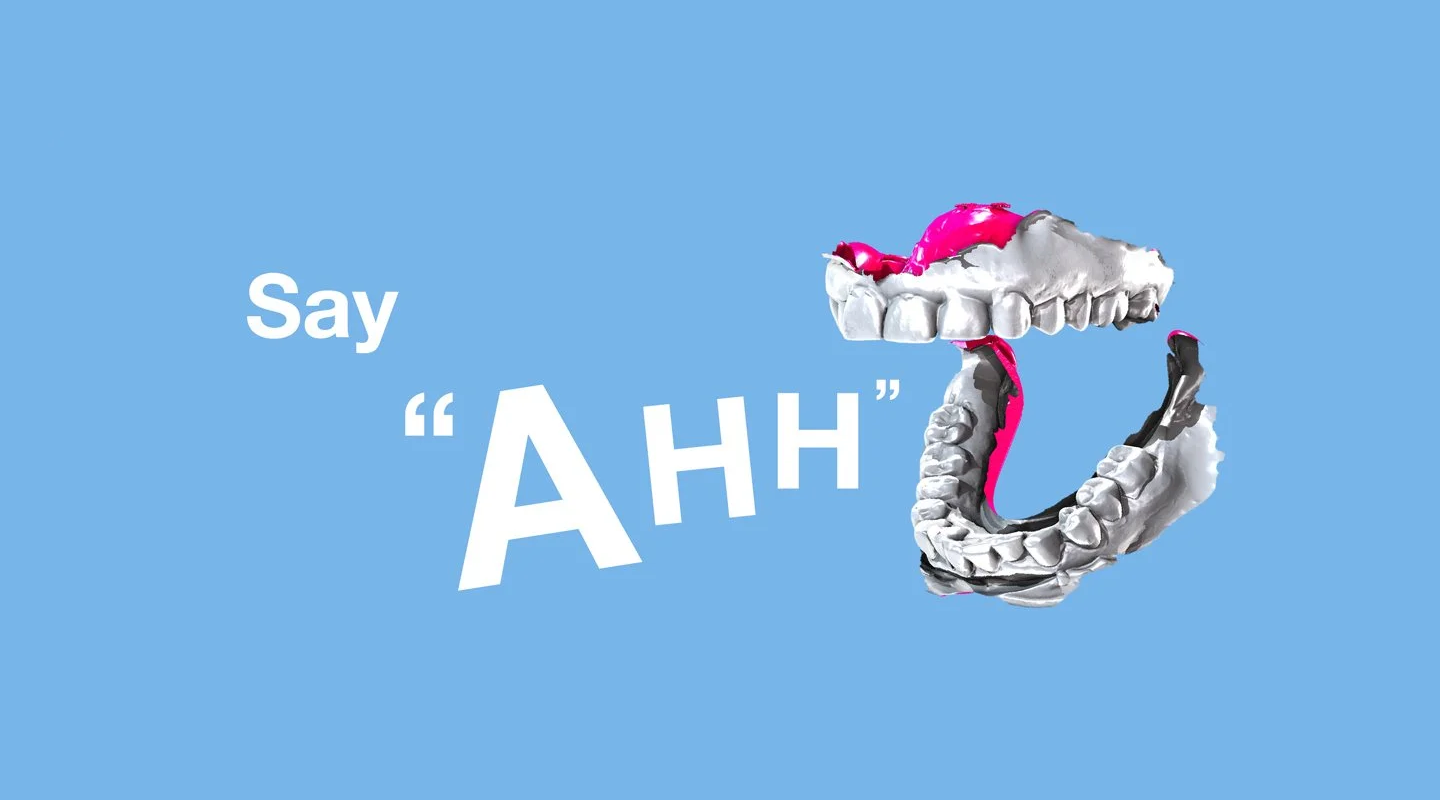

In some dental practices—and at least in large dental laboratories—digitization has arrived. For example, intraoral scanners are becoming more and more popular in fabricating crowns and veneers. However, in the lateral and posterior tooth regions, the accuracy of the scans is quite limited. As soon as a cast of several teeth is required, such as for bridges or aligners, creating a plaster cast from a classic dental impression is still hailed as the most precise method—but unfortunately the most time-consuming.

With CT technology and VGSTUDIO MAX, dental professionals have now found the time-saving shortcut they were looking for. Thanks to automation, they can save a lot of time without having to compromise on the quality they've gotten used to.

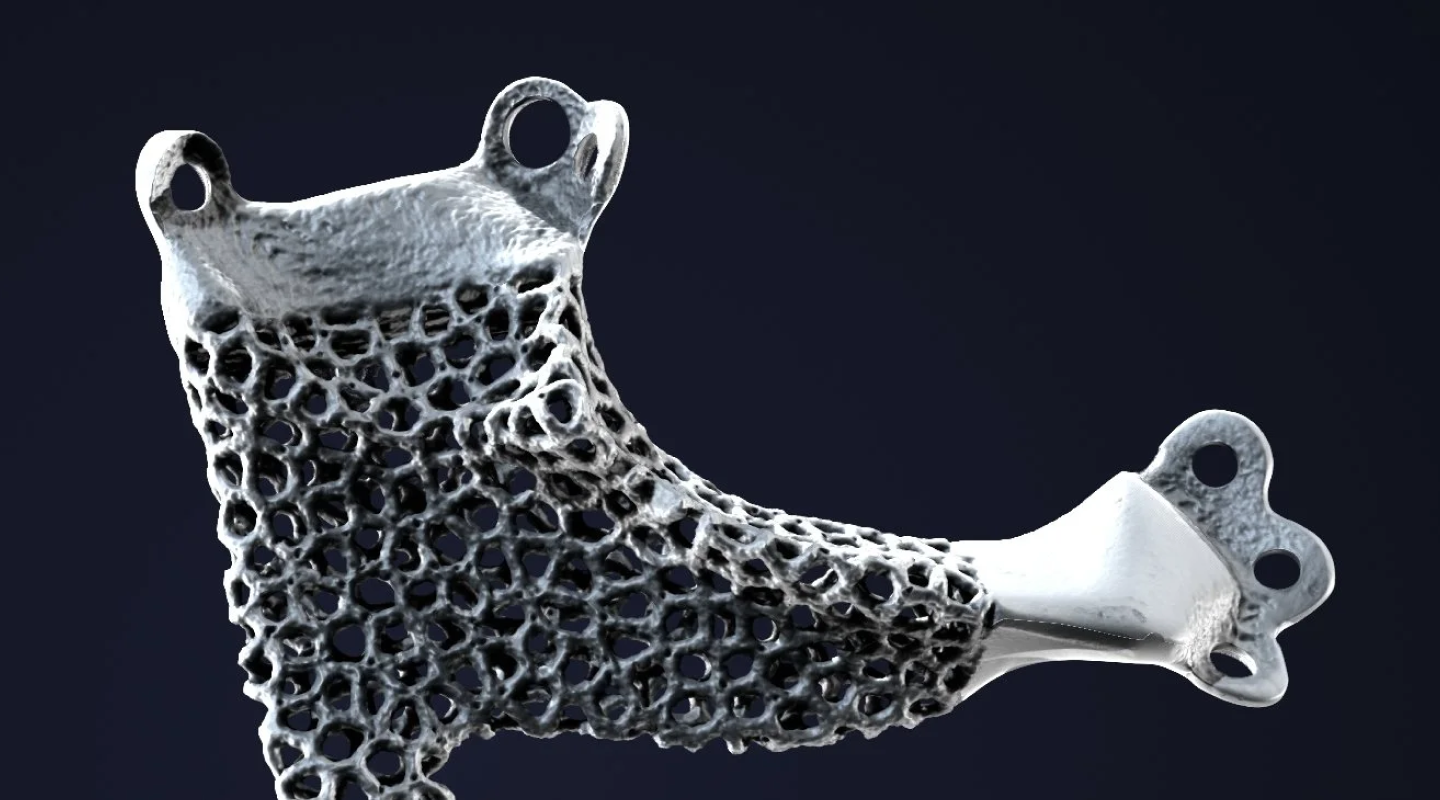

Meets Medical Implants

Conventional, off-the-shelf implants have made it easier for medical professionals to treat the most common patient needs quickly and efficiently. However, modern imaging—combined with additive manufacturing technology—has made it possible to design patient-specific implants to better fit individual needs in more complex cases. Join us as we use VGSTUDIO MAX to examine these customized implants!

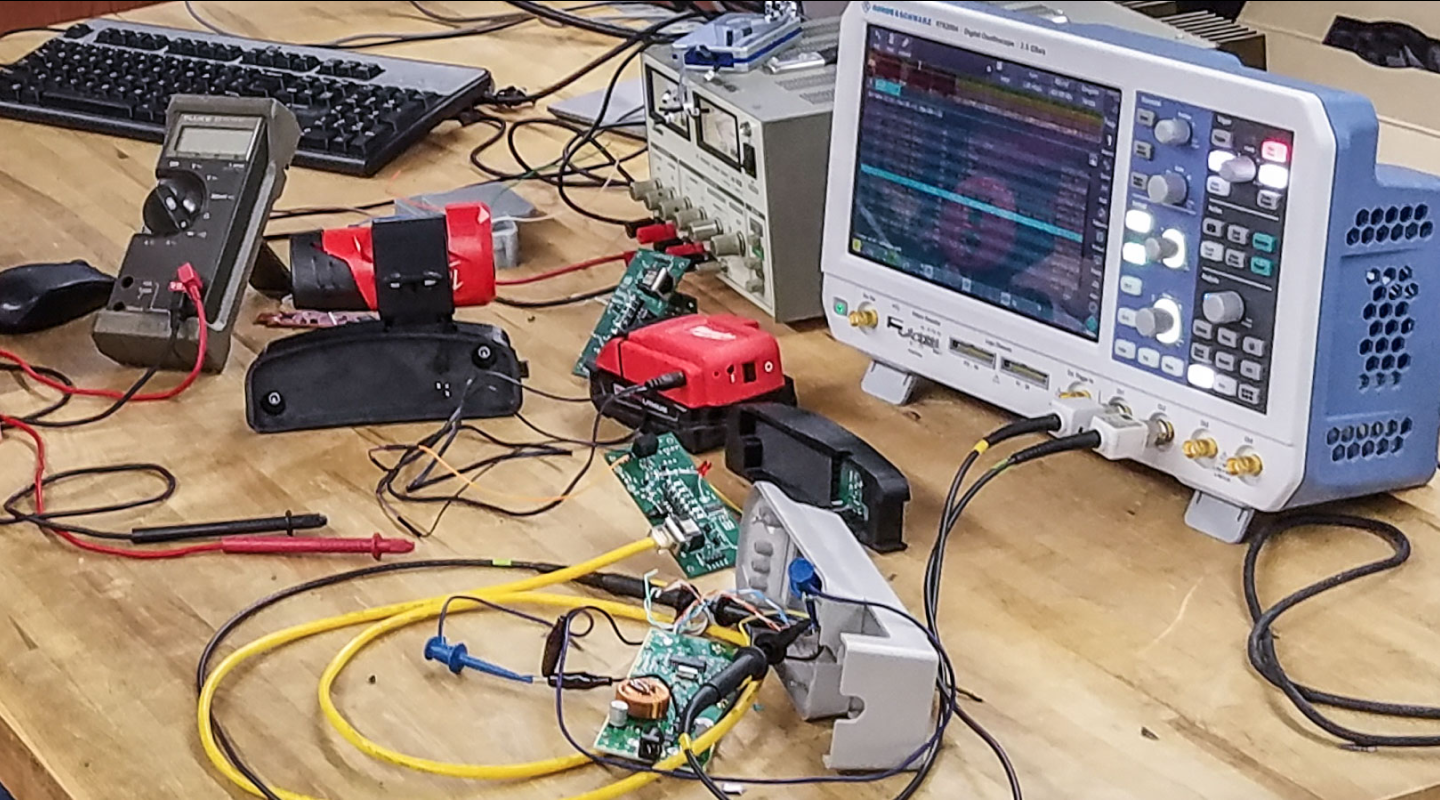

The novel coronavirus (COVID-19), first identified in December 2019, triggered a global scramble for healthcare equipment. Within months, outbreaks in Italy, Latin America, and the U.S. spread rapidly, and by April 2020, the world had changed—hospitals everywhere were running out of time and supplies.

Whether it's a project milestone or a unique experience with Volume Graphics, our Storyteller Team looks forward to hearing from you.

Get in Touch