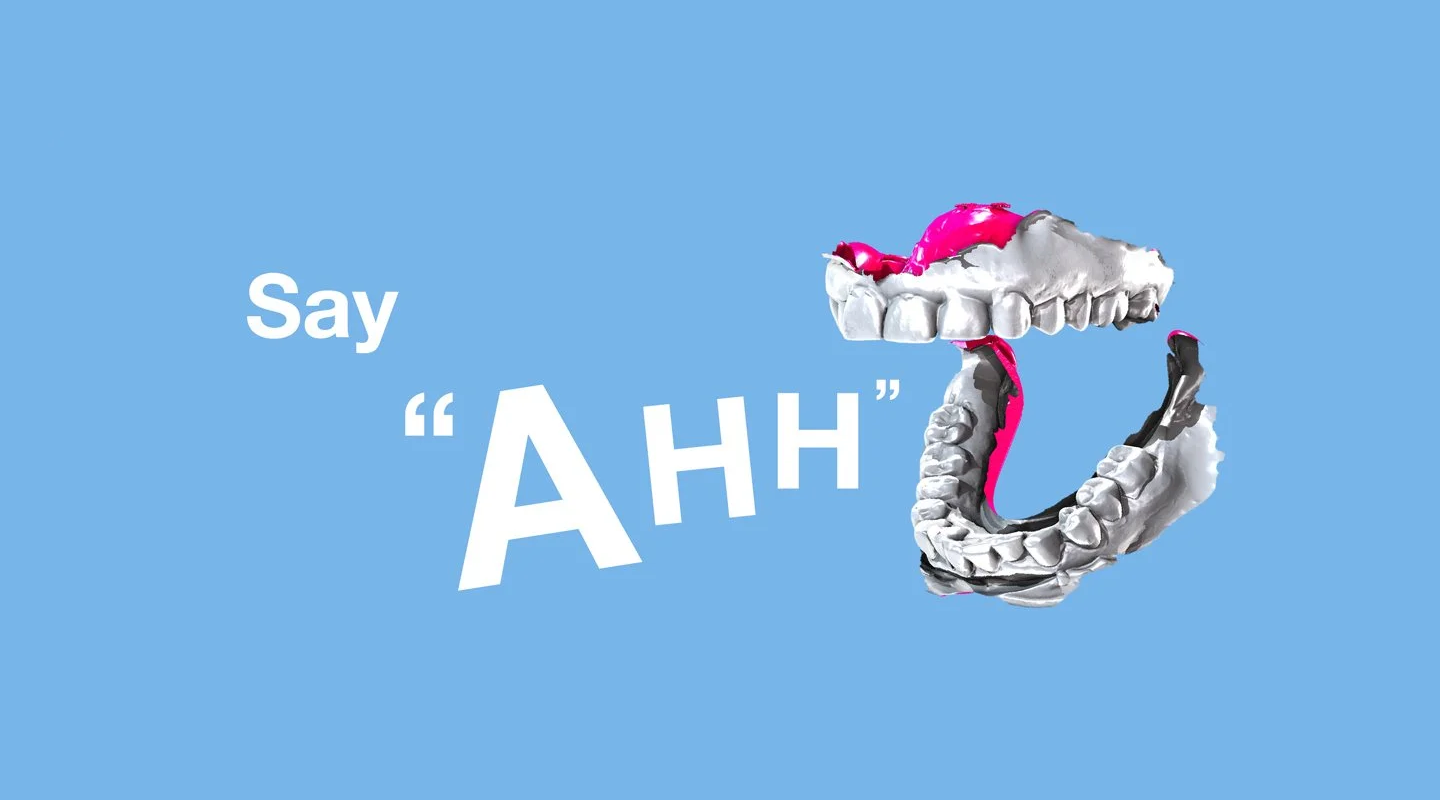

In some dental practices—and at least in large dental laboratories—digitization has arrived. For example, intraoral scanners are becoming more and more popular in fabricating crowns and veneers. However, in the lateral and posterior tooth regions, the accuracy of the scans is quite limited. As soon as a cast of several teeth is required, such as for bridges or aligners, creating a plaster cast from a classic dental impression is still hailed as the most precise method—but unfortunately the most time-consuming.

With CT technology and VGSTUDIO MAX, dental professionals have now found the time-saving shortcut they were looking for. Thanks to automation, they can save a lot of time without having to compromise on the quality they've gotten used to.

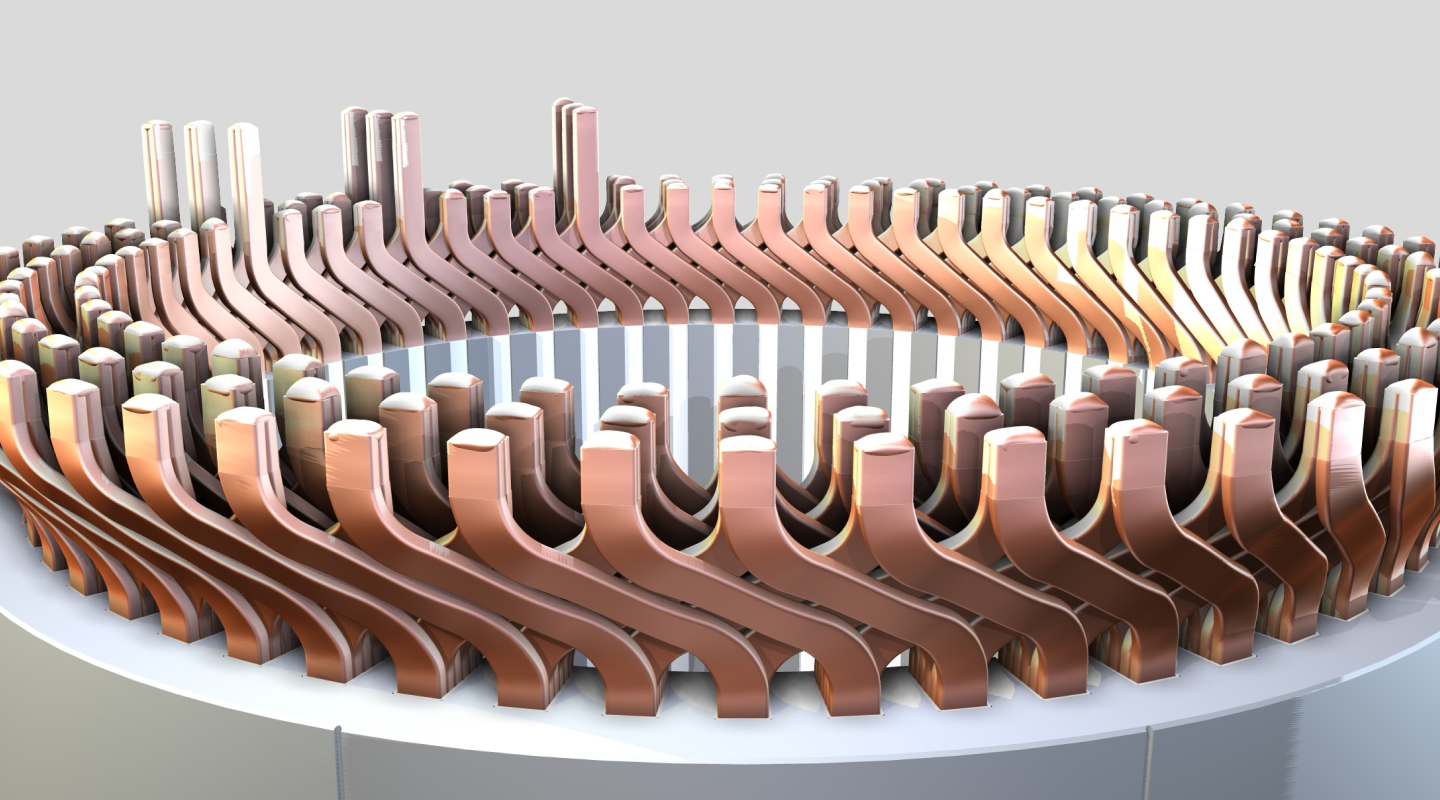

In 1907, cars were just replacing horses. Today, manufacturers are pushing for cleaner EVs—but how can we keep up with rapid tech shifts while inspecting every hairpin?

This story shows step-by-step hairpin inspection with industrial CT and VGSTUDIO MAX.

Whether it's a project milestone or a unique experience with Volume Graphics, our Storyteller Team looks forward to hearing from you.

Get in Touch