The challenge

The aerospace industry is highly competitive and under pressure to increase production rates due to unprecedented backlogs. According to the Centre for Aviation: “At 2024 delivery rates, the global aerospace industry will need almost 14 years to clear the logjam of outstanding orders.”

At the same time, aerospace manufacturers must also meet ever-stricter performance and safety standards, particularly for components such as turbine blades, which need to function under extreme pressure and heat conditions.

Making the complex, multi-faceted inspection process more streamlined and efficient would enable Safran to improve productivity, and decrease the cost of their non-destructive workflow.

To help achieve this while maintaining ultimate accuracy and quality, the team at Safran looked to Hexagon’s non-destructive testing AI modelling solution, VGTRAINER.

The Solution

VGTRAINER from Hexagon enables users to leverage the power, accuracy, and speed of AI-driven data segmentation without the need for specific AI expertise. This easy-to-use solution is designed for inline and high-throughput CT analysis environments, offering fast, stable segmentation for precise, repeatable results at scale.

The Safran inspection routine for the blades previously involved the use of tactile or optical 3D coordinate measuring machines for scanning, but these were not able to achieve the required precision for high-pressure turbine blades. Initial attempts using computed tomography achieved accuracy no better than 100µm, which was insufficient for the critical internal dimensions of these parts. The strong absorption of the turbine blade resulted in substantial image artefacts and noise in certain regions which impede contrast resolution and made finding a proper starting contour for surface determination difficult.

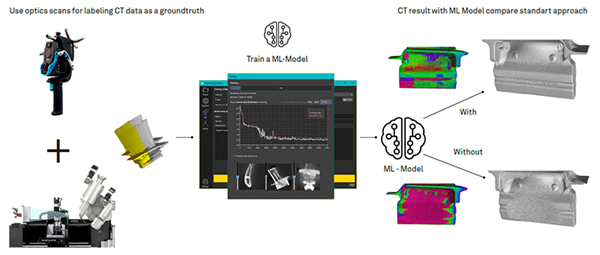

The Safran team imported CT scans into Hexagon’s VGSTUDIO MAX along with corresponding surface optical measurements to define the volume's surface. Safran then leveraged the deep learning capabilities of VGTRAINER by utilising 3D optical scans to train a sophisticated machine learning model within the software (Fig. 1). Deep learning enables the software to take a set of CT scans with a known surface and the deep segmentation model can be trained to the point it is able to predict for each voxel (a 3D pixel) of a CT scan whether it is representative of the surface or not, yielding a proper starting contour.

Figure 1: Trainer model workflow.

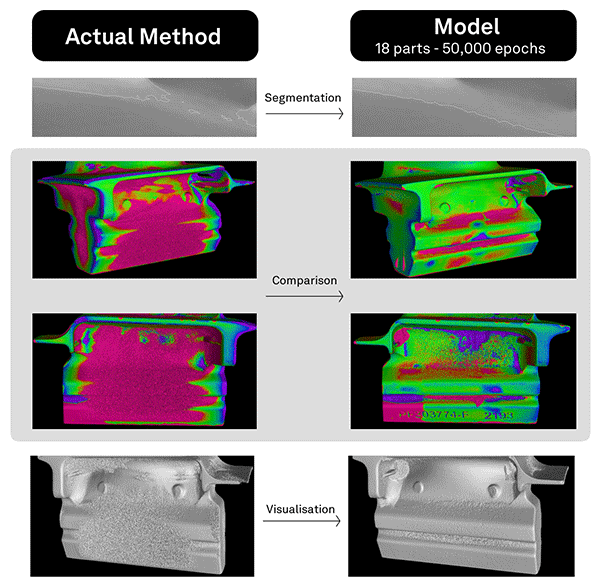

Figure 2: Comparison of traditional method and with implementation of the new model

Hexagon’s VGTRAINER modelling software does not just create a fixed set of training patches upfront, instead it samples new patches in each iteration from the CT scan. This means that after around 50,000 iterations (on only 18 labelled data points) the model has seen all CT scans in the training set while focusing on critical parts with different labels.

This model provides the potential for more accurate CT measurements. Previously, the CT-scanning process was limited by hardware capabilities , but now AI offers solutions that were not possible before. In the future, the power of AI and VGTRAINER may open the door to eliminating the need for dual scanning methods.

Additionally, Hexagon’s VGTRAINER is a standalone software solution that runs on a local workstation without needing to upload any data to the cloud.

The results

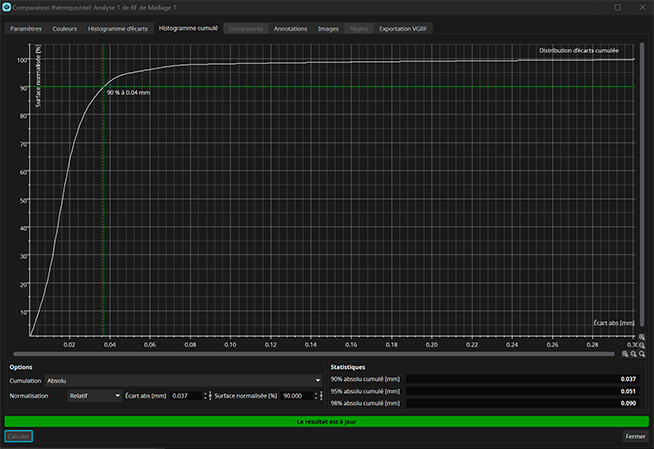

Using Hexagon’s AI and Deep Learning solution has significantly reduced noise and improved segmentation accuracy in challenging regions for Safran during their blade inspection process. For example, during a study, results demonstrated that in the root zone of the turbine blade, the mean deviation was reduced from 188 µm to 36 µm (Fig. 3). Similar improvements were observed in the platform region, where the difference was halved.

By taking the average of manufactured parts, we stay on the safe side while ensuring that the results have a high chance of being close to the nominal shape.

Comparing the golden surface to the nominal CAD, just to show how close the results are to the nominal shape:

Figure 3: Deviation result

The study concluded that the de-noising effect of the Hexagon solution reduced standard deviation and overall improved segmentation accuracy.

The results are clearly visible in the visual data. In Figure 1, the two scan results are shown on the far right. The data obtained using Hexagon’s trainer module (top) is far crisper and has more defined edges which means they can be measured directly from the software. The results without the trainer module (bottom) show significant noise artefacts in the central section.

The value

The impact this can have on the manufacturing operation for Safran is significant. For example, the reduction in scanning methods can streamline the workflow, potentially eliminating the need for additional reference data steps. This simplification through the improvement of CT measurement accuracy drives efficiency by enabling them to rely solely on data acquired from a single source, reducing production timelines and increasing productivity.

VGTRAINER’s ease of operation means advanced AI segmentation is accessible to everyday users, while its on-premises profile ensures complete data security and reliability.

It integrates seamlessly with existing systems like VGSTUDIO MAX, which Safran was already using at multiple sites, meaning VGTRAINER offers enhancements in many other applications. VGSTUDIO MAX is a modular software suite offering the complete spectrum of CT analysis functionality with non-destructive insights at every stage of the production cycle. It helps manufacturers improve quality, reduce costs and accelerate production.

As a cutting-edge solution, VGTRAINER supports SAFRAN’s commitment to innovation and production efficiency.

Now that we have the golden surface and the nominal mesh, we can calculate the difference between the two and use the mesh compensation module to create a compensated mesh that accounts for the shrinkage. The golden surface should also be used for manufacturing geometry correction in the same manner.

Conclusion

The integration of Hexagon's VGTRAINER has proven to be a powerful tool for Safran Tech, offering a more efficient approach to turbine blade inspection. By leveraging the power of AI and deep learning, Safran has enhanced accuracy in its CT measurements and streamlined its inspection processes. The reduction in mean deviation and noise, particularly in key regions like the root and platform zones, highlights the impact on quality and precision. As a result, the elimination of dual scanning methods has and while accurate, the addition of tomography enables the team to control both the internals and externals of the blade, which is useful both for the geometries of complex parts and overall industrial efficiency. However, the VGTRAINER’s ease of use, combined with its ability to operate securely on-premises, ensures that cutting-edge AI technology is available to users without compromising data security. In addition, its seamless integration with VGSTUDIO MAX allows Safran to utilise its existing systems while achieving enhanced levels of operational efficiency.

As the aerospace industry continues to face mounting production demands alongside stringent safety standards, solutions like VGTRAINER represent a significant boost for precision manufacturing use cases. For Safran, this not only helps to reinforce its position as a leader in innovation but also showcases how advanced solutions can drive measurable improvements in quality, efficiency, and competitiveness.