릴리즈는 매번 빠른 셋업을 통해 효율을 증대하며,빠른 반응시간을 통해 자원의 낭비를

방지합니다.또한,AI 툴을 이용하여 데이터를 이용한 작업 흐름을 개선합니다.

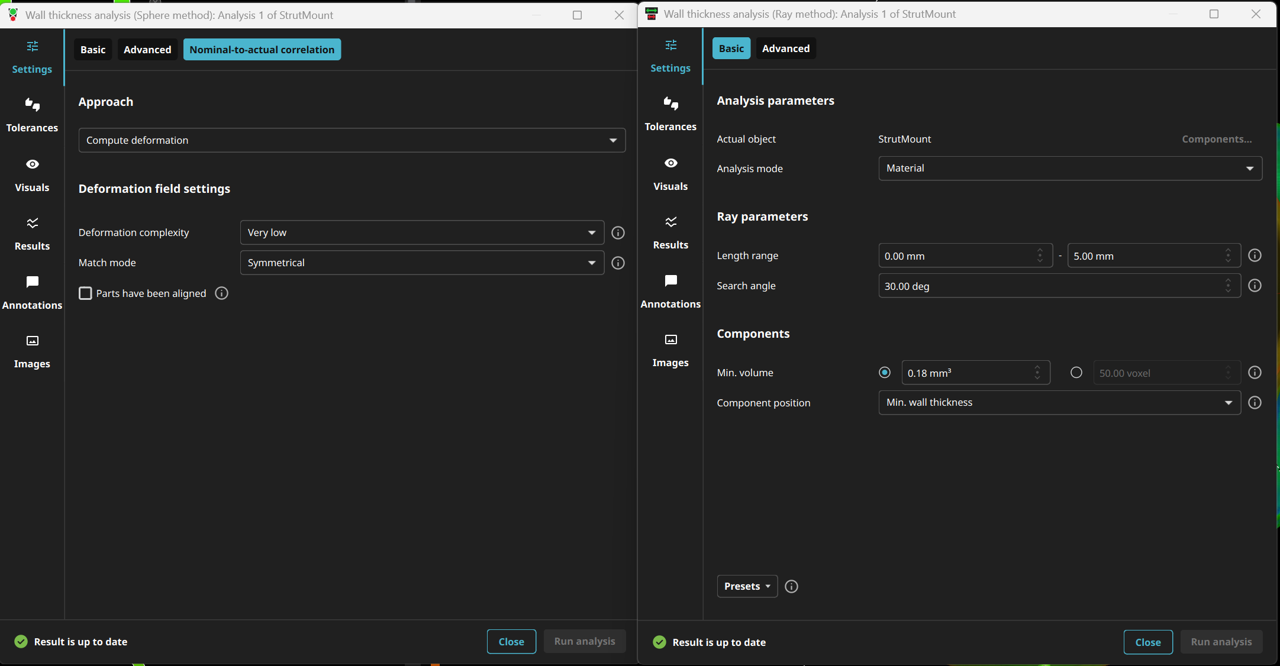

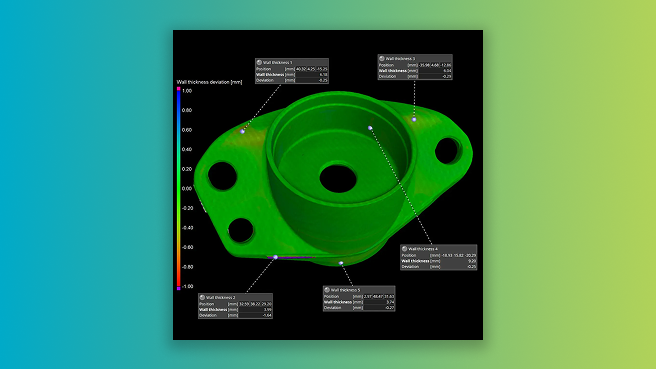

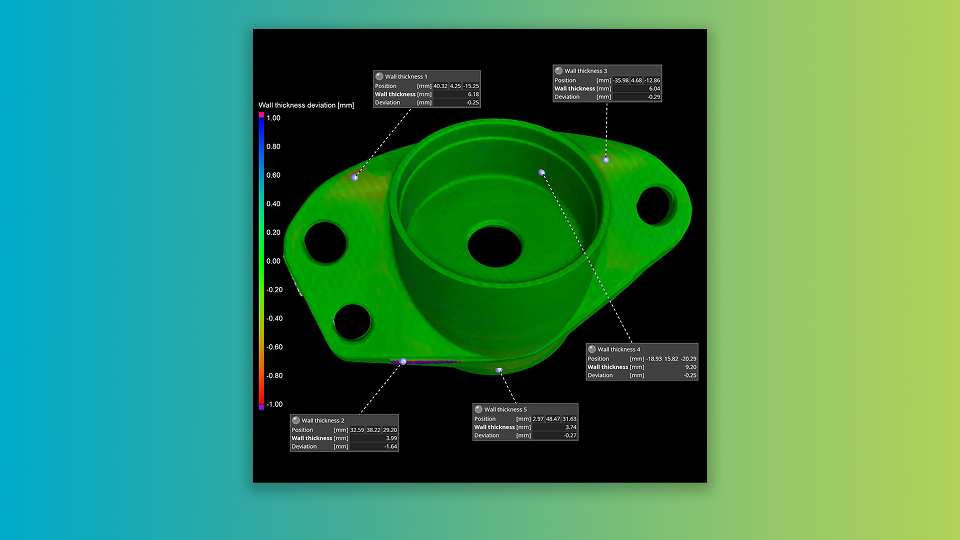

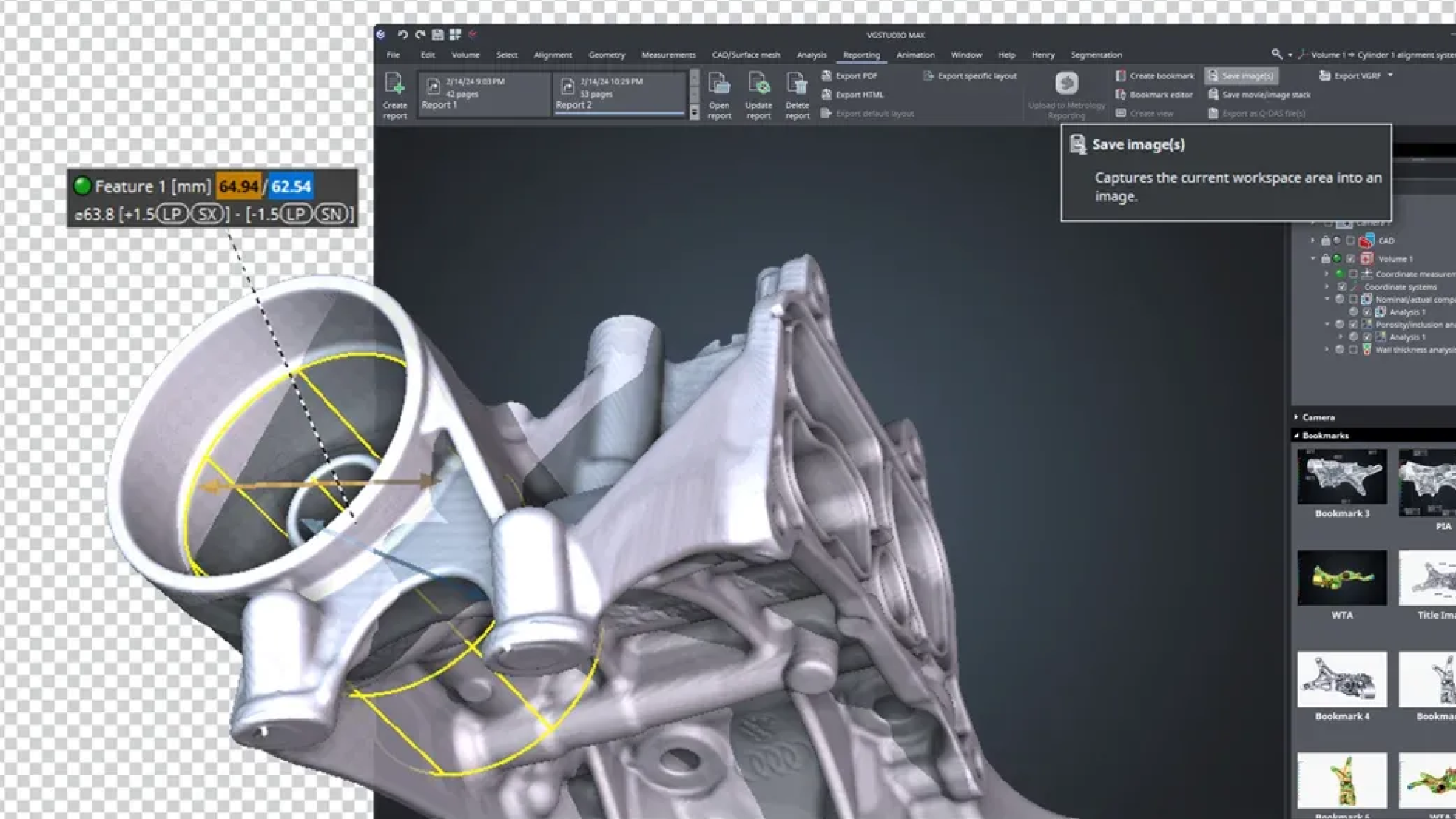

Hexagon VG 소프트웨어 제품 라인 2025.4 버전으로 벽 두께 분석용 사용자 인터페이스는 완전히 재디자인되었습니다. 선 방법 및 구 방법 모두를 위해 모든 필수 설정이 편리하게 요약되어 한눈에 볼 수 있으며,고급 옵션들은 독립된 탭에서 간편하게 사용할 수 있습니다.

새 기능

- 직관적인 디자인: 주요 설정을 즉각 볼 수 있으며,고급 옵션들은 독립된 탭에서 명확하게 정리되어 있습니다.

- 효율적인 작업 흐름: 줄어든 클릭 수와 넓어진 개요,그리고 최대화된 제어를 즐겨보십시오.

- 일치하는 대화상자: 두 대화상자의 워딩과 레이아웃이 표준화되어서 두 방법 간의 매끄러운 전환이 보장됩니다.

새로운 피처와 최적화된 레이아웃은 경험 있는 사용자와 새로운 사용자 모두에게 좋은 접근성을 제공하며 구성요소와 재질 샘플에 대한 정밀하고 효율적인 분석을 가능케 합니다.

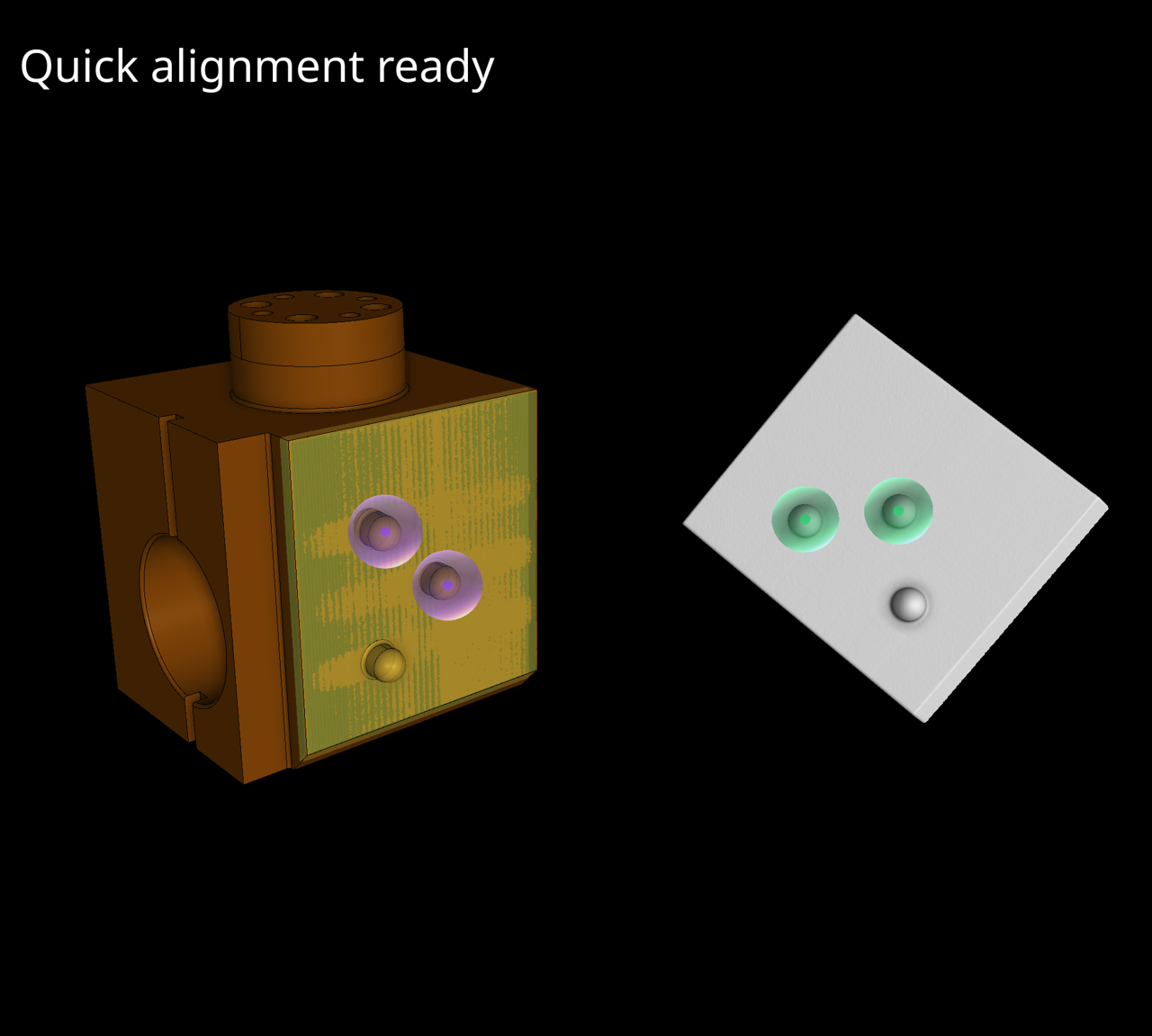

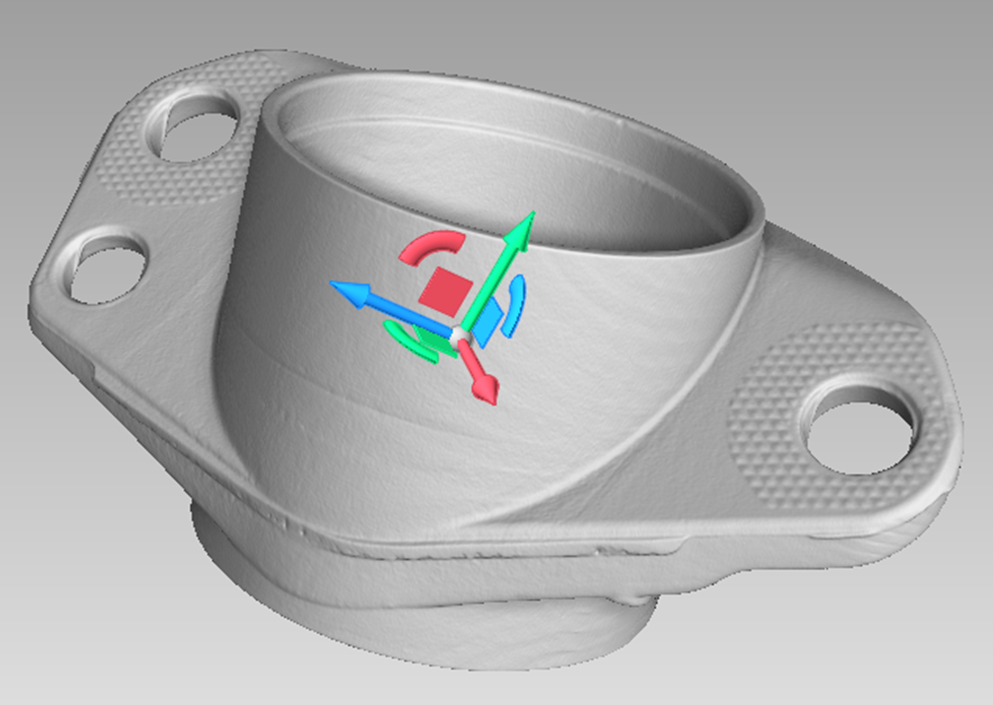

퀵 정렬 방법은 빠르고 사용자 친화적인 방법으로 두 객체에서 1~3개의 매칭 포인트를 선택해서 단 몇 초만에 참조 객체에 부품을 정렬합니다. 이는 다양한 객체 유형(3D 스캔,CAD 모델 또는 볼륨)에서 작업하고 부품이 일부만 중첩되는 경우에도 처리할 수 있으며 정렬을 적용하기 전에 정렬을 미리보기할 수 있습니다.

전형적인 정렬 방법과는 달리 이러한 접근법은 매우 효율적이고 객체의 복잡성과 관계없이 빠릅니다. 또한 최적 맞춤 정렬과 같은 향후 추가적인 미세 조정이나 템플릿 적용을 위한 시작점으로 도움을 줄 수 있습니다.

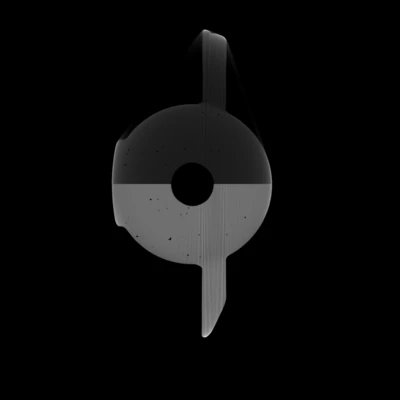

이 중요한 개선 사항은 불완전한 시각적 스캔에 대한 복잡한 모핑을 위해 특별히 설계되었습니다. 시각적 스캔은 보통 변형 계산에서 어려움을 겪었는데 스캐너의 한계로 인해 부품이 누락되는 문제와 특히 일방적인 스캐닝 시나리오에서 정밀한 일치가 필요한 문제 등이 포함되었습니다.

새로운 매개변수를 소프트웨어에 통합하여 이러한 모핑 기술을 상당히 강화하고 사용자가 이러한 과제를 더 효과적으로 해결할 수 있도록 지원합니다.

이러한 개선으로 시각적으로 스캔된 복잡한 부품을 더욱 정확하고 복합적으로 처리하고 까다로운 조건에서도 정확한 정렬과 분석을 보장하도록 합니다. 탁월한 정밀도와 유연성으로 시각적 스캐닝의 고유한 요구 사항을 충족하여 비파괴 평가 프로세스를 향상시키도록 설계된 안정적인 기능으로 작업 흐름을 강화하십시오.

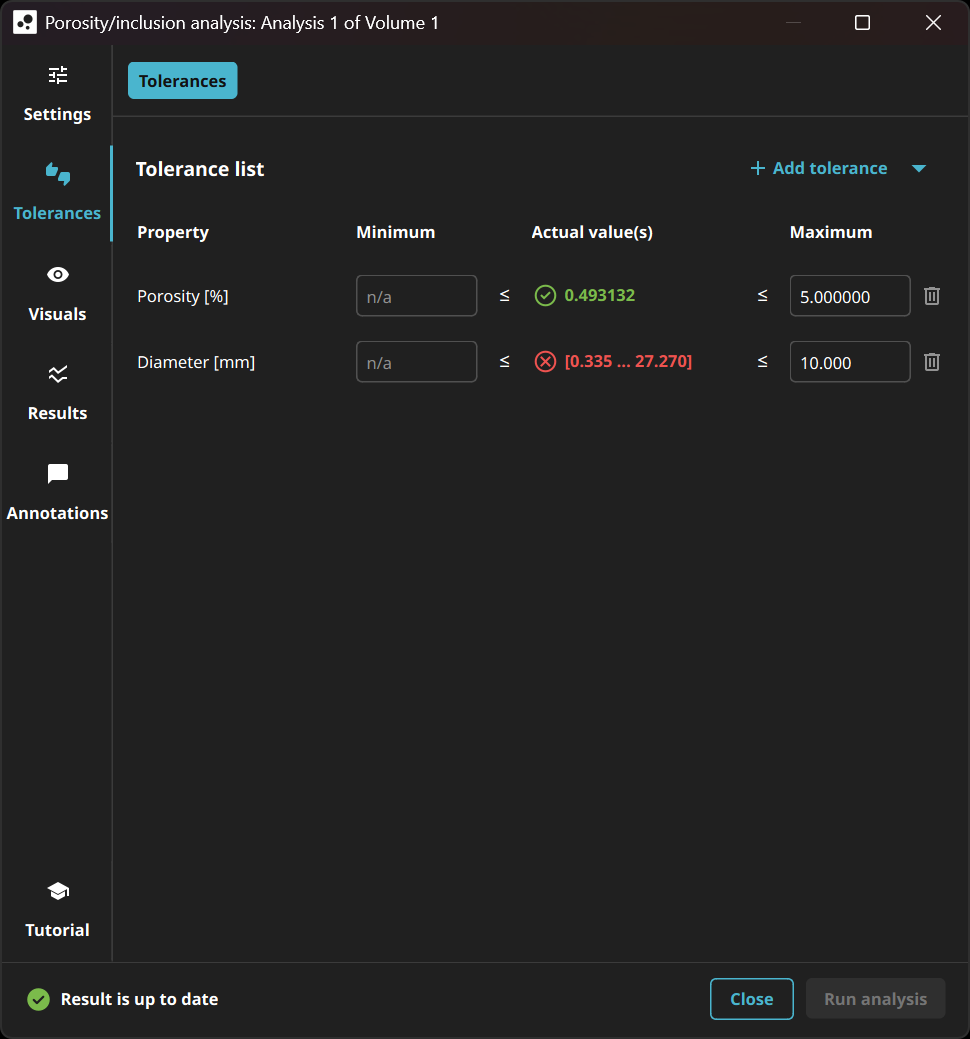

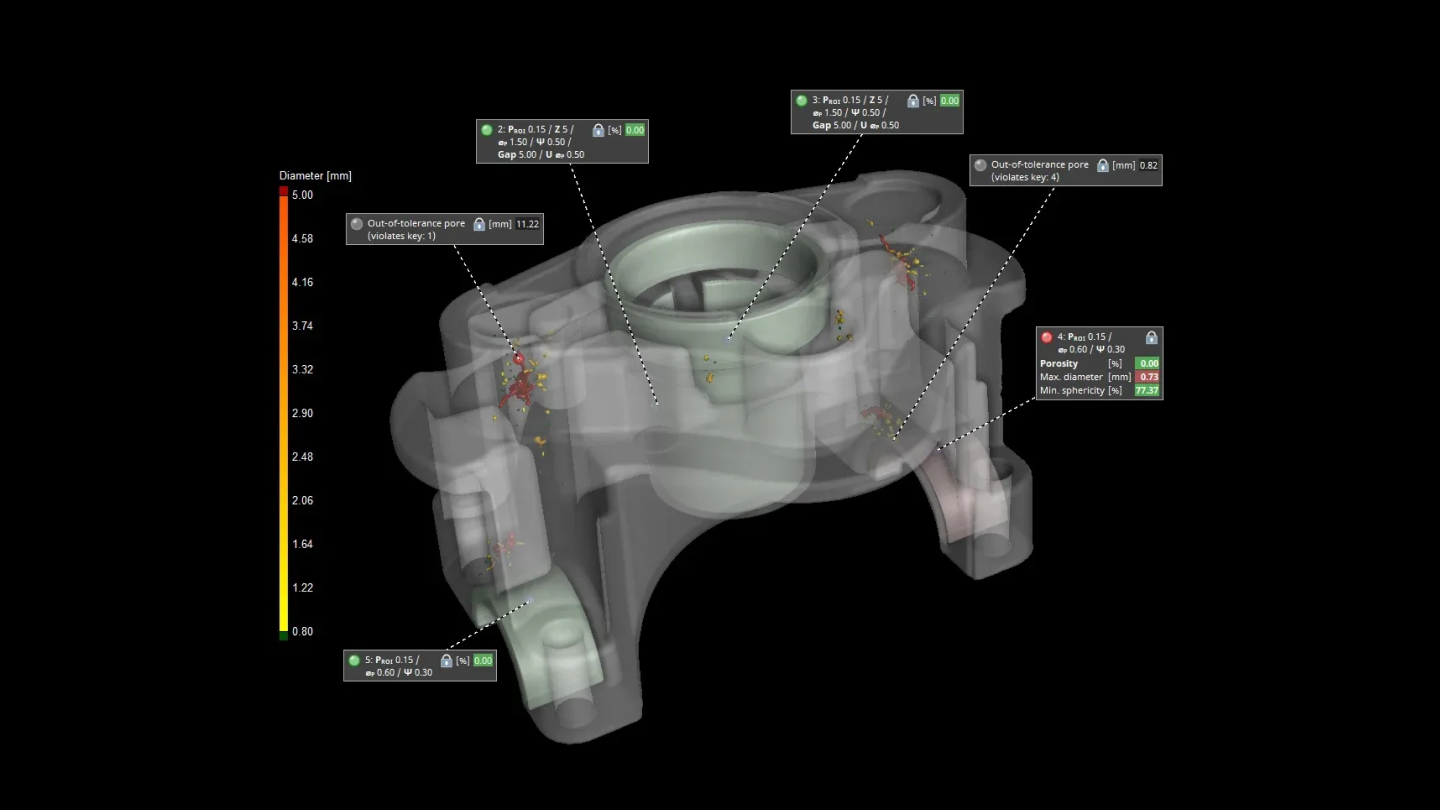

새 허용 오차 페이지는 간단하고 더 포커스되어 있으며 귀하가 허용하려는 속성만 표시합니다. 이는 두 방향(상한 및 하한) 모두에서 각 공극의 정밀한 한계를 정의하고 특정 요구 사항을 충족하기 위해 더 큰 유연성을 제공합니다.

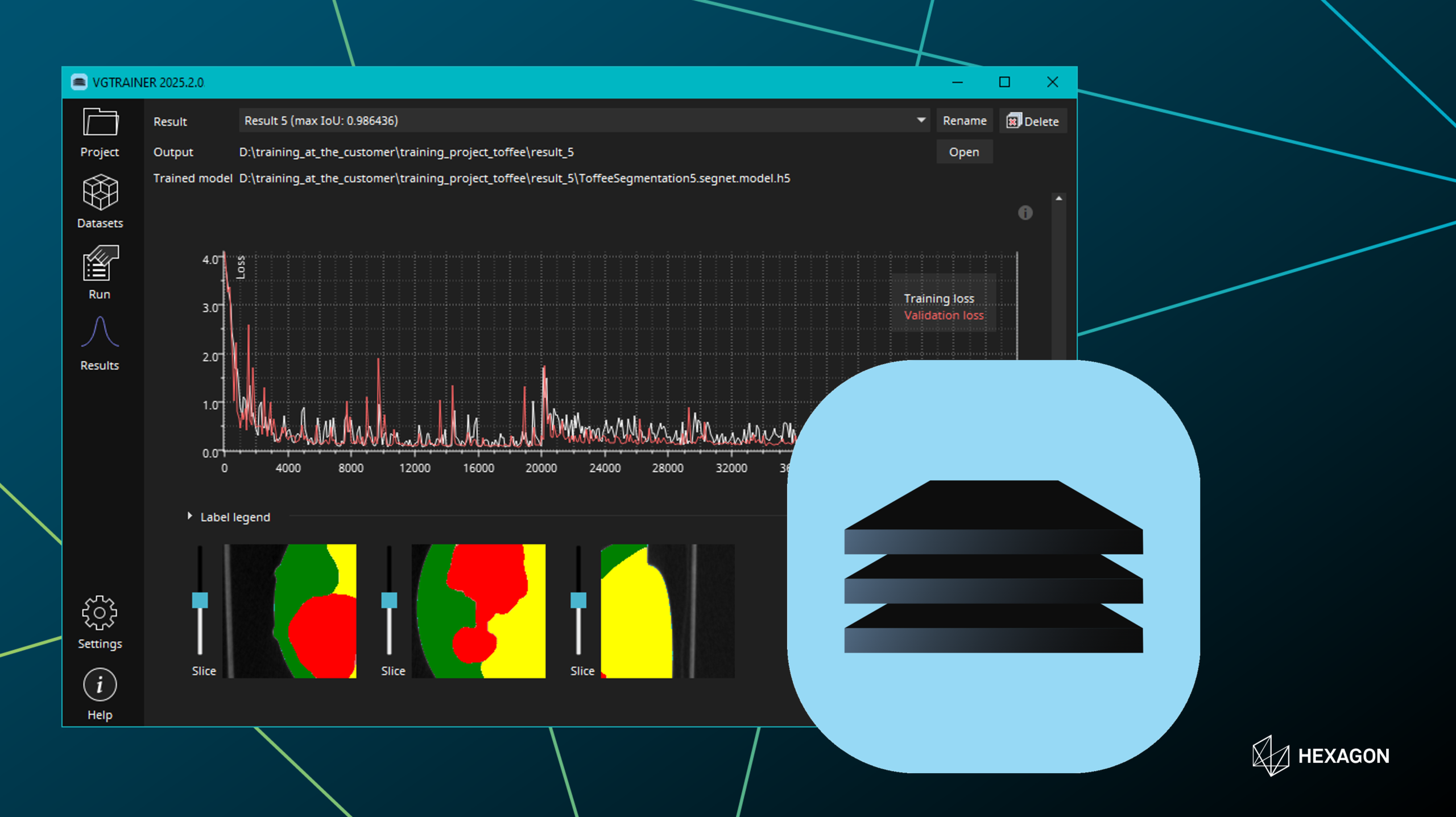

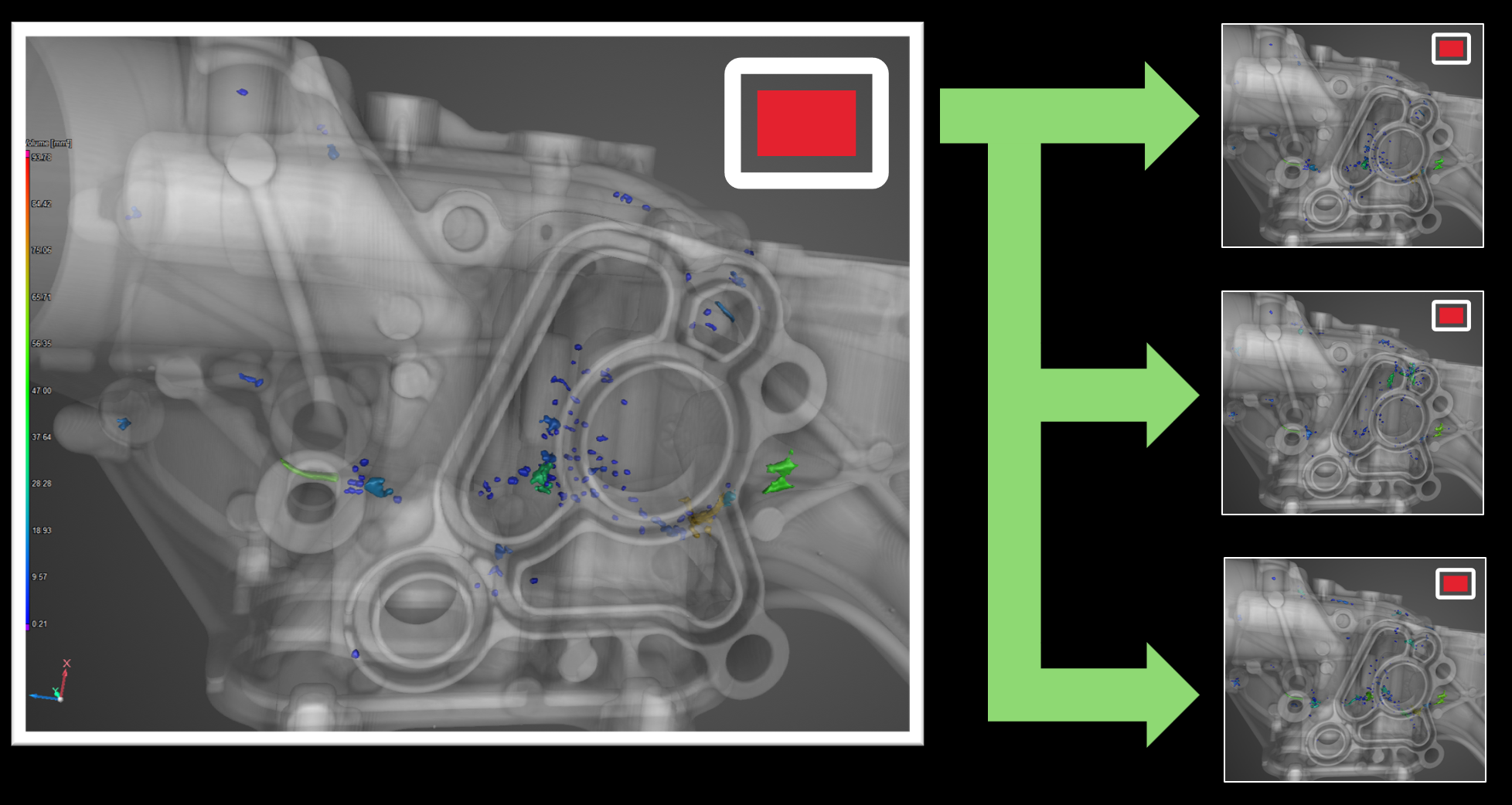

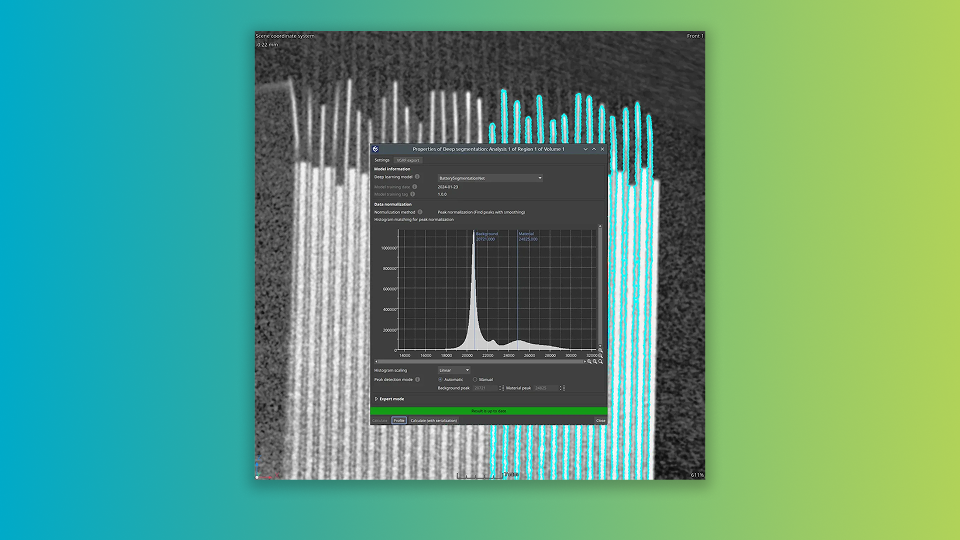

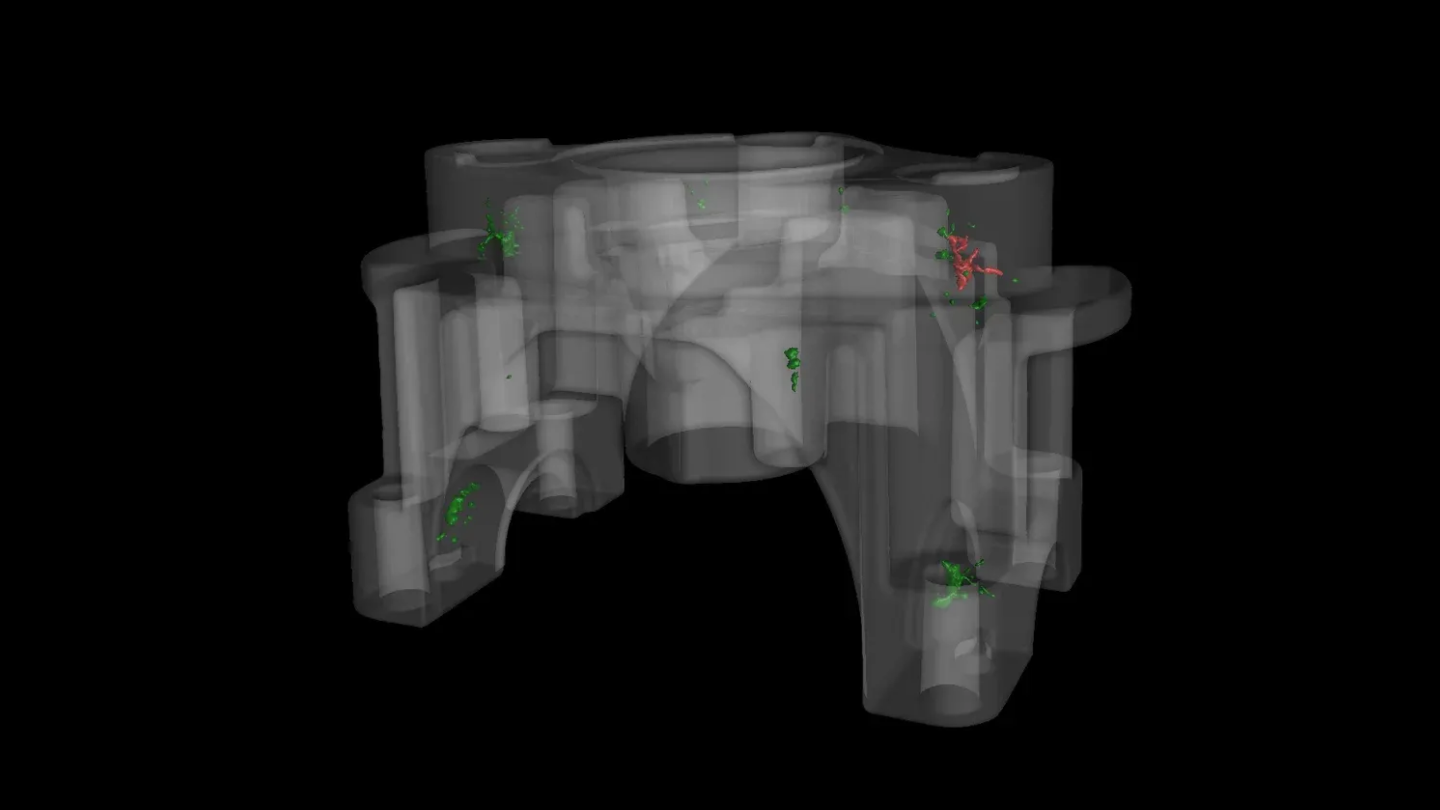

이전에 몇 개의 레이블이 지정된 점으로만 모델을 대규모의 CT 스캔으로 트레이닝할 때는 전체 스캔이 아니라 레이블이 지정된 영역에만 초점을 맞췄습니다.

이제 모델이 트레이닝 중에 전체 스캔을 고려하게 되면서 허위 양성 응답이 감소하고 분할 결과의 전반적인 정확도가 향상됩니다.

교육 프로세스가 더 빨리 시작되어 고객에게 진행 과정에 대한 피드백을 더 신속하게 제공합니다.

또한, 현대적인 하드웨어에서 교육 주기가 가속화되어 시간이 절약되고 효율성이 증대됩니다.

사용자가 프로젝트 및 보고서 내 보기에 사용자 정의 텍스트 설명을 추가하도록 허용함으로써 이러한 피처는 사용자 정의를 향상하고 더 자세한 정보를 제공하여 프로젝트 탐색과 더욱 유익한 보고서 생성을 간편하게 합니다.

자동 이미지 체크박스 제거는 고객들이 이미지 생성 프로세르를 간소화하는 더 강력하고 유연한 보기를 사용하도록 장려합니다. 전환을 용이하게 하기 위해서 기존 프로젝트를 새로운 시스템으로 자동 변환하지만 가끔은 사용자가 이전 이미지와 정확히 일치하도록 보기를 수동으로 조정해야 할 수도 있습니다.

새 옵션은 사용자가 최근 사용한 파일 섹션 전체 또는 썸네일 이미지만 간편하게 숨기도록 합니다. 이는 화면 공유나 프레젠테이션 중에 기밀 정보를 보호하는 것을 돕습니다.

새로운 설정은 경험 있는 사용자가 매크로를 기록하는 동안 자동화 도구의 자동 확장을 비활성화하도록 허용합니다. 이는 장면 트리와 같은 다른 도구를 위한 공간을 더 제공하고 작업공간을 효율적으로 향상합니다.

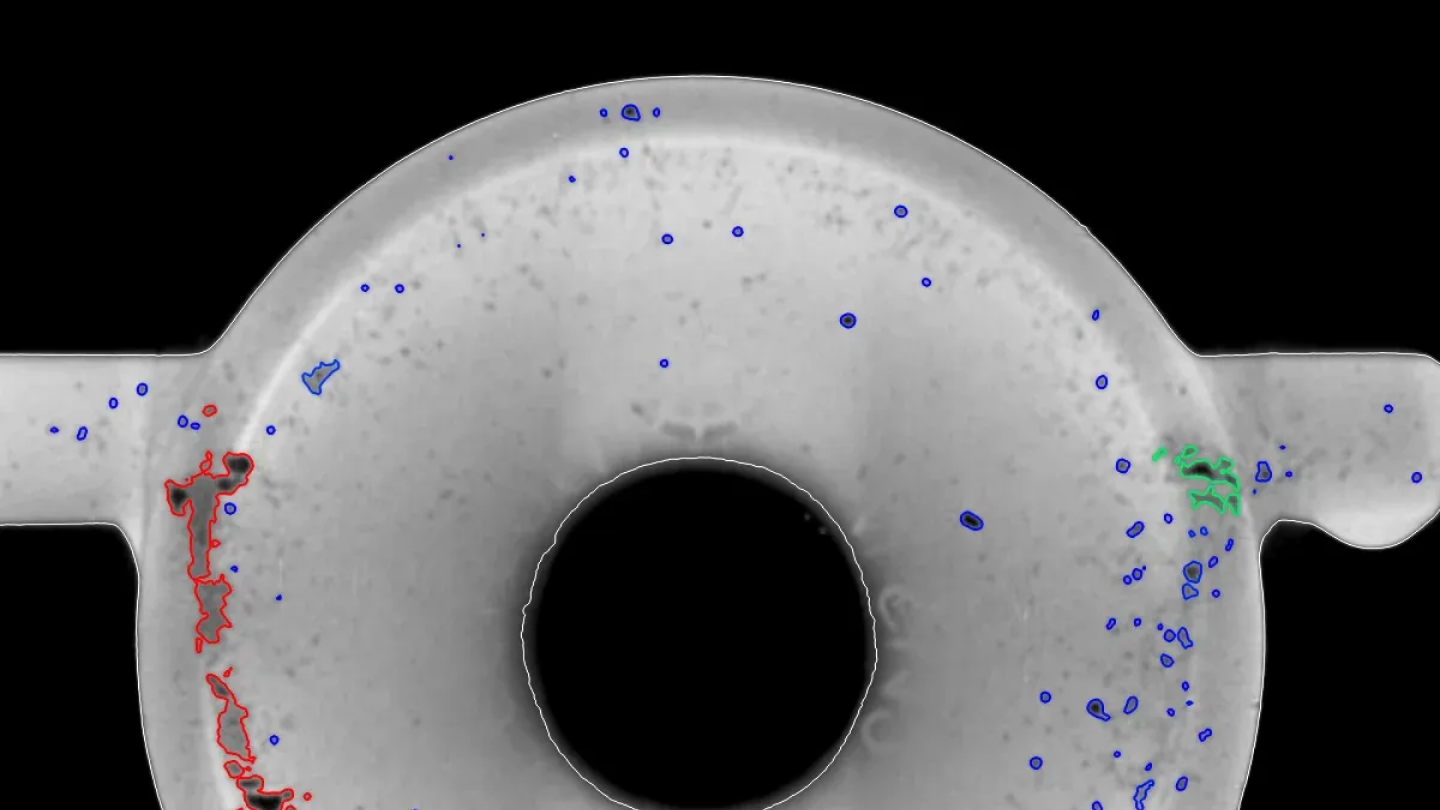

이 비디오에서는 다수의 노이즈 및/또는 아티팩트가 있는 스캔의 공극률 분석을 수행하는 방법에 대해 학습합니다.

저희의 머신 러닝 도구인 "그리기 및 분할"을 사용하여 공극을 포함한 ROI를 빠르고 간편하게 생성하십시오. 그다음에 "결함징후 ROI" 검출 방법으로 공극률 분석을 수행합니다.

이 비디오에서는 그리기 및 분할을 사용하여 CT 스캔에 레이블을 붙이는 방법과 다양한 ROI 작업 도구와 함께 레이블을 최적화하는 방법을 알아봅니다. 마지막으로 귀하는 딥 분할에서 사용하는 이러한 레이블을 내보내는 방법을 학습합니다.

이 비디오에서 우리는 개요 및 분석을 촉진하고 좌표 측정 템플릿,대상 및 지오메트리 요소를 편집하여 다수의 부품이 포함된 프로젝트를 관리하기 위해 향상된 편의성을 제공하는 "좌표 측정 오버뷰" 대화상자를 탐색합니다.

이 비디오 튜토리얼에서는 벽 두께나 부품의 간격 폭을 평가하기 위해 VGSTUDIO MAX에서 벽 두께 분석을 설정하는 방법 또는 명목 부품과 실제 부품의 벽 두께를 비교하는 방법을 보여드립니다.

분석은 두 가지 강력한 방법을 제공합니다.

- 간단한 지오메트리 또는 거의 평행한 구조를 가진 부품의 경우에는 선 방법으로 증명합니다.

- 복잡한 3D 프린트된 구성요소와 같은 더 복잡하고 유기적 형태인 경우에는 구 방법을 탐색해 봅니다.

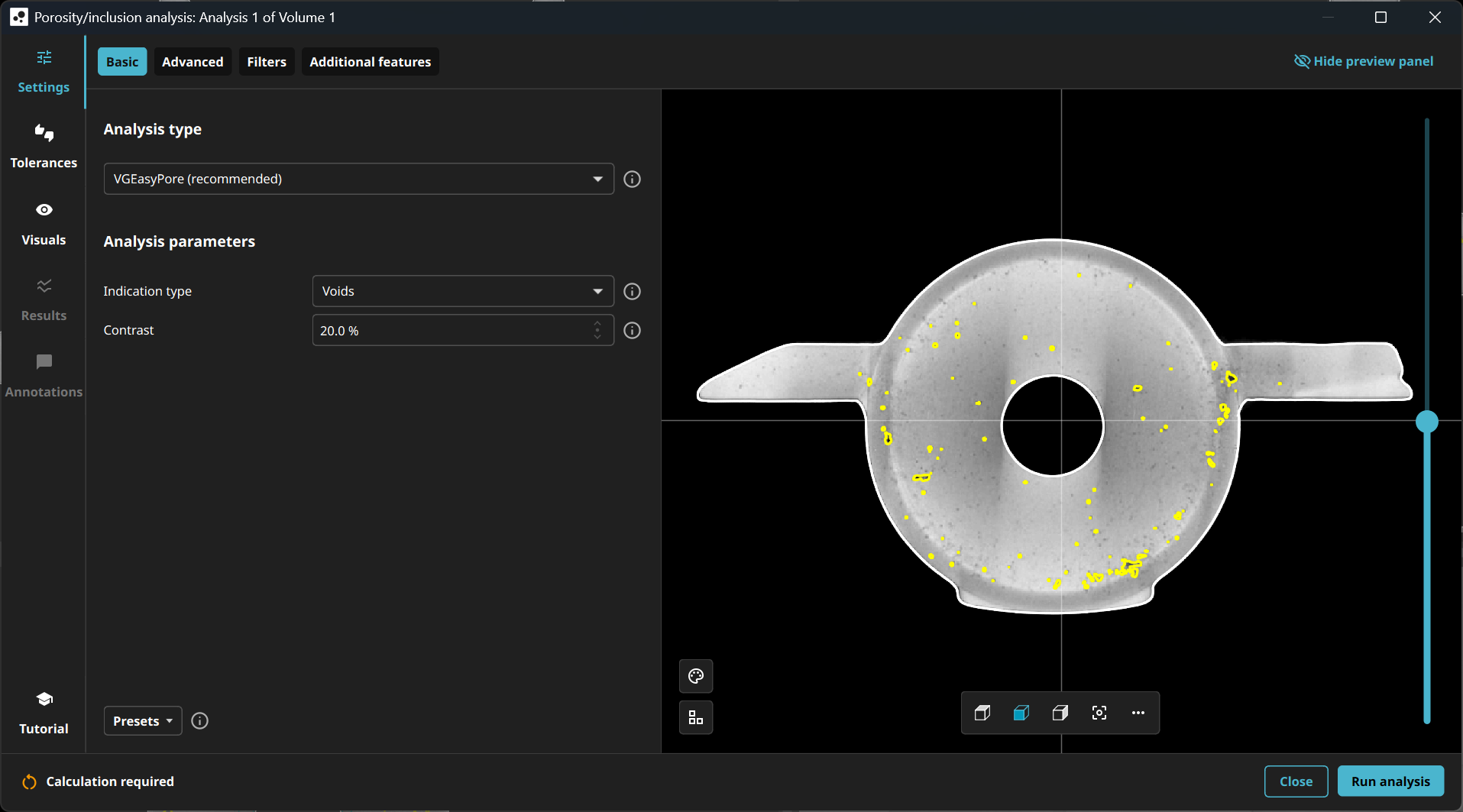

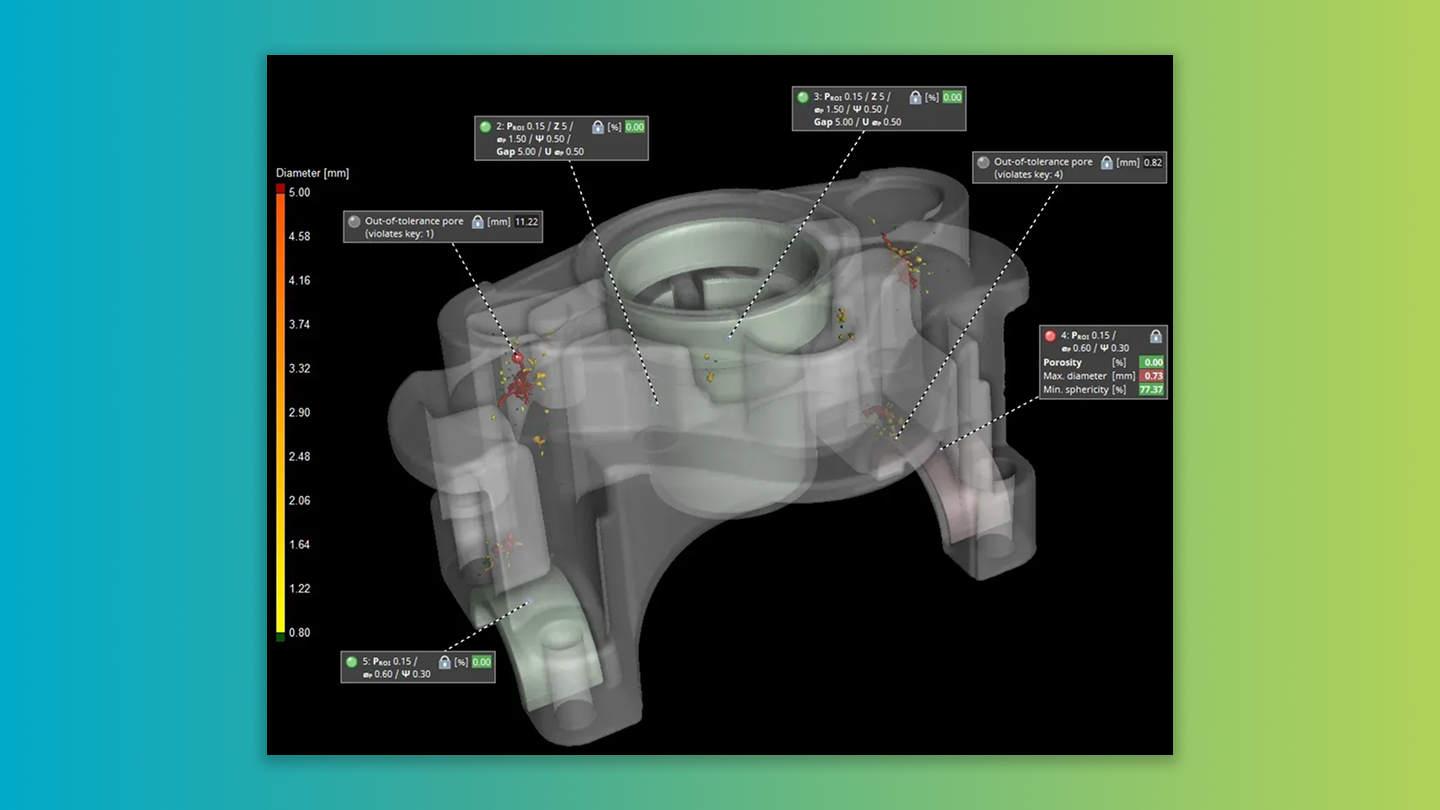

VGSTUDIO MAX 2025.3는 공극률/내포물 분석의 디자인을 완전히 새로 디자인했습니다. 모든 중요 설정이 요약되어 한눈에 볼 수 있으며,고급 옵션들은 독립된 탭에서 간편하게 사용할 수

있습니다.

미리보기는 분석 창에 포함되었으며 인터액티브 미니맵 또한 포함되어 분석 창에서의 현재 위치를

표시합니다. 이는 구성요소에 대한 오버뷰를 항시 보여주며 이를 통해 탐색이 간편해집니다.

새 기능

- 직관적인 디자인: 모든 중요 설정을 즉각 볼 수 있으며,고급 옵션들은 독립된 탭에서 간편하게 사용할 수 있습니다.

- 효율적인 작업 흐름: 더 적은 클릭,더 많은 오버뷰,최대의 제어. 최초로,모든

공극률/내포물 분석 과정을 하나의 해결책으로 통합했습니다. 이를 통해 핵심 기능에 직접

접근할 수 있으며 여러 대화상자 사이를 전환할 필요가 없어 시간을 절약할 수 있습니다. - 모든 것을 한 눈에: 분석 대화상자의 새로운 미리보기는 모든 중요한 정보를 결합하며

인터액티브 미니맵을 통한 쉬운 탐색이 가능합니다.

새로운 기능들과 최적화된 레이아웃은 경험있는 사용자와 새로운 사용자 모두에게 좋은 접근성을

제공하며 구성요소와 재질 샘플에 대한 정밀하고 효율적인 분석을 가능케 합니다.

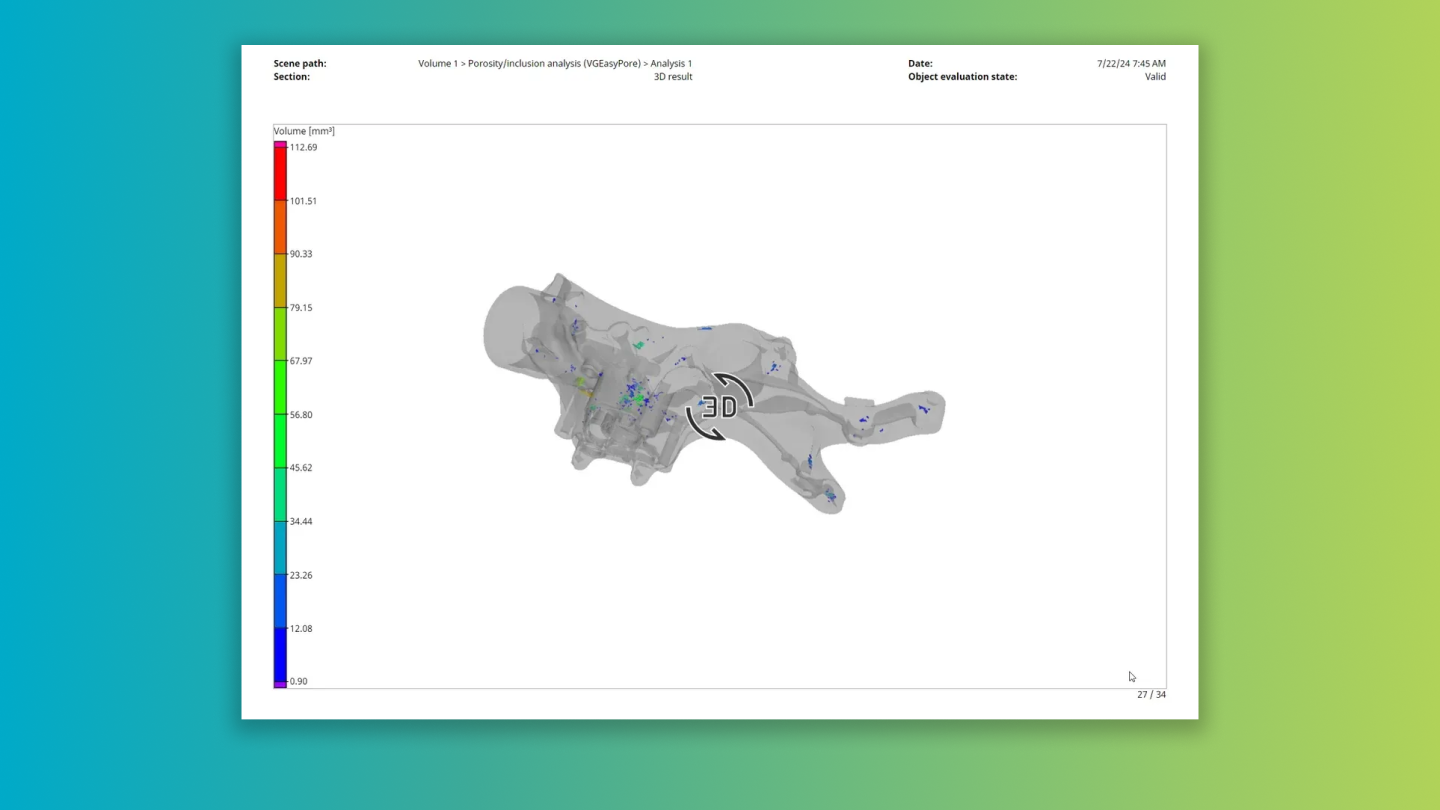

2025.3 버전을 통해,기존의 모든 방법들을 하나의 강력한 분석 및 보고 기능으로 결합한 완전히

새로운 공극률/내포물 분석을 도입했습니다.

새로운 공극률/내포물 분석은 사용자의 작업 방식을 혁신적으로 개선하며 더 빠르고 효율적인

결정을 내릴 수 있도록 도와줍니다. 2025.3 버전은 공극률/내포물 분석의 미래를 정의합니다

— 간편하고 유연하며 강력합니다.

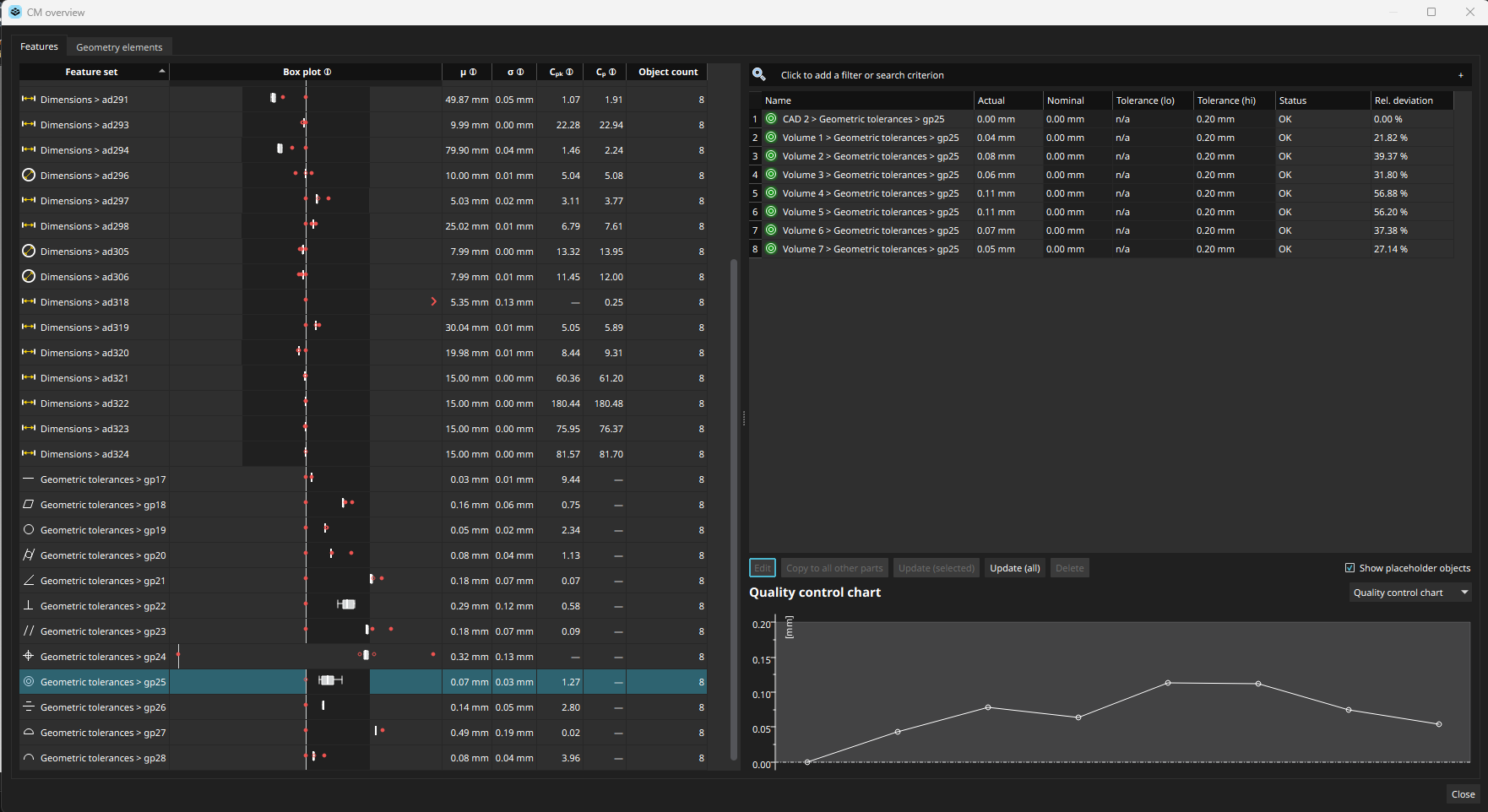

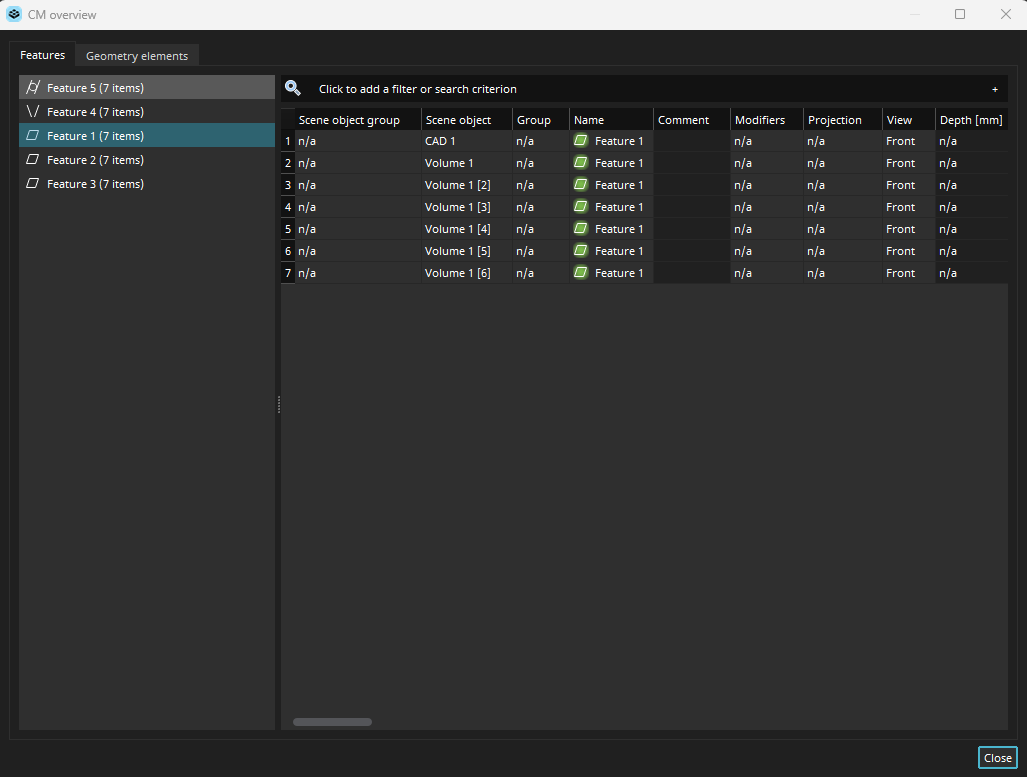

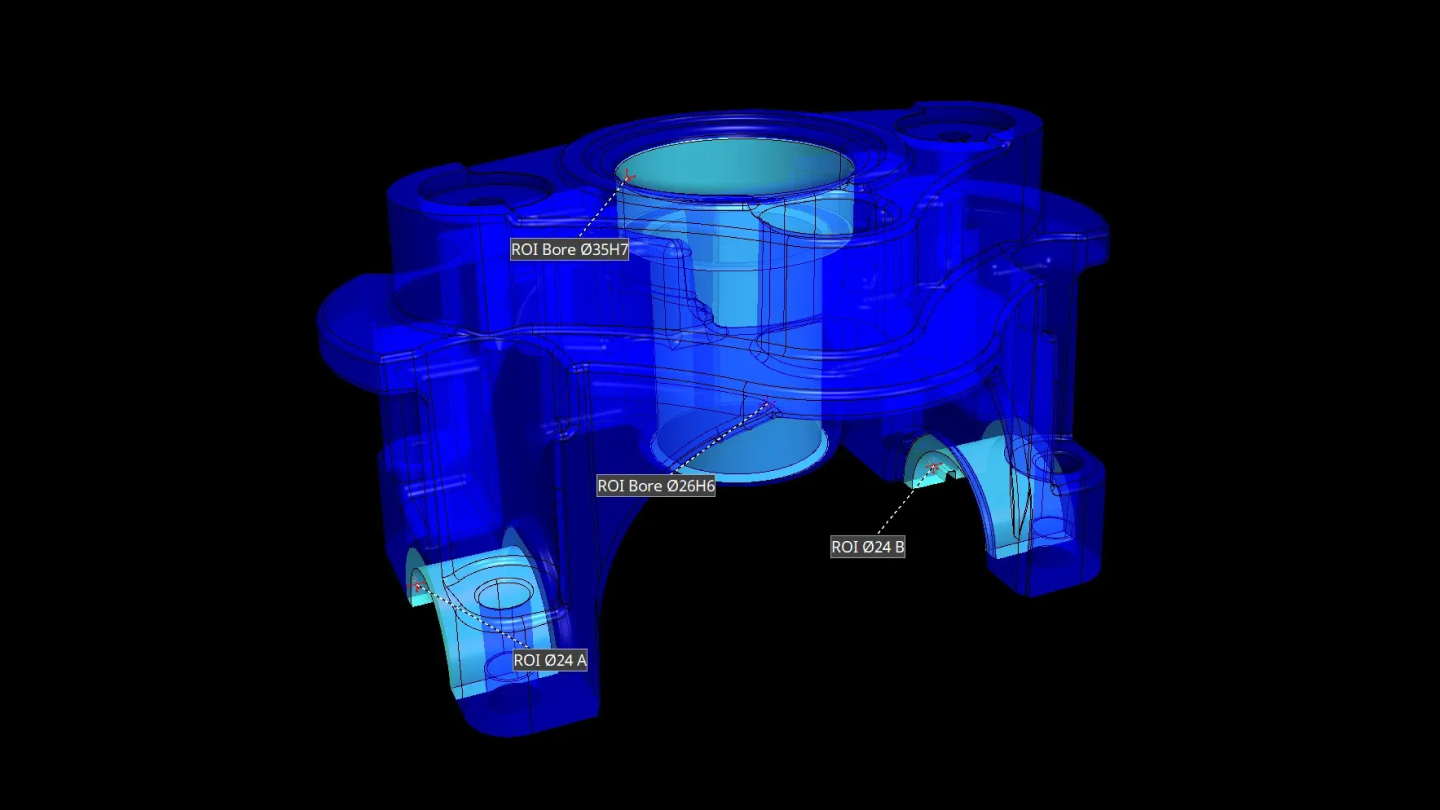

여러 부품의 좌표 측정 기능을 통해 사용자는 다수의 부품에 대해 분석을 확인하거나 측정을 편집할 수 있고 오버뷰를 얻어 작업을 단순화합니다.

개선점에는 다음이 포함됩니다:

- 피처에 대한 기본적 통계를 피처 목록에서 직접 확인

- 여러 부품에 공존하는 개별 피처의 여러 값에 대한 인터액티브한 플롯

- 모든 부품에 걸친 피처와 지오메트리 요소의 직접 편집,제거,그리고 이전을 포함하는 편리한 기능을 통해 프로젝트 구성요소에 대한 효율적이고 더 나은 관리를 보장합니다

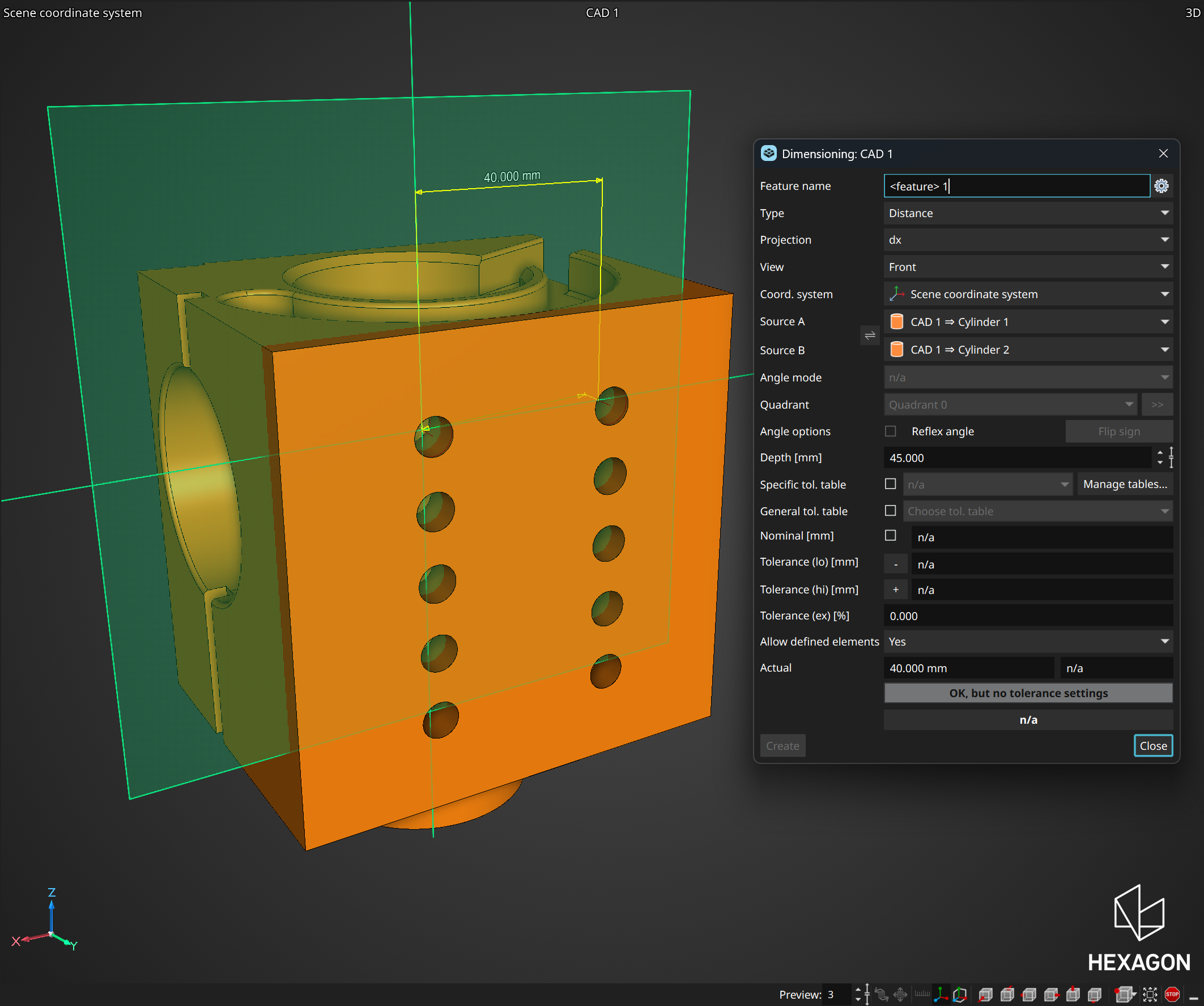

"치수 측정"대화상자가 열린 상태에서,3D 보기에서 직접 측정 선을 드래그하여 치수 측정 피처를 쉽게 생성하고 조정할 수 있습니다.피처를 정렬된 방향으로 위치시키기 쉬우며 최적의 시각화를

실현합니다. 이에 더해,"ALT"키를 누른 상태에서,미리보기 평면에 투영된 치수를 생성할 수 있습니다. 이 개선점을 통해 모든 선이 가시화되며 조절가능한 상태가 되며,이는 재질 내부에

위치하는 경우에도 마찬가지입니다.

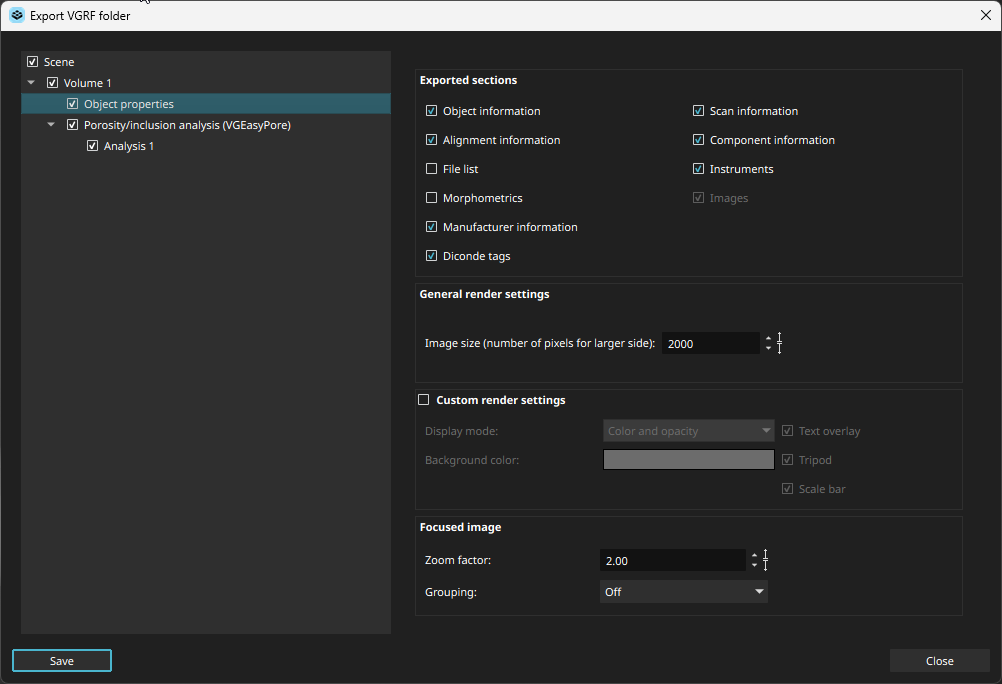

VGRF 내보내기 설정을 내보내기 대화상자로 이동함으로써,사용자는 내보내기시에 직접 설정을 조정할 수 있어 데이터 내보내기가 간편하게 개선되었습니다. 이 개선점을 통해 상이한 구성의 반복되는 보고서에 대해 PDF 또는 Excel 파일을 효율적으로 생성할 수 있습니다. 이에 더해,구식의"VGRF 내보내기"탭은 제거되었습니다.

새로운 보고서를 우선시하기 위해 구식 보고서 도구를 제거했습니다.새로운 보고서는 더욱 강력한 보고 기능으로 보고서를 생성함에 있어 더 부드럽고 효율적인 경험을 가능케 합니다.그럼에도 편리를 위해 임시적으로 이전의 매크로에서는 구식 보고서가 지원됩니다.

이 기능을 통해 사용자는 메쉬와 연관된 메타정보를 볼륨과 마찬가지로 검사 보고서에 포함시킬 수 있습니다. 이 개선점은 보고서의 사용자 정의와 추적 가능성을 개선하며 더 알아보기 쉽고 포괄적인 기록을 제공합니다.

이 개선점은"업체 주소"와"구성요소 비고"와 같은 추가 필드를 통해 볼륨 데이터의 DICONDE 형식으로의 볼륨 내보내기를 개선합니다. 이를 통해 사용자가 부품에 관해 더욱 자세하고 표준화된 정보를 추가할 수 있으며,데이터 관리와 정보전달을 개선합니다.

개선된 메쉬 가져오기/내보내기가 GLB/GLTF,AMF 및 3MF 파일 형식을 지원합니다.이를

통해 3D 표면 데이터를 다른 응용 프로그램과 더욱 쉽게 교환할 수 있습니다. 예를 들어,적층

가공을 위해 생성되어 AMF 또는 3MF 형식으로 저장된 메쉬 데이터를 직접 명목 참조 데이터로

가져오고 사용할 수 있으며,중간 형식으로 변환할 필요가 없습니다.또한,분석 결과로부터

생성된,또는 볼륨 객체로부터 추출된 색상 메쉬를 GLB 형식으로 내보내어 PowerPoint와 같은

다른 응용 프로그램과 간편히 공유할 수 있습니다.

볼륨에서 CAD로의 변환에서의 표면/윤곽 다듬기 기능을 통해 사용자가"객체 변환"대화상자에서 직접 거친 볼륨 또는 ROI 윤곽을 다듬을 수 있으며 리버스 엔지니어링을 단순화합니다. 이를 통해 복잡한 우회 작업의 필요가 없어지며 프로젝트의 구조를 유지할 수 있습니다.또한,매크로 기록이 가능함으로 프로세스의 효율을 높입니다.

이제 고정물 시뮬레이션이 직접 STL 메쉬를 지원합니다.사용자는 광학 스캔과 STL 부품에 시뮬레이션을 실행할 수 있으며 복잡한 볼륨으로의 변환이 필요가 없어 시간을 절약하고 작업흐름을 단순화할 수

있습니다.

이 새로운 기능을 이용하면 사용자가 딥 분할 모델을 데모 용도로 트레이닝할 수 있습니다.

모델에는 만료기간이 적용되며 만료되면 사용할 수 없습니다. 사용하는 경우,프로젝트에 워터마크가 적용됩니다. 이 변경은 비가역적입니다.

짧은 기간의 사용에 이상적입니다.30일 트라이얼 평가,고객 데모,또는 타당성 조사가 이런 경우입니다. 이 피처는 VGTRAINER의 가능성을 테스트할 수 있는 안전하고 비용 대비 효율이 높은 방법을

제공합니다.

이 비디오에서는 공극률/내포물 분석에 경험있는 사용자를 대상으로 최신의 업데이트와 변경사항에 대해 안내합니다.

이 비디오는 VGSTUDIO MAX의 새로운 사용자 인터페이스에서 공극 분석을 실행하는 과정을 보여줍니다.

하이라이트:

- 새로운 직관적인 인터페이스

- 결과 미리보기 및 인터액티브 미니맵

- 도움되는 툴팁

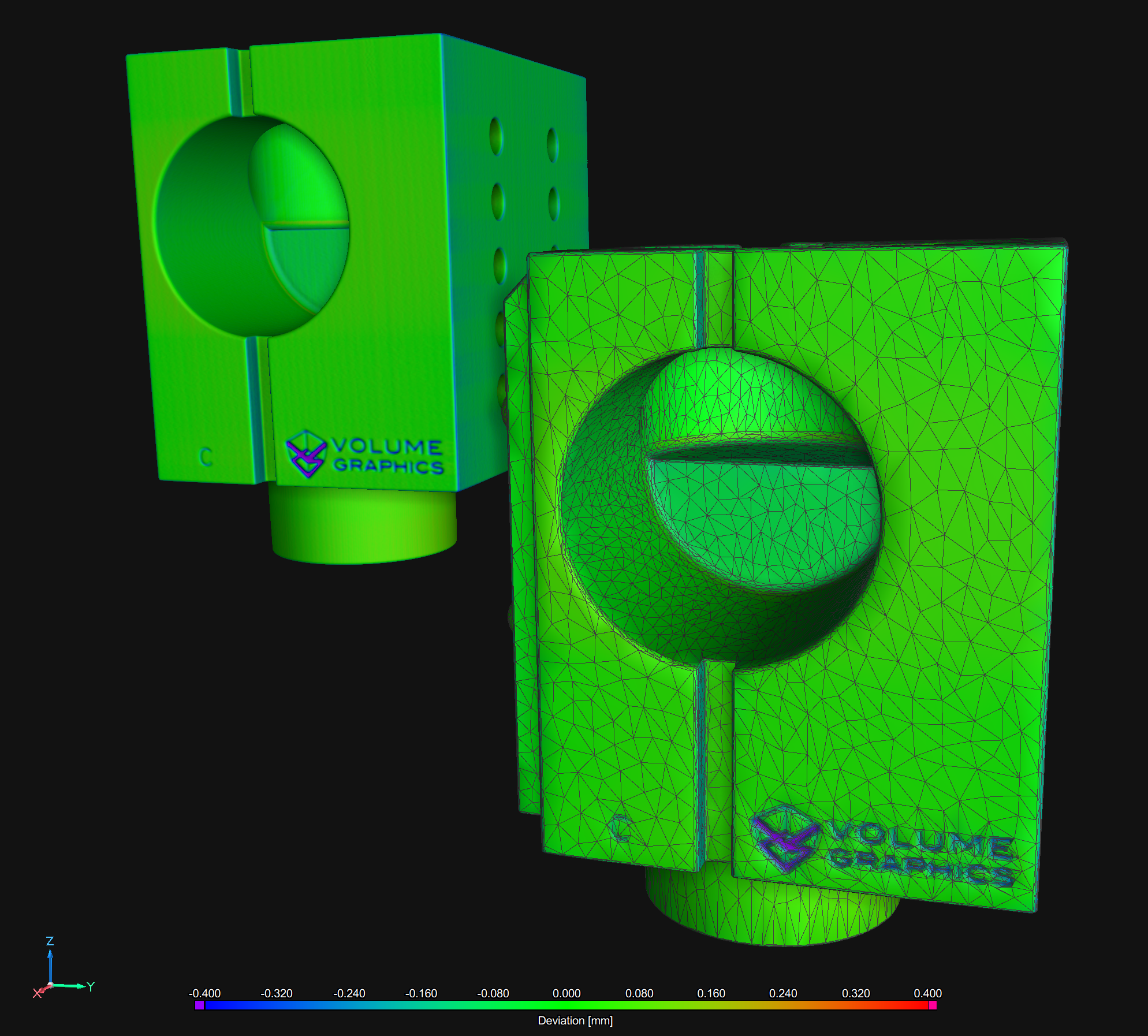

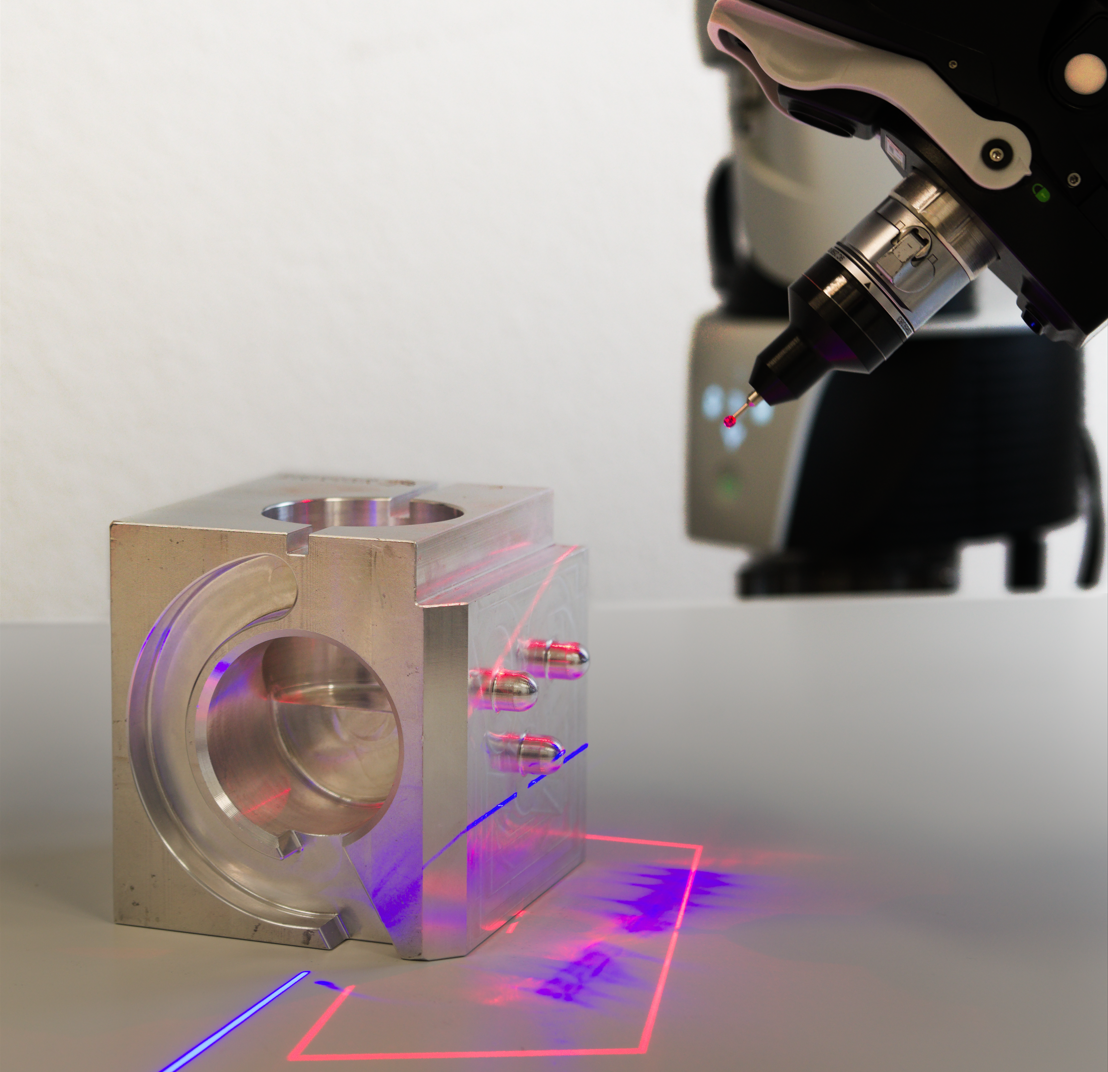

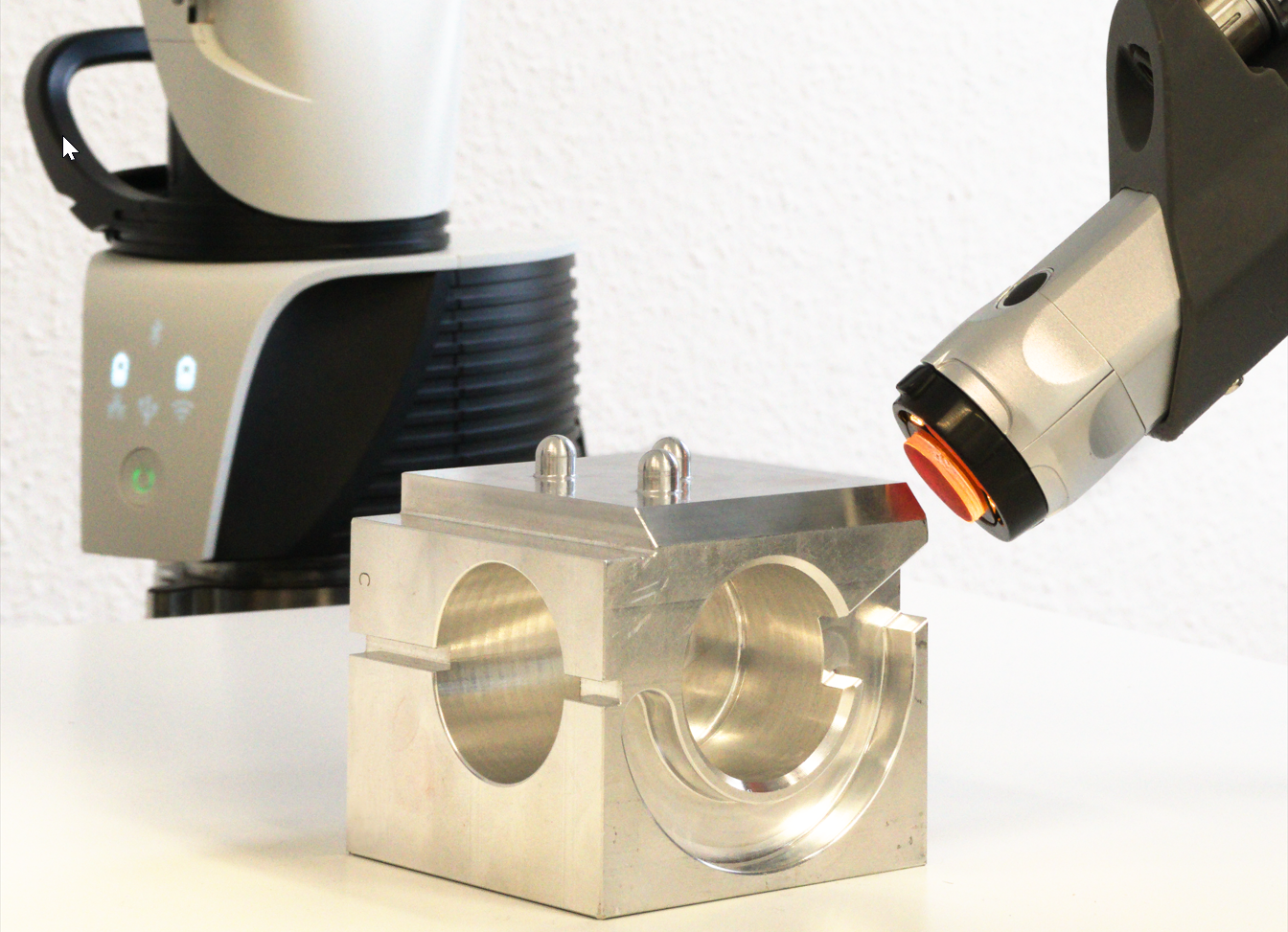

새로운 Hexagon 하드웨어의 통합은 여러 표면 데이터 획득 기술을 단일 소프트웨어를 이용하여 통합하는데 있어서 중요한 발전 단계입니다. 전통적으로,기술에 따라 상이한 소프트웨어 제품을 필요로 했으나,이번 통합으로 VGSTUDIO MAX와 VGMETROLOGY는 Absolute Arm과 AS1 스캐너를 직접 지원합니다.

이 통합은 피처에 대한 접촉식 측정,포인트 클라우드 스캐닝,그리고 표면 메쉬 재구성을 스캔 객체 내에서 가능케 합니다. 이 스캔 객체는 메트롤로지와 리버스 엔지니어링 기능 전체를 지원하며,측정,평가,그리고 자동화를 CT 데이터와 마찬가지로 일관성있게 적용할 수 있습니다.

이 발전 사항은 포괄적인 비파괴검사(NDE)솔루션을 향한 중요한 단계입니다. 이는 여러 데이터 소스에 걸쳐 측정 접근법을 표준화할 뿐 만 아니라 단일 응용 프로그램 내에서 여러 평가를 조합하기 쉽게 만들어 줍니다. 예를 들어,사용자는 CT 데이터를 이용하여 내부 결함을 검출할 수 있고,Absolute Arm을 이용한 접촉식 측정을 통해 위치 편차를 평가할 수 있고,AS1 스캔 데이터를 이용하여 표면 편차를 평가할 수 있으며,GelSight 스캔을 이용하여 표면 거칠기를 분석할 수 있습니다.— 이 모든것이 하나의 플랫폼에서 이루어집니다.

여러 소프트웨어 솔루션을 사용하는 상황에서 발생하는 수고와 불확실성을 줄이고 사용자의 작업 흐름을 최적화하여 분석을 정확도를 높일 수 있습니다.

이 새로운 기능은 GelSight 하드웨어와 GelSight Mobile 소프트웨어의 표면 거칠기 분석을 VG 소프트웨어로 통합하여 VGSTUDIO MAX와 VGMETROLOGY의 분석 능력을 향상시킵니다. 이 통합된 하드웨어를 이용하여,GelSight 패치 및 높이 맵을 획득,가져오기 그리고 시각화할 수 있으며 표면 거칠기 계산을 실행 및 시각화할 수 있습니다. Hexagon의 Absolute Arm과 함께 사용하면 부품의 3D 모델의 정확한 위치에서의 표면 정보에 대한 시각화를 가능케 합니다. 이 고유의 솔루션은 다양한 획득 방법으로 얻은 데이터를 이용하는데 이점이 있으며 표면 분석에 대한 포괄적인 접근법을 제공하고 사용자의 비파괴 평가 과정을 개선합니다.

새로운 좌표 측정 오버뷰 대화상자는 사용자에게 다수의 스캔에 대한 측정과 공차를 효율적으로 분석하는 기능을 제공하여 사용자가 여러 부품이 포함된 측정 프로젝트를 작업하는 방식을 크게 변화시킵니다.

이 포괄적인 오버뷰 대화상자에서,객체들은 직관적으로 이름과 그룹에 따라 그룹화되어,매끄러운 탐색과 분석을 가능케 합니다. 표 보기는 사용자에게 다수의 스캔에 존재하는 모든 지오메트리 요소 및 피처의 평가를 가능케 하여 사용자가 프로젝트 데이터에 대해 전체적으로 파악할 수 있습니다. 추가적으로,이 객체들의 일부 매개변수는 표에서 동시에 편집될 수 있습니다.이는 모든 스캔에 걸친 일관적인 업데이트를 보장합니다.

오버뷰 대화상자는 여러 부품에 대해 실행된 좌표 측정을 작업하는 새로운 방법을 제공하며,해당 시나리오에서 효율을 크게 개선합니다.

사용자의 모델을 몇번이고 사용할 수 있습니다. 미세 조정은 적은 데이터를 사용하여 빠른 시간에 기존의 딥 분할 모델을 새롭지만 유사한 검사 작업에 대해 조정할 수 있습니다.

공극 검출 모델을 처음부터 트레이닝하는 경우 많은 수의 CT 스캔이 필요할 수 있지만,사용자의 특정 작업에 맞는 적당한 미리 트레이닝된 모델을 미세 조정하는 것은 두 개 또는 세 개의 레이블된 CT 스캔으로 가능할 수 있습니다.

모델의 미세 조정은 조정해야 할 생산 라인이 여러개인 시나리오에서,또는 마모나 파손에 대한 대응으로써 이상적입니다. 이는 모델이 사용자의 특정 기능적 필요성에 맞추어 조정됨을 보장합니다.

이 기능은 평면 내에서의 객체의 인터액티브 이동을 개선합니다.

변환 삼각대가 평면 핸들을 포함하며 사용자는 이를 통해 평면 내에서 수고를 들이지 않고 객체를 이동할 수 있습니다.

이 추가적인 핸들은 객체의 변환을 단순화하며,더 직관적이고 효율적인 작업 흐름을 제공합니다.

이 능력은 특히 광학 스캔을 통한 포인트 클라우드를 이용한 작업에서 한 평면에 대해 여러 패치가 필요할 때 유용합니다.

이 개선을 통해,사용자는 단 하나의 마우스 액션을 통한 정확한 평면 이동을 달성하고 프로세스를 매끄럽게 만들어 전체 작업 과정의 효율을 높일 수 있습니다.

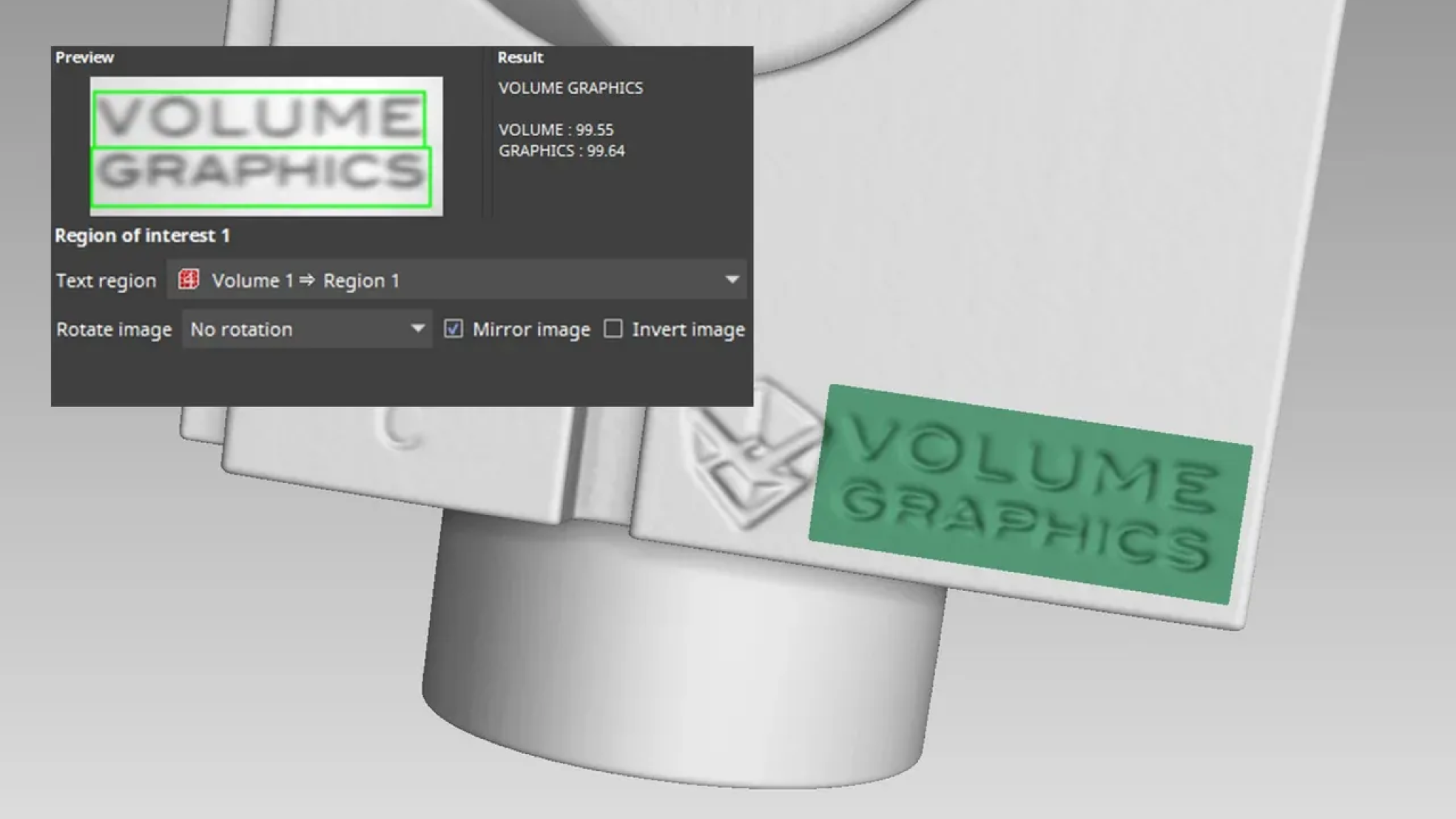

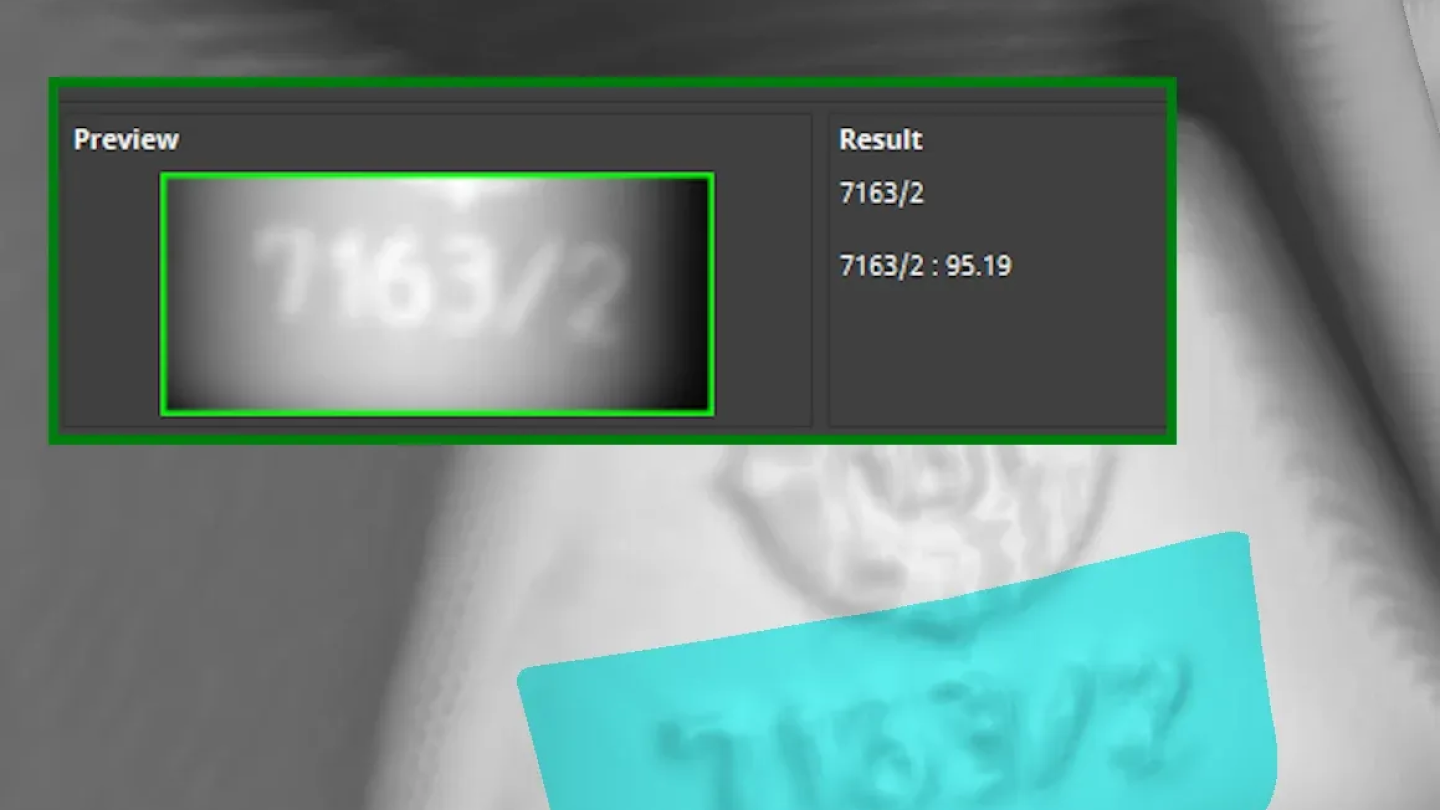

이 새로운 기능은 광학 문자 인식의 정확도를 높이기 위해 데이터 품질 또는 폰트로 인한 잘못된 인식을 개선했습니다.예를 들어"1"을"I"로,또는"5"를"S"로 인식하는 경우가 해당됩니다.

문자 교체와 예상 텍스트 형식(예:특정 위치의 숫자로만 구성된 항목)에 기반한 제약의 적용을 통해,이 기능은 이러한 오인식을 상당부분 자동으로 교정할 수 있습니다.

이 개선 사항은 사용자의 분석에서 텍스트 인식의 신뢰를 높여줄 것입니다.

이 기능을 통해 사용자의 볼륨 데이터와 연관된 DICONDE 태그의 값을 더 쉽게 편집하고 DICONDE 형식으로 내보낼 수 있습니다.

사용자의 데이터가 원래 DICONDE 형식인 경우,또는 다른 형식에서 가져온 경우 모두 이 기능은 볼륨 메타정보를 변환하고 표준화하기 위한 매끄러운 작업 흐름을 제공합니다.

이 기능은 DICONDE 형식을 준수하는 저장 시스템과의 호환되어 더 나은 데이터 관리를 가능케 합니다.

VG 소프트웨어는 오는 가을의 2025.3 릴리즈부터 더 이상 레거시 보고서를 포함하지 않습니다.

3.4.4 버전에서 도입되어 꾸준히 개선되어 온 통합된 보고서 편집기는 보고서 문서를 생성하고 적응하는데 필요한 모든 기능이 포함된 솔루션이며,레거시 보고서의 능력을 넘어섭니다.

2025.3 버전부터는 레거시 보고서를 생성할 수 없습니다.

이 보고서를 위해 디자인된 매크로는 다음의 버전들에서 작동하지 않습니다.

안정적인 피처와 개선된 기능을 이용하려면 통합된 보고서 편집기로의 전환을 추천드립니다.

저희는 사용자의 피드백을 중요하게 생각하며 이 변경사항에 대해 필요한 경우 도와드릴 준비가 되어 있습니다.

이 이전에 관해 도움이 필요하거나 문의사항이 있으시면 연락을 주십시오.

VG 소프트웨어의 더 효율적이고 강력한 보고서 기능을 함께 맞이하세요.

이 중요한 개선 사항은 높은 형태 구성 복잡도을 보이거나 부분 스캔의 복잡한 케이스에 맞추어져 있습니다.

이 기능은 평면 내에서의 객체의 인터액티브 이동을 개선합니다. 변환 삼각대가 평면 핸들을 포함하며 사용자는 이를 통해 평면 내에서 수고를 들이지 않고 객체를 이동할 수 있습니다. 이 추가적인 핸들은 객체의 변환을 단순화하며,더 직관적이고 효율적인 작업 흐름을 제공합니다.

이 능력은 특히 광학 스캔을 통한 포인트 클라우드를 이용한 작업에서 한 평면에 대해 여러 패치가 필요할 때 유용합니다. 이 개선을 통해,사용자는 단 하나의 마우스 액션을 통한 정확한 평면 이동을 달성하고 프로세스를 매끄럽게 만들어 전체 작업 과정의 효율을 높일 수 있습니다.

품질 보증은 고품질의 데이터로 시작합니다. 이런 이유에서 VGSTUDIO MAX는 데이터 품질 분석에 대한 최신의 ASTM 1695 표준을 지원하며,사용자가 CT 시스템의 품질을 효율적으로 추적 관찰할 수 있습니다.

선명도와 노이즈의 변동을 검출하여 측정의 일관성을 확보하고 현재와 미래를 위해 산업 표준을 준수합니다.

이 새로운 기능은 그리기 및 분할 레이블 및 생성되는 관심 영역에 사용되는 색상을 사용자가 지정할 수 있도록 하여 개선된 사용자 정의성을 제공합니다.

히스토그램 비닝에 대해 수동 넓이를 정의할 수 있으며,여러 데이터에 걸쳐 데이터 범위의 변동에 상관 없이 일정한 빈 크기를 보장할 수 있습니다.

이 능력을 이용하면 사용자의 분석에서 더 나은 호환성과 균일성을 이룩할 수 있으며 이를 통해 더 정확한 비교와 통찰을 얻을 수 있습니다.

Microsoft는 윈도우 10에 대한 고객지원을 2025년 10월에 중단합니다. 이 변화와 함께,VG는 2025.3버전부터 윈도우 10에서 실행되는 응용 프로그램에 대한 공식 지원을 중단합니다.

해당되는 사용자들은 VGSTUDIO,VGSTUDIO MAX,VGMETROLOGY,VGinLINE 및 다른 VG 소프트웨어 제품을 계속 사용하려면 운영체제를 업그레이드하기를 추천드립니다.

사용자의 VG 소프트웨어 패키지가 최신의 플랫폼에서 작동함을 보장하기 위해 필요한 단계이며,더 나은 성능,보안,그리고 호환성을 제공할 수 있습니다.

업그레이드 도움이 필요하거나 질문이 있다면,당사 고객지원 팀에 연락하십시오.

VGSTUDIO MAX에서의 섬유 복합 소재 분석의 설정은 매우 복잡할 수 있습니다.

이 단계별 튜토리얼은 다음과 같이 구성됩니다:

VGSTUDIO MAX에서 복합 소재에 대한 섬유 방향을 결정하는 방법.

분석을"평면 투영"모드에서 설정하여 분석 결과의 타당성을 검증하는 방법

"통합 메쉬"모드를 이용하여 프로세스 시뮬레이션을 검증할 때 시뮬레이션 엔지니어에게 필요한 형식으로,또는 구조 시뮬레이션의 입력 데이터로써 방향 텐서에 대한 정보를 생성합니다.

사용자 정의된 보고서 레이아웃을 기본값 레이아웃으로 저장하고 다른 보고서에 대해 사용할 수 있습니다. 그렇지 않은 경우,이 튜토리얼을 참고하여 배워보십시오.

지금 시청

- 다수의 볼륨에 매크로 적용

- 다수의 볼륨 객체에 매크로를 실행하여 소중한 시간을 절약하는 방법을 알아봅니다.

- 매크로에 바로가기 할당

- 매크로에 대해 바로가기를 사용하여 복잡한 작업 흐름을 하나의 버튼으로 실행하는 방법을 알아봅니다.

"뷰"를 이용하여 개별 객체에 대한 시각화 및 작업공간 설정을 정의 및 적용하여 프로젝트를 쉽게 다루고 보고서를 효율적으로 생성할 수 있습니다. 뷰를 객체 사이에 쉽게 이전하고 평가 템플릿에 포함시켜 유연한 자동화를 준비할 수 있습니다.

최고의 정밀도를 경험하세요. 자동화되고 수치적으로 검증된 방법을 이용하여 빔 경화 아티팩트에 대처하세요. 단지 좋은 추측을 제공하는 목적이 아닙니다.정밀한 계산을 통해 정확한 보정 결과를 얻는것이 목표입니다.

기하 공차의 인터액티브 3D 색상 오버레이를 통해 보고서를 개선하여 수치 결과의 이해도를 높입니다.

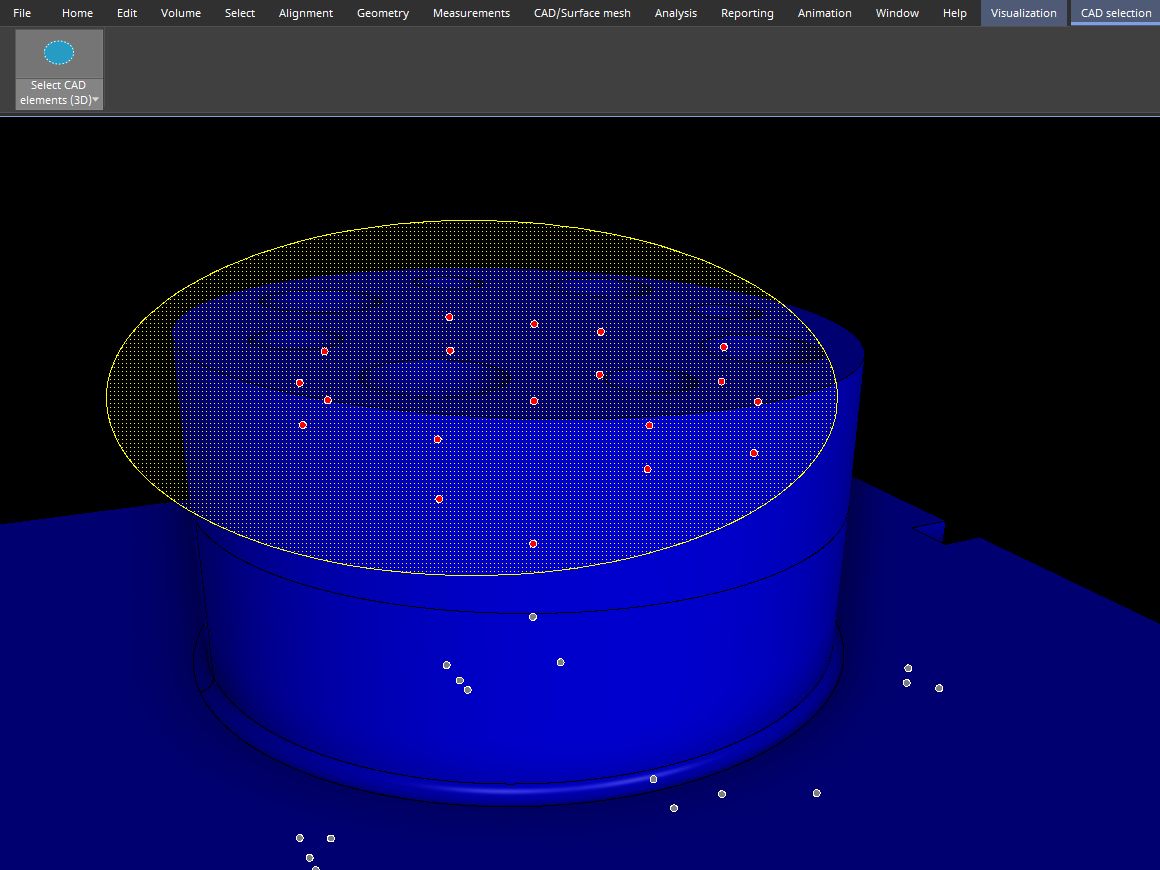

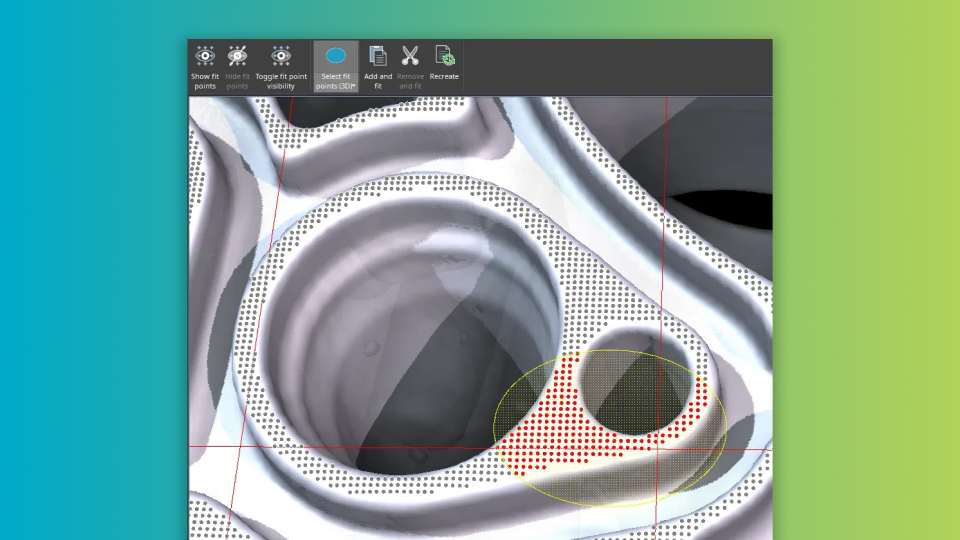

3D 보기에서 직사각형,타원,그리고 올가미와 같은 직관적인 도구를 사용하여 다수의 CAD 면을 선택할 수 있습니다. 이 기능은 객체의 정렬과 핏포인트 선택 등 복잡한 구성요소를 이용한 작업에 유용합니다.

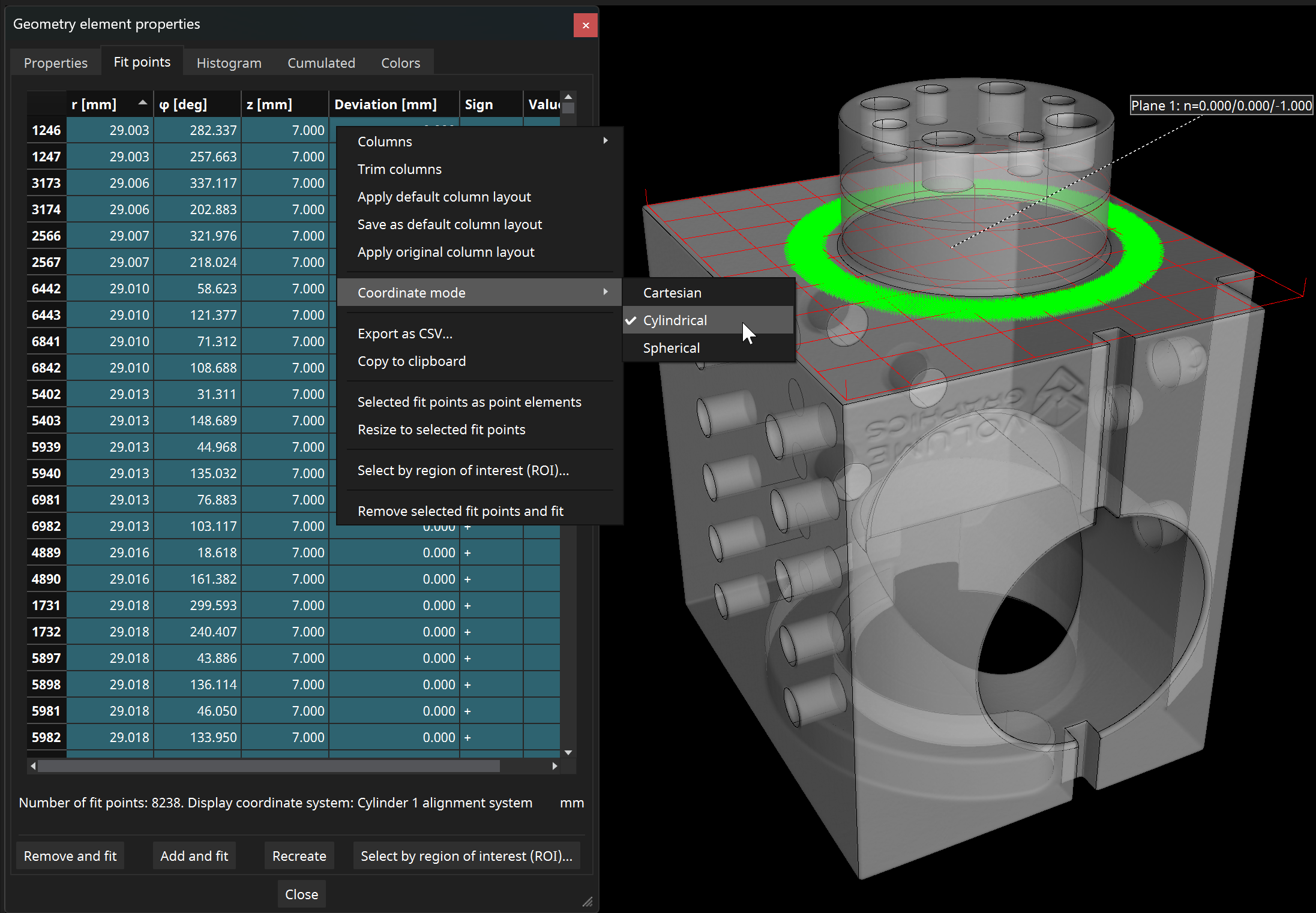

회전 대칭 부품에 대해 핏포인트 표를 원통 또는 구면 좌표로 전환하여 가져오기,내보내기 및 편집 과정에서 이점을 얻을 수 있습니다.

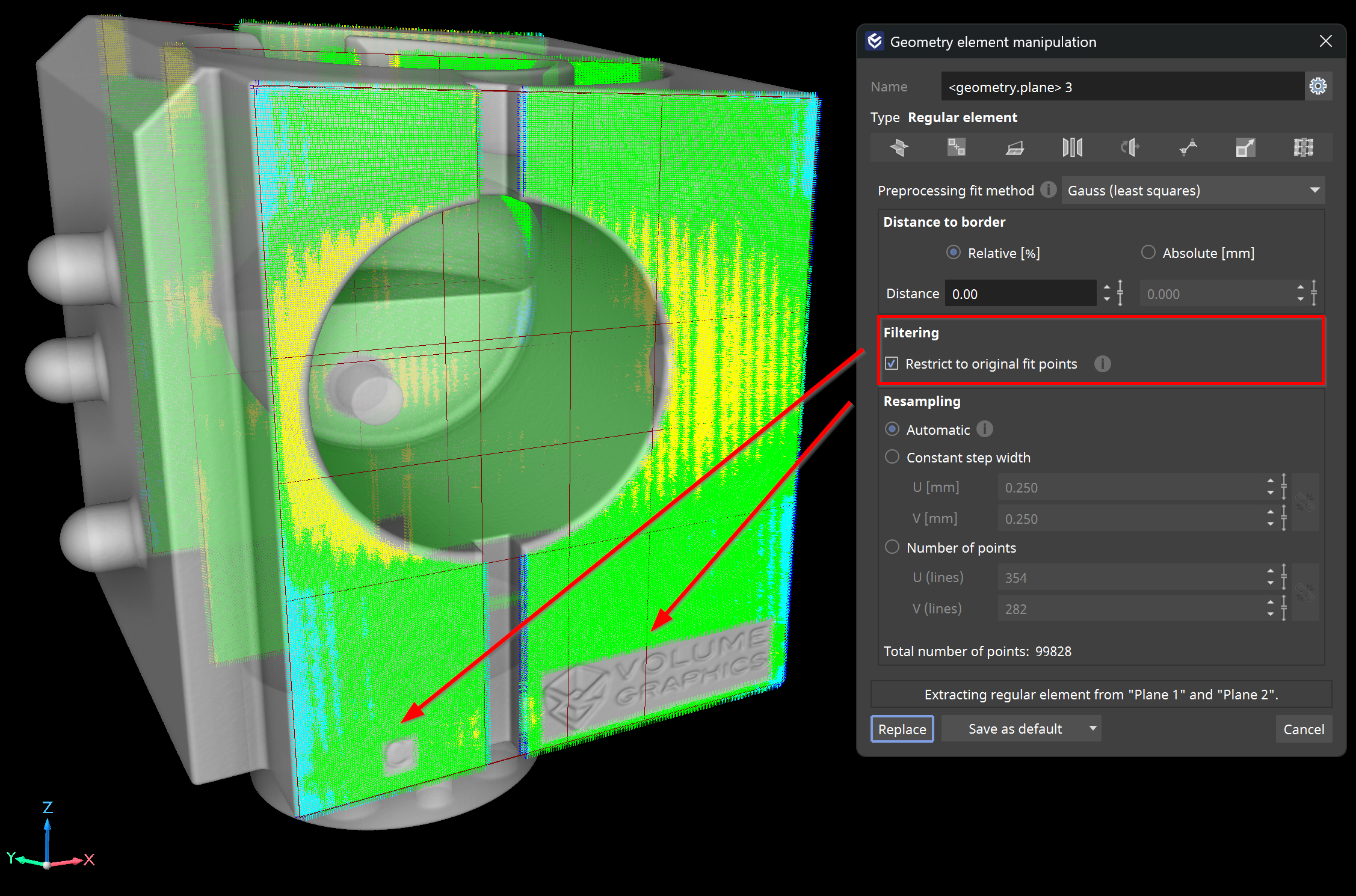

"원래 핏포인트에 제한"옵션을 이용하여 정규 요소가 원하는 영역에서만 핏포인트를 샘플링하도록 할 수 있습니다. 이는 원치않는 영역에서의 샘플링을 제한하며,측정 정확도를 높입니다.

추출된 ROI에 대한 고급 표면 결정의 개선된 계산 속도를 체험하고 볼륨 데이터 분리 전과 후의 작업 흐름의 타이밍에 대한 유연성을 경험할 수 있습니다.

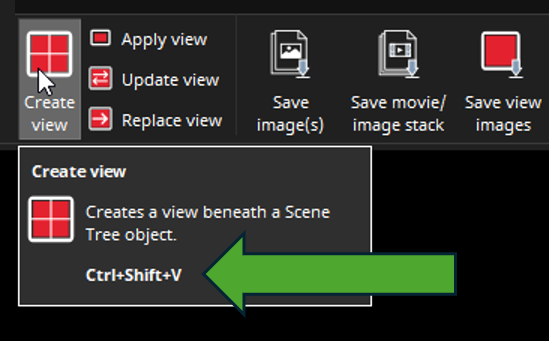

리본 인터페이스의 명확한 도구 설명 표시를 이용하여 응용 프로그램 바로가기를 익힐 수 있습니다. 이 개선점은 VG 제품군에서 기능을 익히는데 도움을 줍니다.

새로운 .xvgi 파일 유형을 이용하면 수동 데이터 가져오기의 필요가 없어 유연한 데이터 처리가 가능합니다. VG 소프트웨어 이용를 자동화하기 위해 Python 참조 구현을 사용하세요.기존의 .vgl 파일 없이도 가능합니다.

객체 속성에 태그 번호가 표시되어 DICONDE 메타데이터의 태그를 쉽게 식별할 수 있으며 데이터 확인 절차를 개선합니다.

이상치를 제외하는 자동 비율 조정 색상 매핑을 이용하여 실제 편차에 집중할 수 있습니다. 따라서 색상 오버레이가 부품에 대한 왜곡 없는 시각적 평가를 제공합니다.

선택된 색상 오버레이와"구성요소만 표시"체크박스 설정은 저장되어 북마크,애니메이션,그리고 객체 특정 뷰를 포함한 모든 자동 이미지 생성 기능에 적용됩니다. 이는 보고서 및 프레젠테이션을 위해 개선된 옵션을 제공합니다.

플로팅 라이선스를 이용하고 인프라 옵션을 확장하여 VG 소프트웨어를 가상 머신에서 유연하게 실행할 수 있습니다.

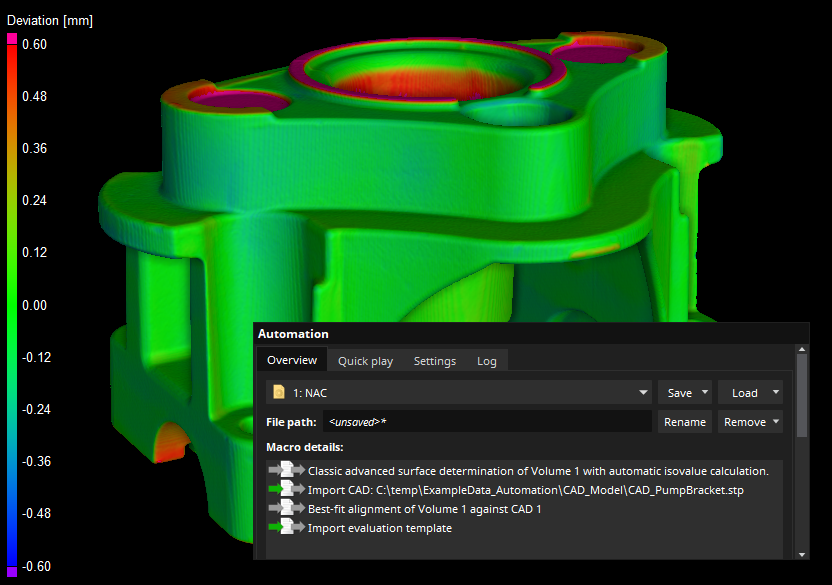

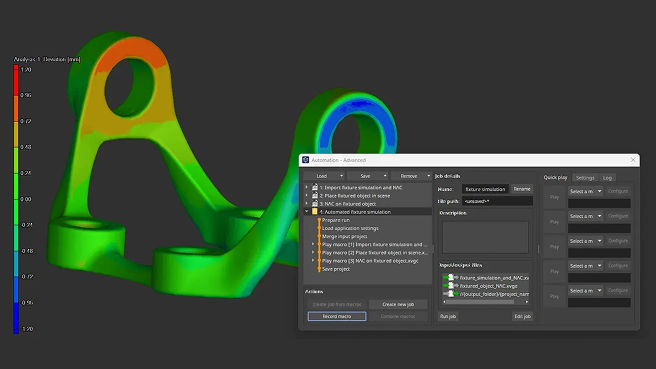

VGSTUDIO MAX 또는 VGMETROLOGY에서"자동화"도구를 이용하여 작업 흐름을 가속화할 수 있습니다. 단일 작업 단계에 대한 매크로를 생성하여 작업 흐름의 일부를 자동화 하거나 검사 계획(작업)을 생성하여 검사 전체를 자동화할 수 있습니다. 작업 파일은 검사에 필요한 모든 데이터를 포함하며 따라서 동료 또는 고객과의 교환이 간편합니다.또한 다른 at-line 또는 in-line CT 시스템과 함께 사용할 수 있습니다.

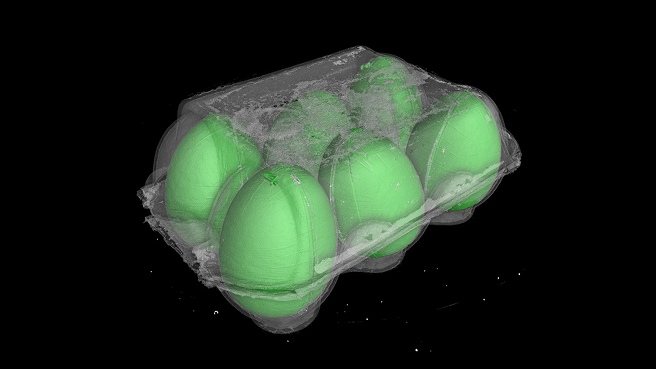

여러 부품을 함께 스캔하는 경우를 위해 특별히 설계된 이 직관적인 기능을 이용하여 전체 볼륨 데이터를 개별 볼륨 객체로 쉽게 분리할 수 있습니다. 이 도구는 작업 흐름을 단순화할 뿐만 아니라 강력한 세분화, 이름 지정, 데이터 축소 방법에 대한 옵션을 제공합니다. 또한 누락된 부품을 검출하고 분리된 각 개체에 대해 각각의 프로젝트 파일을 생성하는 기능이 포함되어 더욱 쉽게 자동화를 수행할 수 있습니다.

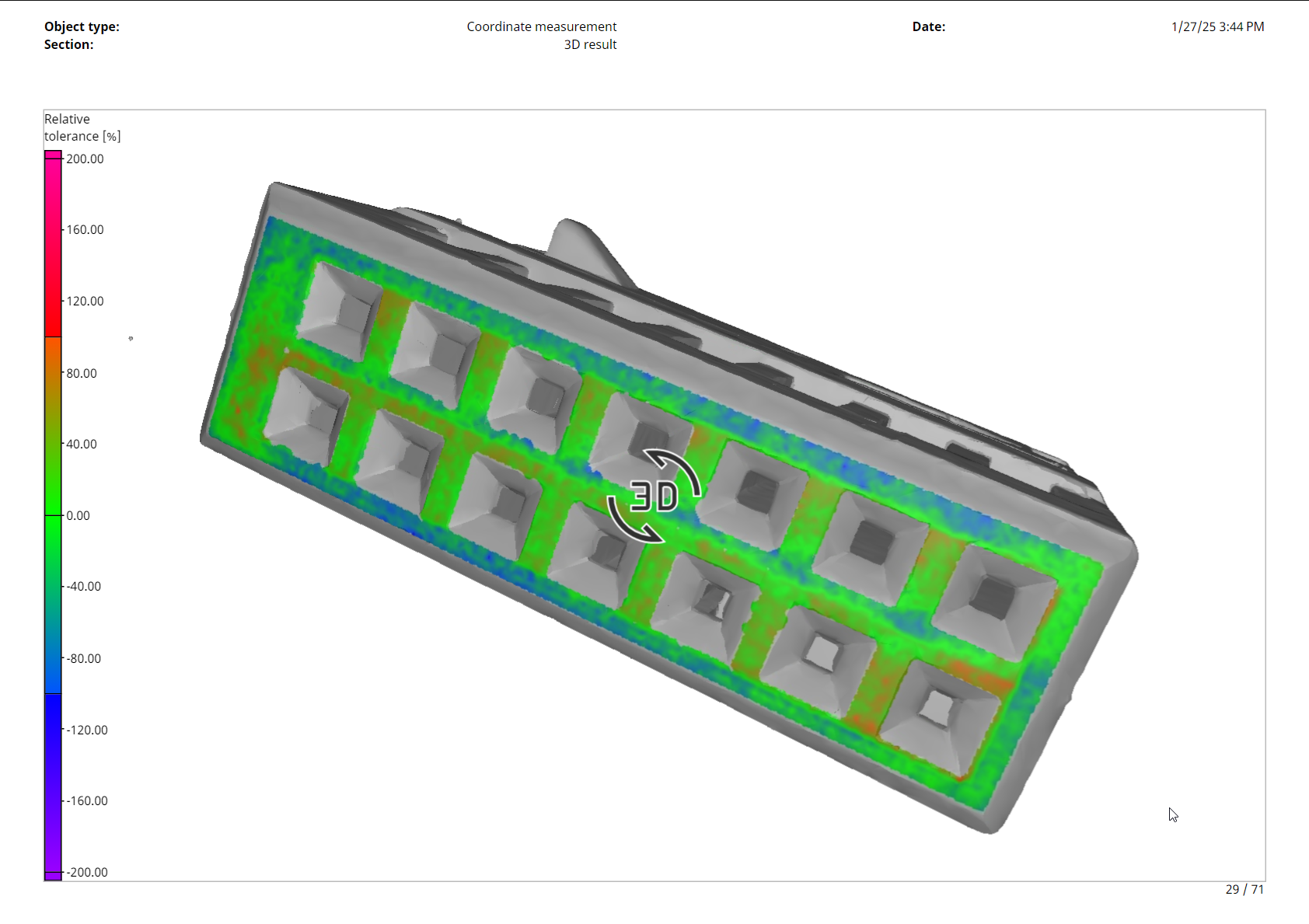

이 혁신적 도구로 백분율 값을 사용하여 편차를 평가하고 개선된 분석 능력을 사용하십시오. 절대 벽 두께, 절대 편차, 명목값 대비 백분율 편차 등 다수의 치수를 통해 구성요소의 안정성을 포괄적으로 이해할 수 있습니다. 색상 오버레이, 히스토그램, 허용 오차, 개별 주석과 같은 기능으로 백분율 편차를 쉽게 분석할 수 있습니다.

상대 벽 두께 결과에 대한 Q-DAS 내보내기

공차가 적용된 상대 벽 두께 결과를 Q-DAS 형식으로 원활하게 내보내어 데이터 분석의 수준을 향상시킬 수 있습니다. Q-DAS 제품군과의 개선된 호환성과 통합을 경험하세요.

더 쉬워진 PDF 보고서 탐색

이제 PDF 보고서에도 보고서의 관련 섹션으로 직접 연결되는 목차가 포함됩니다. 이 지능적인 기능을 이용하여 보고서를 빠른 속도로 읽어 향상된 사용자 경험을 누릴 수 있습니다.

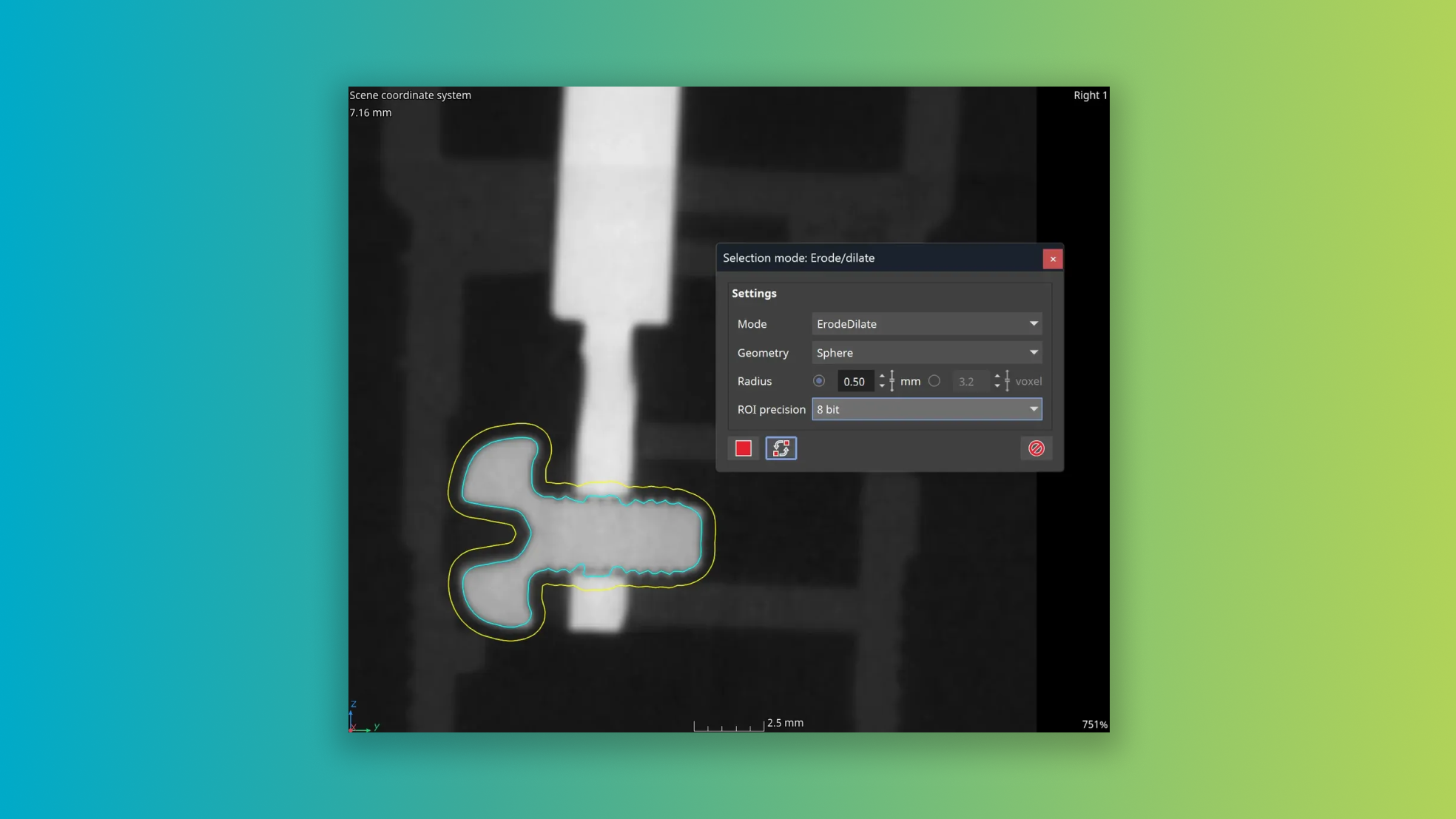

'직사각형 3D'와 '타원 3D' 관심 영역(ROI) 생성 기능으로 완전히 새로운 인터액티브 경험을 제공합니다. 쉽게 사용할 수 있는 이러한 기능으로 3D 보기에서 간단한 기본도형(직사각형과 타원)을 사용하여 볼륨 ROI를 생성할 수 있습니다. 폴리라인 3D와 비슷하지만, 폴리라인의 복잡도 없이 클릭하고 드래그만 해도 ROI를 완성할 수 있습니다.

관심 영역(ROI)을 이동하거나 회전, 또는 다른 객체에서 복사할 때 상위 볼륨의 복셀 그리드와의 정렬이 어긋날 수 있습니다. 새로운 버전에서는 장면 트리와 객체 속성에서 정렬 상태를 한 눈에 확인할 수 있습니다. 클릭 한 번이면 관심 영역을 재정렬할 수 있으며, 이를 자동화된 시나리오를 위해 기록할 수도 있습니다.

그 어느 때보다 개인 간 협업을 쉽게 수행할 수 있습니다! 제목 표시줄의 새 링크를 통해 VG 커뮤니티로 이동하세요. 성공적인 사례를 공유하고, 조언을 얻고, 제품의 최신 소식을 확인하세요.

이 비디오에서는 고정물 시뮬레이션에 필요한 분석을 수행하고,필요한 매크로를 기록하며,최종적으로 VGinLINE에서 실행할 수 있는 작업으로 매크로를 결합하는 방법을 보여드립니다.

비디오 튜토리얼을 시청하려면 여기를 클릭하십시오.

OCR 분석에 대한 비디오 튜토리얼을 통해 VGSTUDIO MAX에서 텍스트 인식을 수행하는 방법에 대한 두 개의 다른 접근법을 보여드립니다.

- Performing an OCR analysis using geometry element-based ROIs(영문)

- Performing an OCR analysis using manually defined ROIs(영문)

동영상 튜토리얼을 시청하려면 여기를 클릭 하십시오.

편차 분석의 개선: 명목 부품과 실제 CT 스캔의 벽 두께 편차에 허용 오차를 적용합니다. 벽 두께에 대한 절대적 치수 대신 사용할 수 있는 새로운 기능입니다.

시각화,허용 오차 적용,보고서 생성,그리고 명목 부품과 실제 스캔 사이의 편차를 평가할 수 있습니다. 고유한 적응형 변환 기술을 이용하여 계산된 편차가 명목 및 실제 부품의 표면 점에 정확히 대응함을 확인할 수 있습니다.

혁신적인 머신 러닝 기반 솔루션은 노이즈가 많고 품질이 낮은 데이터에 대해 성능이 검증되었으며 따라서 빠르게 이루어진 CT 스캔 데이터를 다룰 수 있습니다.

시간 절약: 단순화된 처리 과정을 통해 데이터의 로드,모델의 선택,계산 및 다음 분석을 위한 결과 관심 영역의 적용을 간단하게 수행할 수 있습니다.

자동화에 최적: 사용자의 편의를 위해 디자인된 딥 분할 도구는 자동화된 검사 작업흐름에 무리없이 결합할 수 있습니다.

산업 표준 지원: 딥 분할 모듈은 산업 표준 ONNX 모델 형식과 호환합니다.작업과 데이터에 특화된 딥 러닝 모델을 사용할 수 있습니다.

직관적인 새로운 리본 탭에서 모든 필요한 편집 도구를 사용할 수 있습니다. 시각화의 조정,선택,추가,맞춤,제거,그리고 핏포인트 다시 생성등을 하나의 리본에서 사용하세요. 속성 대화상자에서 찾거나 원하는 핏포인트의 위치를 추측할 필요가 없습니다. 지오메트리 요소를 선택하고 해당 탭을 선택하여 측정 템플릿의 사용성을 크게 개선할 수 있습니다.

객체의 선택이 어느때보다 쉬워졌습니다: 사각형,타원,또는 올가미를 선택하고 3D 창에 직접 그릴 수 있습니다. 객체의 질량 중심이 강조표시되면,해당 객체가 장면 트리에서 선택됩니다. 3D 창에서 객체를 직접 추가하고 제거할 수 있습니다 — WYSIWYG.

즉각적인 허용 오차 상태: 개별 공극에 대해 직관적인 색상 코딩 형식을 통해 허용 오차 상태를 즉각적으로 볼 수 있습니다. 원하는 허용 오차를"활성 열"로 선택하고 녹색(허용 오차 만족)및 빨간색(허용 오차 초과)을 확인할 수 있습니다.

빠른 표면 결정: 공극 분석을 실행하기 전에 표면 결정 실행을 잊어버리셨나요? 문제없습니다. 분석 대화상자의 새로운 바로가기를 통해 공극 및 내포물 분석을 위해 기본값 표면 결정을 생성할 수 있습니다.따라서 효율적이고 부드러운 작업 흐름이 가능합니다.

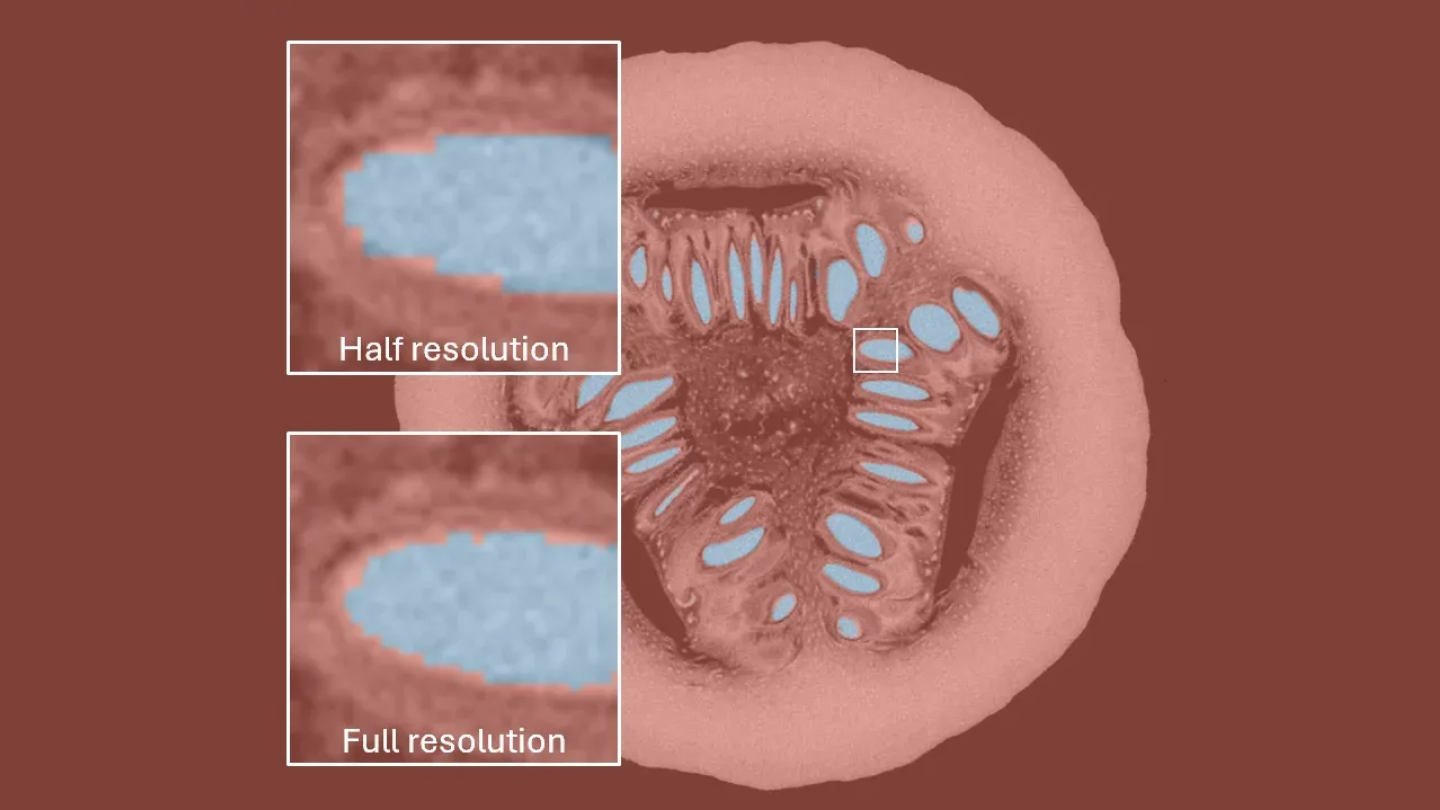

그리기 및 분할의 사용에 있어서 정확도보다 속도가 중요할 때에는,해상도를 줄여 분할의 속도를 높일 수 있습니다.

해상도를 반으로 줄이면,분할의 속도가 8배 빨라집니다.작업시간을 효율적으로 계획할 수 있습니다.

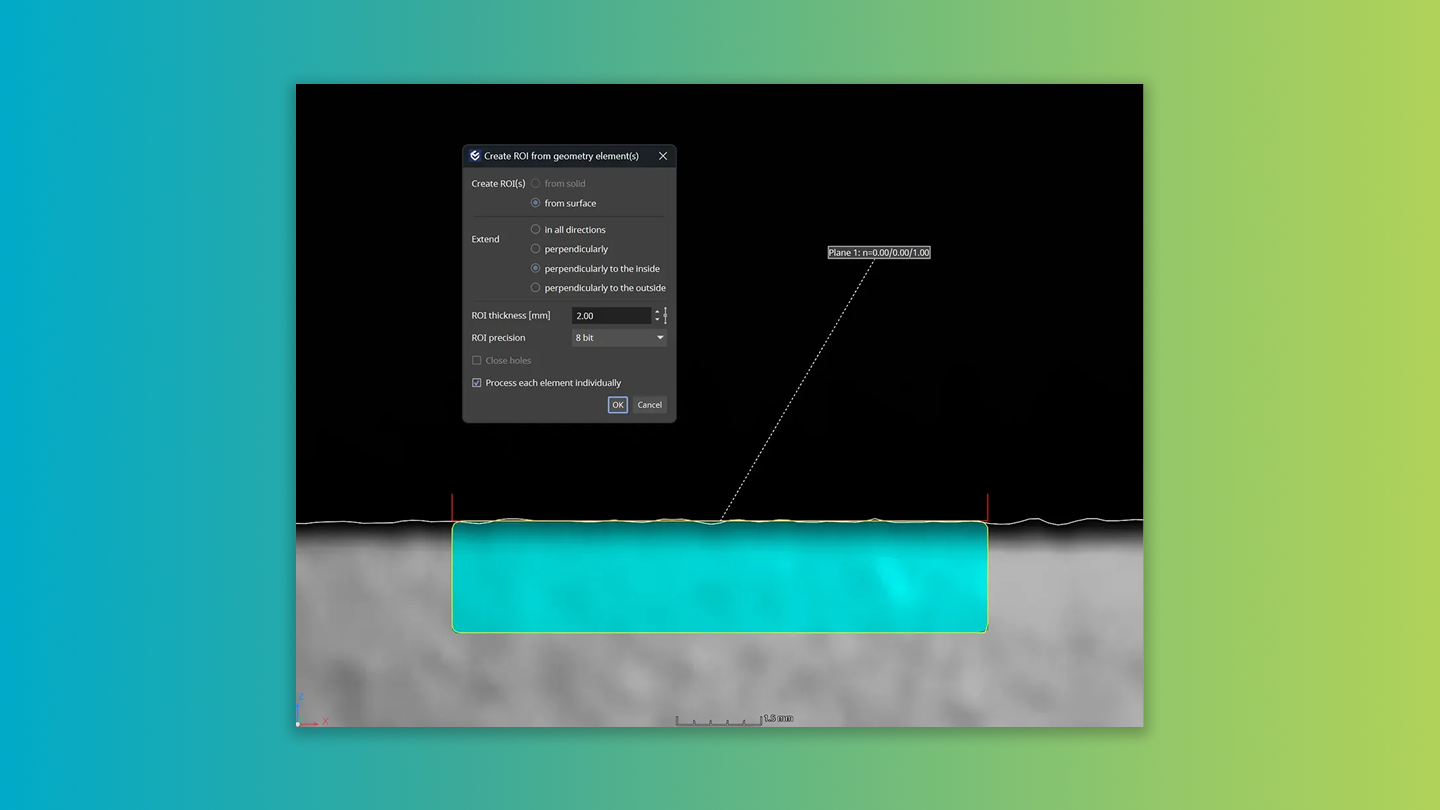

You can now create ROIs with a defined thickness from the surface of ideal geometries, making it simpler to streamline ROI creation for various analyses, including P 203. Choose from various expansion modes: in all directions, perpendicular to the surface, or exclusively to the inner or outer side based on the surface orientation.

여러개의 객체에 대해 ROI 렌더링을 한번에 활성화 또는 비활성화할 수 있습니다. 렌더링의 전환에 대한 매크로 단계가"ROI 렌더링 활성화"및"ROI 렌더링 비활성화"두 개로 분리되어 더 명확한 자동화 시나리오를 사용할 수 있습니다. 정확한 매크로 작업의 재생을 통해 사용자 경험이 개선되었습니다.

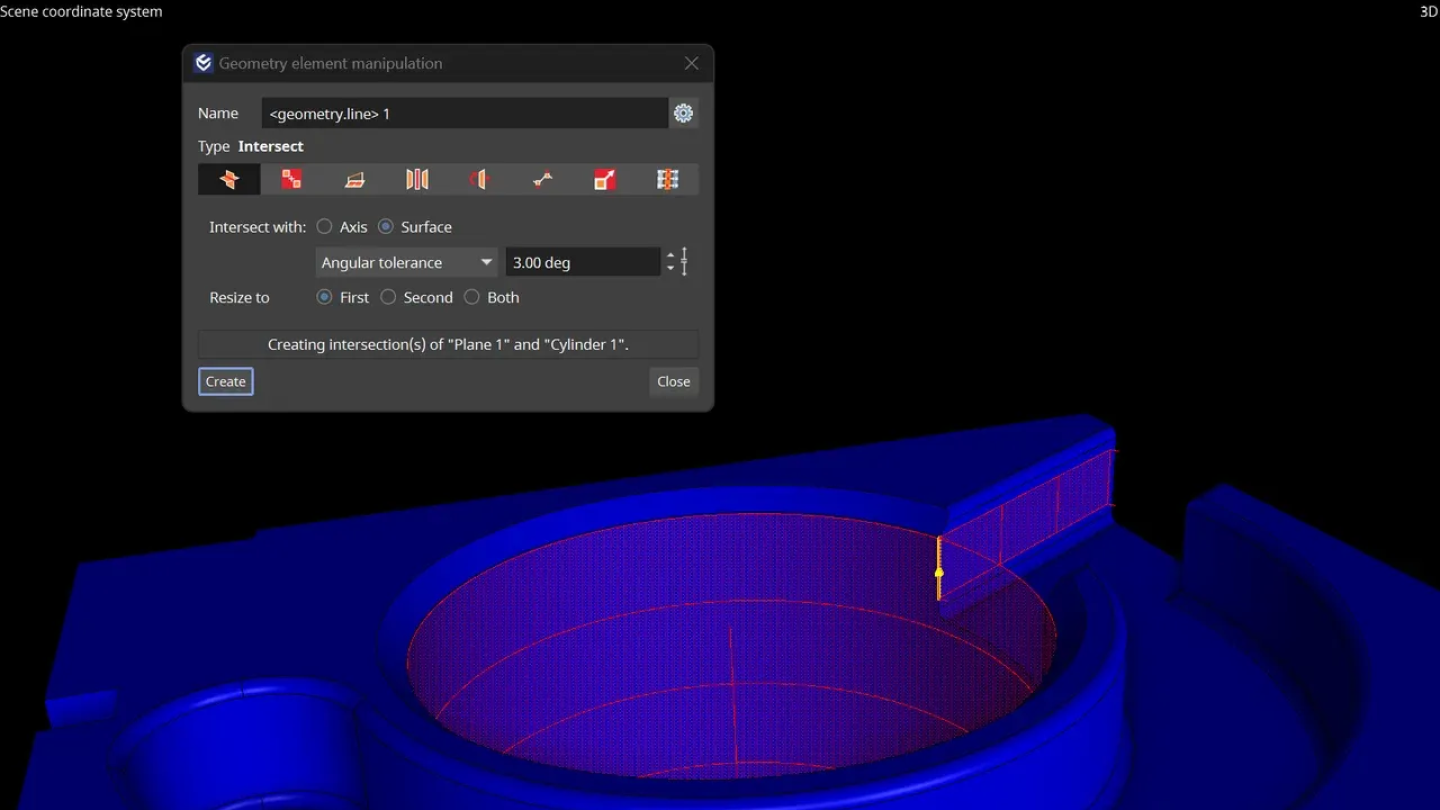

복잡한 해결책 대신 간단히 새로운 기능을 사용하십시오. 원기둥의 측면과 그에 평행한 면 사이에서 원하는 크기의 교차선을 생성할 수 있습니다.

This dynamic feature utilizes the color bar settings configured directly in the analyses, offering an enriched context to interpret results in your reports. Elevate your reporting experience and data interpretation capacity with this unique update.

보고서에서 표의 셀을 허용 오차 상태에 따라 색상 할당

개별 셀에 허용 오차 상태에 기반한 색상 코드를 적용할 수 있습니다. 이 즉각적인 시각적 효과는 결과 표의 가독성을 개선하고 부품의 허용 상태를 결정짓는 기준에 대한 더 빠른 확인을 가능하게 합니다. 색상을 적용하여 데이터를 직관적이고 빠르게 파악하십시오.

보고서에서 정보 필드 이름 숨기기

보고서에서 임의의 정보 필드의 이름을 숨길 수 있습니다. 이 기능을 통해 사용자의 텍스트와의 유연한 결합이 가능하며 더 명확한 보고서 페이지를 생성할 수 있습니다. 개선된 보고서 설정을 통해 더 많은 제어와 디자인의 자유도를 경험하세요.

분석 변경시 북마크 이미지 무효화

이제 분석 결과가 변경되면 북마크 이미지에"비동기화"상태가 표시됩니다. 자동화된 시나리오에서,모든"비동기화"이미지에 저장 전 자동 업데이트가 적용됩니다.따라서 북마크 이미지가 프로젝트의 현재 상태를 정확히 반영함이 보장됩니다. 이 동적 업데이트를 통해 데이터에 대한 개선된 제어와 시각화를 경험하십시오.

메타정보를 이용하여 객체의 이름 변경

메타정보 필드중 하나를 이용하여 객체의 이름을 변경할 수 있습니다. 이 기능은 매크로에서의 사용이 용이하며 자동화 시나리오에서 객체에서 OCR을 통해 인식한 텍스트를 객체의 이름에 할당할 수 있습니다. 이 최신 기능을 통해 데이터 관리의 효율과 제어를 개선할 수 있습니다.

최신의 멀티 스레드 메쉬 단순화 기능을 통해 효율을 개선하십시오. 볼륨을 메쉬로 변환하거나 3D 데이터를 보고서로 변환할 때,이 새로운 기능은 표면 메쉬에서 삼각형의 개수를 획기적으로 줄일 수 있고 계산을 대폭 가속화할 수 있습니다. 혁신적인 업데이트를 통해 더욱 빠른 계산을 이용하십시오.

VGSTUDIO MAX에서 잘 알려진 이 기능을 VGMETROLOGY에서도 사용할 수 있습니다.

새로운 업그레이드를 통해 고정된 객체를 장면에 위치시키는 과정의 매크로 기록이 가능합니다.고정물 시뮬레이션을 완전히 자동화된 작업흐름에서 활용할 수 있습니다.

이 업그레이드를 통해,폴더에서 매크로를 찾는데 시간을 낭비하지 않아도 됩니다. 이 기능은 작업 흐름에 크게 도움이 될 수 있습니다. 더 빠르게,효율적으로 작업할 수 있습니다.

Users can now run the application and create reports in Italian, Spanish, and Russian.

이 비디오에서는 공극 검사 작업 흐름을 자동화하는 방법을 볼 수 있습니다. VGSTUDIO MAX의"자동화"도구를 이용하여 이전에 정의된 작업흐름의 개별 단계에 대해 매크로를 기록하여 조정할 수 있습니다. 마지막에는,매크로를 하나의 작업으로 결합하여 임의의 데이터에 대해 실행할 수 있습니다. VGSTUDIO MAX를 통해 검사에 들이는 수고를 자동화 처리를 통해 몇번의 클릭으로 줄일 수 있습니다.

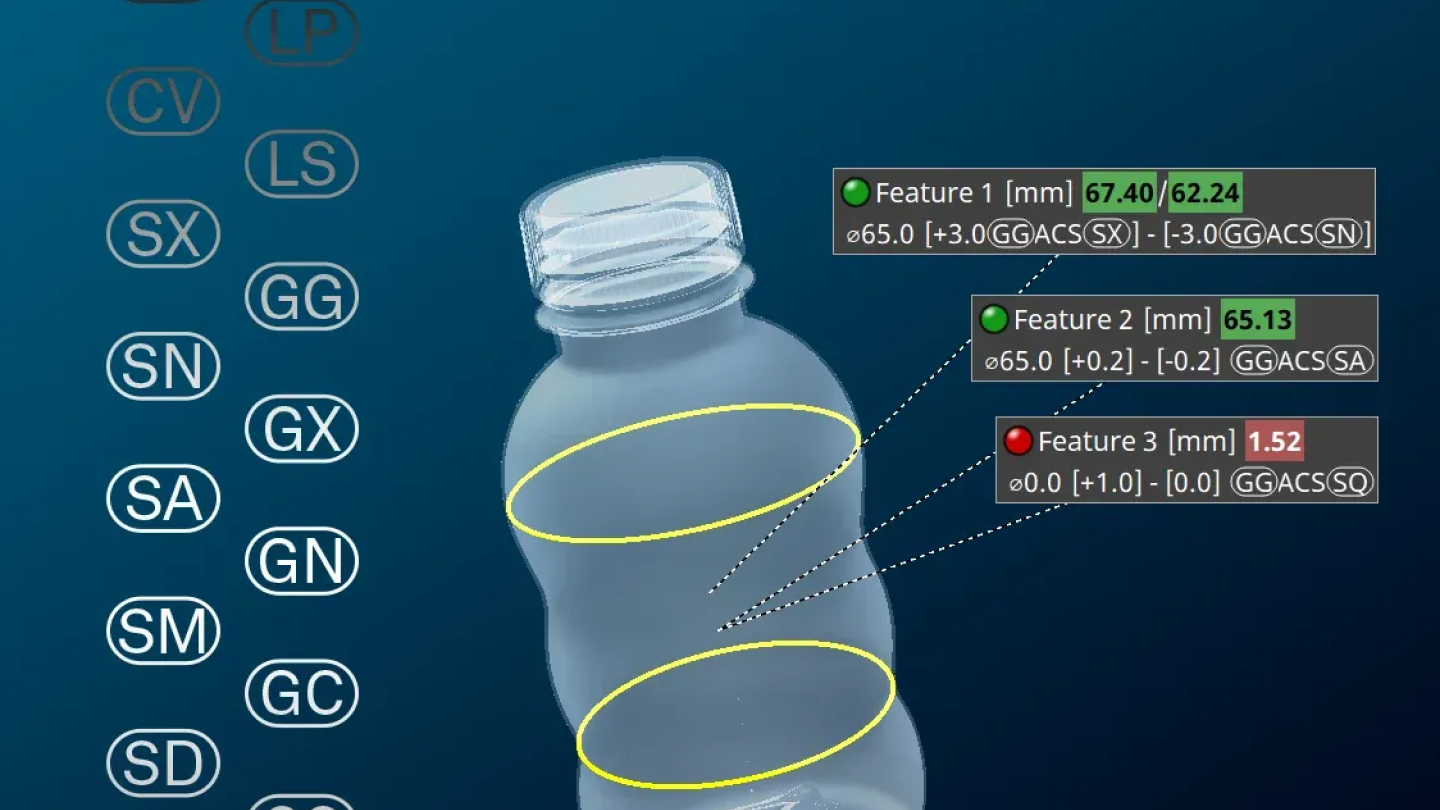

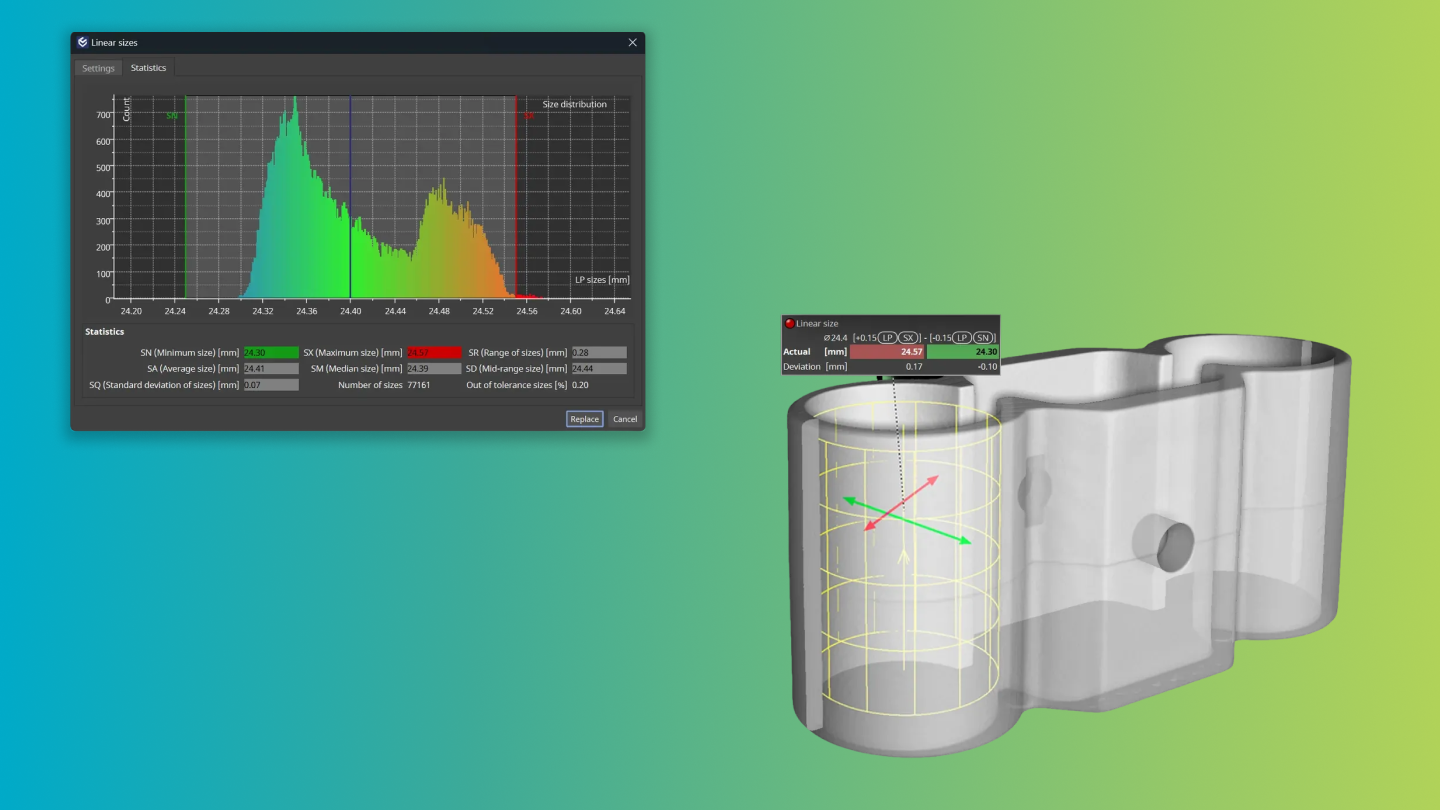

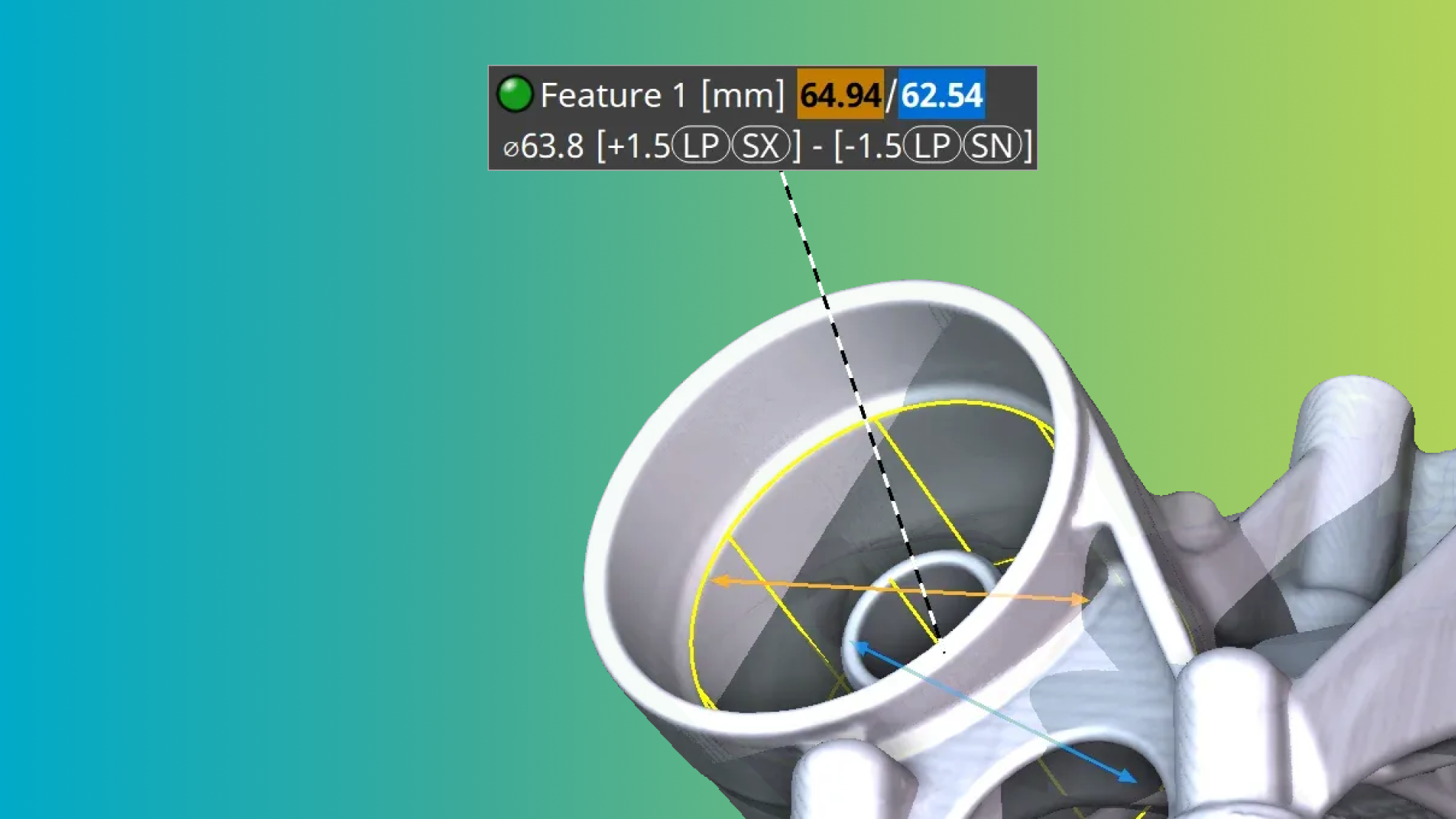

이제 선형 크기에 순위(예를 들어 중간값 크기)또는 ACS(임의 횡단면에서의 크기 측정)보조키를 사용할 수 있습니다.

이 보조키의 사용이 요구되는 ISO 14405-1에 따른 측정 작업을 이제 "선형 크기" 대화상자에서 간단히 해당 보조키를 선택하여 해결할 수 있습니다.

LP(로컬 2점 크기)또는 ACS(임의 횡단면)와 같은 선형 크기를 계산하면 다수의 치수를 얻게 됩니다. 일반적인 경우 하나의 크기 값(최대(SX)또는 최소(SN))에 공차를 적용할 뿐이지만,이제 측정에 관한 더 많은 정보가 제공됩니다: "선형 크기"대화상자의 새로운 탭은 측정된 모든 크기의 히스토그램 및 다수의 통계값을 제공하며 이를 통해 수치 분포와 공차역에 관한 직관적인 오버뷰를 얻을 수 있습니다.

개선된 OCR 분석은 VGSTUDIO MAX와 VGinLINE의 자동 텍스트 인식 능력을 크게 개선하였으며 결과의 사용자 정의 옵션이 강화된 보고서를 지원합니다. 부품의 ASCII 텍스트는 자동으로 인식되어 객체의 메타정보로 이전됩니다.이는 검사 작업 또는 보고서에서 사용할 수 있습니다.

이전의 OCR 분석의 새로운 인스턴스를 생성할 수는 없지만,분석을 포함하는 기존의 검사 작업과 평가 템플릿은 계속 사용할 수 있습니다. 새로운 OCR 분석의 사용을 권고합니다.이전의 버전은 2025.2 버전의 소프트웨어부터는 사용할 수 없습니다.

PMI를 포함한 CAD 고급 가져오기 기능은 이제 선형 크기의 보조키 기호를 해석하여 이에 따라 가져오기시에 적절한 선형 크기 측정을 실행할 수 있습니다.

추가 가져오기 옵션을 통해 기본값 보조키를 선택할 수 있으며 이는 PMI 데이터에서 지정된 보조키가 없는 선형 크기에 적용됩니다.

이제 2D 보기에서 맞춤된 원과 두개의 반대 방향의 평행한 선에 대해 정규 요소를 생성할 수 있으며 이를 선형 크기 측정과 여러 기하 공차에 사용할 수 있습니다. 이는 요소의 특정 횡단면(SCS)에서 선형 크기를 측정해야하는 경우 특별히 유용합니다.

- "분석 영역"의 새로운"자동"모드는 표면 결정의 설정을 고려합니다. 이는 공극률/내포물 분석을 이용한 일상 작업을 더 신속하게 만들어 주며 오류를 줄일 수 있습니다.

- 공극의 시각화는 기본값에서"윤곽선만 렌더링"으로 설정되어 있으며 따라서 검출된 공극의 음영값이 표시됩니다.

- 새로운 기본값 보고서 사전 설정"최대 5개"를 이용하여 표준 보고서에서 가장 큰 5개의 편차에 대한 이미지를 포함시킬 수 있습니다. 더 많은 또는 더 적은 개수를 원한다면,또는 특정 값을 초과하는 편차만을 포함시키고자 한다면,공극률/내포물 분석의"규칙"탭에서 사용자 지정할 수 있습니다.

- 공극률/내포물 분석 대화상자가 시각적으로 개선되어 기능적으로 연관있는 탭만 표시됩니다.

- 공극간의"정확한 간격"을 위해 복셀 기반 계산을 확장하였습니다:이제"간격"매개변수에 대해 허용 오차를 적용하여 공극 간의 실제 간격을 평가할 수 있습니다.

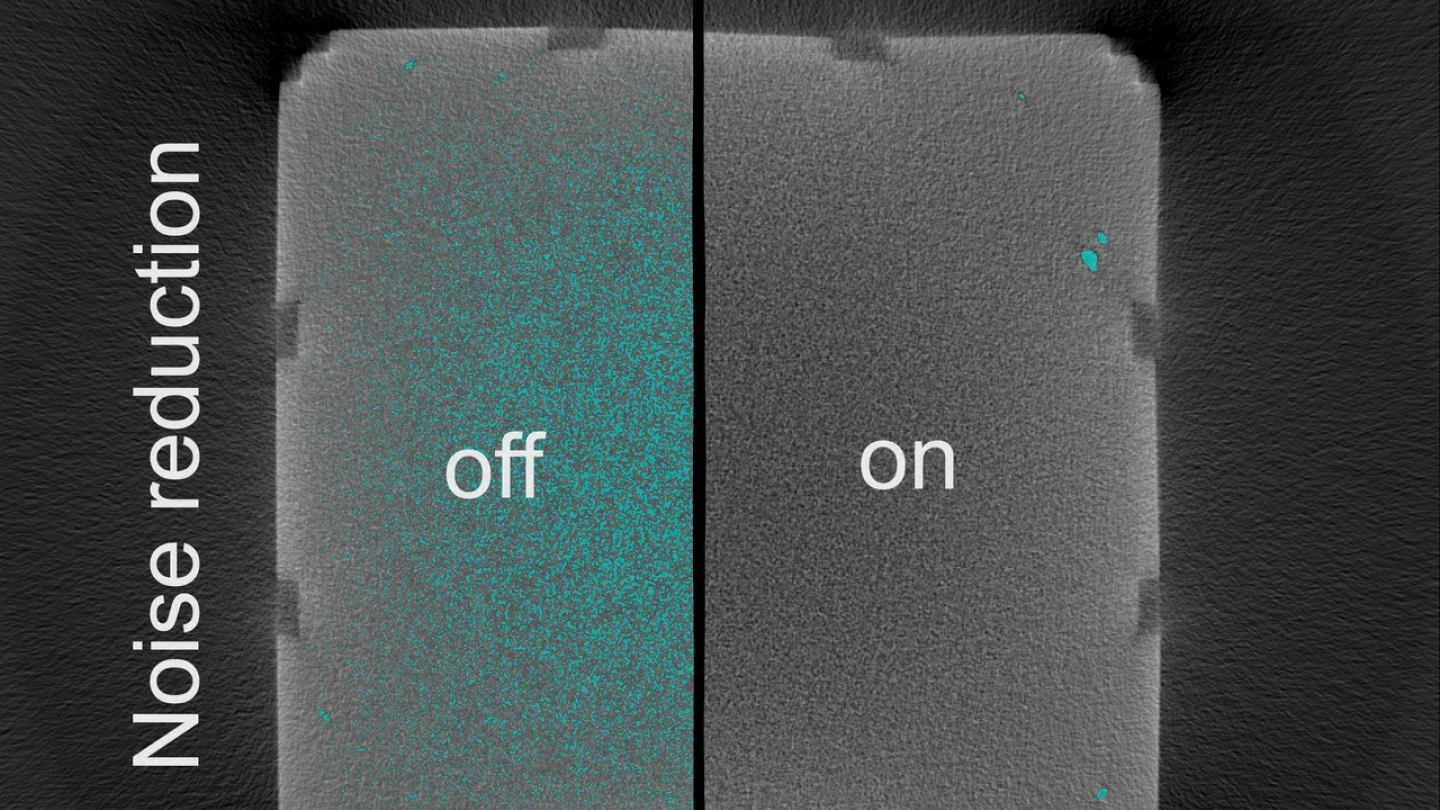

데이터에 노이즈가 많다면,VGEasyPore 는 다수의 노이즈 파티클을 검출할 수 있습니다. VGEasyPore 대화상자에서"노이즈 감소"옵션을 활성화 하면,처음부터 노이즈를 필터링할 수 있습니다. 이를 이용하면 공극 또는 내포물의 검출을 위한 매개변수의 조정이 쉬워집니다.

또한 — 다수의 미세한 노이즈 파티클을 평가하는 경우가 아니라면 — 공극률/내포물 분석의 실행 속도가 더 빨라질 수 있습니다.

작은 ROI(관심 영역)에 VGEasyPore 분석을 실행할 때(예를 들어,CT 스캔에 다수의 부품이 존재하며 이 중 하나만 분석)선택된 단일 부품 데이터의 비중에 따라 VGEasyPore 의 실행 속도가 개선됩니다.

사전 설정중 하나를 기본값으로 설정하여 분석의 기본값 설정을 변경할 수 있습니다. 예를 들어,0.5 mm 이하의 공극을 고려하지 않으려면,필터를 이에 맞게 설정하고 이를 기본값 사전 설정으로 저장합니다. 이를 이용하여 분석을 실행할 때 마다 시간을 절약할 수 있습니다.

이 사전 설정은 새로운 기본값 사전 설정을 저장하거나 기존의 저장된 사전 설정을 기본값 사전 설정으로 선택하기 전까지 적용됩니다.

보고서 텍스트 색상의 사용자 정의

더욱 개선된 보고서 사용자 정의:이제 모든 텍스트 레이아웃 요소에 대해 임의의 색상을 설정하여 특정 결과나 사용자 지정 텍스트를 강조표시할 수 있습니다.

검사 부품에 대한 여러 개의 동영상 또는 이미지 스택을 한번에 내보내기

"동영상/이미지 스택 저장"대화상자의 새로운 대기열 기능은 다수의 내보내기 작업을 매개변수화하고 대기열에 관리하며 이후 모든 이미지 스택 또는 동영상을 한번에 내보낼 수 있습니다.

이제는 다음 내보내기를 매개변수화하고 시작하기 전에 이전 내보내기 작업의 완료를 대기할 필요가 없으므로 내보내기 처리의 효율을 높입니다.

VGSTUDIO MAX의 배터리 분석 모듈을 이용한 배터리 셀 양극 오버행의 연속 검사를 실행할 때,허용 오차가 적용된 양극 오버행 속성을 Q-DAS 형식으로 내보낼 수 있습니다. 이를 통해 분석 결과를 Q-DAS 소프트웨어에서 통계 프로세스 제어에 사용할 수 있습니다.이는 예를 들어 프로세스 또는 기계 능력 분석,또는 특정 기간에 걸친 결과 모니터링(트렌드 분석)에 사용됩니다.

새로운 설명 텍스트는 "북마크"와"자동화"도구의 목적과 기능에 대한 이해를 도우며 소프트웨어에 대한 접근성을 개선합니다.

이제 매크로를 통해 변형 필드의 계산을 자동화할 수 있습니다. 이를 통해 변형 필드를"형태 메쉬"또는"보정 메쉬"기능에서 사용할 때 시간을 단축할 수 있으며 또한 적응형 ROI 또는 좌표 측정 템플릿에 대해서도 사용할 수 있습니다.

최신의 NSI 형식을 직접 가져올 수 있으며 이를 위해 특별한 도구가 필요하지 않습니다. 이를 통해 최신의 NSI 형식을 이용한 작업이 더 쉬워집니다.

이 비디오에서,재구성 대화상자의 여러 탭에 대한 가이드를 제공합니다.이를 이용하여 기본적인 콘 빔 재구성을 위한 설정을 쉽고 빠르게 실행할 수 있습니다.

동영상을 보려면 여기를 클릭 하십시오.

이 비디오에서,전형적인 주조 부품에 대한 P 203 공극 분석의 작업 흐름을 소개합니다. 여기에서,주물 전체에 전역 공극 키를 적용하고,특정 테스트 영역에 자유형식 ROI 공극 키를 이용하여 검사하고 허용 오차를 적용합니다.

동영상을 보려면 여기를 클릭 하십시오.

포괄적인 검사 결과를 간편하게 공유할 수 있습니다. 새로운 HTML 형식은 부품이나 결과의 3D 보기와 같은 인터액티브 요소도 포함하는 올인원 솔루션입니다. 이 문서들은 그 자체로 완료성을 가지며 특별한 뷰어 애플리케이션이 필요하지 않습니다.Edge 나 Chrome 같은 Chromium 기반 브라우저를 이용할 수 있습니다.

산업기준에 부합하는 보조키를 통한 크기 측정의 단순화 이는 2점 크기[LP],외피 요구사항(E),그리고 [GG]와 같은 전역 보조키 기호를 포함하며,수많은 크기 측정에 대한 쉬운 평가기능을 제공합니다.

일괄 처리에서 로드된 파일들이 최근 파일 목록에 나타나지 않습니다. 따라서 수동으로 처리된 프로젝트들에 대한 접근을 알아보기 쉽게 유지할 수 있습니다. 그렇지만 이전의 설정을 선호하는 경우,언제든지 환경설정에서 바꿀 수 있습니다.

구 반경을 길이 단위로 지정할 수 있으며,이는 비등방성 데이터에서도 사용할 수 있습니다. 확실히 개선된 성능을 느낄 수 있습니다.계산 시간이 50배 이상 빨라졌습니다 — 이는 특히 큰 반경값을 적용할 때 해당됩니다.

이미지 스택 가져오기와 내보내기의 PNG 형식 사용

PNG를 저장 또는 데이터 교환 형식으로 사용함으로써 추가적인 파일 변환과정이 필요없습니다. 볼륨 데이터의 가져오기와 내보내기시에 더 빠른 작업이 가능합니다.

새로운 DICONDE 내보내기

볼륨 데이터를 DICONDE 형식으로 내보낼 수 있습니다.이는 기존의 태그를 포함합니다. DICONDE 에서 가져온 볼륨이 아닌 경우,필수 태그들이 즉각적으로 생성됩니다.

네이티브 PNG 형식 지원을 통해 이미지 저장 기능이 개선되었습니다.이는 무손실 압축과 알파 채널을 포함하는 3D 보기 이미지를 지원합니다. 부분적으로 투명한 움직이는 이미지로 프레젠테이션을 돋보이게 할 수 있습니다.

이전에는,DICONDE 태그와 같은 메타정보를 장면의 볼륨 사이에서 전송할 수 없었습니다. 이 기능을 통해,필수 정보를 쉽게 이동할 수 있으며,이는 스캔 결과에서 완전히 새로운 볼륨을 생성할 때에도 마찬가지입니다. 이 개선을 통해 작업과정의 추적 가능성을 보장하며,이는 작업의 일관성에 도움을 줍니다.

그리기 및 분할 미리보기의 신속한 전환

"O"키를 누르면 그리기 및 분할 미리보기를 일시적으로 끌 수 있습니다. 이 신속한 변환은 음영값과 분할 미리보기 사이의 즉각적인 비교를 가능하게 합니다.따라서,분할을 실시간으로 평가하며 정확한 클래스 할당을 기다리고 있는 나머지 복셀에 그리기를 실행할 수 있습니다.

ROI에 대한 자동 색상 부여

그리기 및 분할로 생성된 ROI는 해당 레이블에 따라 자동으로 색상이 부여됩니다 이를 통해 분할 후 쉽게 구분할 수 있습니다. 이는 분할된 클래스의 시각적 구분은 2D와 마찬가지로 3D에서도 제공됩니다.

P 202의 등가 직경

P 202 표준에서 흔히 사용되는 매개변수 "등가 직경"을 VGSTUDIO MAX에 포함하였습니다. 이제,공극률 분석에 최대 등가 직경 허용 오차를 추가할 수 있습니다.

P 203 자유형식 ROI 허용 오차 상태의 시각화

P 203 의 다중 ROI를 다루는 기능이 더 간편해졌습니다. 각 ROI의 빨간색 또는 녹색으로 색상 코딩된 허용 상태를 즉각적으로 볼 수 있습니다. 이를 통해 허용 오차를 벗어난 ROI를 즉각적으로 인식하고 그 위치를 파악할 수 있으며,상관관계의 인식 및 분석이 쉬워집니다.

VGEasyPore 상대 모드의 개선

VGEasyPore 의 상대 모드의 공극 검출을 더 간편하고 정밀하게 개선했습니다. 이 업데이트 버전*은 로컬 조정형 알고리즘을 통한 정밀한 공극 식별을 가능하게 합니다.여기서는 음영값의 절대값을 설정할 필요 없이 대비 백분율을 간단히 설정할 수 있습니다. 기본 대비 값 20%는 대부분의 데이터에 적당한 값이며,더 이상의 조정이 필요없는 경우가 많습니다.

*이전의 상대 모드도 여전히 사용 가능하며,따라서 기존의 분석과 VGinLINE 작업의 문제없는 작동을 보장합니다.

더 빠른 VGEasyPore

VGEasyPore 가 많은 결함징후를 보이는 데이터에서 최대 3배 빨라졌습니다**. 이 유의미한 성능 개선을 통해 노이즈가 포함된 데이터를 이용한 분석에서 시간 절약을 기대할 수 있고 작업 흐름의 효율을 개선할 수 있습니다.

**새로운 복셀 정확도의 계산으로 인해 복셀 수와 작은 결함징후는 이전의 결과와 차이를 보일 수 있으나,검출된 결함징후의 결과 표의 부피와 형태 관련 값은 영향이 없으며 변동이 없습니다.

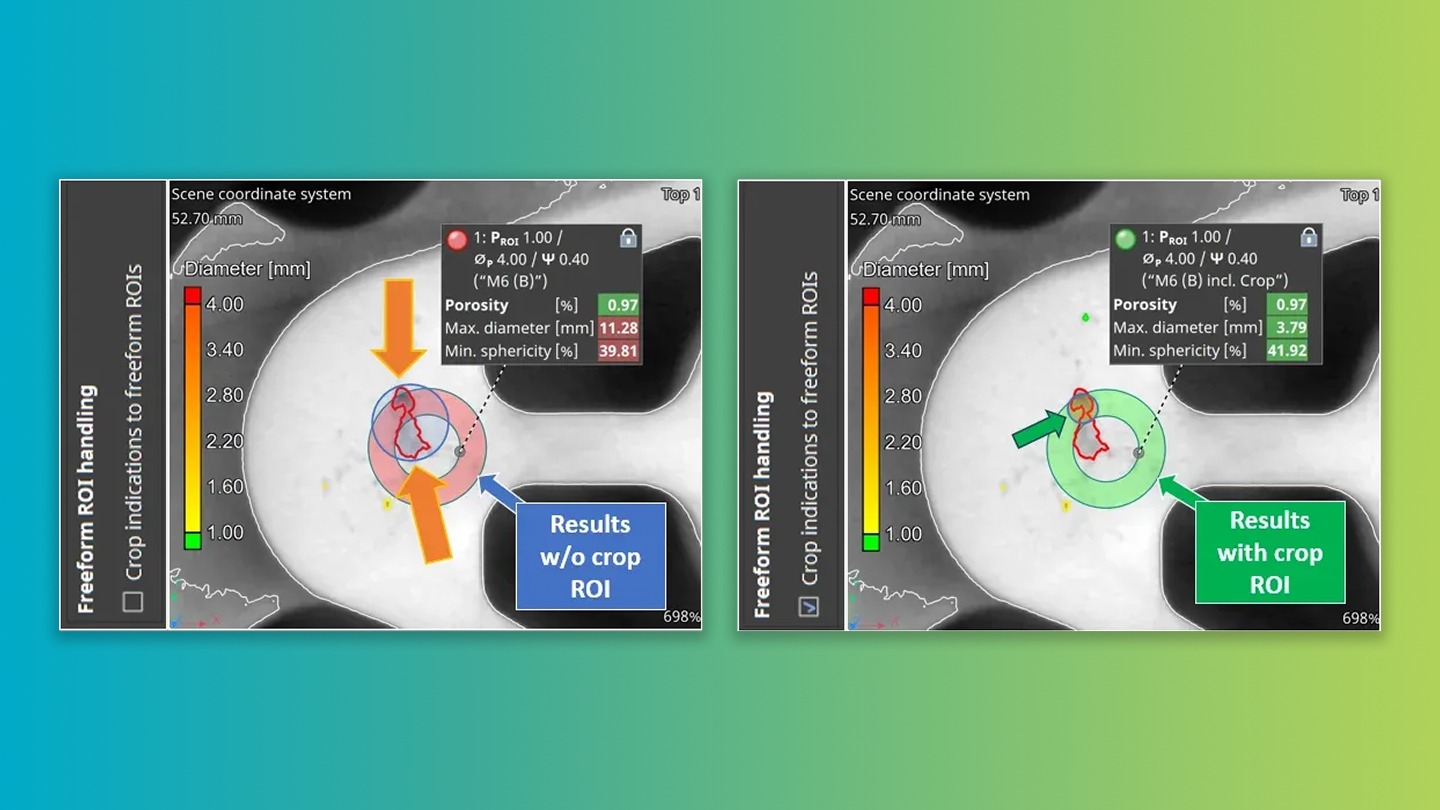

새로운 기능 "결함징후를 자유형식 ROI 경계에서 자르기"를 이용하면 공극의 매개변수들이 ROI 곙계 내에서만 계산될지 또는 경계와 상관없이 계산될지를 선택할 수 있습니다. 이는 특히 검출된 공극중 ROI 경계와 교차하는 공극에 해당하며 P 203 공극 키를 이용하여 허용 오차가 적용된 ROI의 공극 분석 결과에 큰 영향을 줍니다.

새로운 설정은 주물 공정에서 사용할 수 있으며,선택된 ROI에 대한 P 203 공극 키 코드의 적용에따른 공극률 평가에 대해 응용 프로그램에 특정된 사용자 정의로의 저장을 가능하게 하여 허위 음성 결과를 방지할 수 있습니다*.

이는 또한 새로운 기본값 설정입니다.하지만 이전의 설정을 사용하려면,새로 생성되는 분석에 대해 이를 비활성화할 수 있습니다. 기존의 분석과 평가에는,이전 버전과의 일관성을 유지하기 위해 이 설정이 이미 비활성화되어 있습니다.