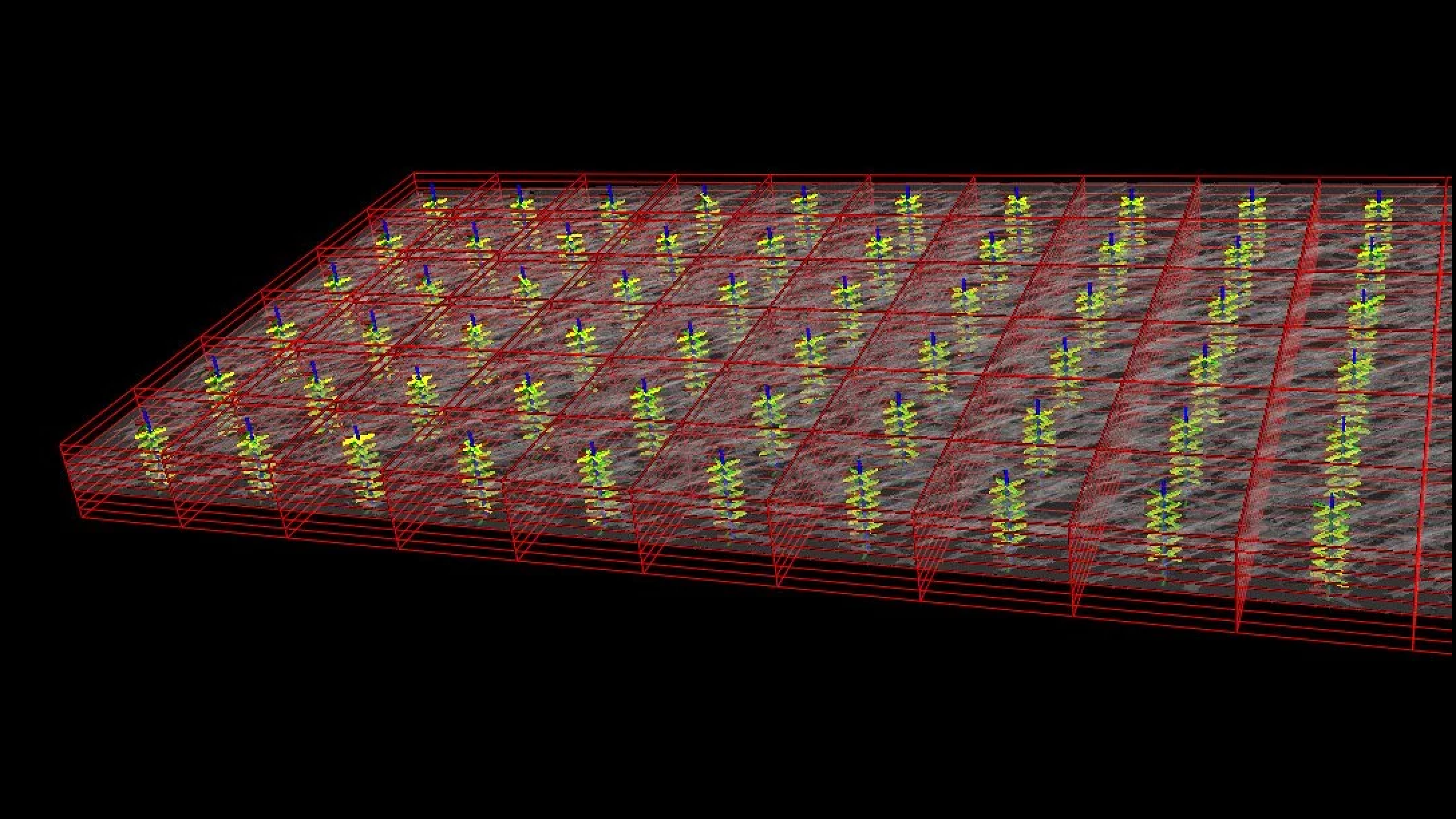

Mesh mode

Use mesh mode to generate input data for mechanical or thermal simulations or to validate process simulations.

In this mode, you can:

- Evaluate the orientation tensor, including the corresponding eigenvalues and eigenvectors, the fibre volume fraction, and the matrix porosity* for each mesh cell

- Visualise fibre volume fraction and orientation tensors, along with their principal orientations, in 2D or 3D

- Export results as .csv files for use in 3rd-party finite element analysis (FEA) software

- Create simple regular volume meshes. Complexly shaped volume meshes can be imported (from Patran, Nastran, Abaqus, or Magma) or generated using the Volume Meshing module.

- Extrude shell meshes with one click and set the numbers of cells in a thickness direction of the structure

*Porosity/Inclusion Analysis module required

Planar mesh mode

Use planar mesh mode for sheet-like structures with almost planar orientation distributions (e.g., most composites manufactured by compression molding), especially woven fabrics.

In this mode, you can:

- Derive local planar histograms for each mesh cell.

- Evaluate main directions of the local histograms and the deviation angles in cases where the orientation tensor does not provide meaningful information, which is helpful for woven fabrics

- Compute orientation tensors, fibre volume fraction, and matrix porosity.*

*Porosity/Inclusion Analysis module required

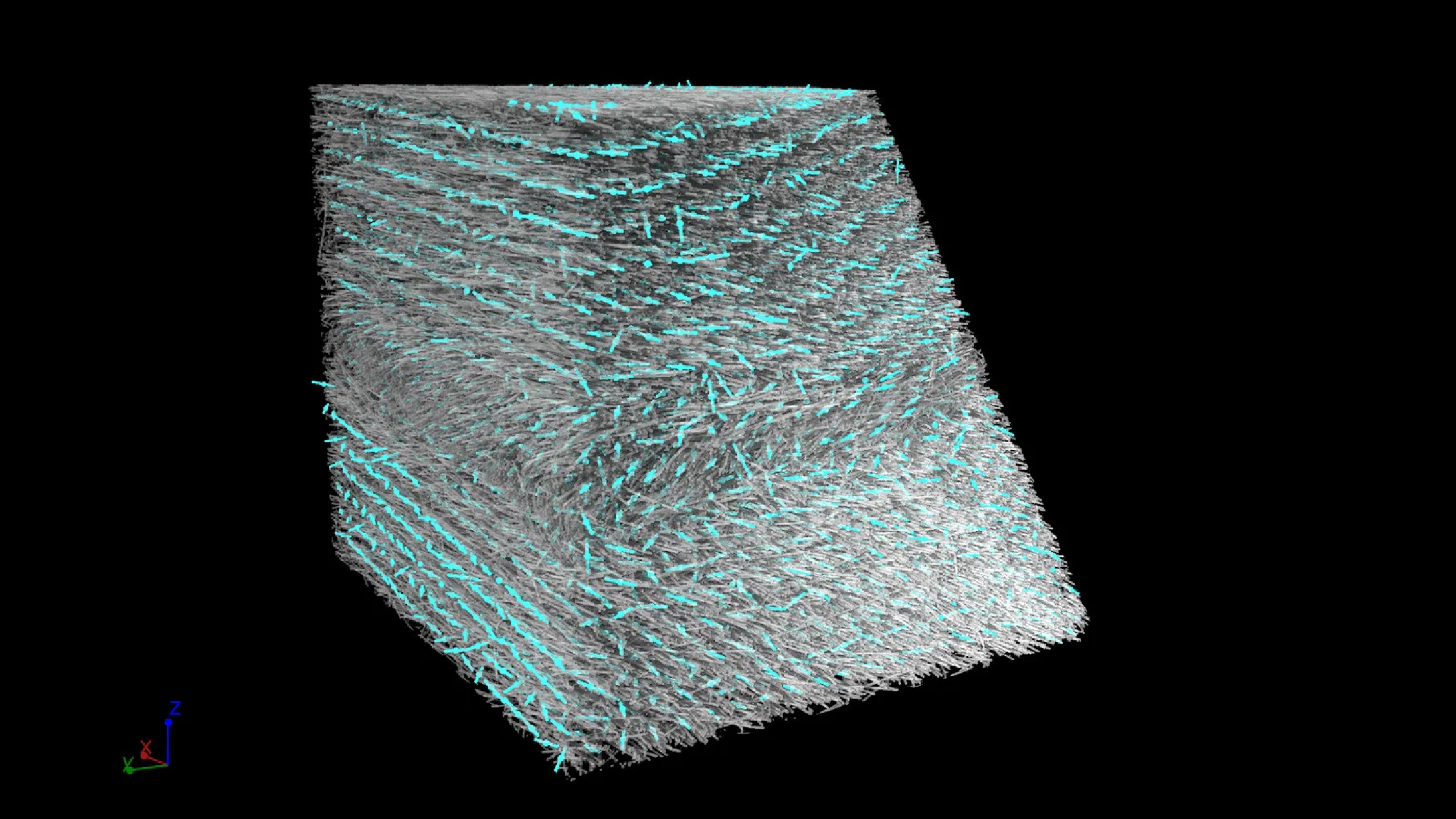

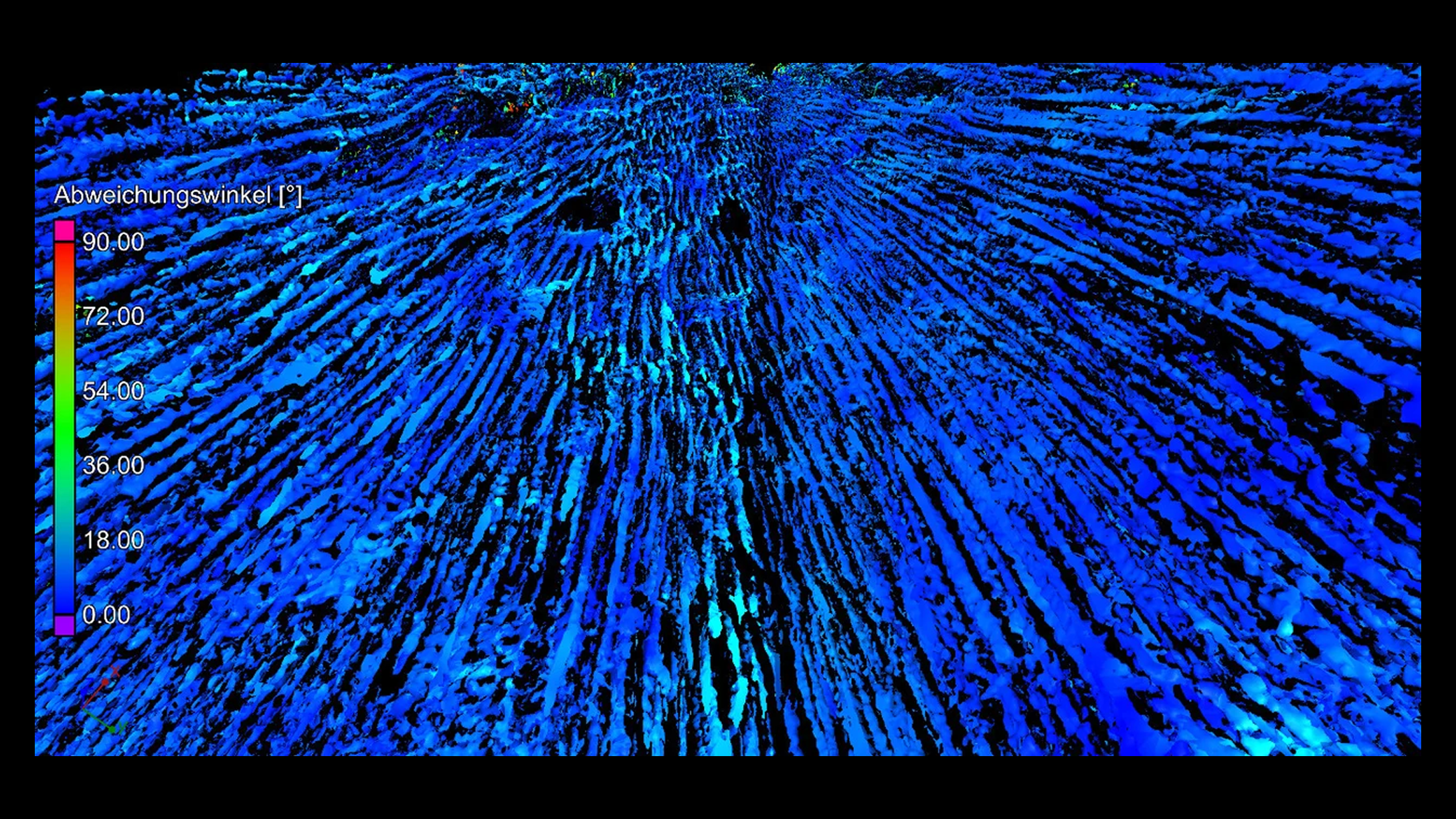

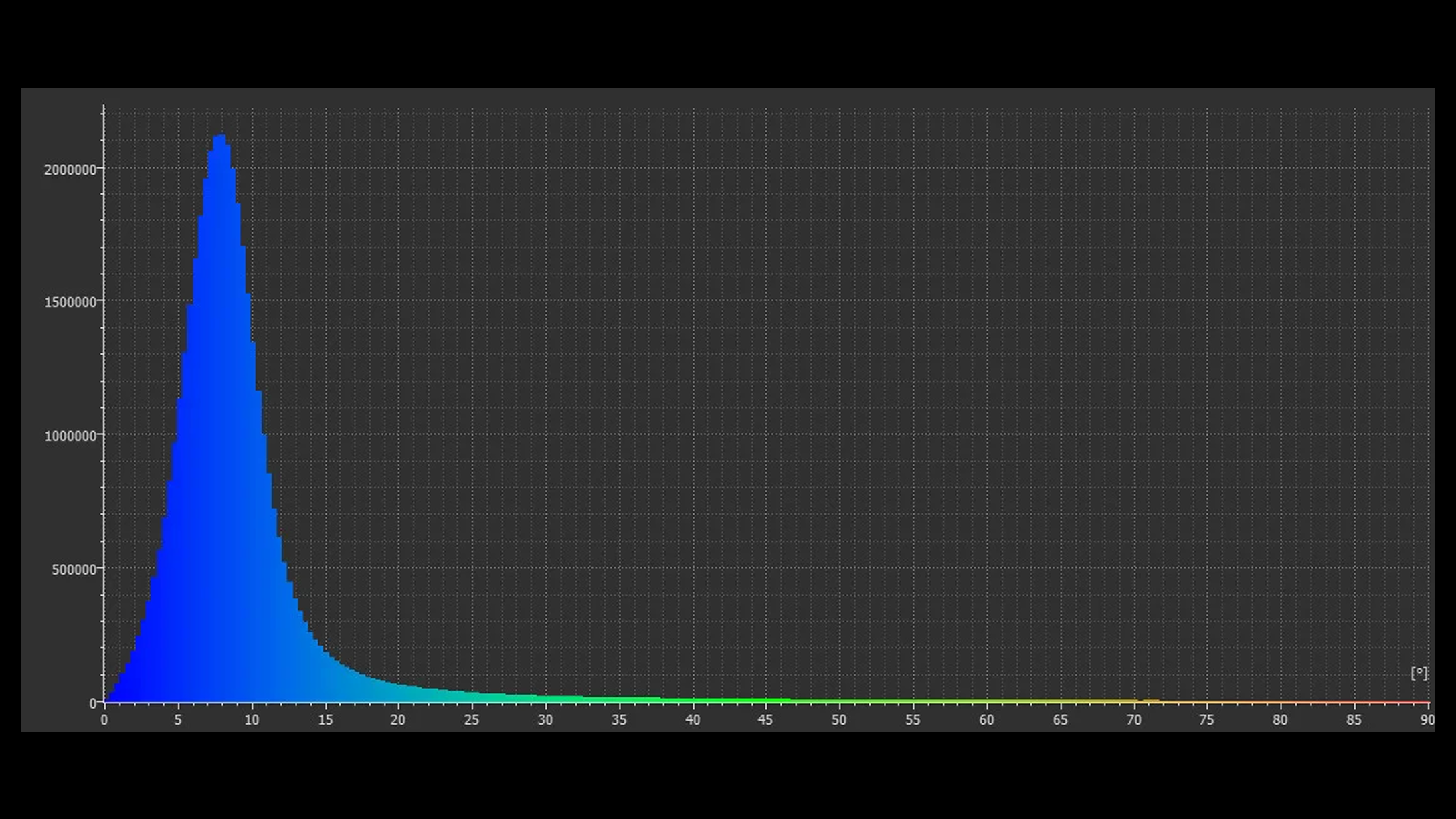

Reference orientation mode

Use reference orientation mode for materials with unidirectional orientation distributions, like pultruded materials, 3D-printed fibre material in certain regions, or natural material, like wood.

In this mode, you can:

- Evaluate the deviation between the local orientation and a global reference orientation and visualise it via color coding

- Plot a global deviation angle histogram

Calculate orientation statistics with confidence, even with low-contrast images or lower resolutions, without compromising accuracy. Our software intelligently analyses the local neighborhood, eliminating the need to segment every single fibre and enabling thorough investigation of materials at lower resolutions.

Quickly calculate orientation statistics with our fast-processing capabilities. Select your preferred statistic and receive it in the exact format you require. Effortlessly map results, such as orientation tensors or fibre volume fraction, directly onto your finite element (FE) meshes for simulation, or plot them over thickness for deeper insights.

This module is tailored to meet the diverse needs of your material types and production processes. Access specialised analysis modes for every class of fibre composite material and manufacturing method.

Contact us today—our team is ready to assist!

Request a quote