We never thought we'd say it, but in some cases, less is indeed more. Less weight, less time, less budget—but more speed. At least, that is what UPBracing, the student team from Paderborn University (Universität Paderborn), had in mind when they set to work on their agile, lightweight design for FormulaStudent, an international design and race competition for university student teams. Their main goal: to reduce the weight of a 500-gram wheel carrier.

What Is a Wheel Carrier?

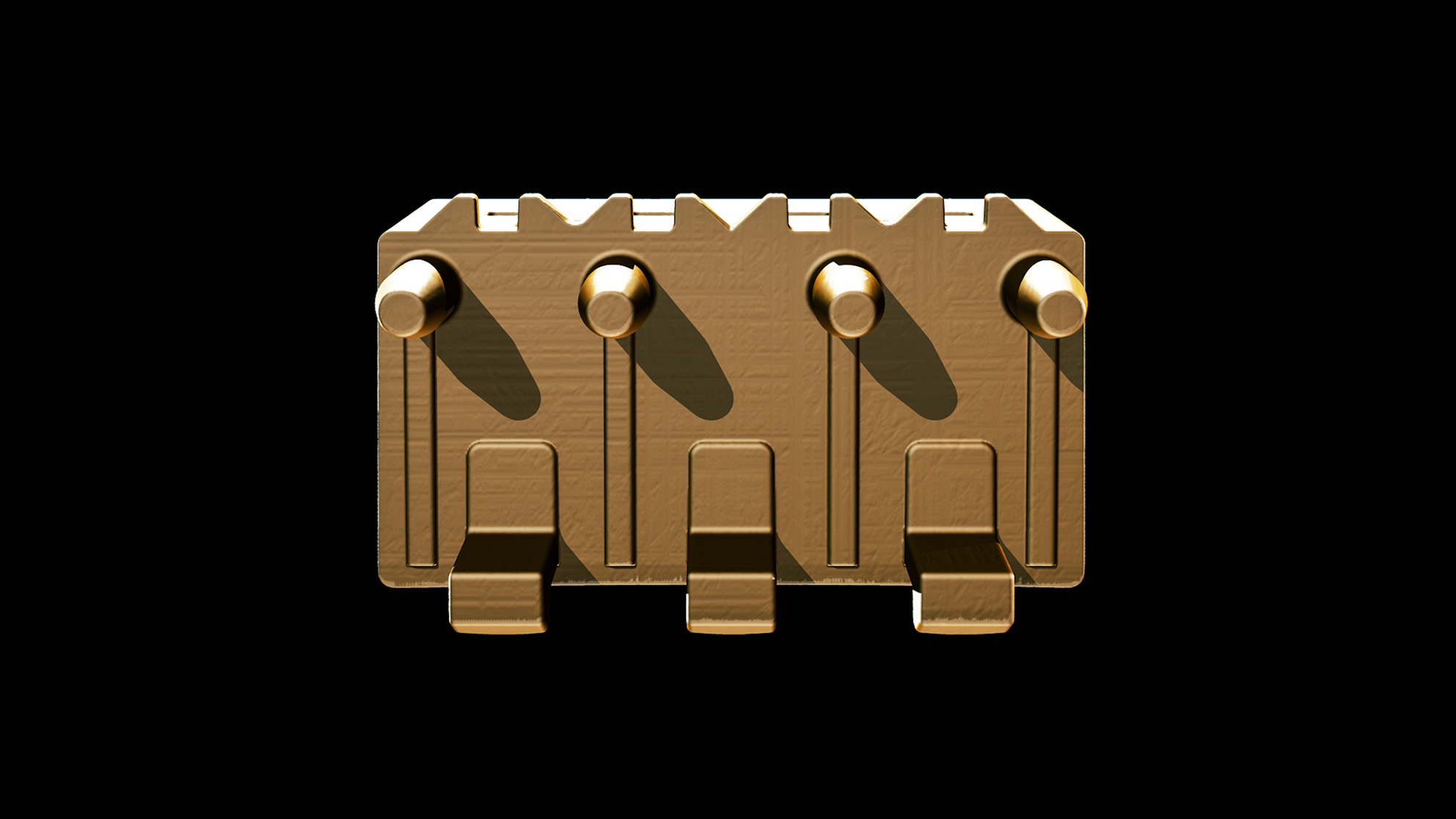

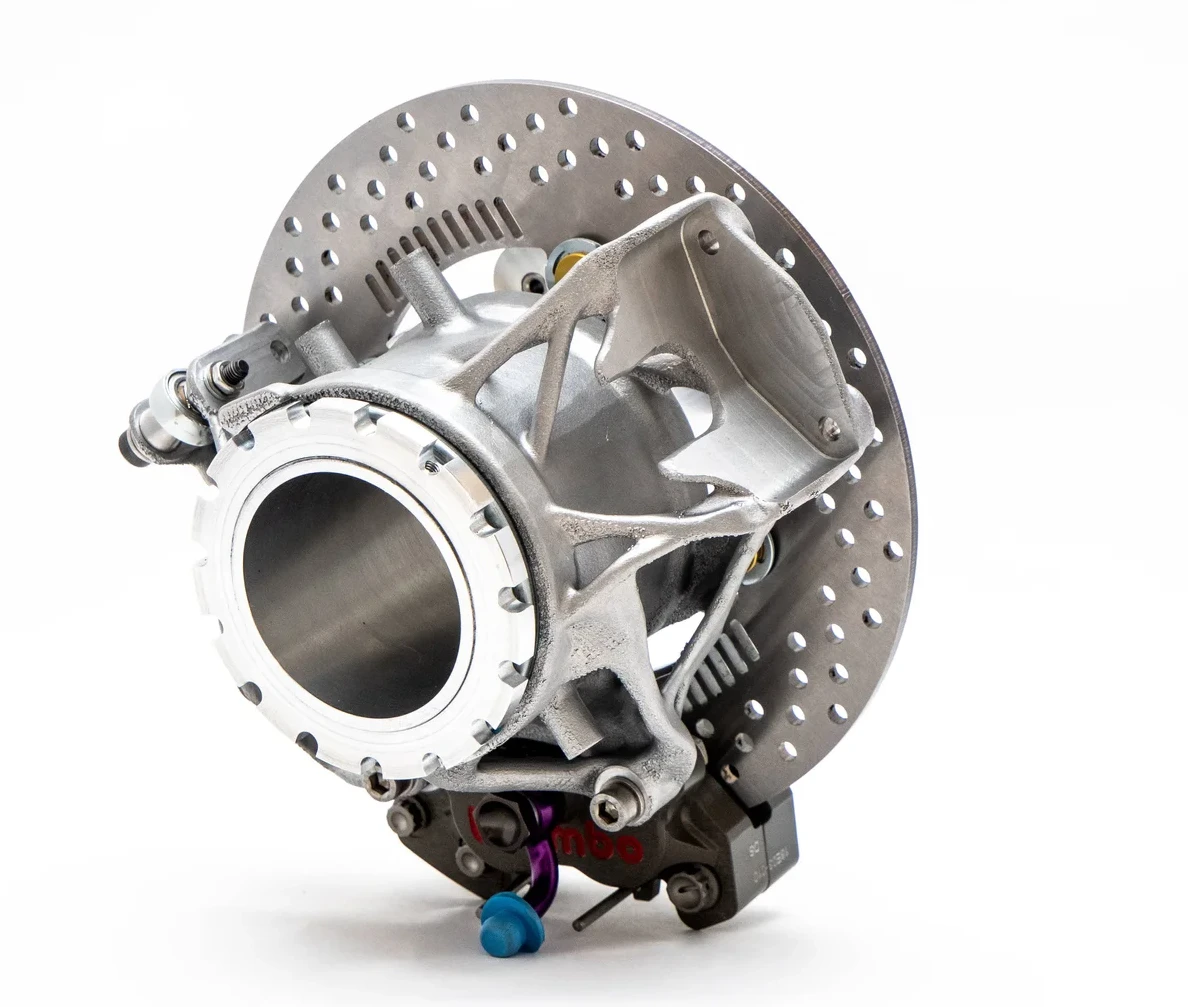

The wheel carrier supports a car's wheel bearing. It connects to the brake disc, the brake caliper, and the drive shaft.

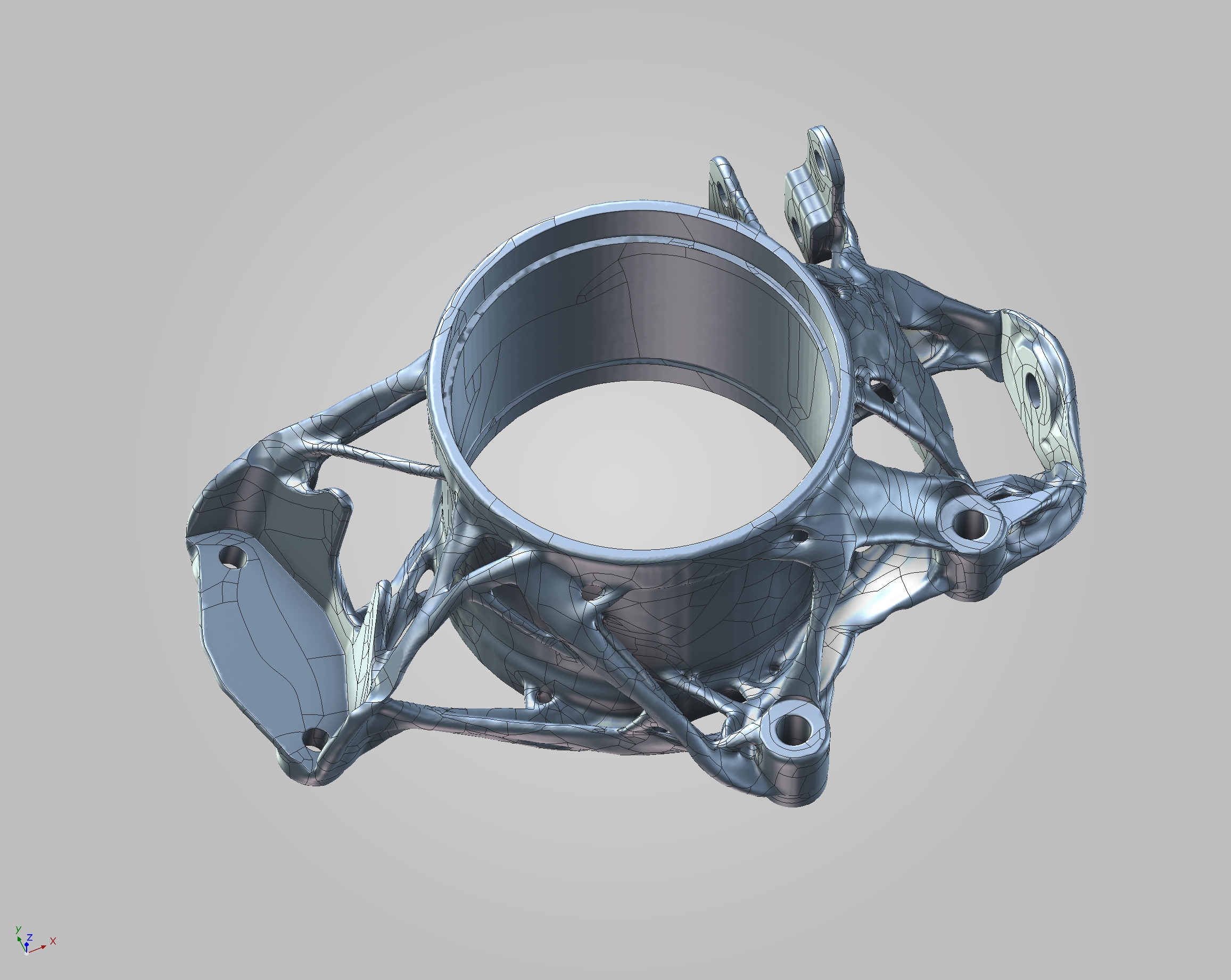

An existing complex design from a previous vehicle had produced a 500g-component. However, by using generative design, UPBracing was able to design a component weighing 265 grams—47 percent lighter than the traditional milling design!

Every gram counts!

When Design Meets Manufacturing

The efforts of UPBracing are a perfect example of how design and manufacturing can come together to—quite literally—drive innovation. For this, the team used two types of software: MSC for the design stage, and VGSTUDIO MAX for the inspection stage.

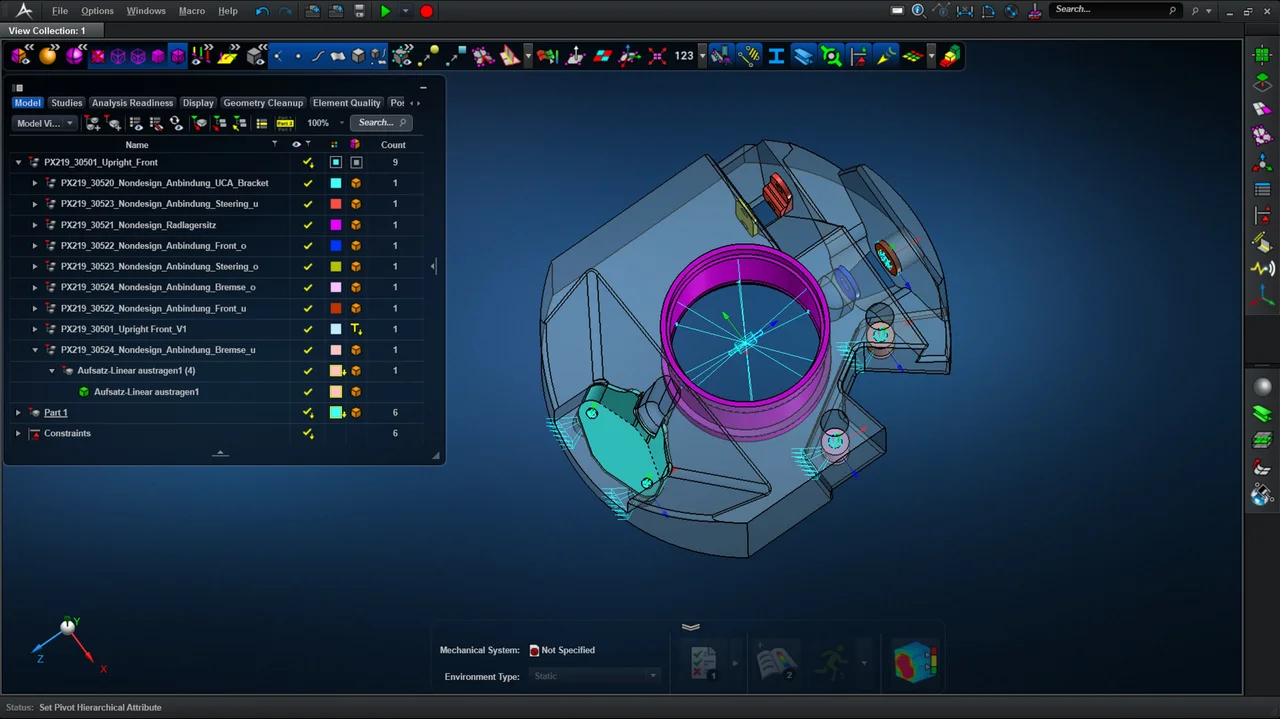

MSC Apex interface showing design space and loads

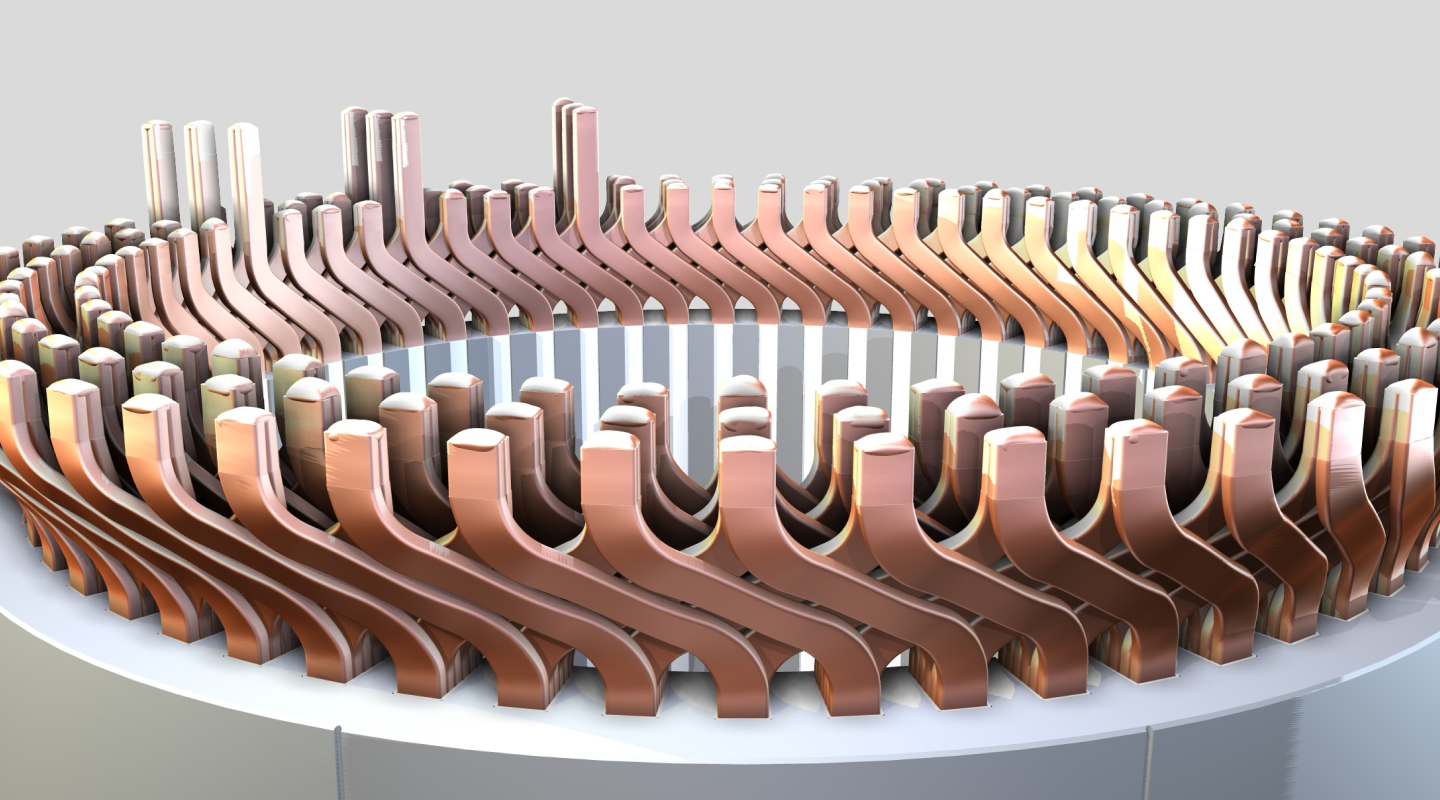

Generative design allowed the team to create a process-driven, optimized geometry of the carrier without the need for manual user interaction. With the help of MSC software, they were able to define both design and non-design spaces, set dozens of load cases, and optimize the design based on these factors. This allowed them to generate a number of designs and choose the most promising.

Generative design is a completely automated iterative design process that involves generating and finetuning outputs within certain constraints.

Designers have the possibility to adjust the loads and spaces to see if and how the geometry grows.

Think of a tree: branches grow from a trunk in a manner that depends entirely on its constraints. For example, if wind blows from the right, the tree adapts and reinforces that side.

The tree also avoids and grows around natural obstacles, like rocks.

For complex parts like the wheel carrier, additive technology is the perfect counterpart to generative design and helps bring the part to life in stages—one branch at a time.

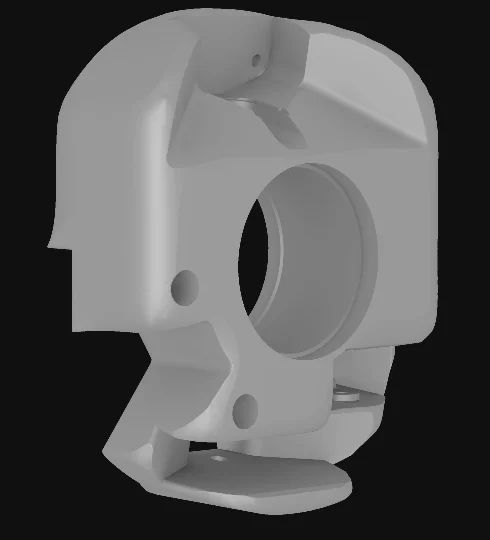

Pictured: generative design iterations

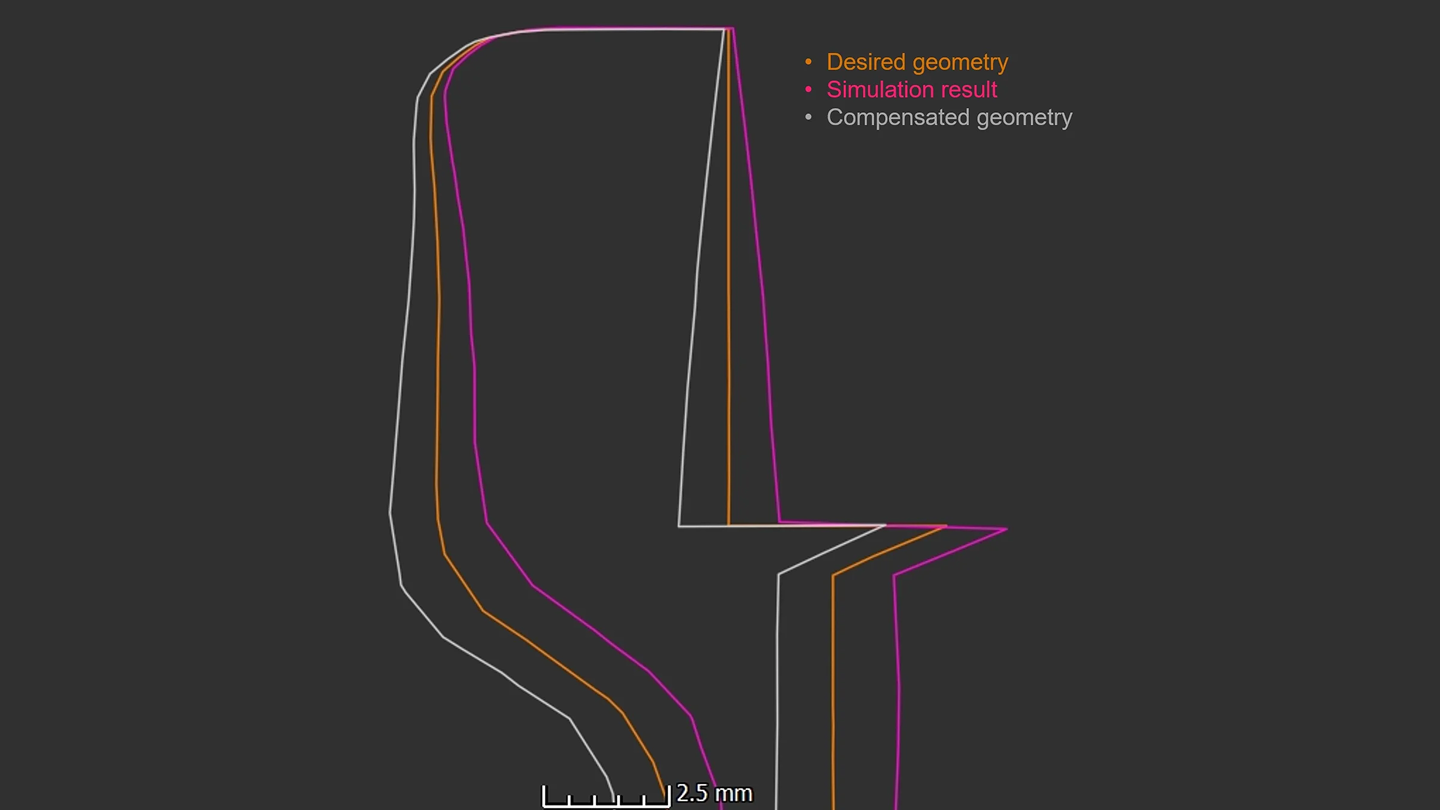

After they had the design, the team ran simulations to test for stresses, distortions, cracks, and hot spots during manufacturing. This helped reduce the final maximum deviation from 0.8 mm to 0.2 mm.

Finally, after much fine-tuning and after manufacturing simulations detected no failure in the part, the team finally had their virtual model—all they needed to do was manufacture the part itself. This is where VGSTUDIO MAX comes in.

VG + MSC Teamwork: Compensation Loops

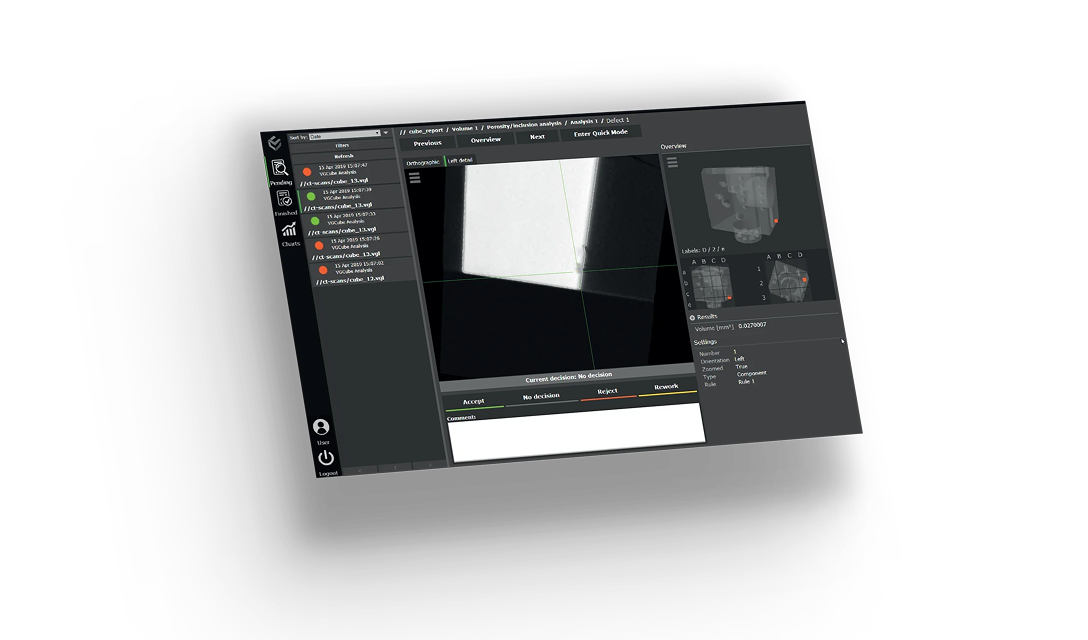

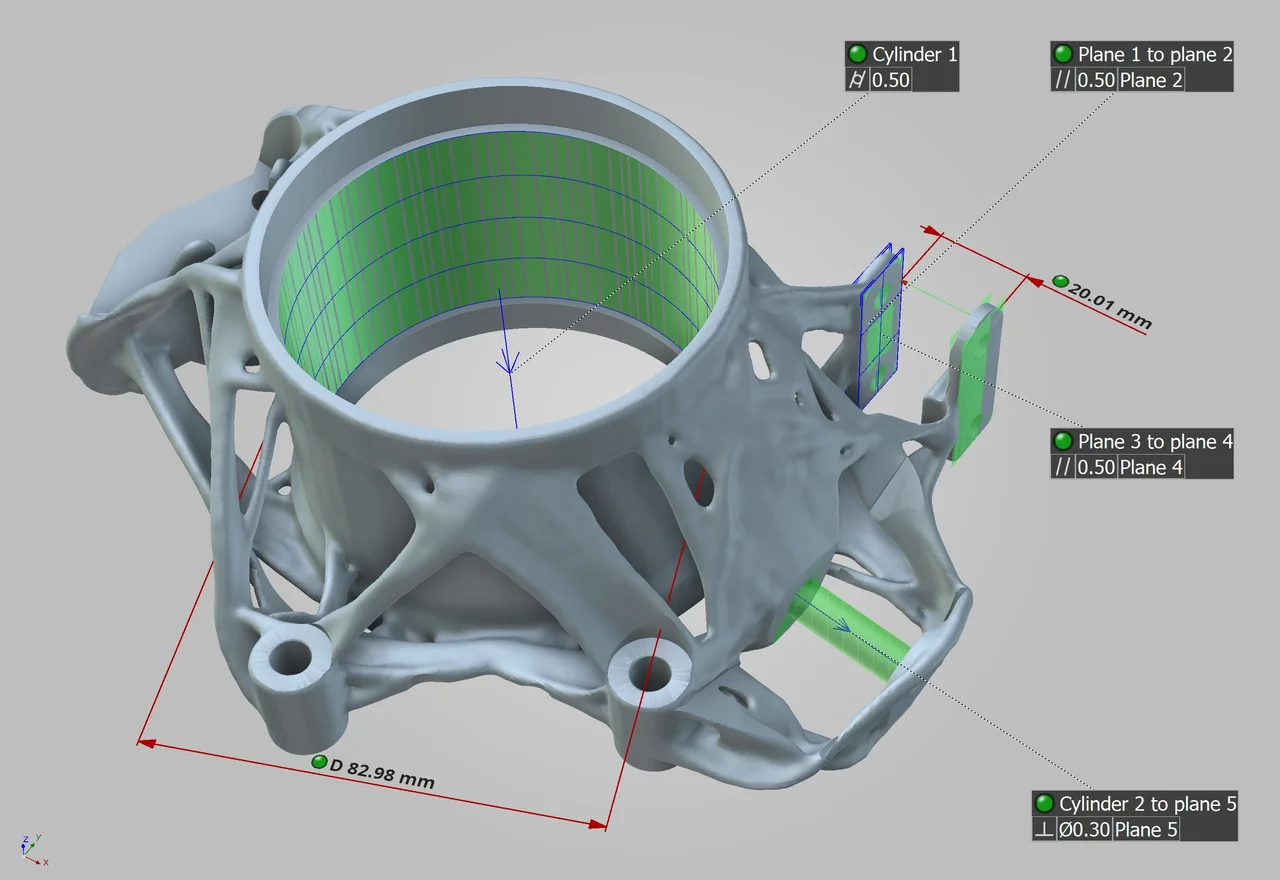

To ensure that the part was as precise as possible, MSC and Volume Graphics initiated a series of "compensation loops": the initial mesh was exported to VGSTUDIO MAX and evaluated with geometric dimensioning and tolerancing (GD&T). The metrology was copied from the nominal to the simulation results, and the results of the process simulation were evaluated.

After that, a measurement plan was created based on the requirements of the design department to determine single dimensions and 3D shape tolerances.

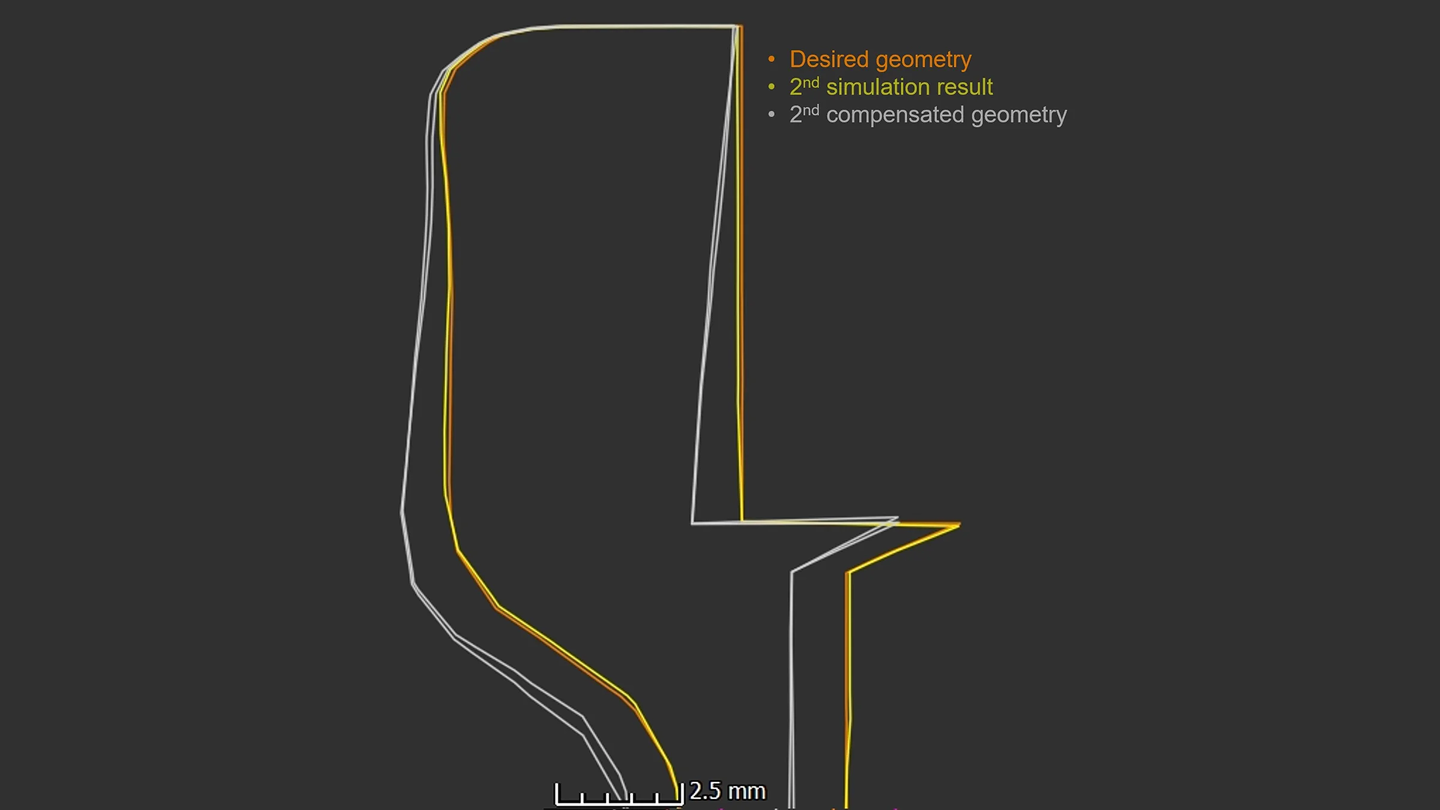

Metrological evaluation of the simulated mesh

Based on the measurement plan, mesh compensation was conducted to compensate for the difference between the simulated results and the nominal. Only a partial compensation was possible, but it was enough to feed the compensated model back into Simufact to verify process outcomes.

This saved the team a lot of time—and money—it would have spent not only on physical testing but also on production, as the part was tested, corrected, and simulated virtually. In other words, the part had already gone through multiple iterations without having to be manufactured once.

First attempt at the compensation

This loop was repeated several times. The team copied the metrology from the nominal object to the second simulation result, and the process simulation was reevaluated. From that, the team generated a second compensation, which was used to compensate all remaining deviations. The compensated model was re-simulated to verify process outcomes.

Results of the compensation loop

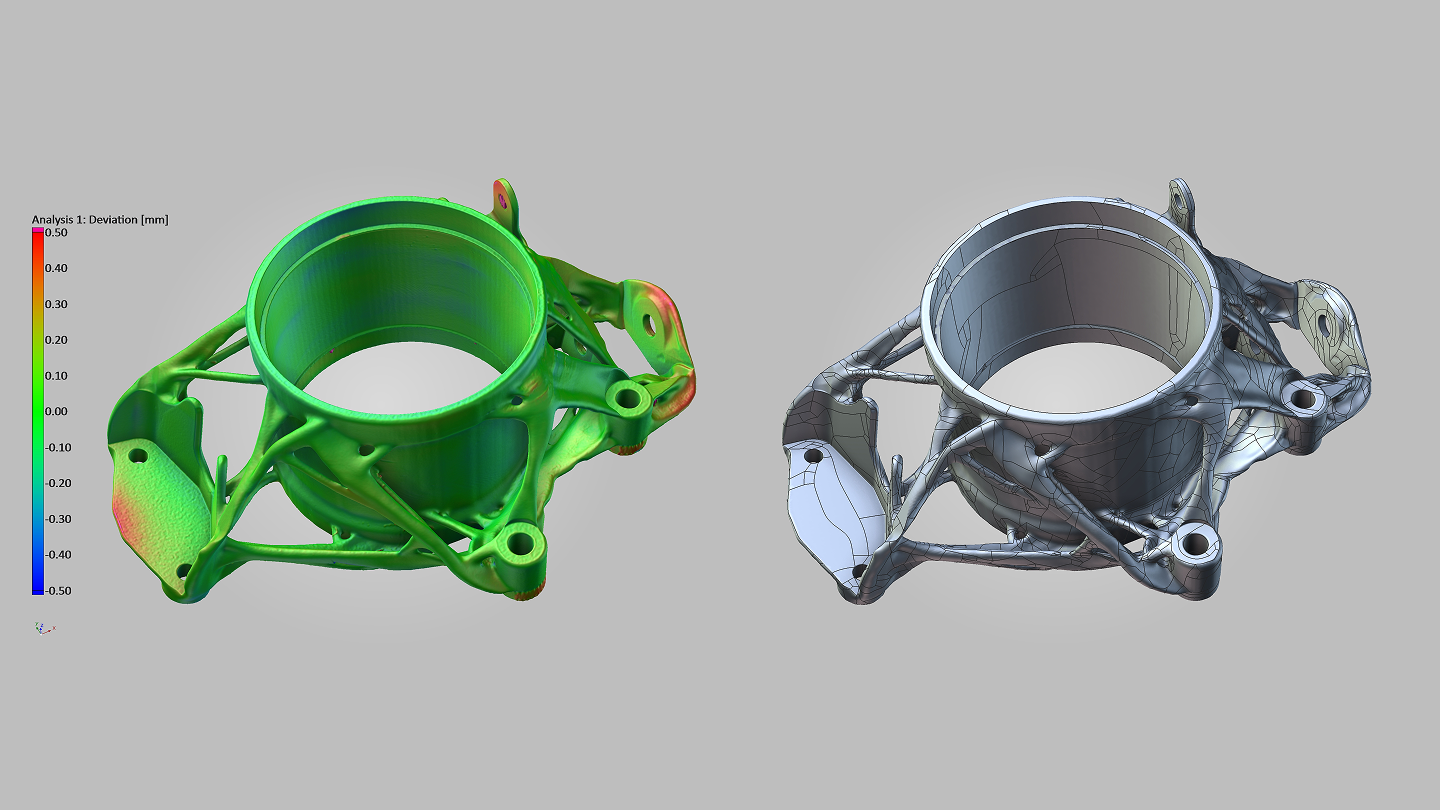

Once it was optimized, the team printed it out and milled the contacting surfaces. To ensure the highest quality, CT scanning was used as a non-destructive means of testing. The team used VGSTUDIO MAX to analyze the CT scans of the part, and the results were good: a nominal/actual comparison showed that distortions were higher than simulated but still within a good range, and metrology showed that the dimensions were within tolerance.

Nominal/actual comparison

Virtual Teamwork

The FormulaStudent team at Paderborn University relied on several software solutions to design the wheel carrier: MSC Apex Generative Design, which helped them run fast and smooth simulations and achieve a weight reduction of 47 percent; Simufact Additive, which reduced manufacturing-induced distortions; Nastran, which calculated stress after the manufacturing; and VGSTUDIO MAX, which was used to analyze the results non-destructively.

Race car driving is most often associated with drivers trying to outmatch each other in terms of speed, but even virtually, different solutions worked hand in hand to deliver the best possible outcome for the design competition. What previously took weeks to achieve is now possible in just a few days.

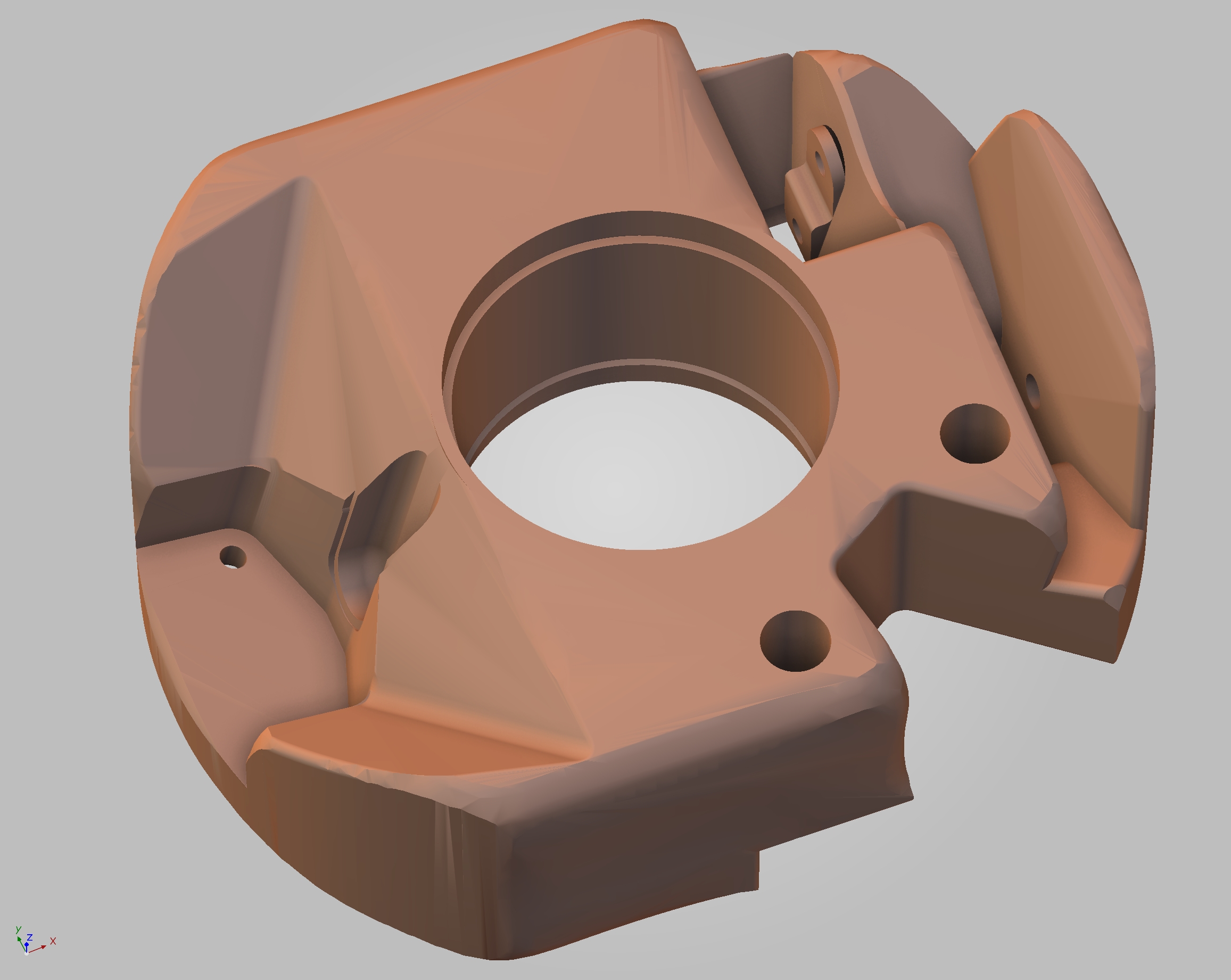

Design space vs. results of the generative design:

Before

After