Rely on us to stay ahead of the game so you can, too. We invest in and leverage state-of-the-art technology, ensuring our hardware-independent applications remain at the forefront of industry standards. With ongoing new feature rollouts and close partnerships with industry leaders, you can trust the tools you use today will also be the solutions you need for the future.

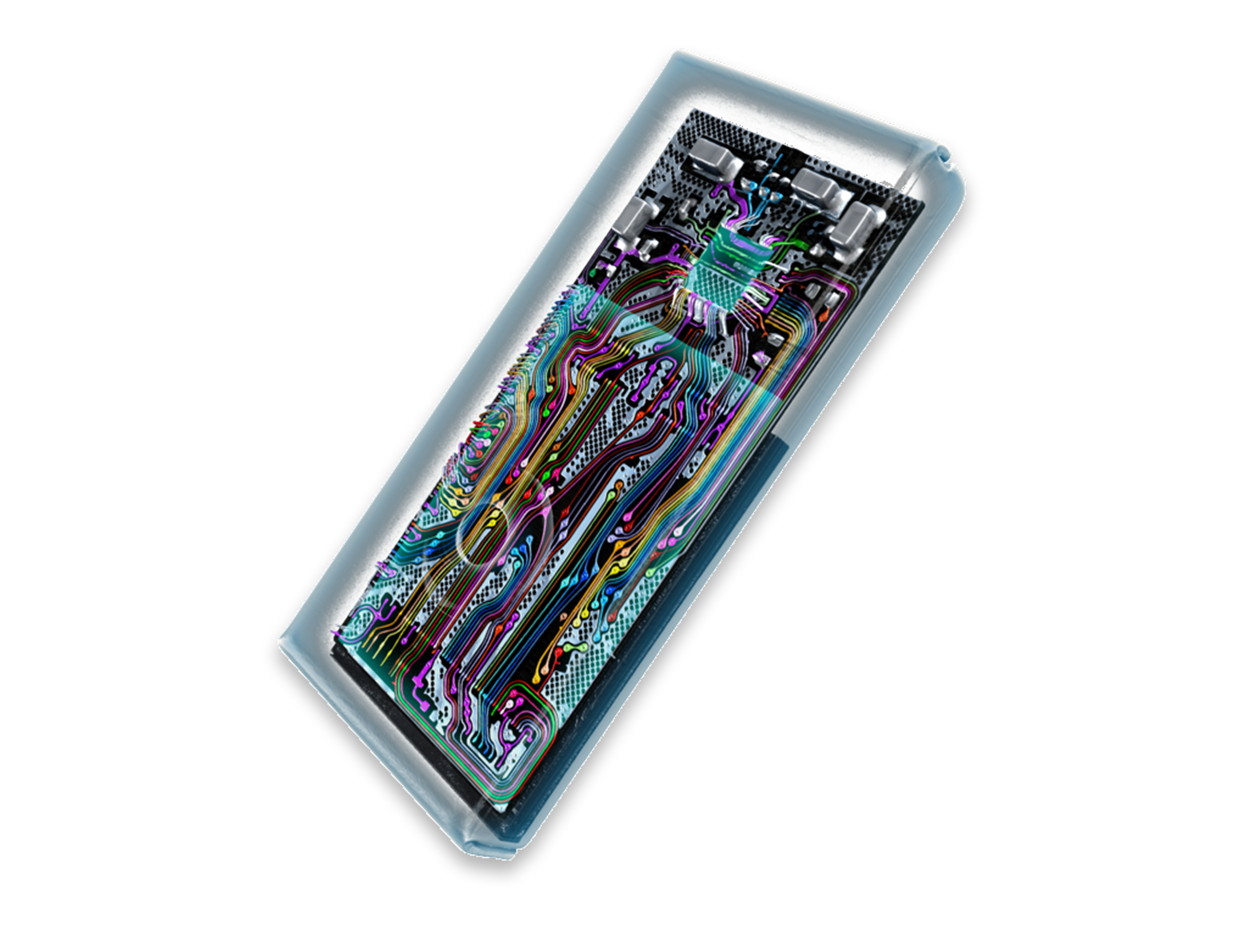

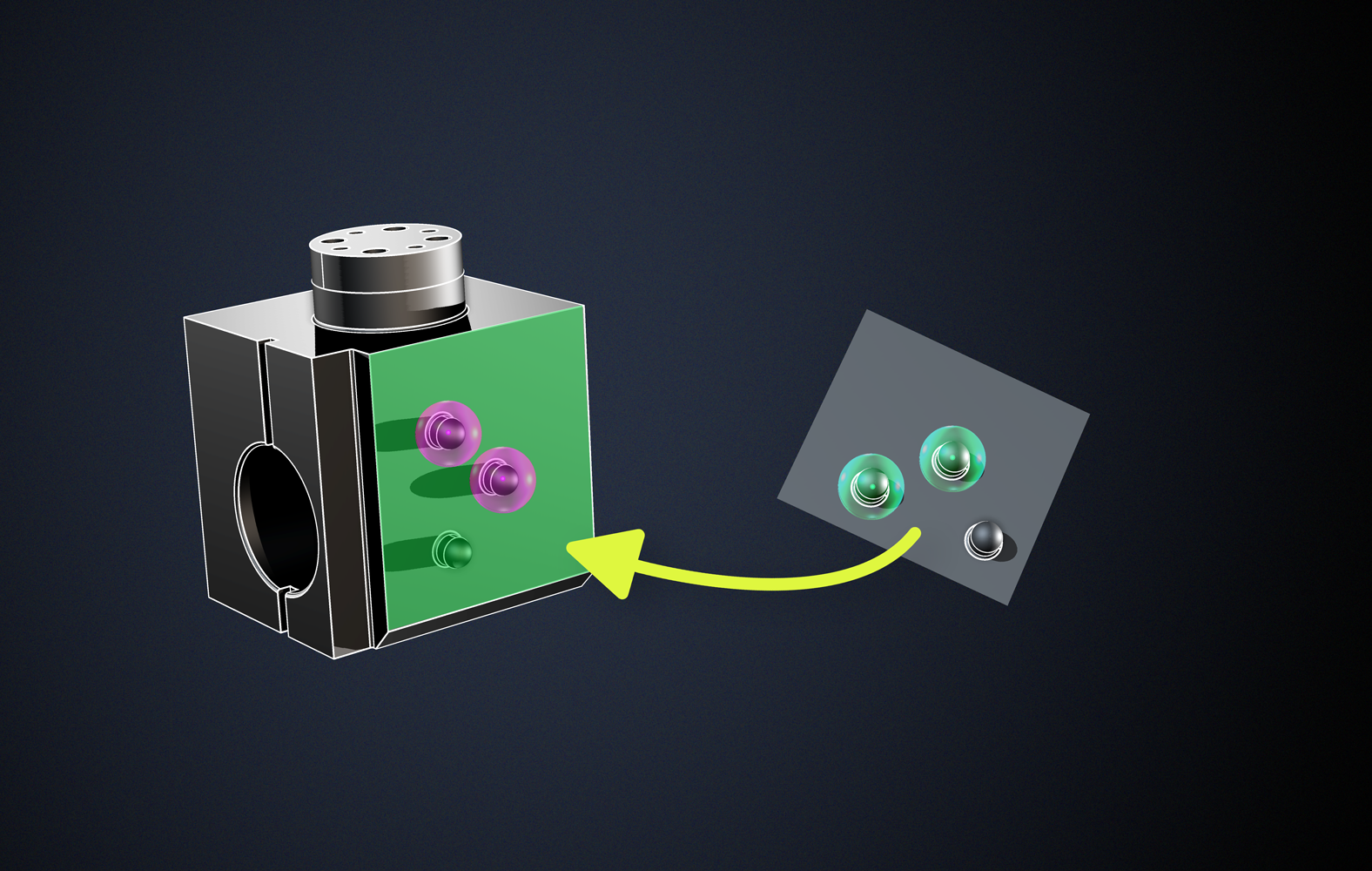

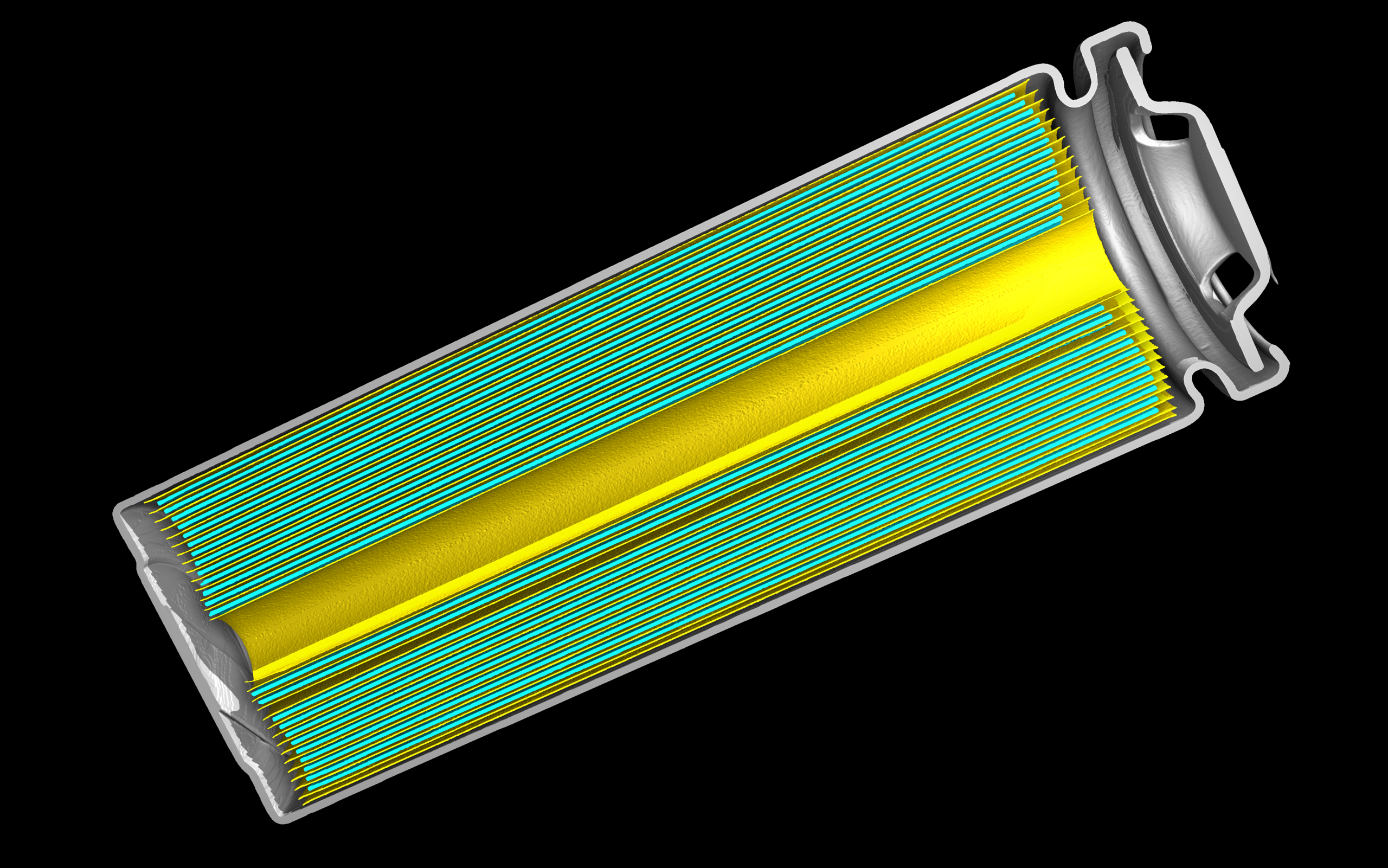

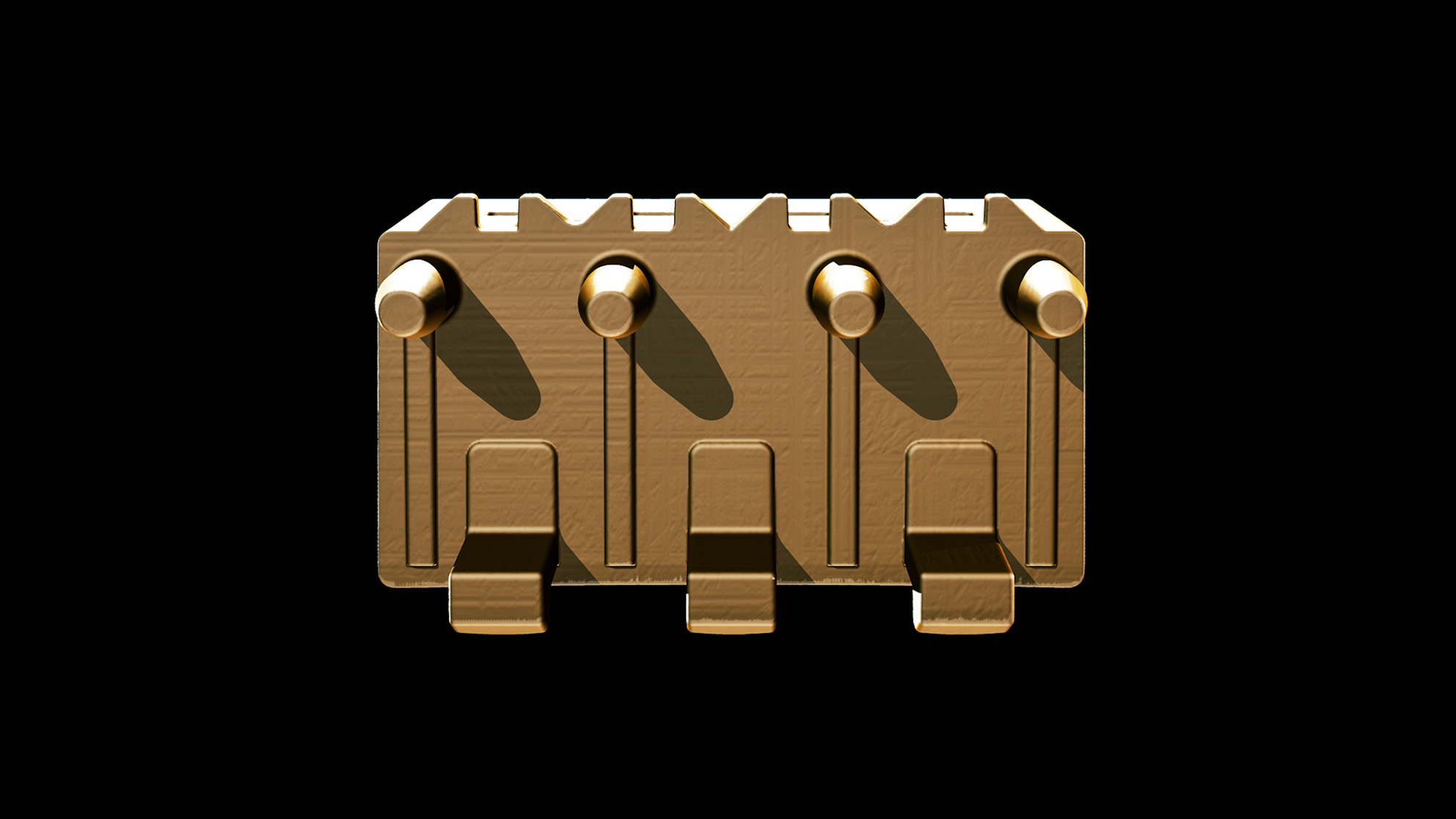

Transform industrial NDT data into clear, actionable insights. Ensure precision, accuracy, and efficiency at every product lifecycle stage. Detect defects, validate dimensions, and optimise production and part design. As the de facto industry standard, VG software doesn’t just enable you to do most 3D data analysis tasks. It helps you to do them better.

Know you're choosing the best in the game when you go with the ones who created it. Rely on our quarter-century track record in pioneering CT analysis software that has been tested and refined by industry pacesetters in applications where precision is non-negotiable. Put your data to work effortlessly with intuitive reporting and collaboration tools.