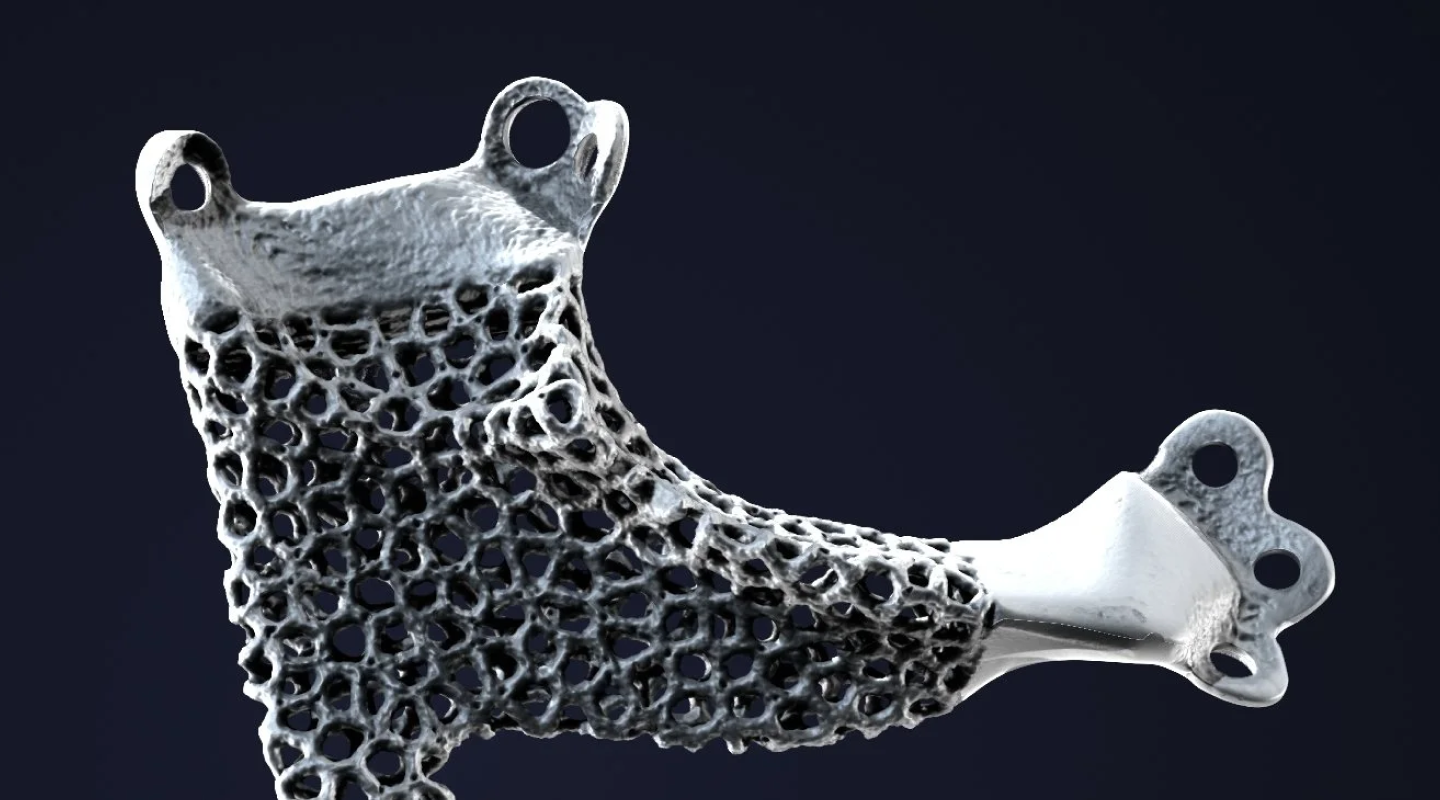

Meets Medical Implants

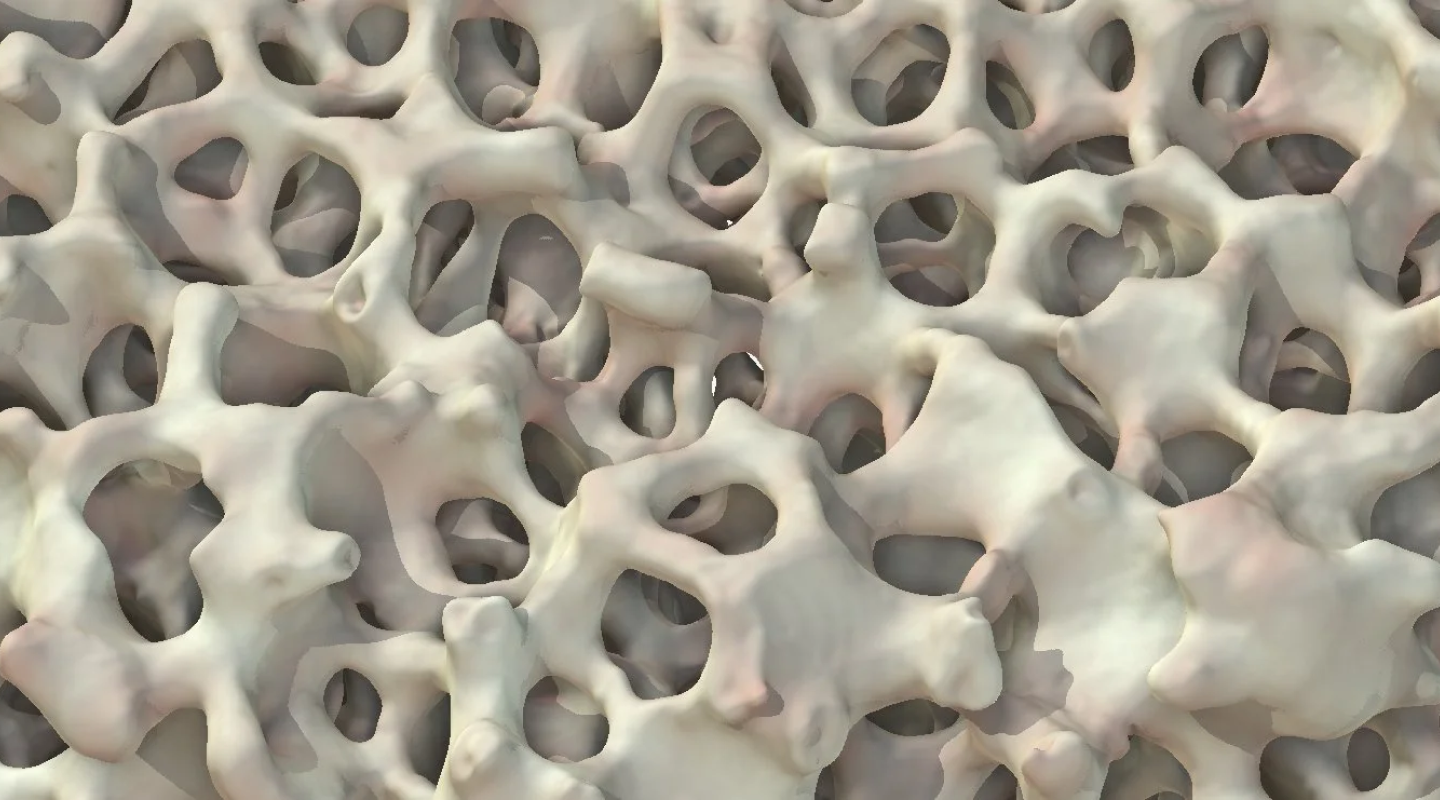

Conventional, off-the-shelf implants have made it easier for medical professionals to treat the most common patient needs quickly and efficiently. However, modern imaging—combined with additive manufacturing technology—has made it possible to design patient-specific implants to better fit individual needs in more complex cases. Join us as we use VGSTUDIO MAX to examine these customized implants!

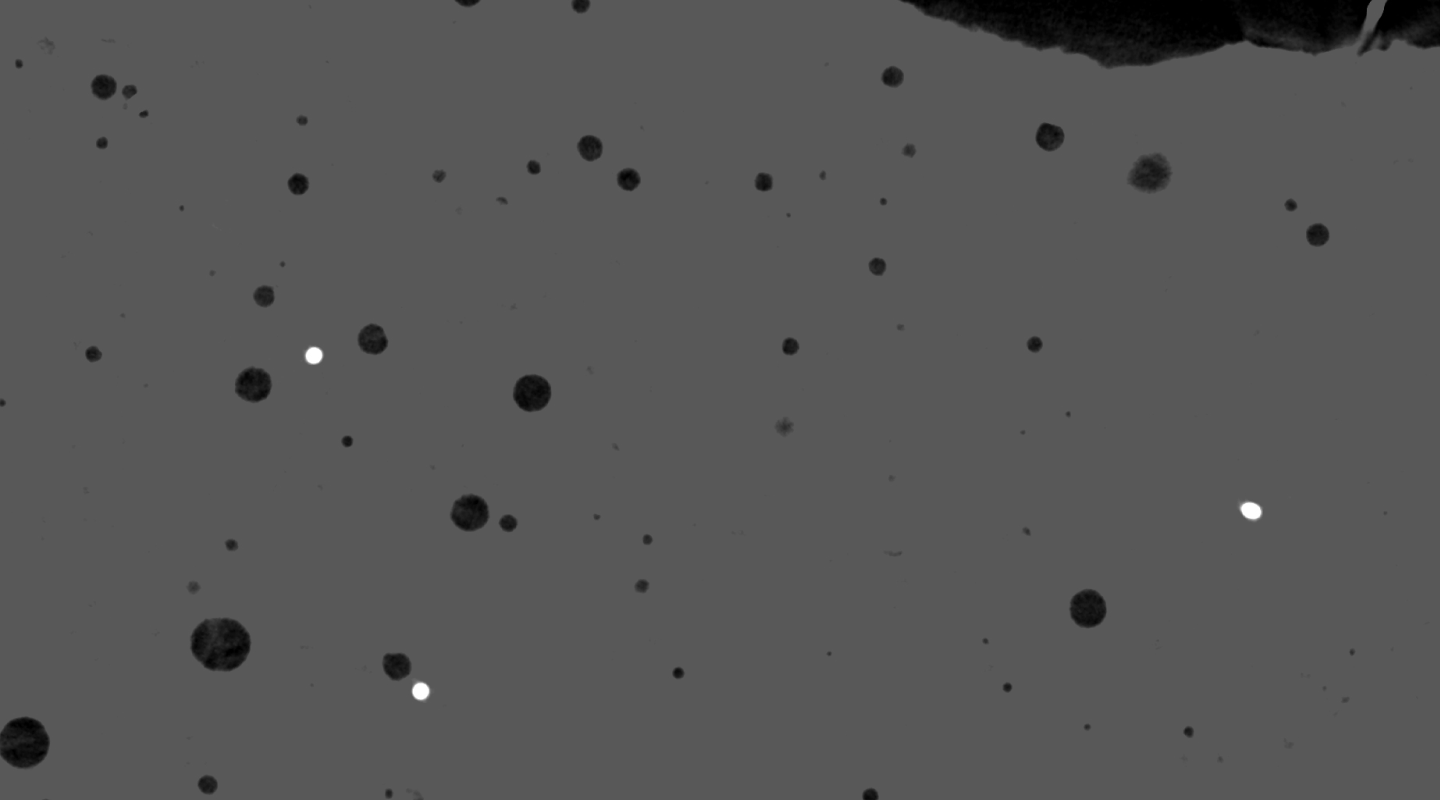

The Power of Annotations

Sometimes, analyses leave you with thousands of results—a dream for the project, but a reader's nightmare! Check out how you can use rule-based annotations on VGSTUDIO MAX to leave your reports looking crisp and clean.

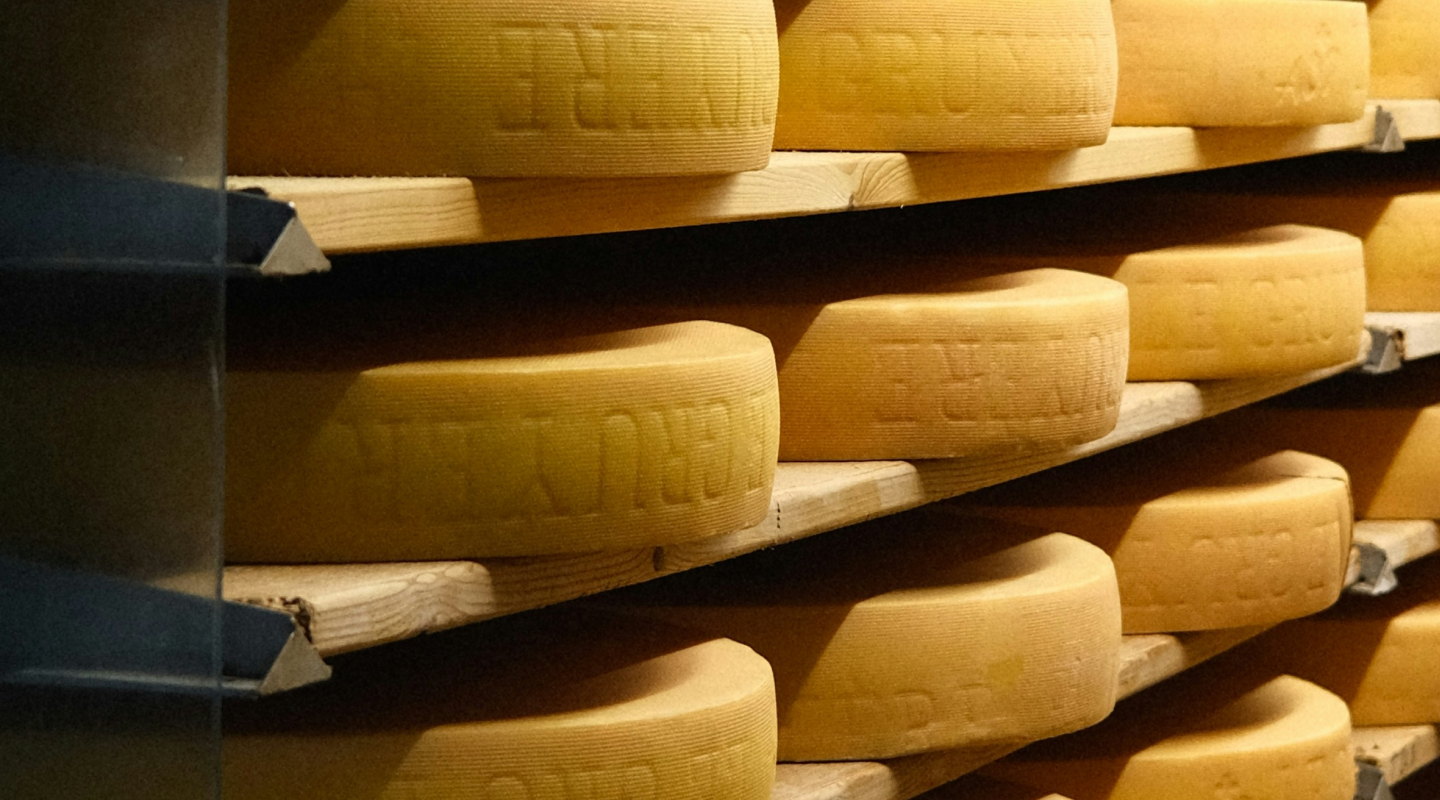

Holes have become an icon of Swiss cheese, but in the past years, their numbers have been mysteriously dwindling. Only one question remains—where have all the holes gone? Join researchers at Agroscope as they combine CT technology and agricultural science to unravel and understand the mystery behind disappearing holes in Swiss cheese.

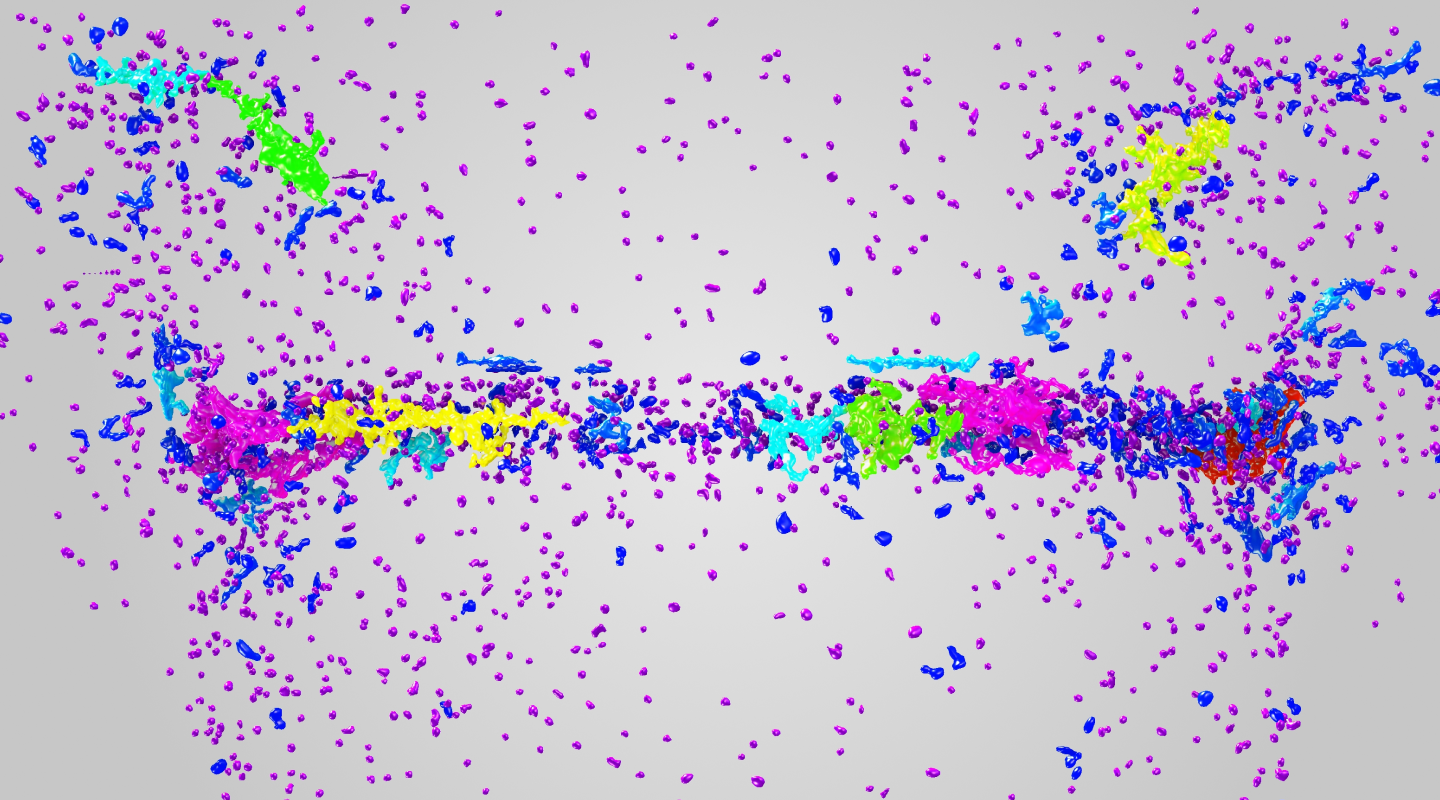

As you may well know, too much porosity can damage the part, but inclusions can damage the tool. If only there was a way to keep an eye on both types of defects at the same time. Check out this workaround on combining voids and inclusions in one analysis!

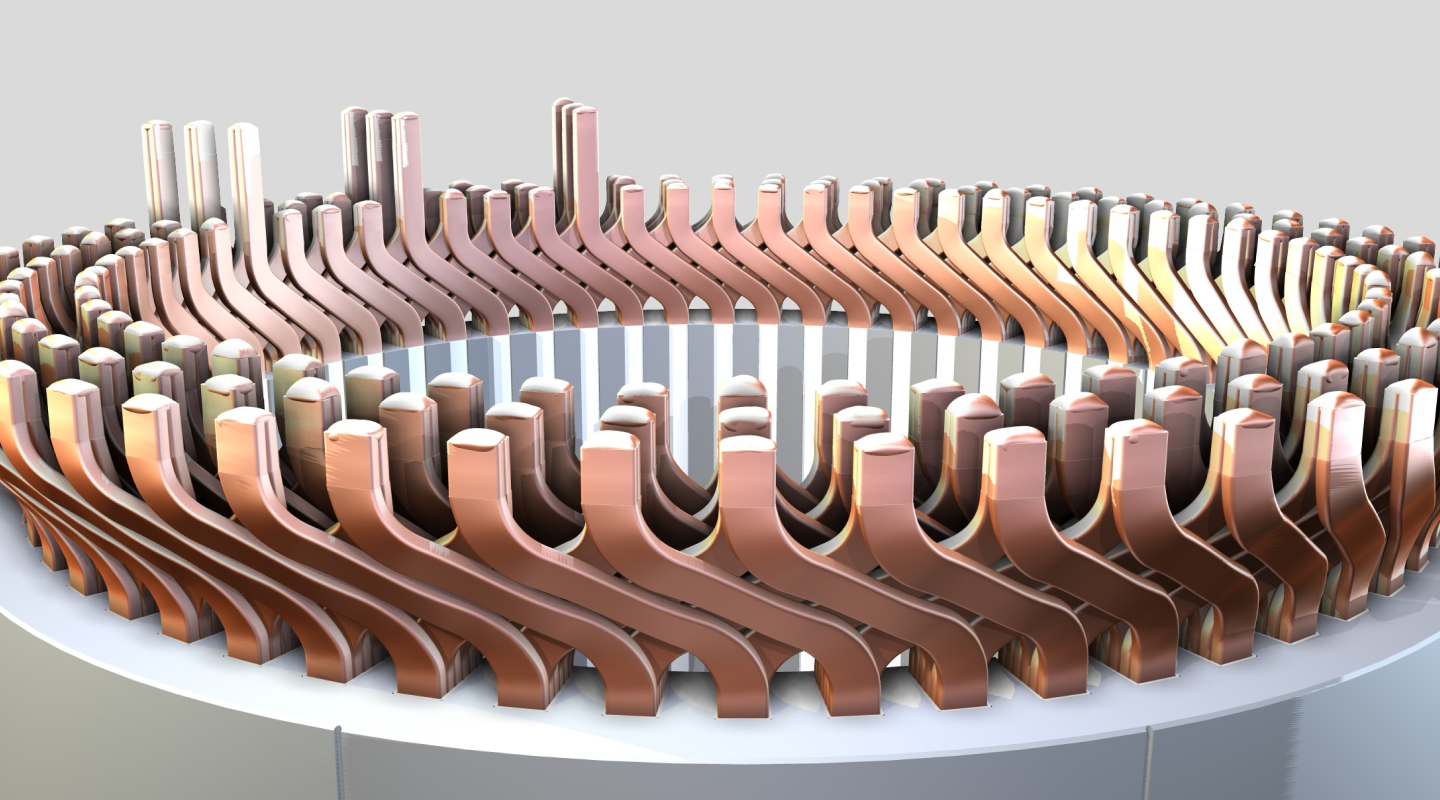

In 1907, cars were just replacing horses. Today, manufacturers are pushing for cleaner EVs—but how can we keep up with rapid tech shifts while inspecting every hairpin?

This story shows step-by-step hairpin inspection with industrial CT and VGSTUDIO MAX.

Directional Variability

You know what they say—at some point, you gotta just go with the flow. That applies to analyses, too. With directional variability, we can see how analysis values change along a specified direction. Join us as we use VGSTUDIO MAX to explore directional variability in porosity/inclusion, foam/powder, and gray value analyses!

Whether it's a project milestone or a unique experience with Volume Graphics, our Storyteller Team looks forward to hearing from you.

Get in Touch