Inspect your parts automatically and non-destructively with industrial computed tomography (CT) using VG software. Automation with VGSTUDIO MAX is simple to set up and works with almost every CT system.

VG software provides you with ready-to-use solutions that are both fast and flexible: Whenever parts need to be analyzed repeatedly, powerful automation functions are at your side to help speed up your work.

Even if your scanned objects rarely repeat, it could still be well worth automating the recurring parts of your workflow that are general enough to be applied to all kinds of objects.

The automation features in VGSTUDIO MAX:

- Are a great help when you are working with scans of a series of parts or with scans that contain multiple parts at once.

- Reduce the possibility for errors.

- Ensure that inspection results for different parts are comparable.

- Reduce the time needed to go from the initial scan of an object to the results that you need to generate from it.

- Can either be included in otherwise manual workflows or handle a complete inspection for you.

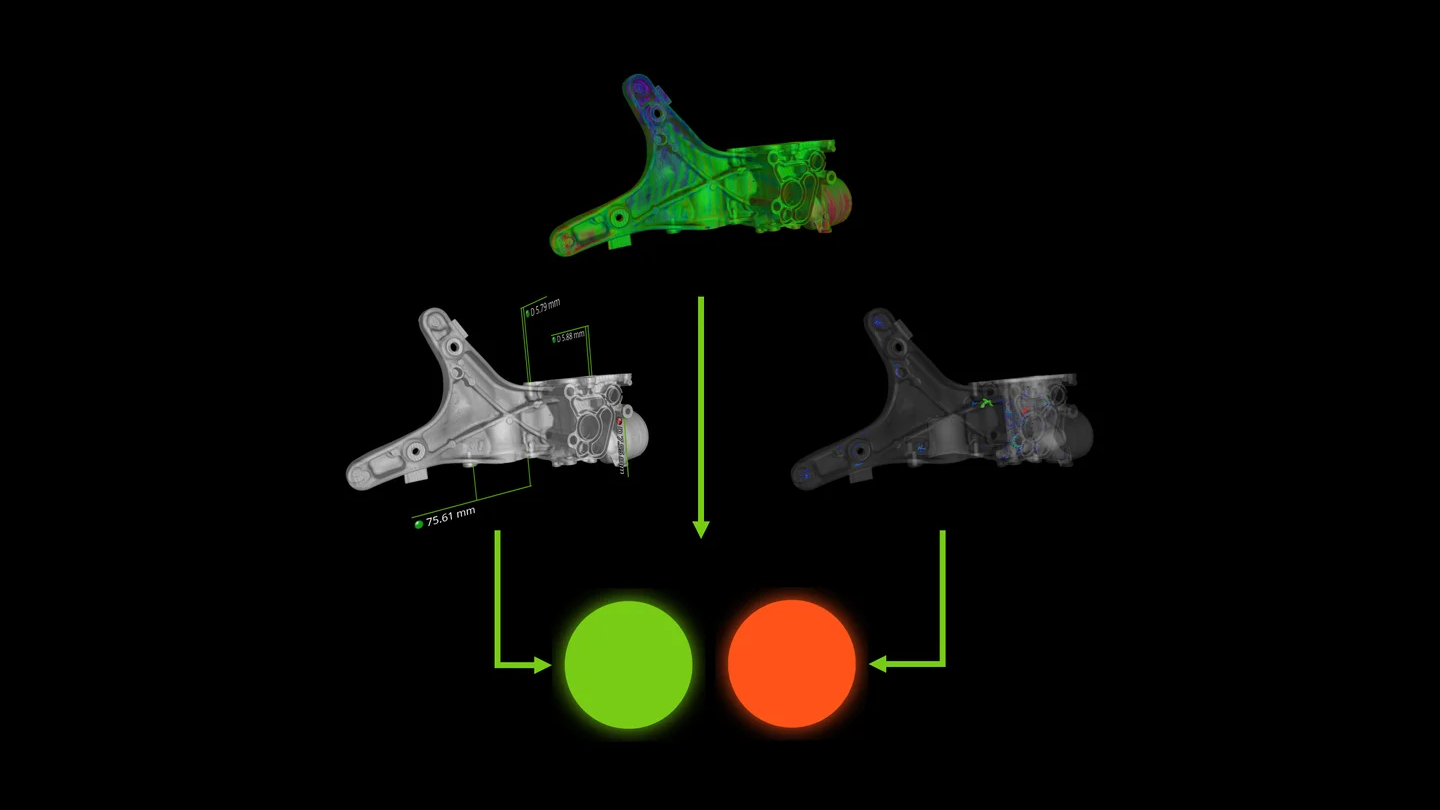

Templates contain rules on how to combine the tolerance results of the individual analyses and measurements into a single state that describes the quality of the inspected part.

Analyses and measurements are at the center of any part inspection in VGSTUDIO MAX. An analysis is mainly defined by the specific parameters that you set up for it, the region of a part that it should run on, and tolerances that you want to apply to the result values. Coordinate measurement results are defined by fitting reference geometries to your scanned part and using these to derive geometric dimensions and tolerances. To make analyses and measurements reusable, you can combine parameters, tolerances, and other settings into templates.

Templates:

- Allow you to export and reuse defined analyses and measurements.

- Contain everything that is necessary to reproduce the exact same results on the part they were set up on and can be applied to different scans of similar parts to create comparable results.

- Contain rules on how to combine the tolerance results of the individual analyses and measurements into a single state that describes the quality of the inspected part.

- Can contain rules for how results are visualized, for example, which parts of the result should be highlighted via automatically generated images or annotation markers.

- Can be copied to similar areas within a single part to inspect repeating features using patterns.

- Can be applied either manually or automatically as part of a macro or inspection plan.

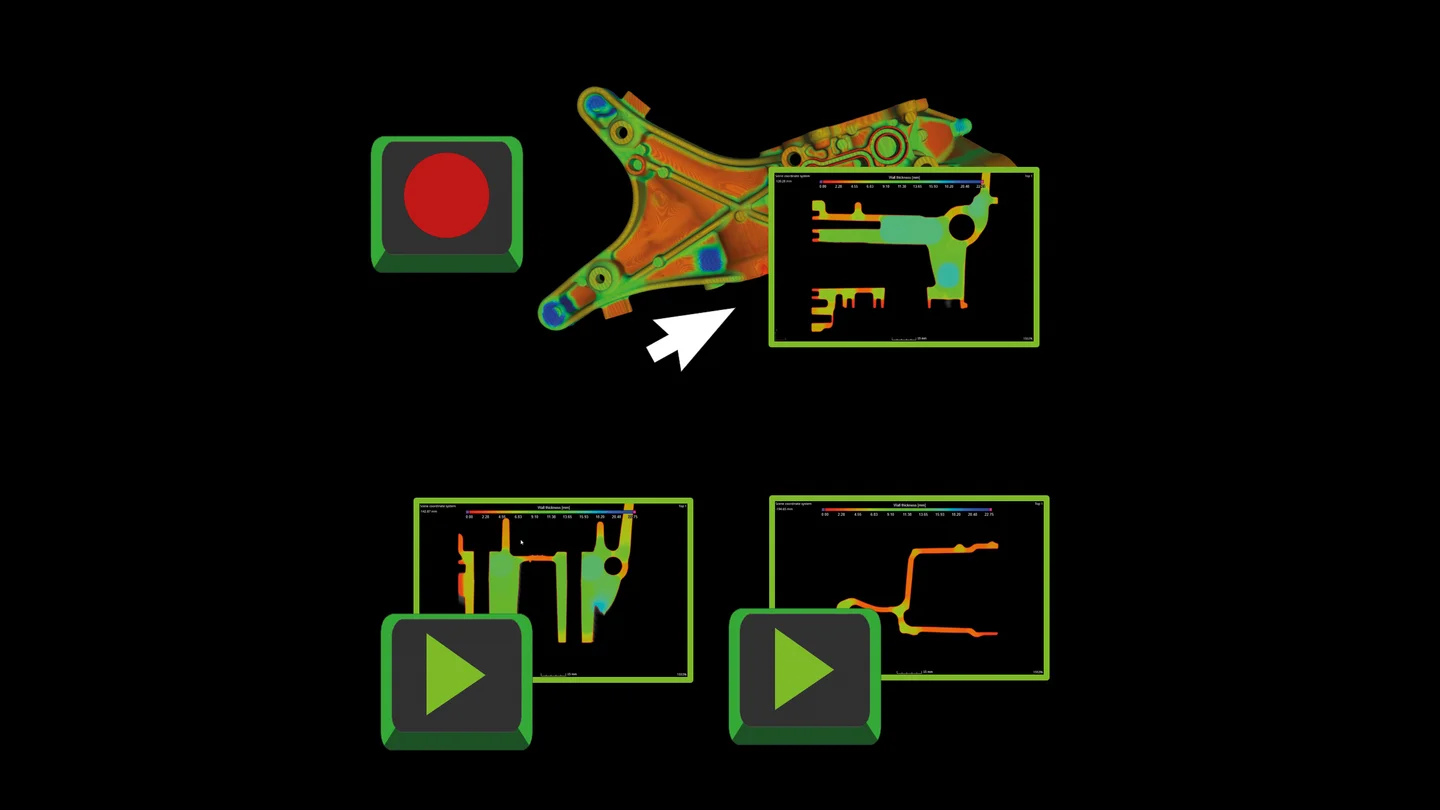

With macros, you can automate almost all of the functionality that VGSTUDIO MAX provides.

Whenever you find yourself repeating the same steps in the same order at different times, a macro might be of help. Whether it's a surface determination, analysis, or conversion to a different format, once set up, the convenience macros provide is at your disposal whenever you start up VGSTUDIO MAX. Macros record individual interactions with the software for storage and later use across different projects and application restarts.

Macros:

- Can automate almost all of the functionality that VGSTUDIO MAX provides.

- Store an operation, objects that the operation was applied to or that it was created for, and information about any files that were read or written during its execution.

- Are intuitively created by just recording user interactions with the software and can be played back with the press of a button.

- Are the building blocks for all semi- or fully automated workflows.

- Are independent from individual projects and persist across application restarts.

- Are managed via a dedicated tool, which can also be used to combine, shorten, and append macros.

- Can be shared with colleagues for standardization.

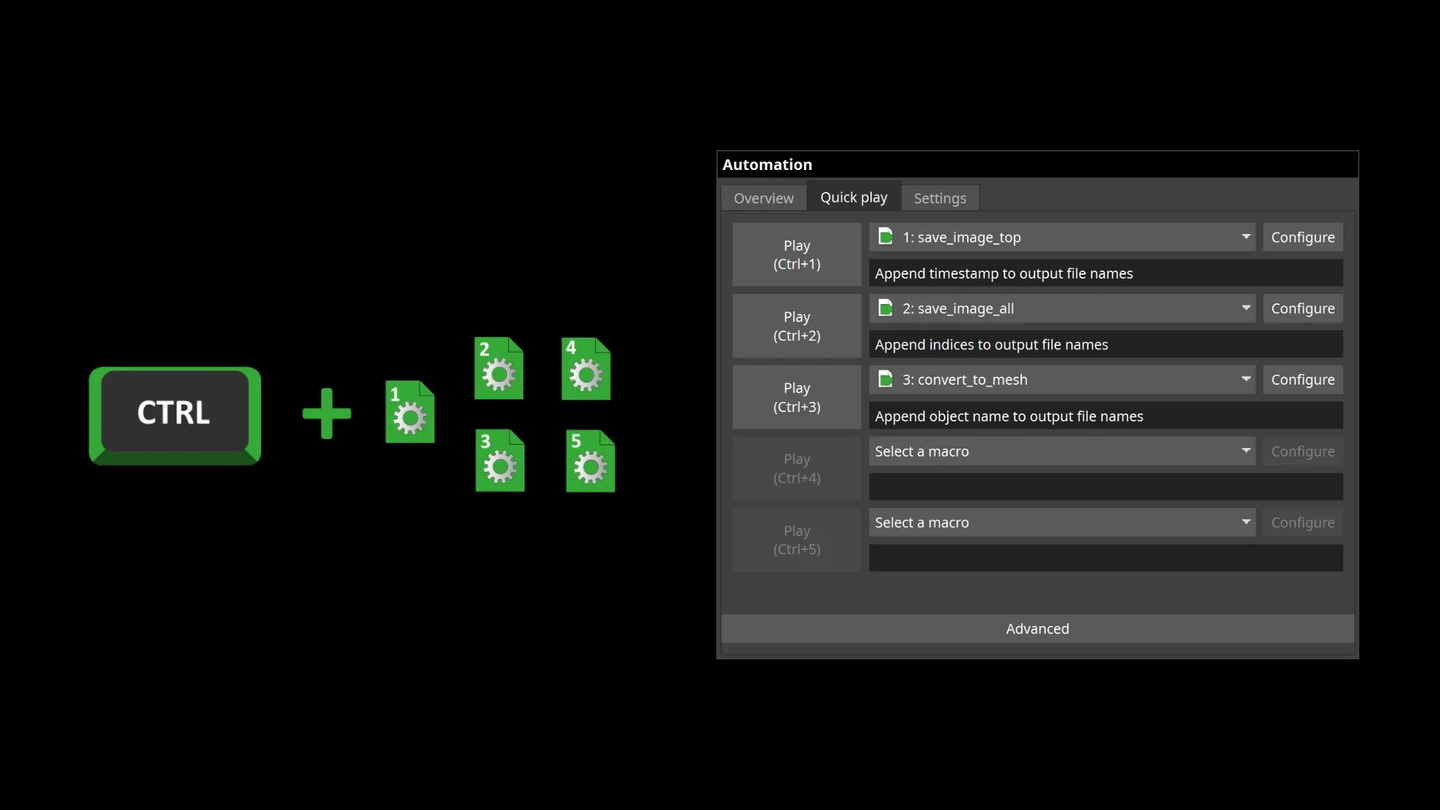

Quick play for macros allows you to access arbitrary functionality that you have recorded at any time via the press of a button.

To further streamline your workflow, you can assign macros to specific keyboard shortcuts and set rules for the data your macros may output.

Quick play for macros:

- Allows you to access arbitrary functionality that you have recorded at any time via the press of a button.

- Can quickly become part of your daily workflow, as its configuration is preserved across application restarts.

- Allows you to choose from a number of options to make sure output files are named sensibly and do not conflict with previously created data. For example, converted and exported meshes may automatically use the name of the volume they originated from when being saved to disk, while saved images might just be appended with a timestamp to easily create a series of different views of an object.

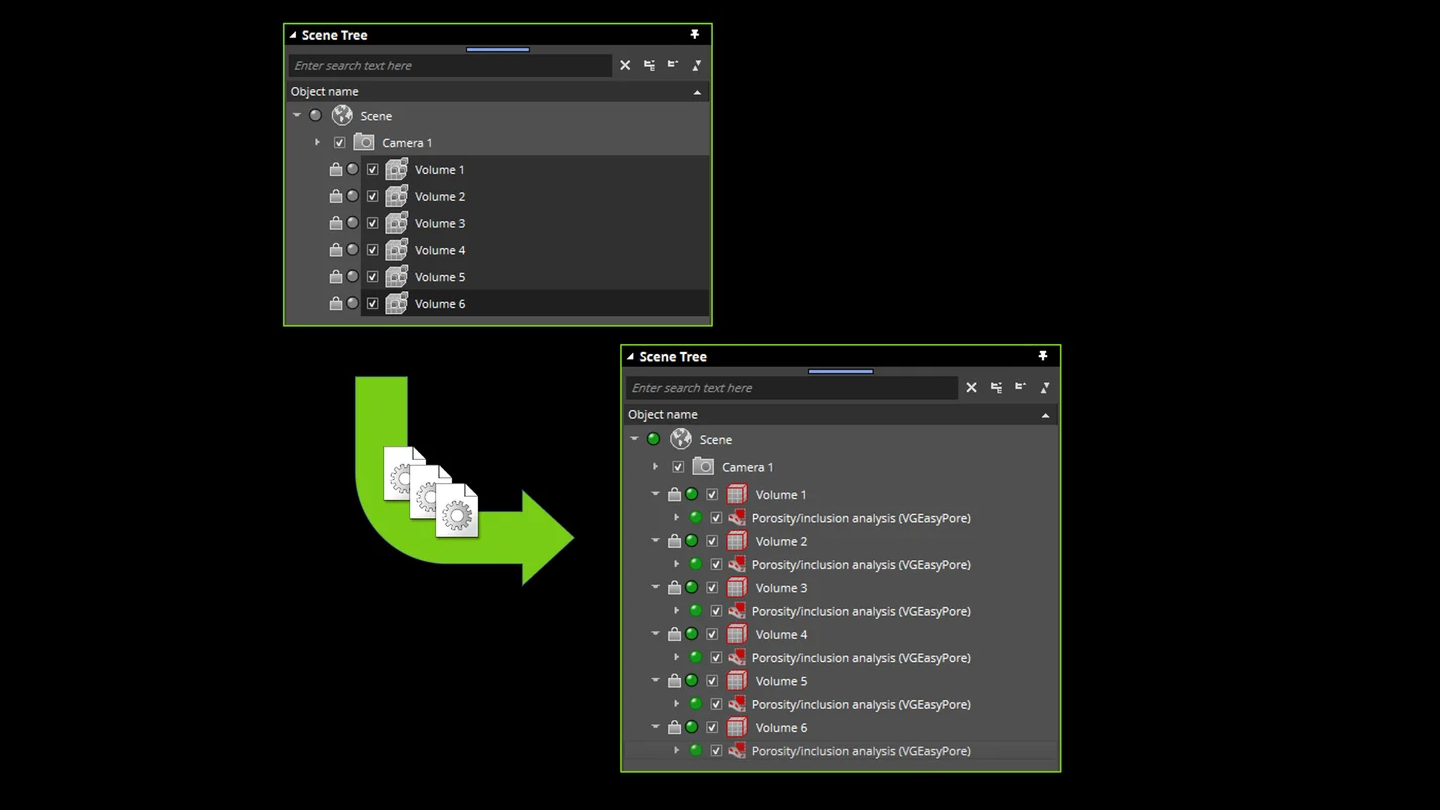

Multi-apply for macros enables you to handle similar pieces that were part of the same scan in the same way.

Especially when dealing with small objects, you may find yourself having several objects of the same type in a project. Usually it makes sense to treat these different parts the same—any operation that applies to one of them should also apply to all the others.

Multi-apply for macros:

- Enables you to handle similar pieces that were part of the same scan in the same way.

- Allows recording of the operations that you want to do on a single piece, and then applies them to the rest of the pieces in your scene automatically.

- Makes sure that any output that is produced does not conflict with previously created files by providing appropriate naming strategies.

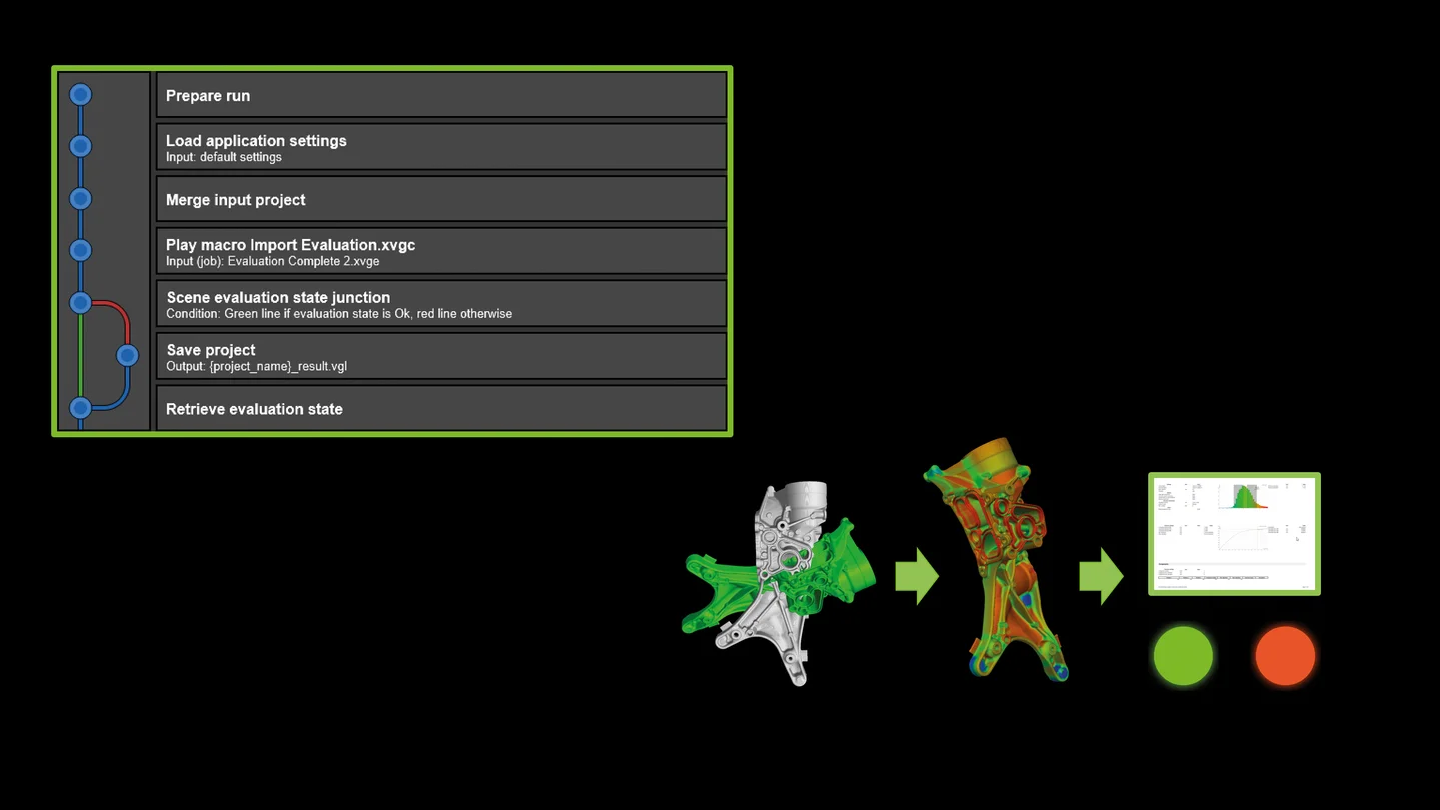

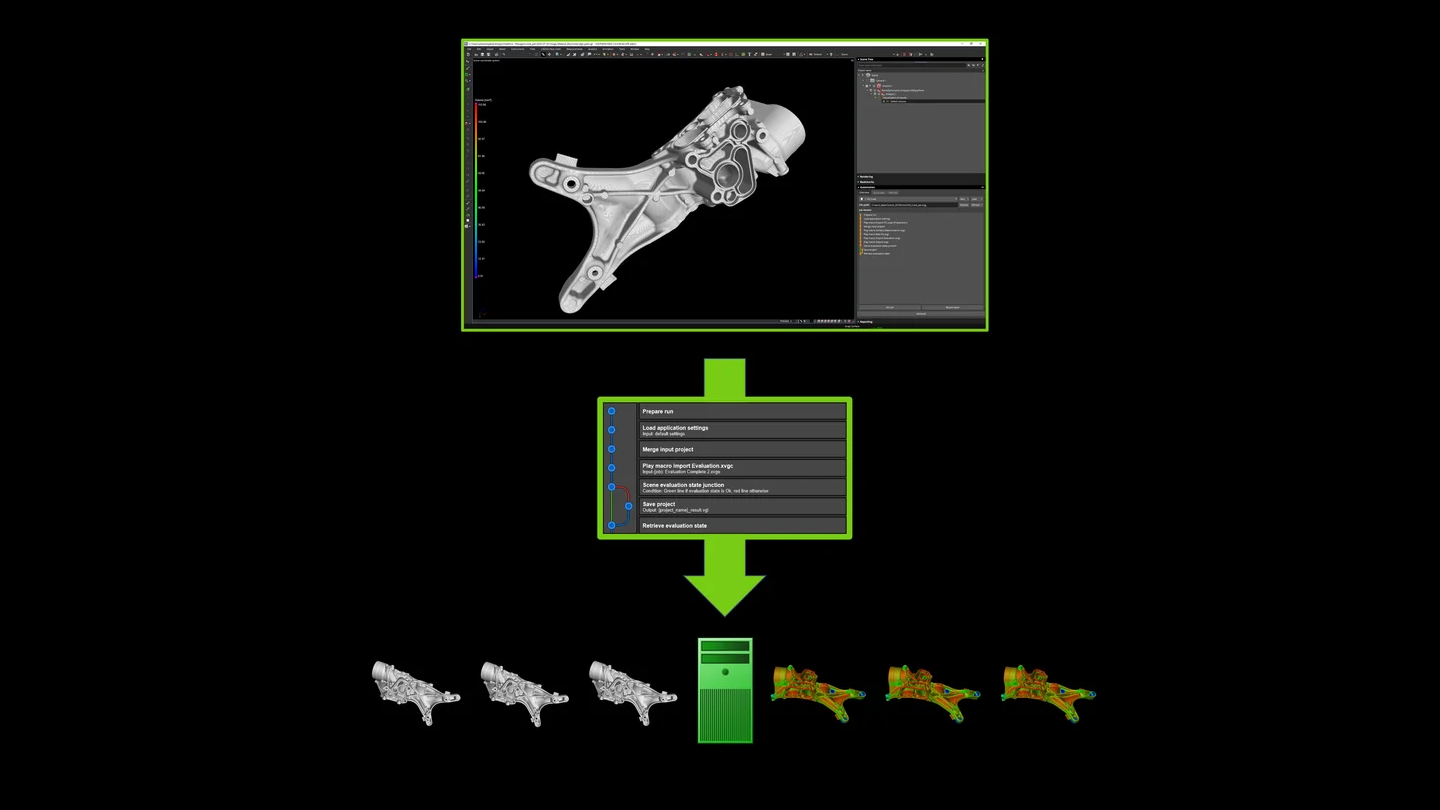

Inspection plans describe the complete path from an input scan to a part's final tolerance state, reports, or any other kind of result.

Macros, analyses, measurement plans, and any additional dependencies like reference meshes or report layouts can be combined into a standalone inspection plan which can be used for automation.

Inspection plans:

- Describe the complete path from an input scan to a part's final tolerance state, reports, or any other kind of result.

- Enable you to easily inspect a series of parts by applying plans to a batch of projects.

- Allow you to choose input files depending on the meta information of the inspected part, enabling the inspection process to react to part specifics. For example, parts originating from different cavities in a tool might be registered or analyzed using different reference geometries.

- Can perform operations dependent on intermediate results. For example, parts that pass inspection might only require storage of a report, while parts that fail could store the complete scan for detailed analysis later on.

- Are stored as self-contained VGinLINE jobs and can be easily archived, shared, and applied to appropriate input scans with VGSTUDIO MAX.

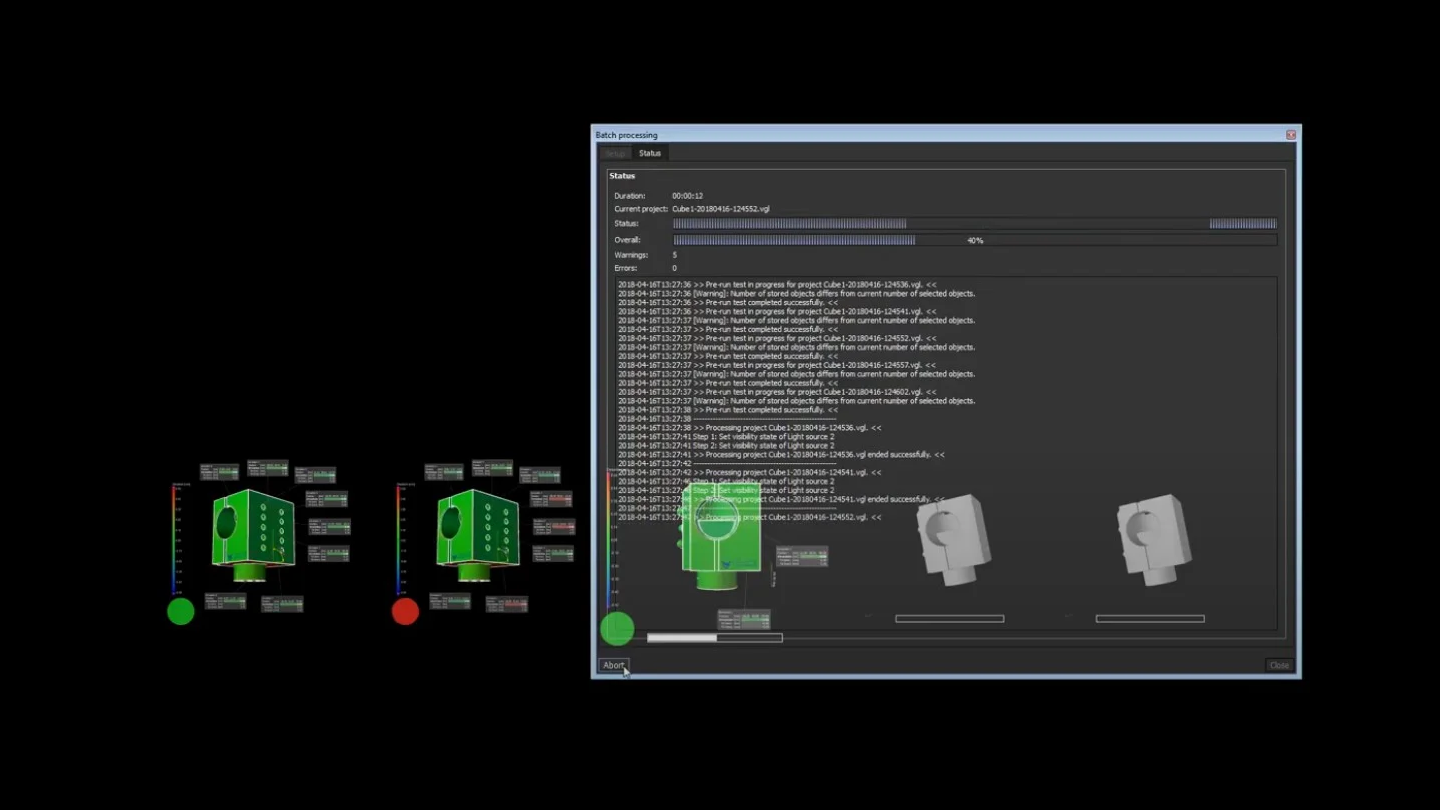

Batch processing allows you to apply both macros or VGinLINE jobs to a number of input projects without the need for further user intervention.

Whenever you are working with a series of scans, automation via batch processing comes in handy.

Batch processing allows you to:

- Apply both macros or VGinLINE jobs to a number of input projects without the need for further user intervention.

- Prepare a series of parts for subsequent manual processing in a convenient and reproducible manner.

- Completely inspect a series of parts.

With VGinLINE, you can fully automate your inspection of incoming CT data.

Inspection plans not only make it easy to automatically create reproducible results in VGSTUDIO MAX, but can also serve as a steppingstone to the full automation of your inspection process using VGinLINE, Volume Graphics' solution for autonomous inspection.

With VGinLINE, you can:

- Fully automate your inspection of incoming CT data.

- Seamlessly reuse inspections plans that you set up and used with VGSTUDIO MAX.

- Automatically take care of any input or generated output data.

- Connect to subsequent systems by passing on pass/fail decisions, full results, or data for statistical process control.

Save time and reduce potential errors in recurring inspections of the same parts.

Save time on repeated operations within single parts, multiple parts in a single project, or across whole batches of projects.

Easily transition from manual to semi-automated and fully automated inspection scenarios.