Turbine blades are a critical component for jet engines. Ensuring their quality is not just a safety consideration; high-quality turbine blades ensure optimal engine performance, fuel efficiency, durability, and reduced emissions.

It’s important to remember here that the aerospace industry is not like the high-volume world of automotive where samples from the production line are tested. In aerospace, every blade must be tested.

Of course, embedding rigorous inspection processes into manufacturing also helps to detect potential turbine blade issues before they lead to failures. But such a rigorous inspection routine can involve multiple processes, such as tactile or optical 3D coordinate measuring machines (CMMs) for the external dimensions in tandem with computed tomography (CT) for internal dimensions and structure.

One manufacturer, Safran Tech, identified this as an area where efficiency improvements could be made. Safran Tech is part of Safran Group - the world’s second largest aircraft equipment manufacturer, employing over 92,000 people and generating 27.31 billion euros in revenue (2024).

In some dental practices—and at least in large dental laboratories—digitization has arrived. For example, intraoral scanners are becoming more and more popular in fabricating crowns and veneers. However, in the lateral and posterior tooth regions, the accuracy of the scans is quite limited. As soon as a cast of several teeth is required, such as for bridges or aligners, creating a plaster cast from a classic dental impression is still hailed as the most precise method—but unfortunately the most time-consuming.

With CT technology and VGSTUDIO MAX, dental professionals have now found the time-saving shortcut they were looking for. Thanks to automation, they can save a lot of time without having to compromise on the quality they've gotten used to.

Reconstructing a Fountain Pen

Gifts often hold great sentimental value—so great, in fact, that it is hard to believe such a small chip can make such a huge dent in function. At least, that was the case when a customer had a beloved fountain pen that no longer wrote. Check out this story of how they used VGSTUDIO MAX to segment, measure, and reconstruct parts of the pen!

In the early 18th century, sculptor Barthélemey Giubal brought five figures to life for the palace gardens in Lunéville: the singer Arion and his four accompanying putti. In 1766, Prince Elector Charles Theodore had these sculptures brought to Schwetzingen. Now, centuries later, they will be journeying home—as 3D scans. Join Benjamin Moreno and Vincent Lacombe as they scan the sculptures in Schwetzingen Palace!

Beetles date back to the Carboniferous (ca. 360–300 Ma), but early fossils are rare—until CT analysis and 3D scanning revealed beetles preserved in dinosauriform coprolites. Join Martin Qvarnström and his team at Uppsala University as they uncover these prehistoric secrets and, using VGSTUDIO MAX, piece together part of a timeline 230 million years ago.

A Piece of Cake

Let's say you invited some virtual friends over for some virtual cake. The question is, how do you even cut this thing? Where's the cake shovel? By using the clipping tools of VGSTUDIO MAX, you will learn that there are many ways to slice a cake—even a virtual one.

By using ROIs, you can really make your surface shine! Check out how we can quickly and easily polish the surface of a propeller.

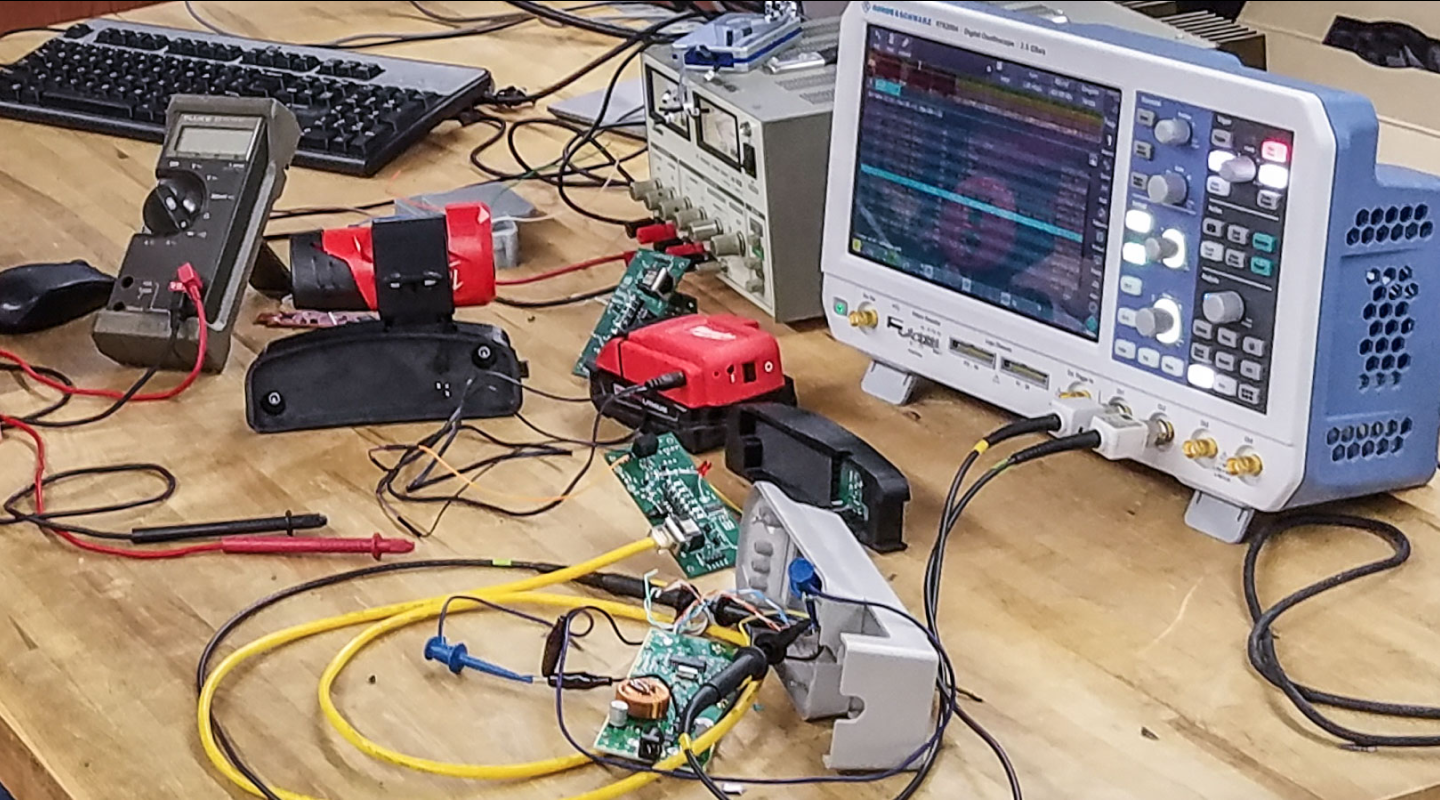

The novel coronavirus (COVID-19), first identified in December 2019, triggered a global scramble for healthcare equipment. Within months, outbreaks in Italy, Latin America, and the U.S. spread rapidly, and by April 2020, the world had changed—hospitals everywhere were running out of time and supplies.

Whether it's a project milestone or a unique experience with Volume Graphics, our Storyteller Team looks forward to hearing from you.

Get in Touch