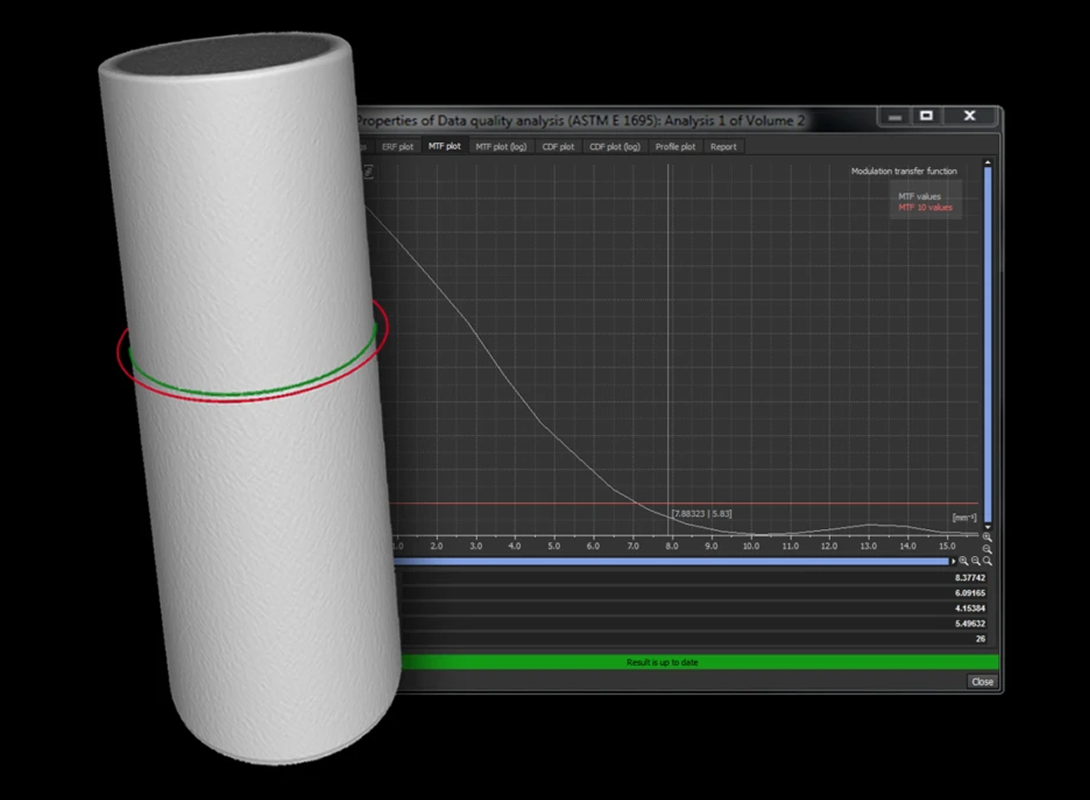

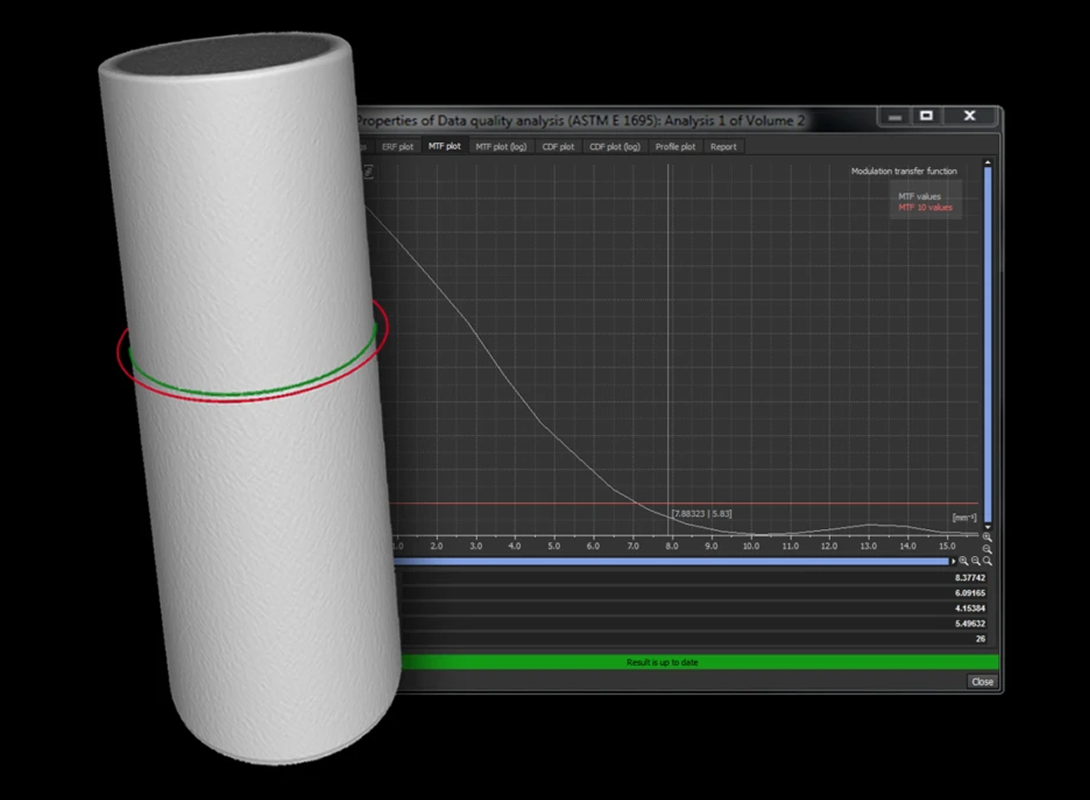

Monitor the data quality of your CT scans over time by keeping track of the spatial resolution and gray value contrast resolution. This ensures a consistently high-quality basis for your analysis and measurement results. VG software supports data quality analysis according to ASTM E 1441 and ASTM E 1695.

Explore supported data types

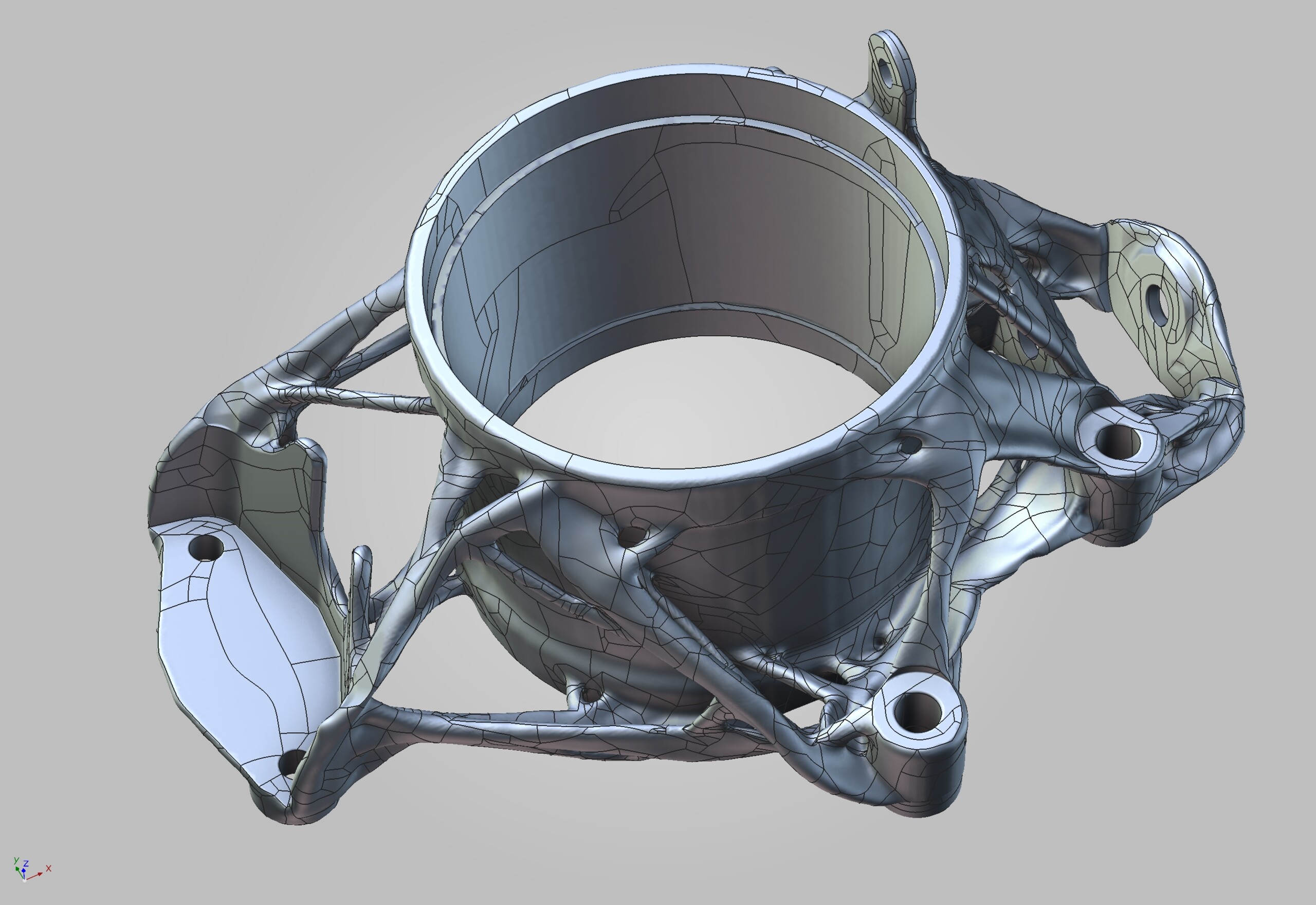

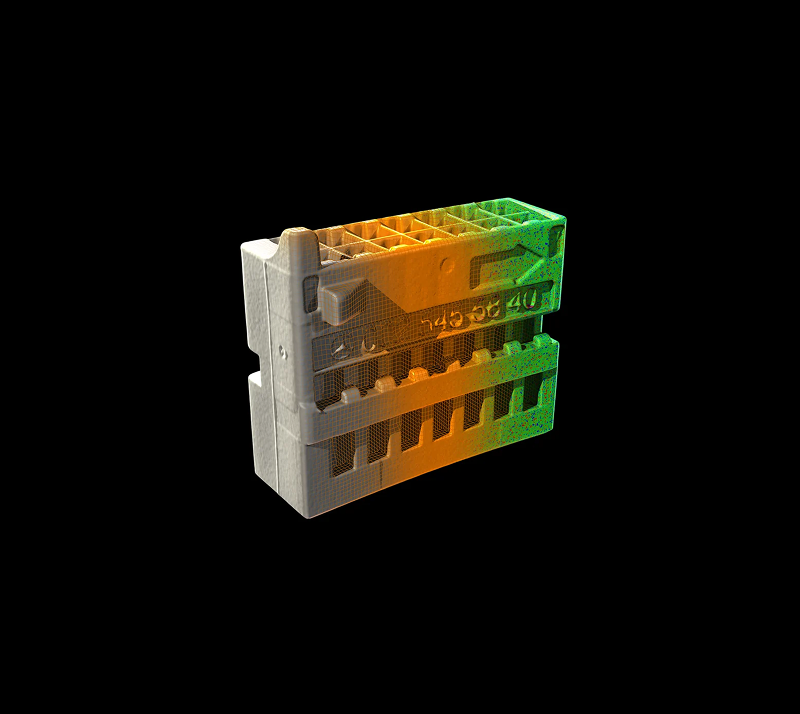

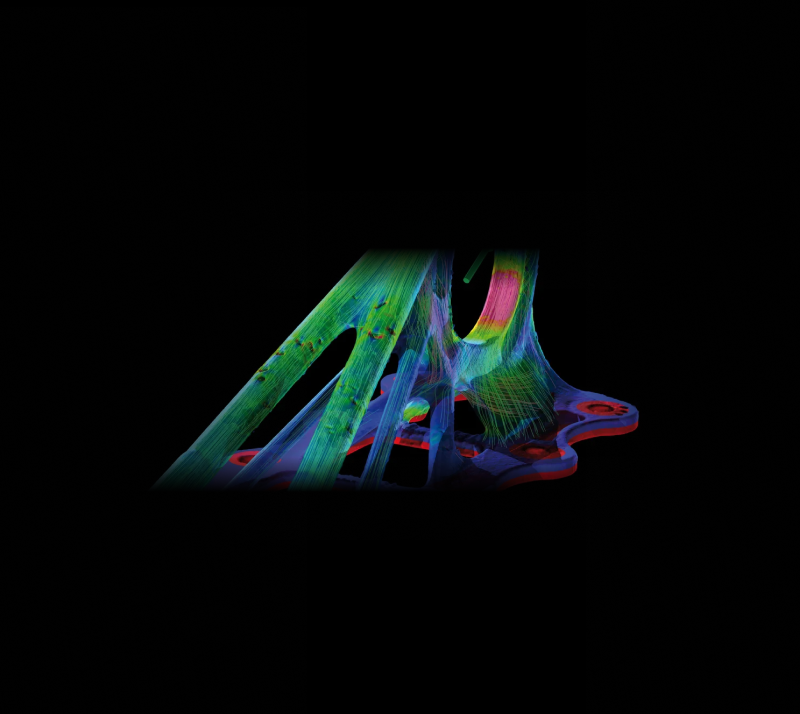

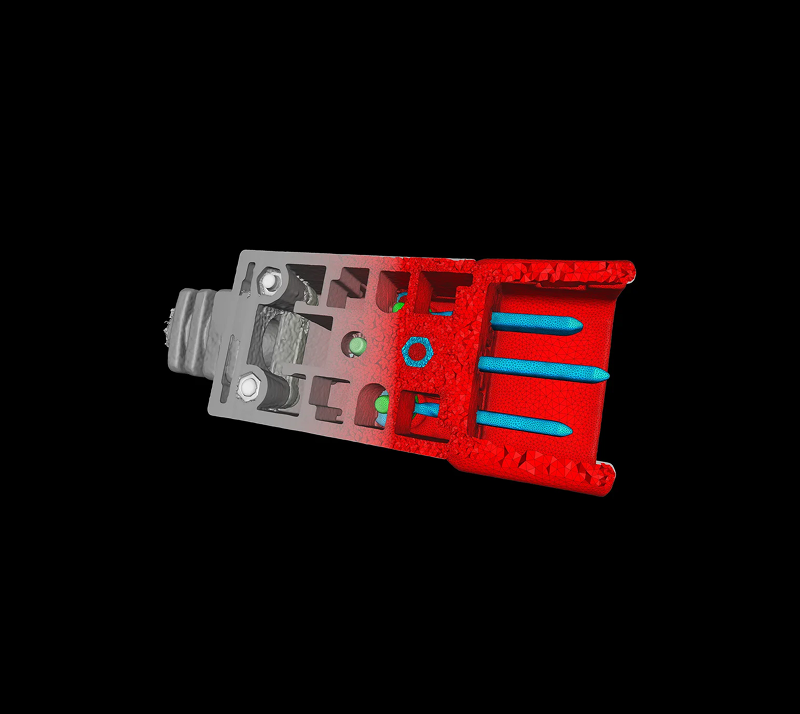

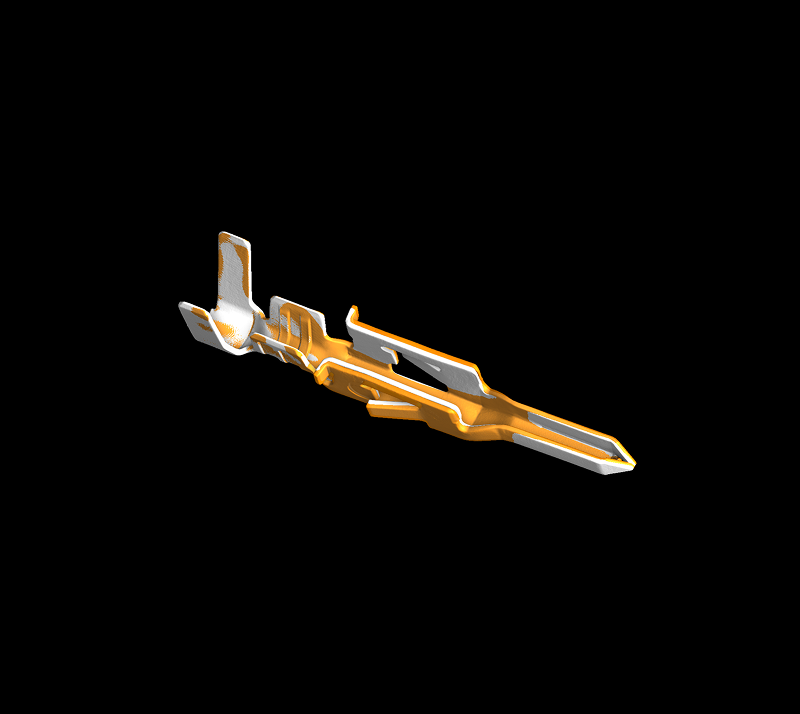

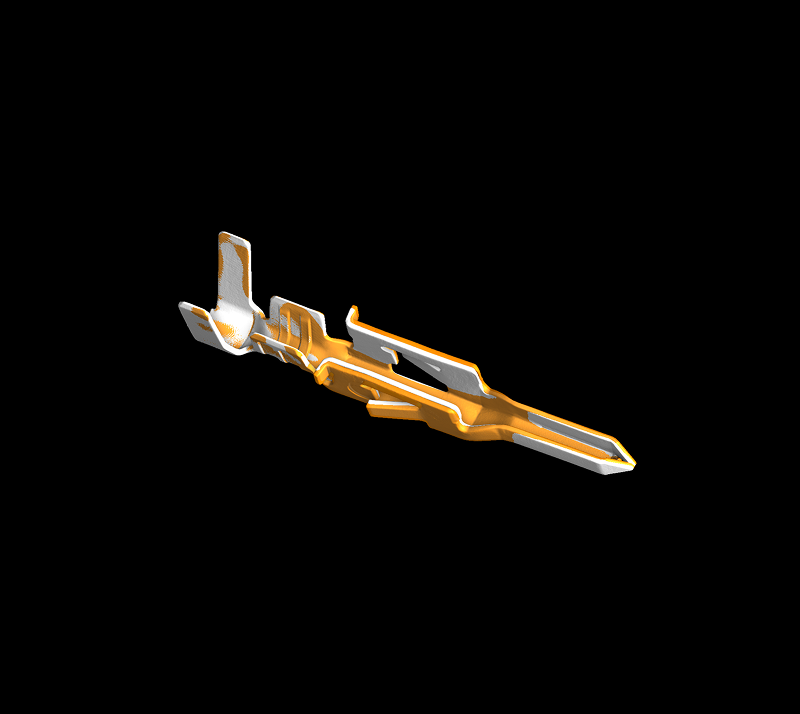

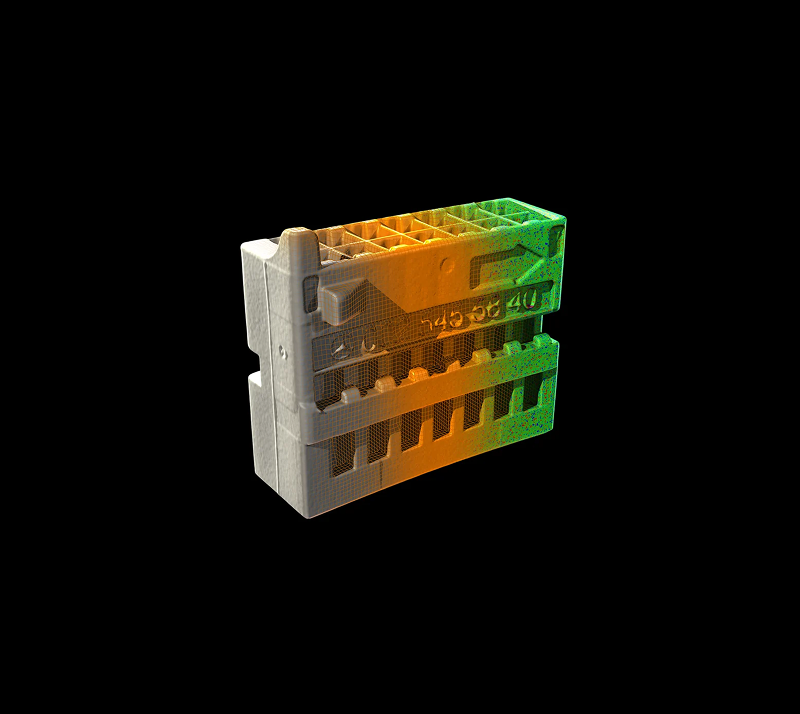

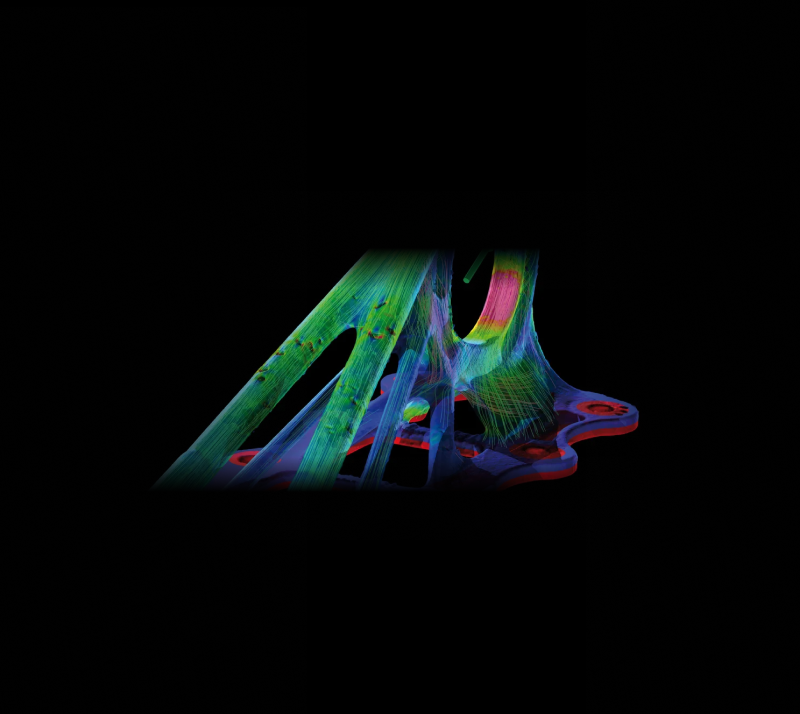

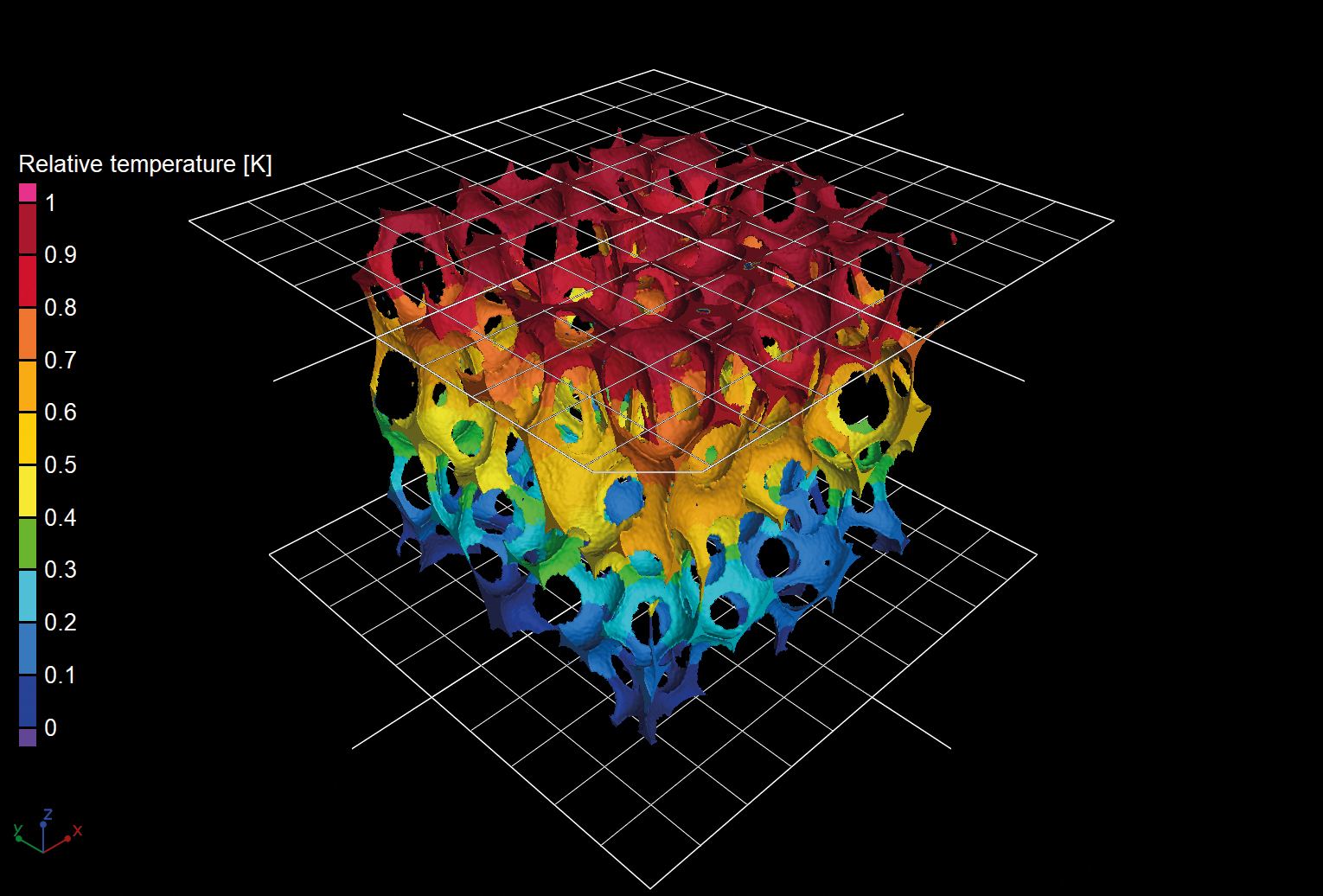

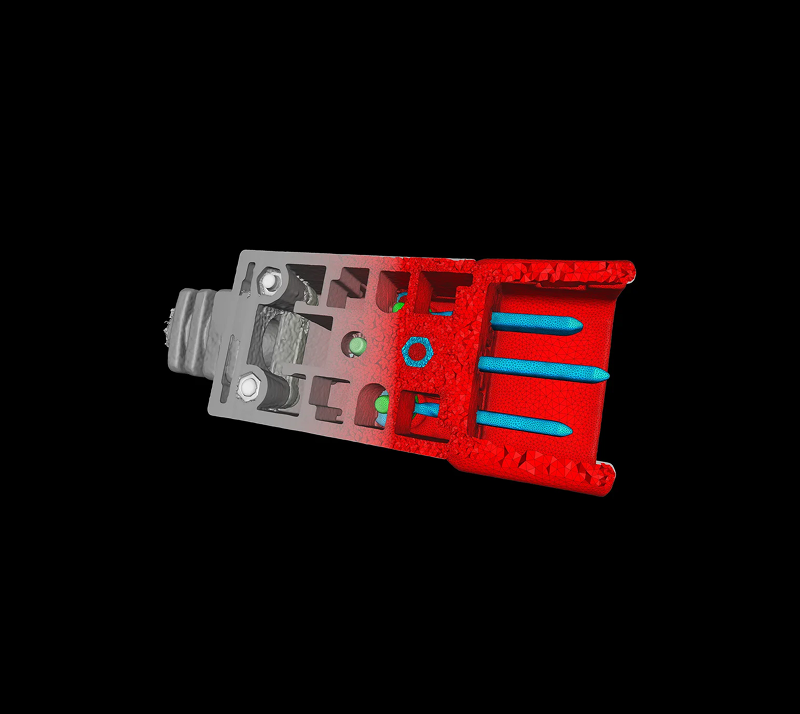

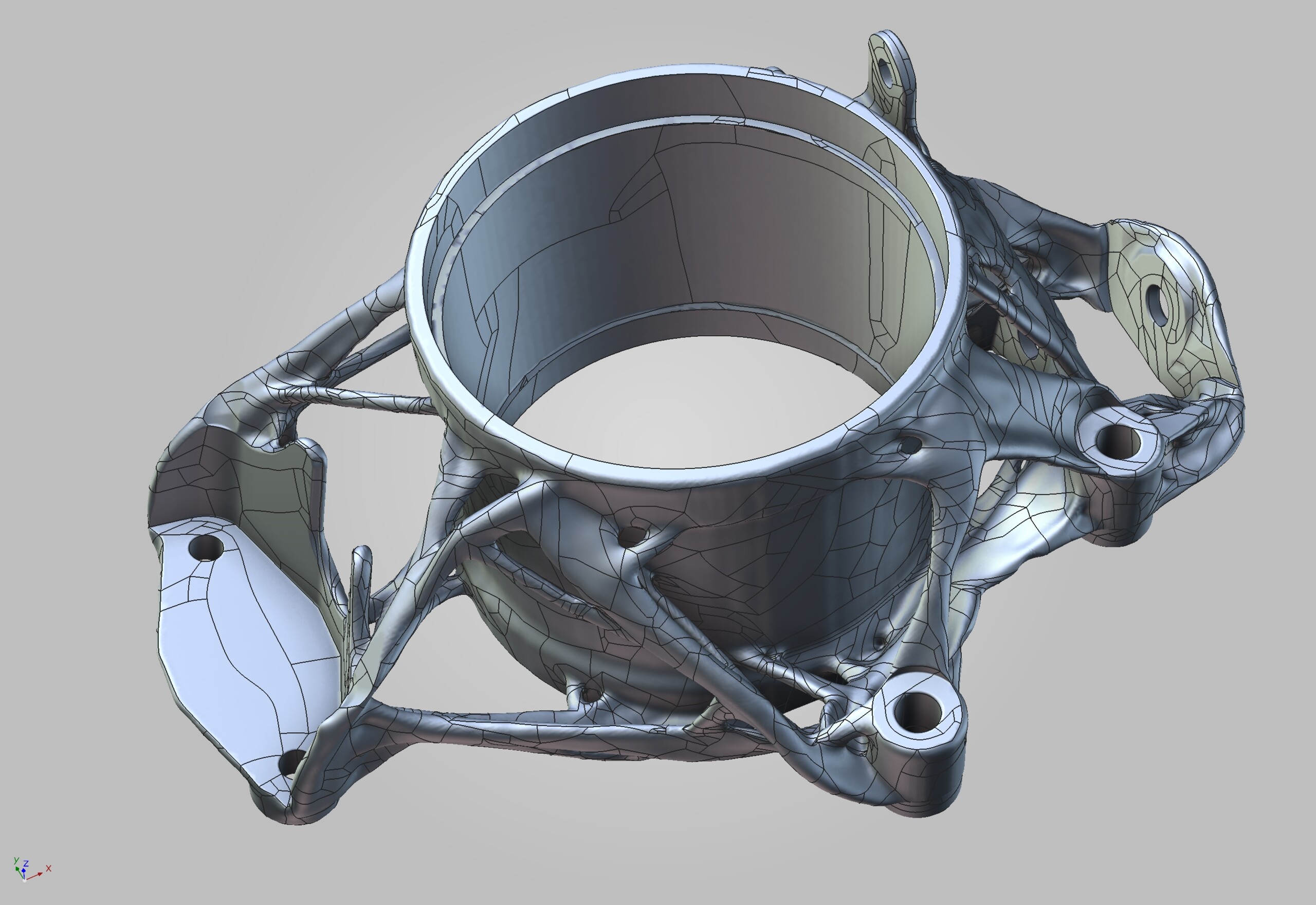

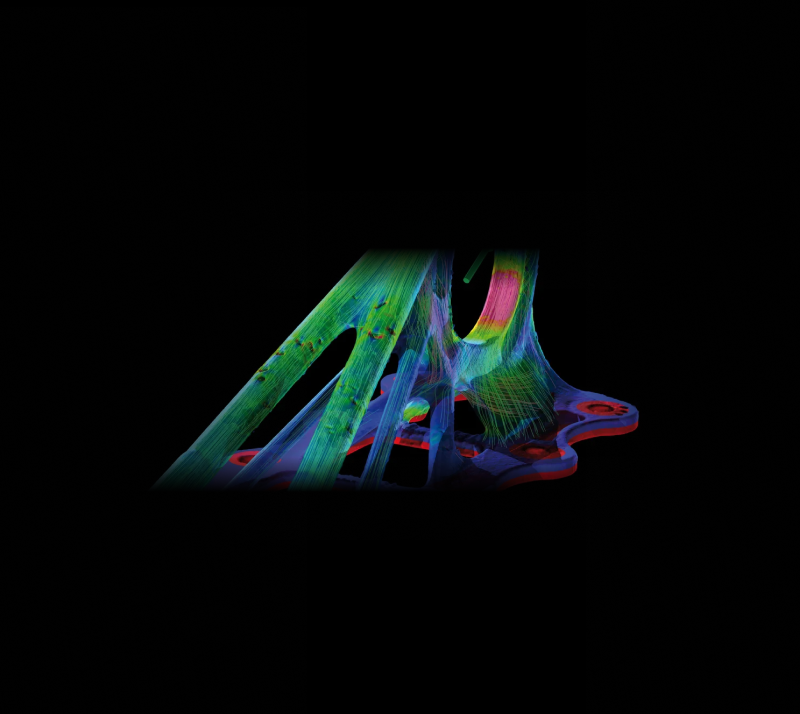

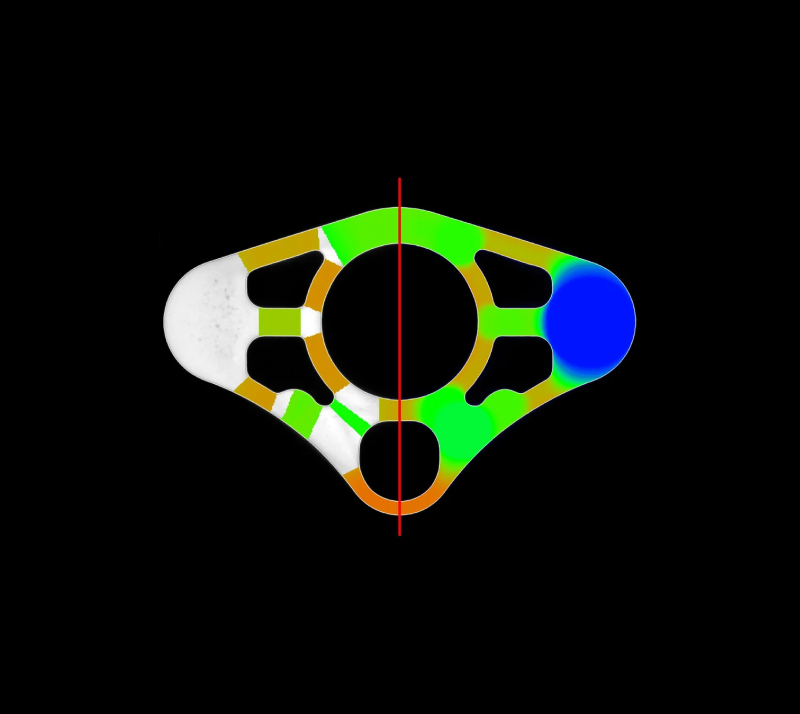

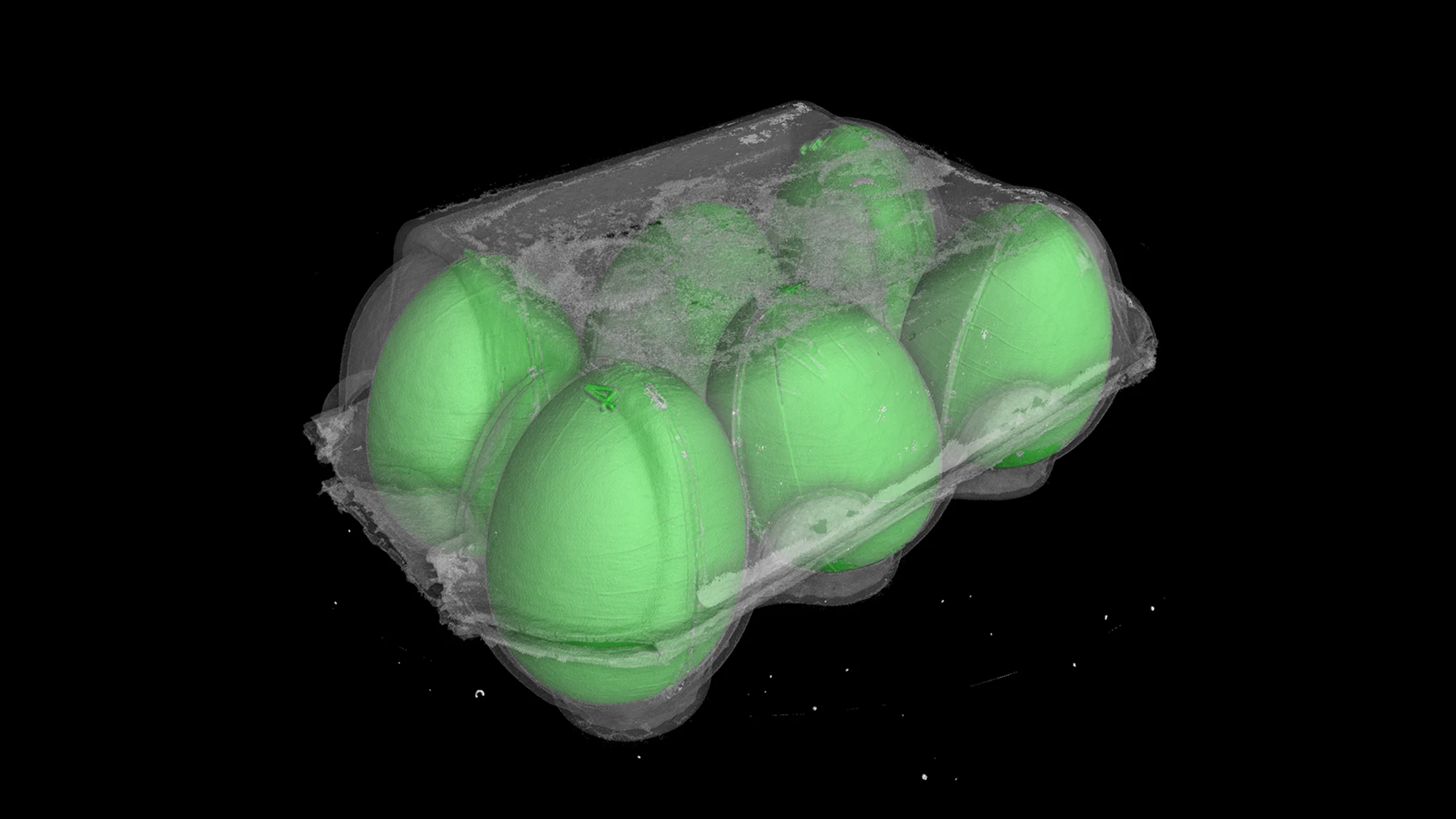

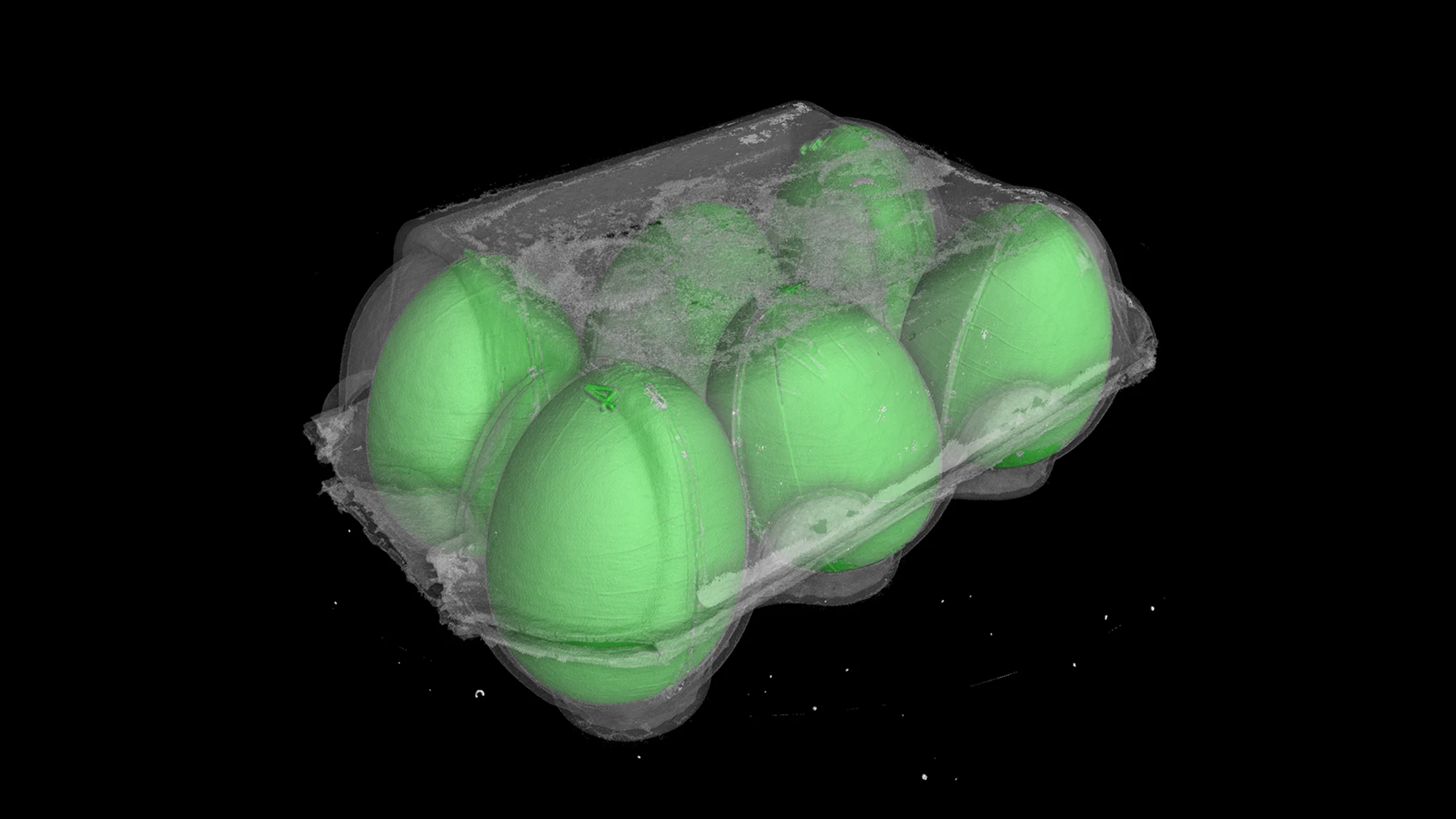

Transform your data into captivating 3D and 2D visualisations with VG software. Impress and influence peers, decision-makers, and the public with stunning animations and exploded views—your only limit is your RAM.

Learn more

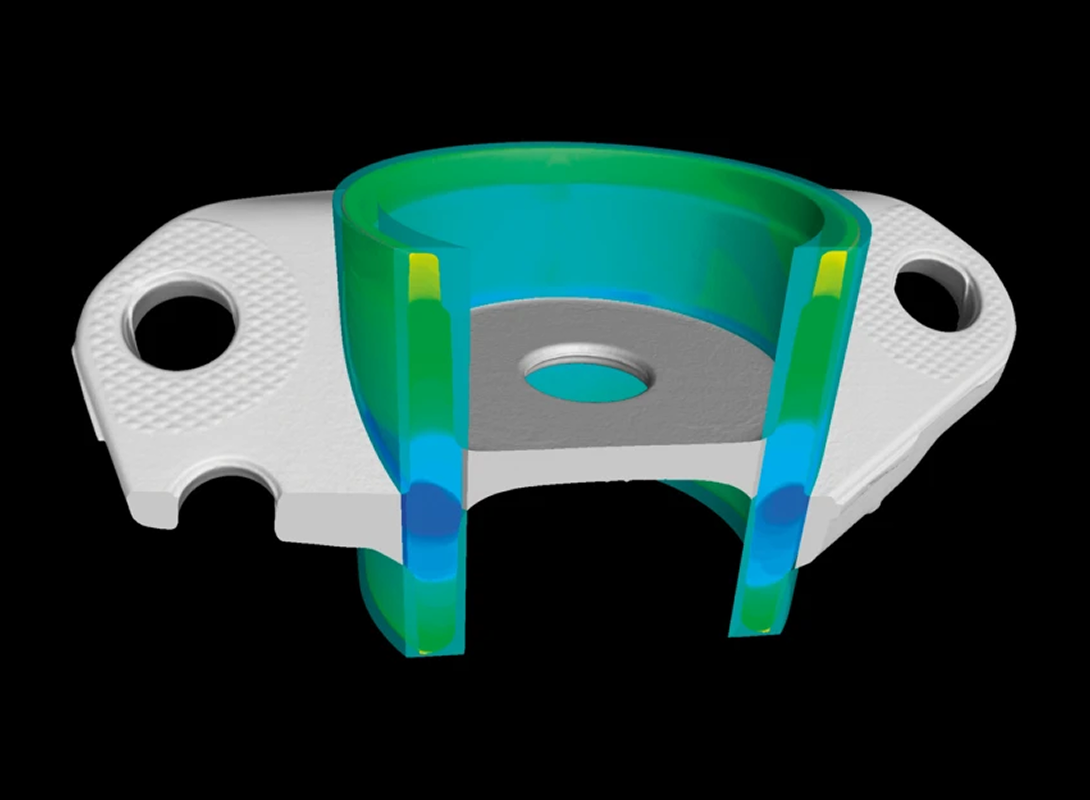

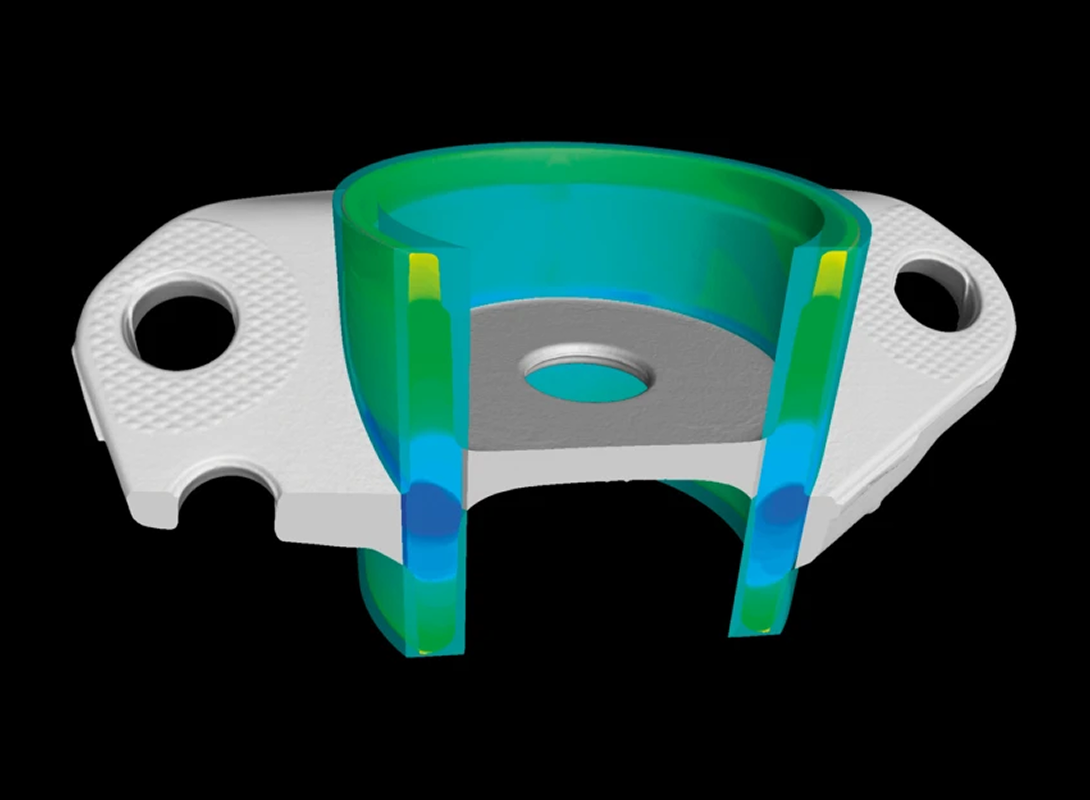

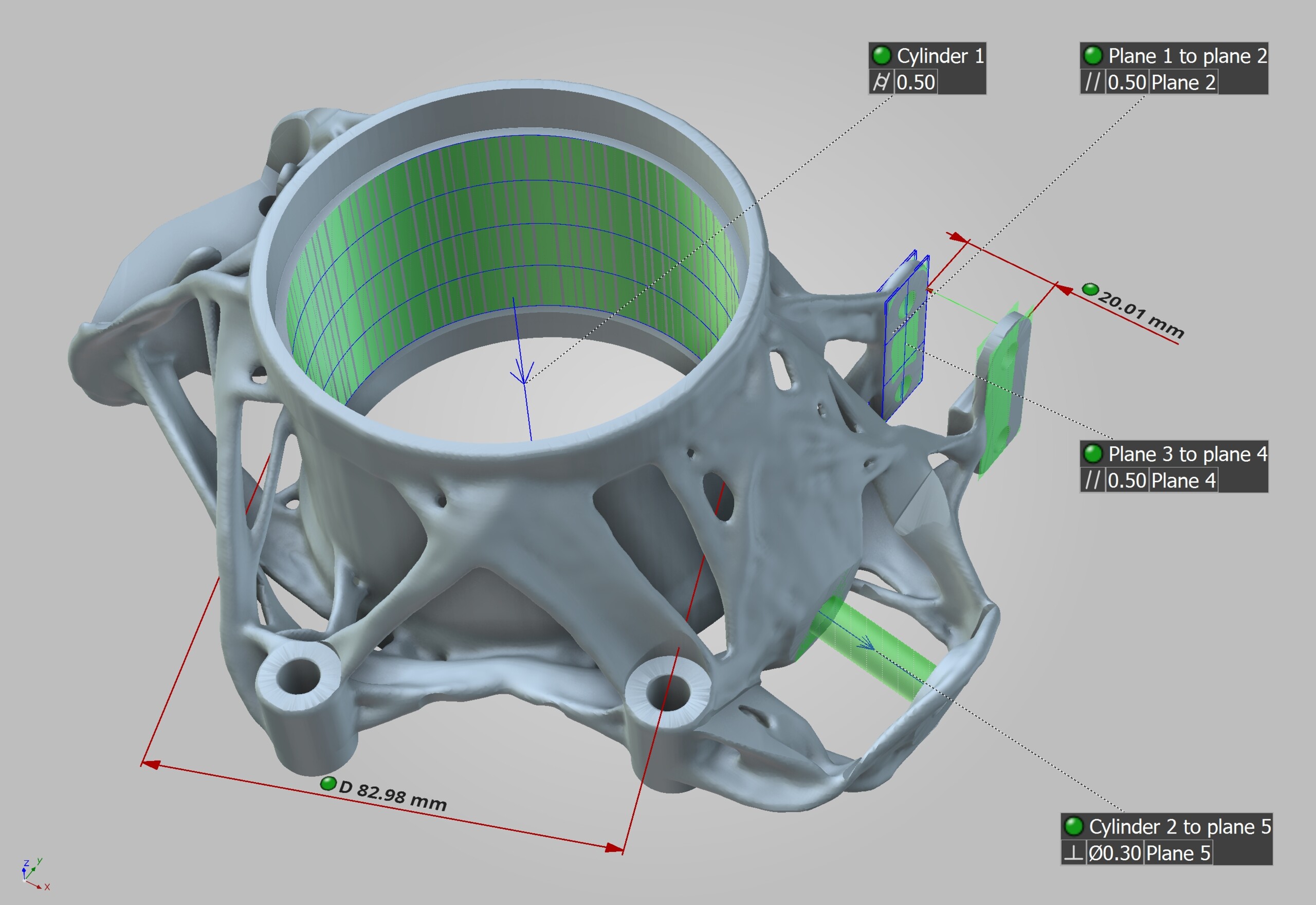

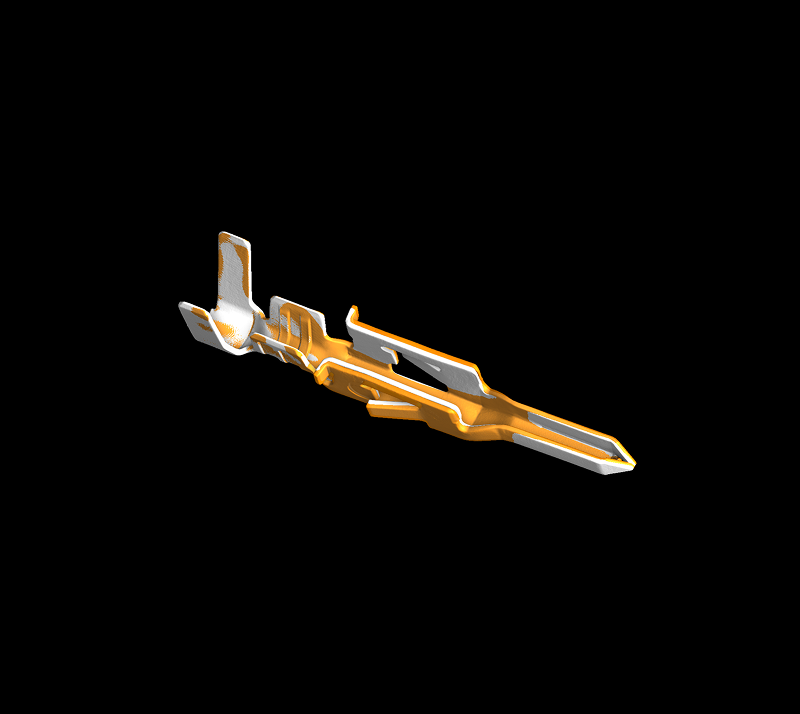

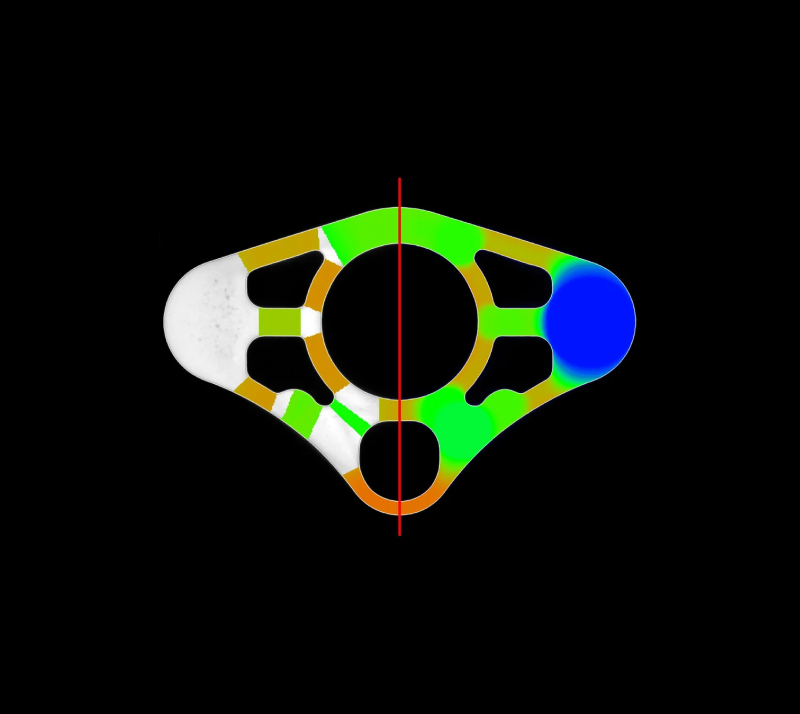

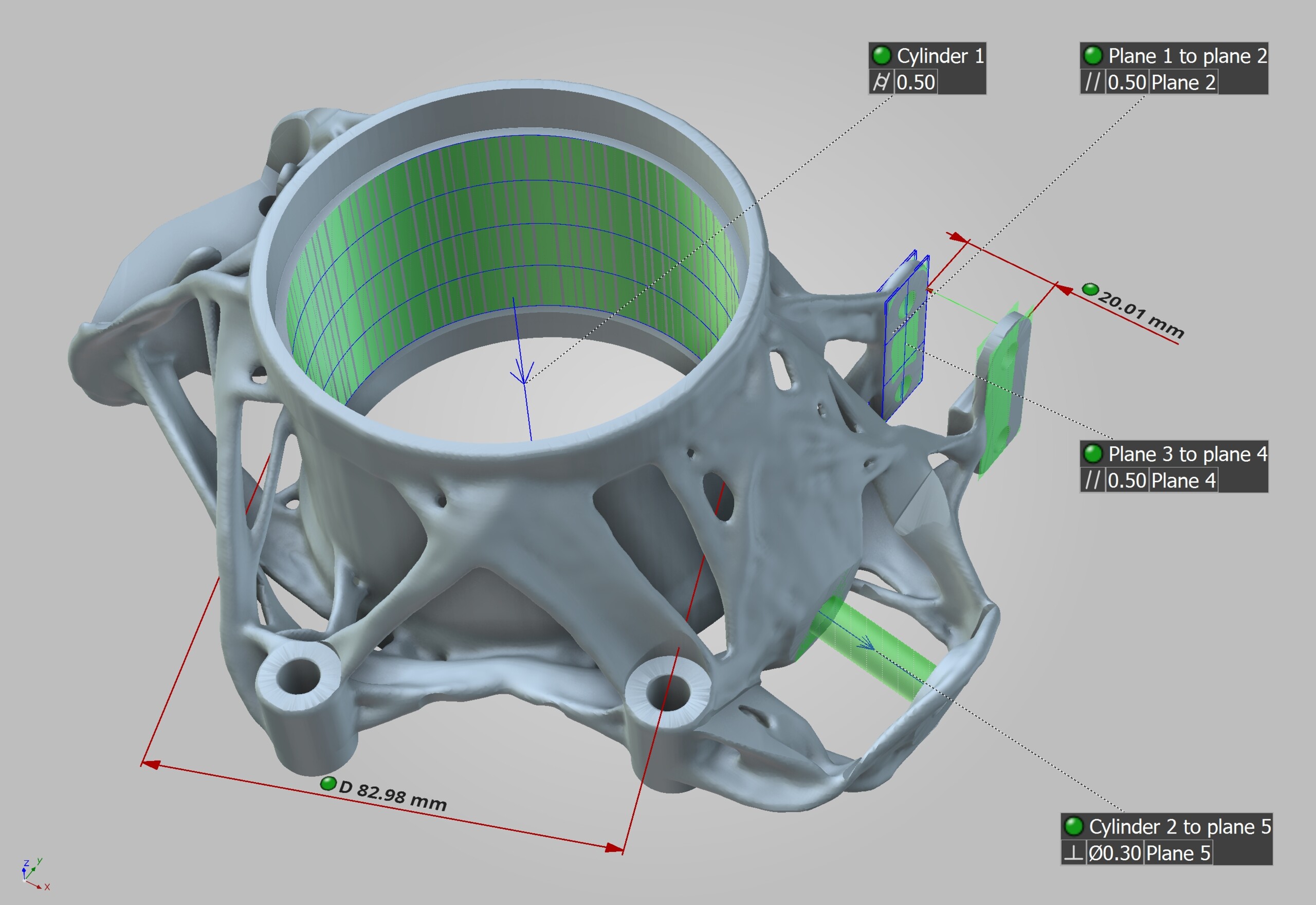

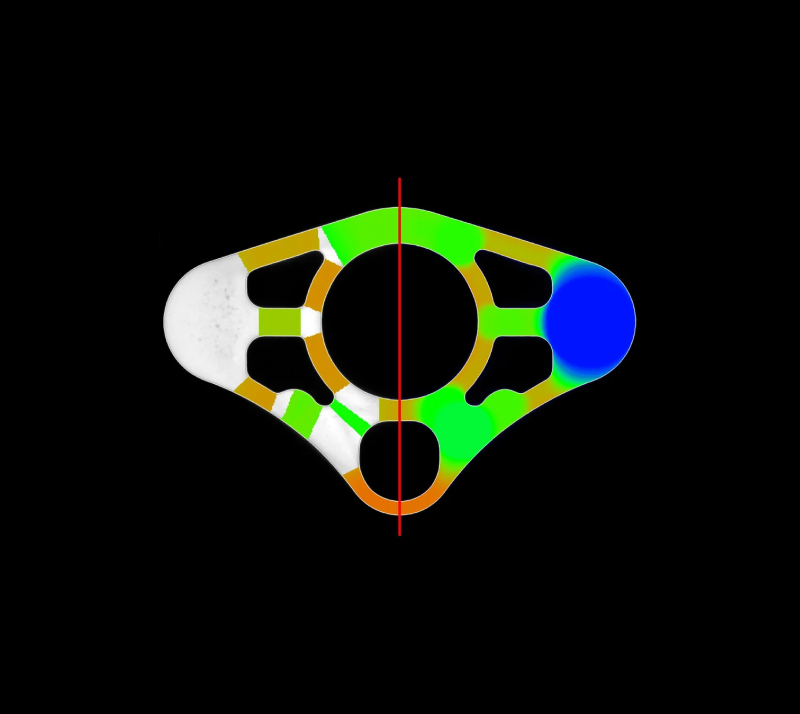

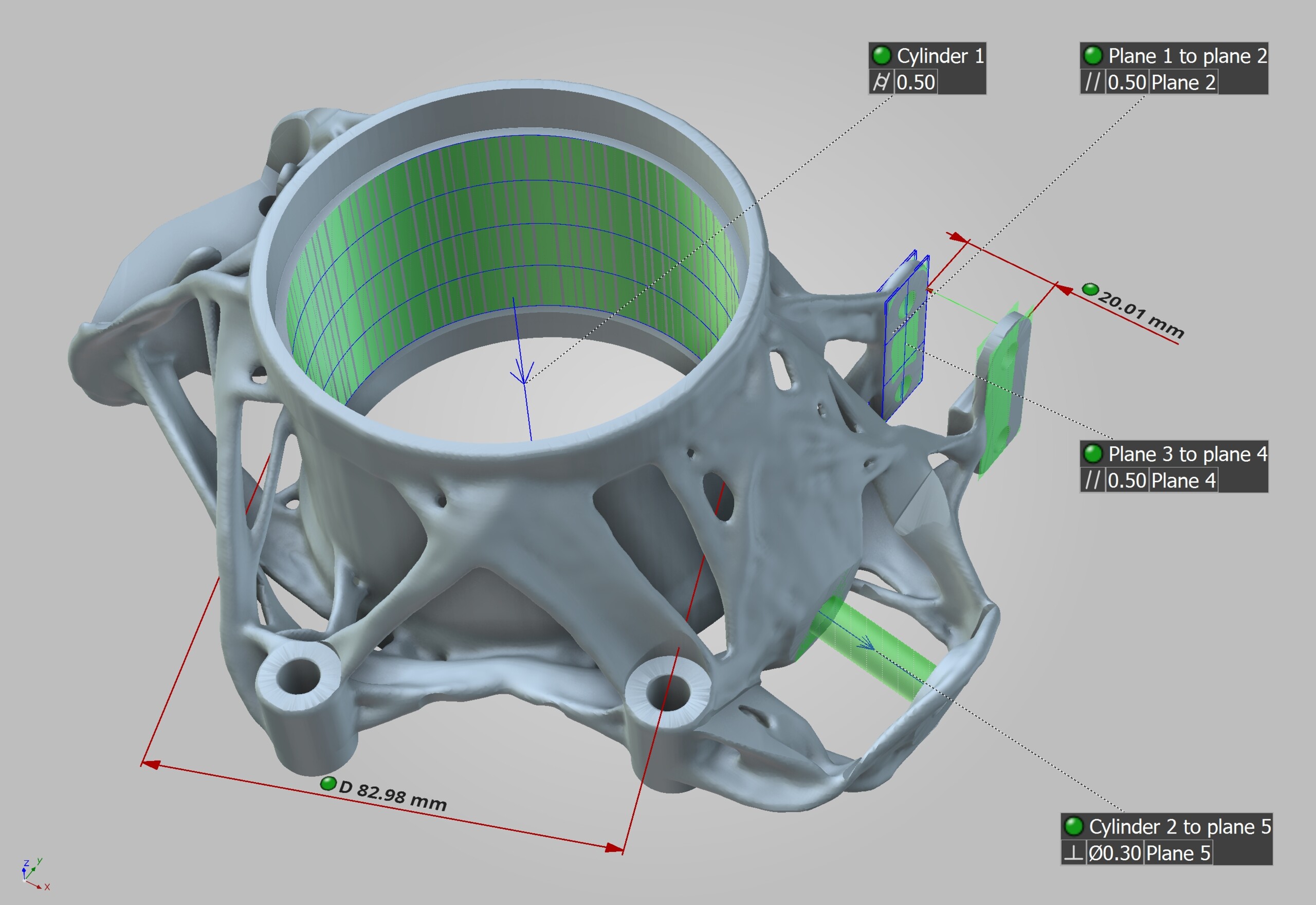

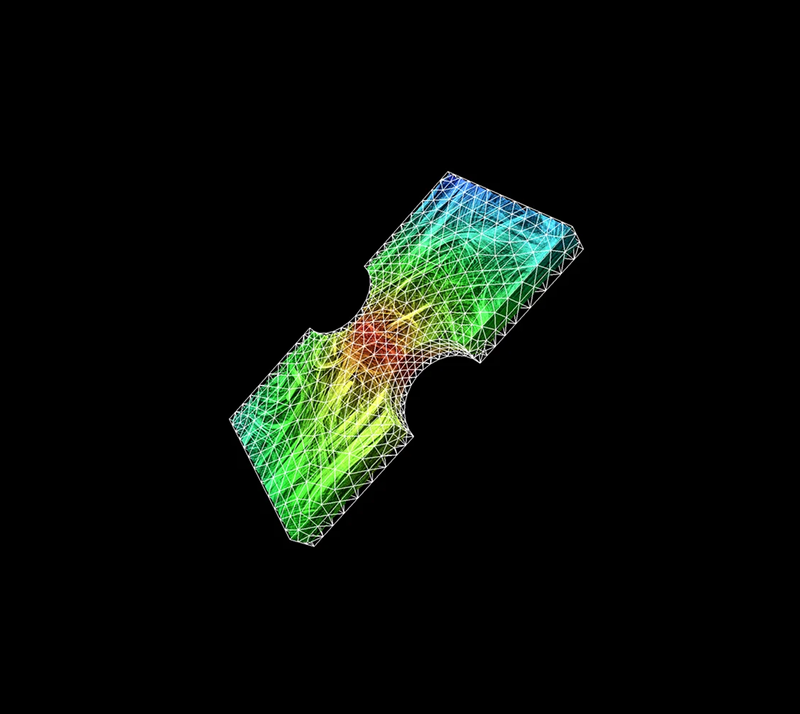

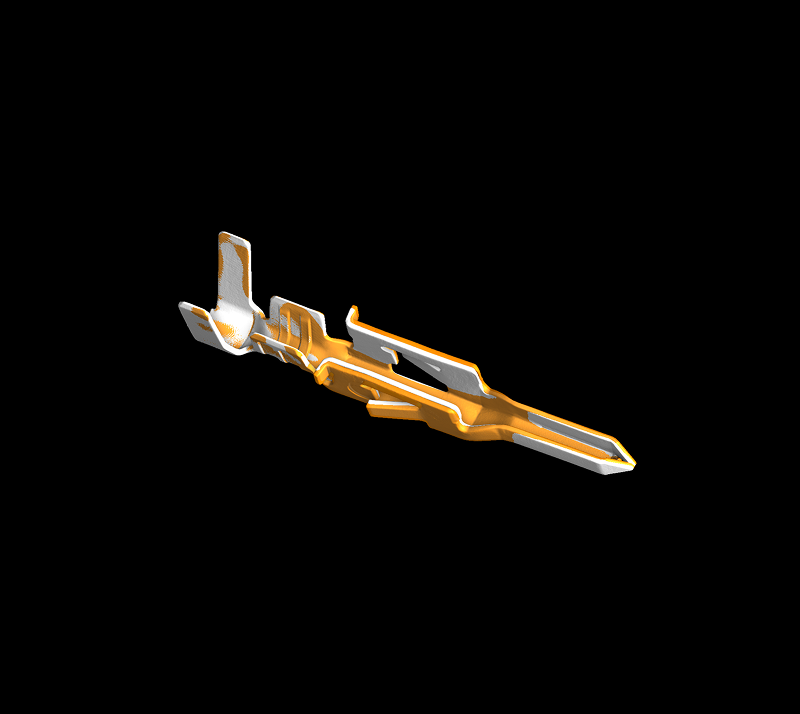

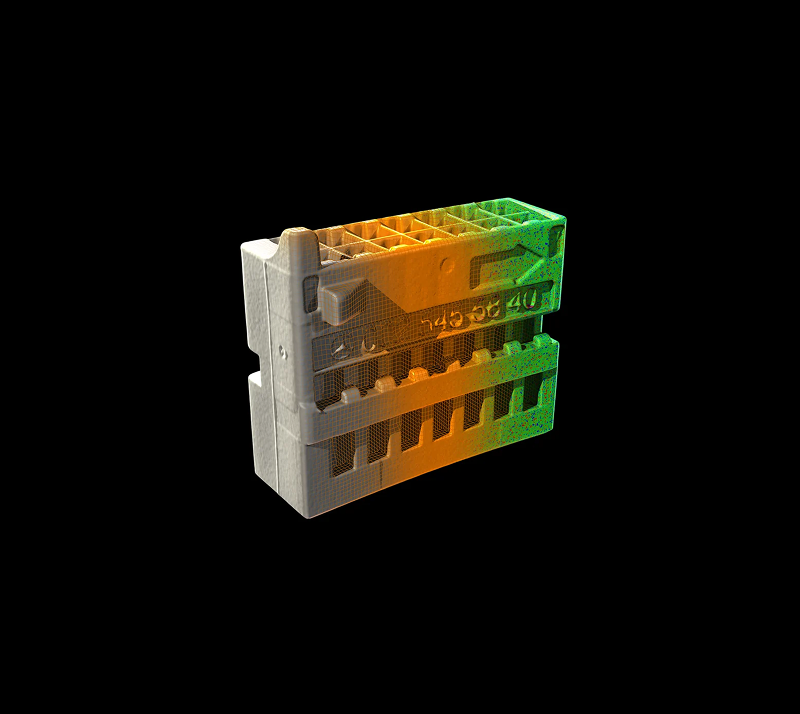

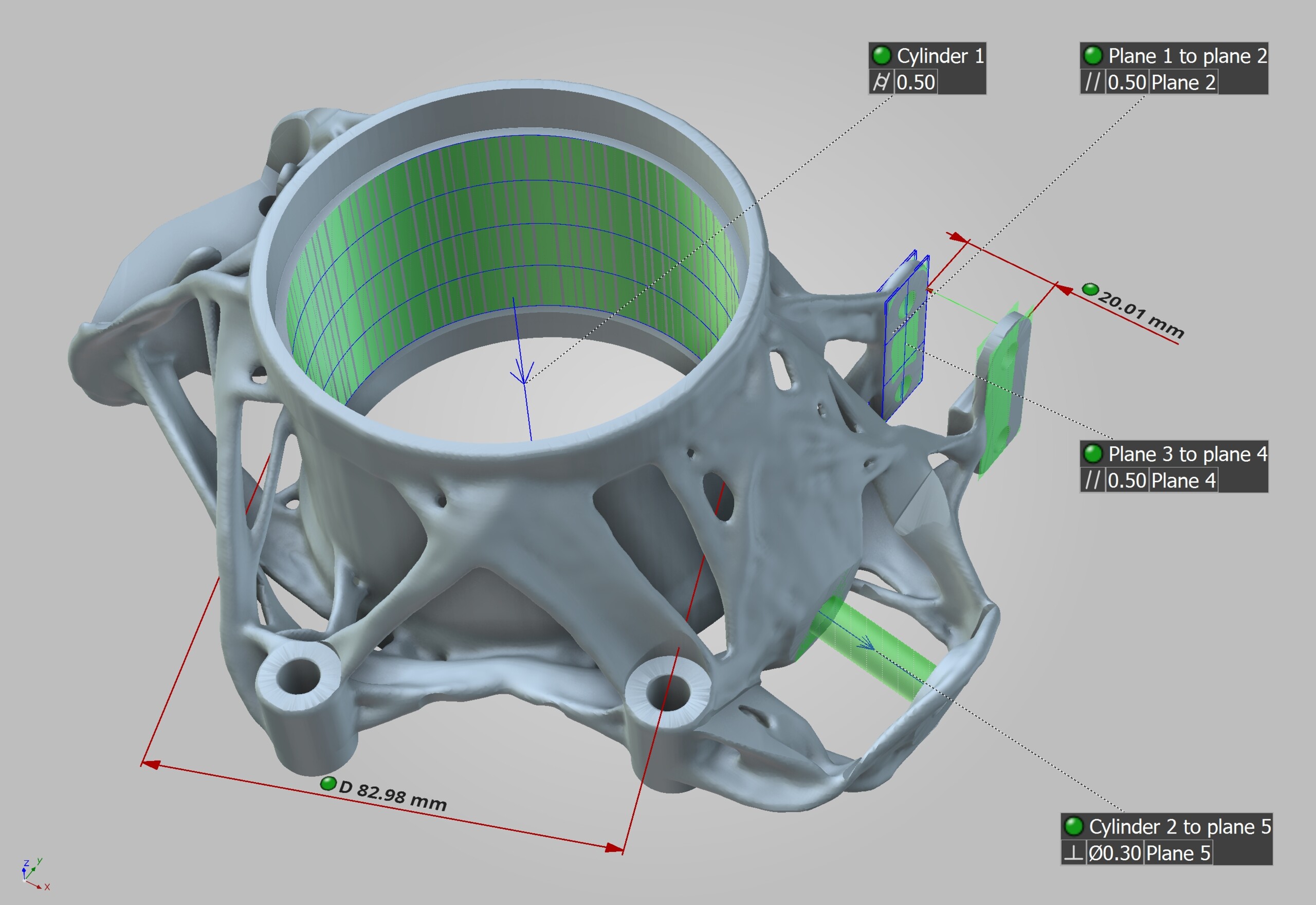

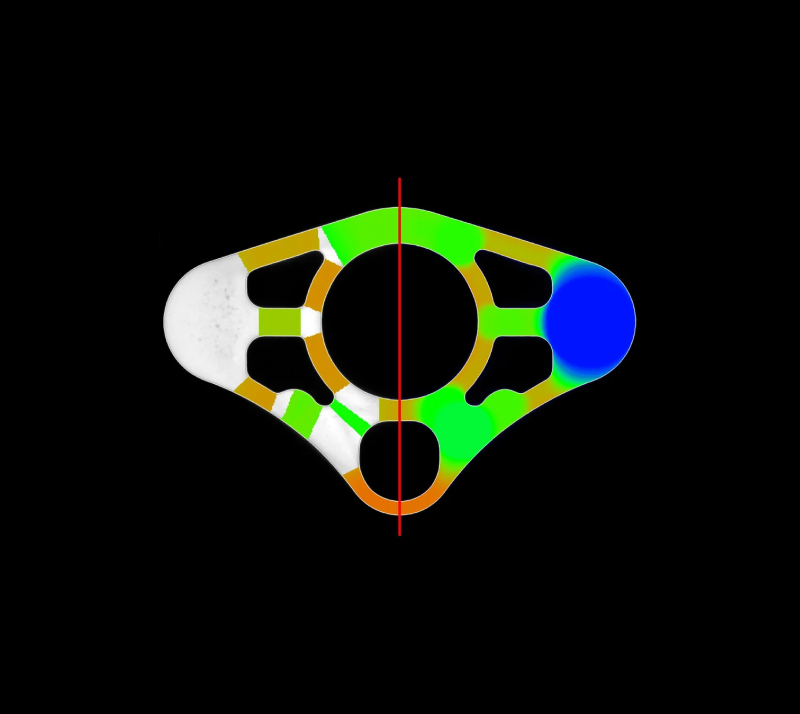

All CT-based metrology relies on accurate surface determination in the voxel model, which reduces measurement uncertainty. Our surface determination feature minimizes measurement uncertainty by being subvoxel-accurate and locally adaptive, enabling the measurement of details smaller than a voxel. It processes grey values based on surrounding voxels for greater accuracy and includes an interval-based mode for high-accuracy, adaptive surface determination in automated environments with variable grey values. Additionally, it features a multi-material mode for simultaneous surface determination of multiple materials, producing one component per material.

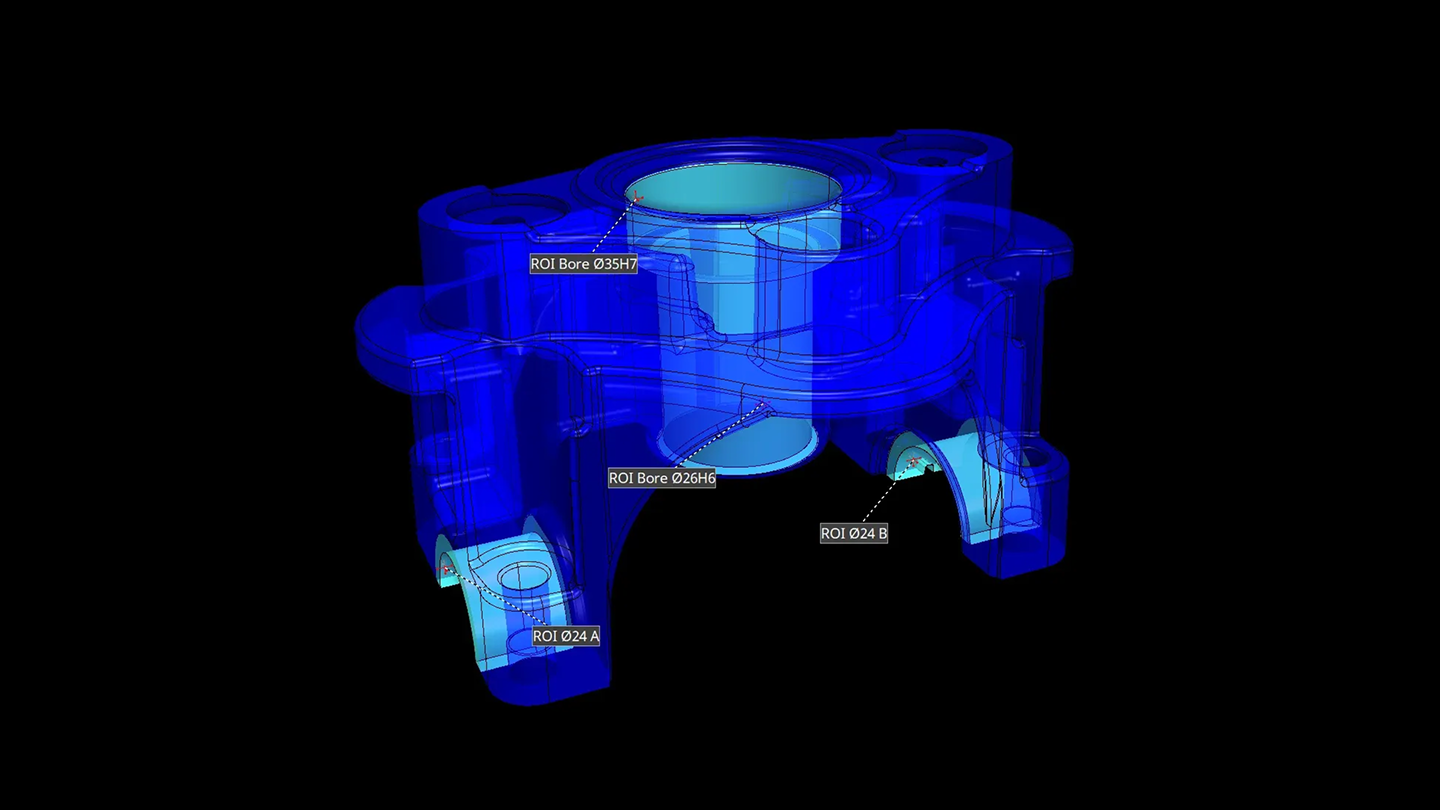

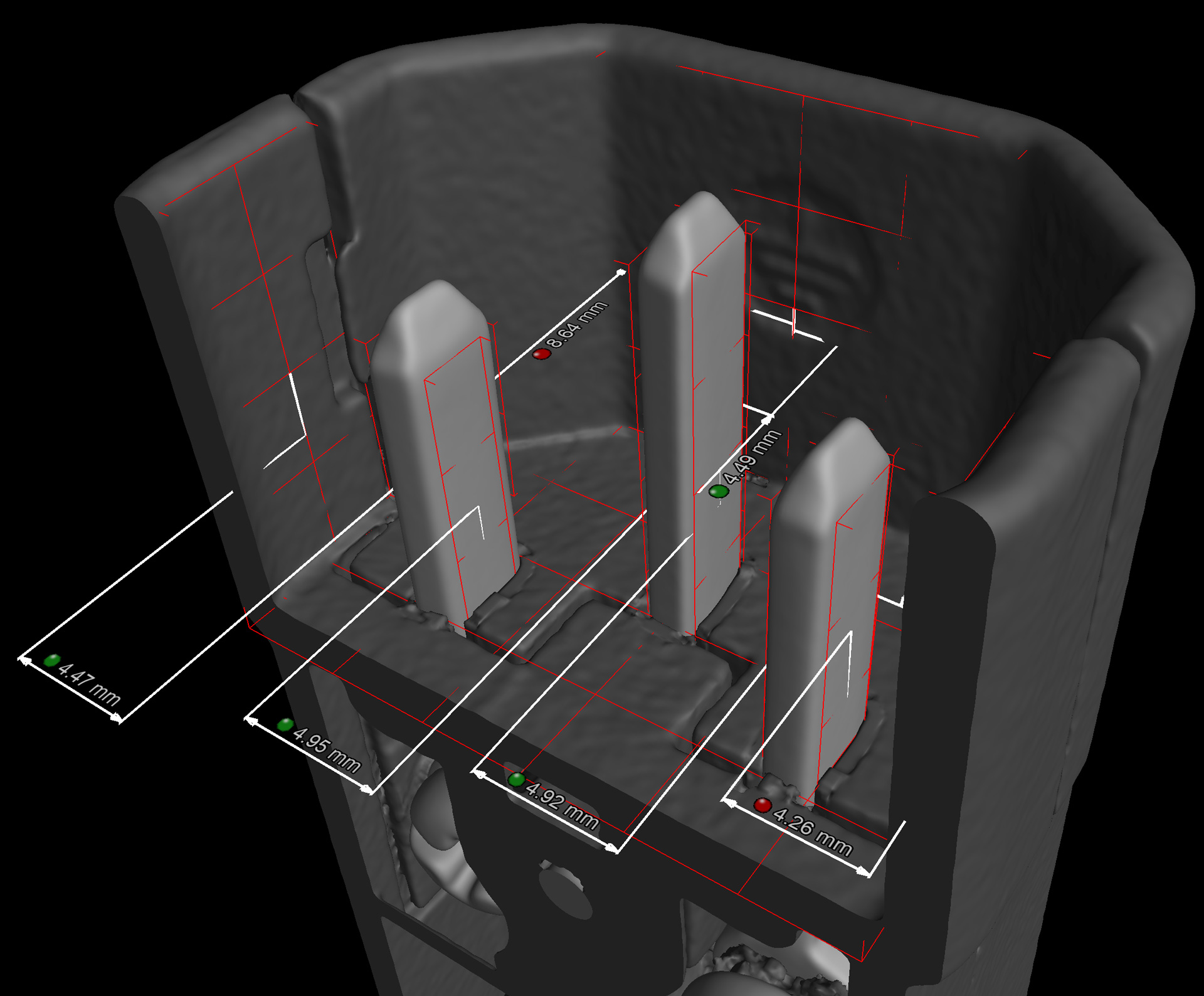

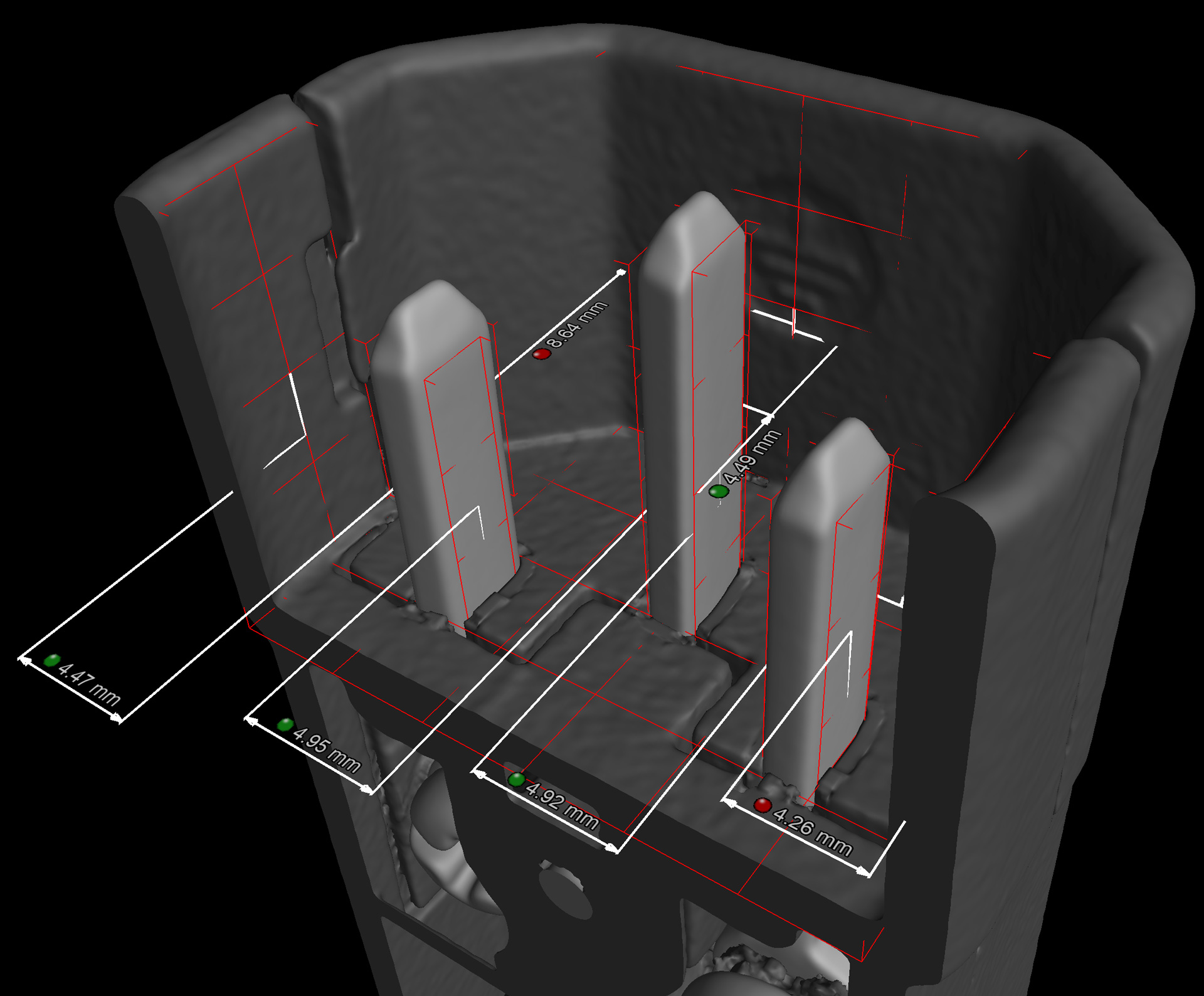

Our software offers essential alignment features, including Simple 3-2-1 alignment and Simple alignment, to ensure precise positioning. It also provides fundamental reference measurement tools, such as distance, polyline length, and angle measurement instruments. The Snap Mode feature also allows instruments to snap to surfaces easily, simplifying the measurement process.

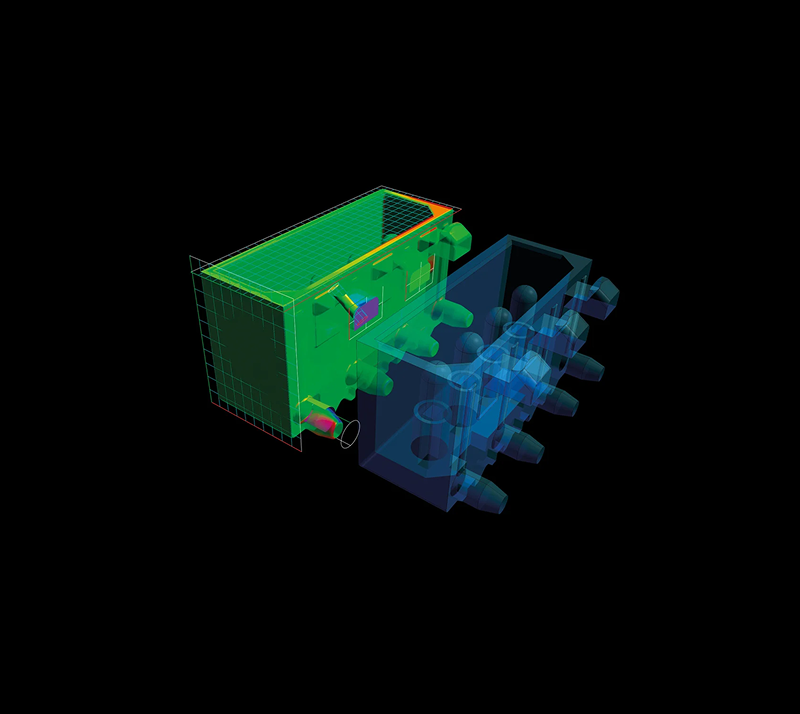

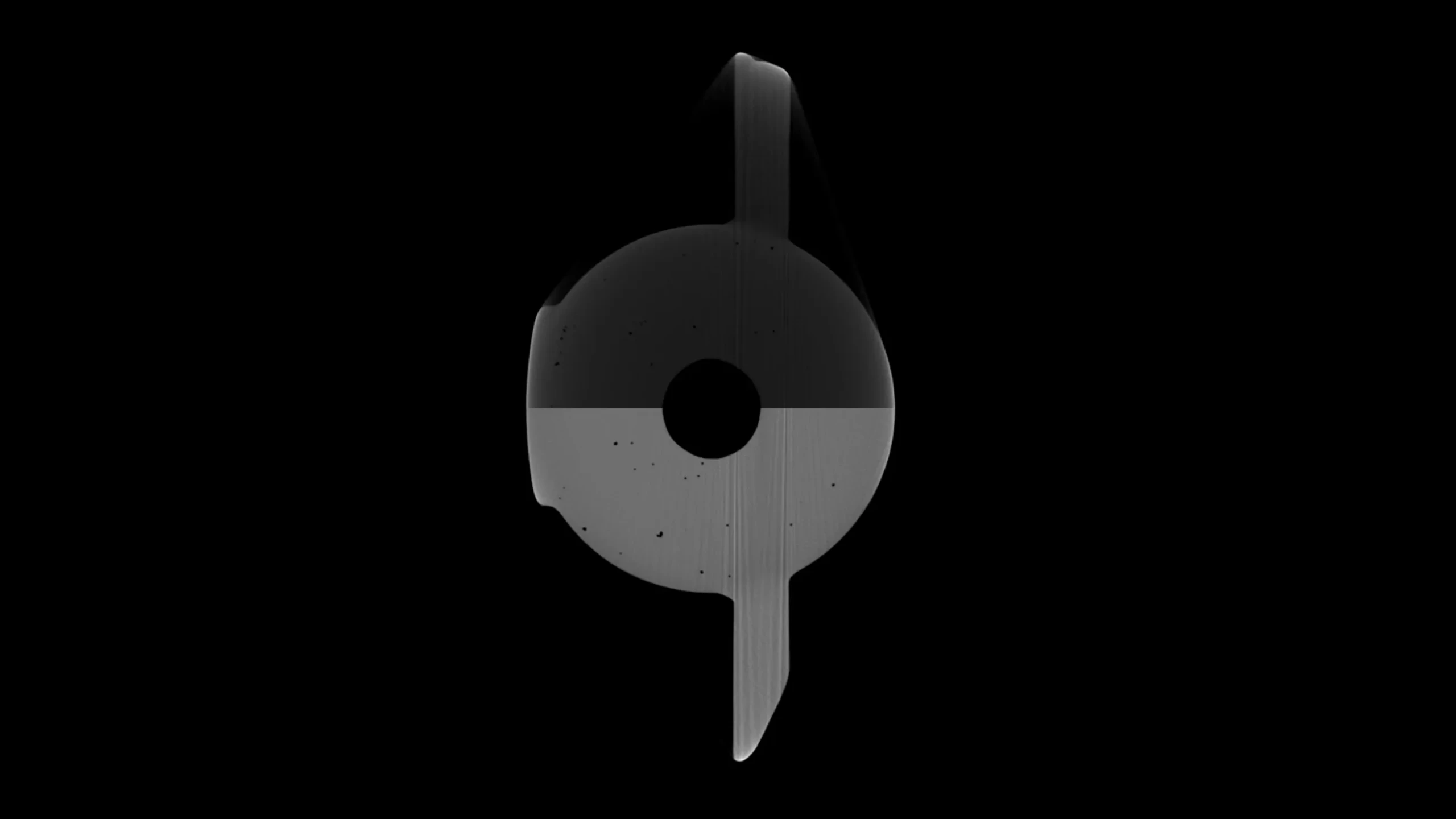

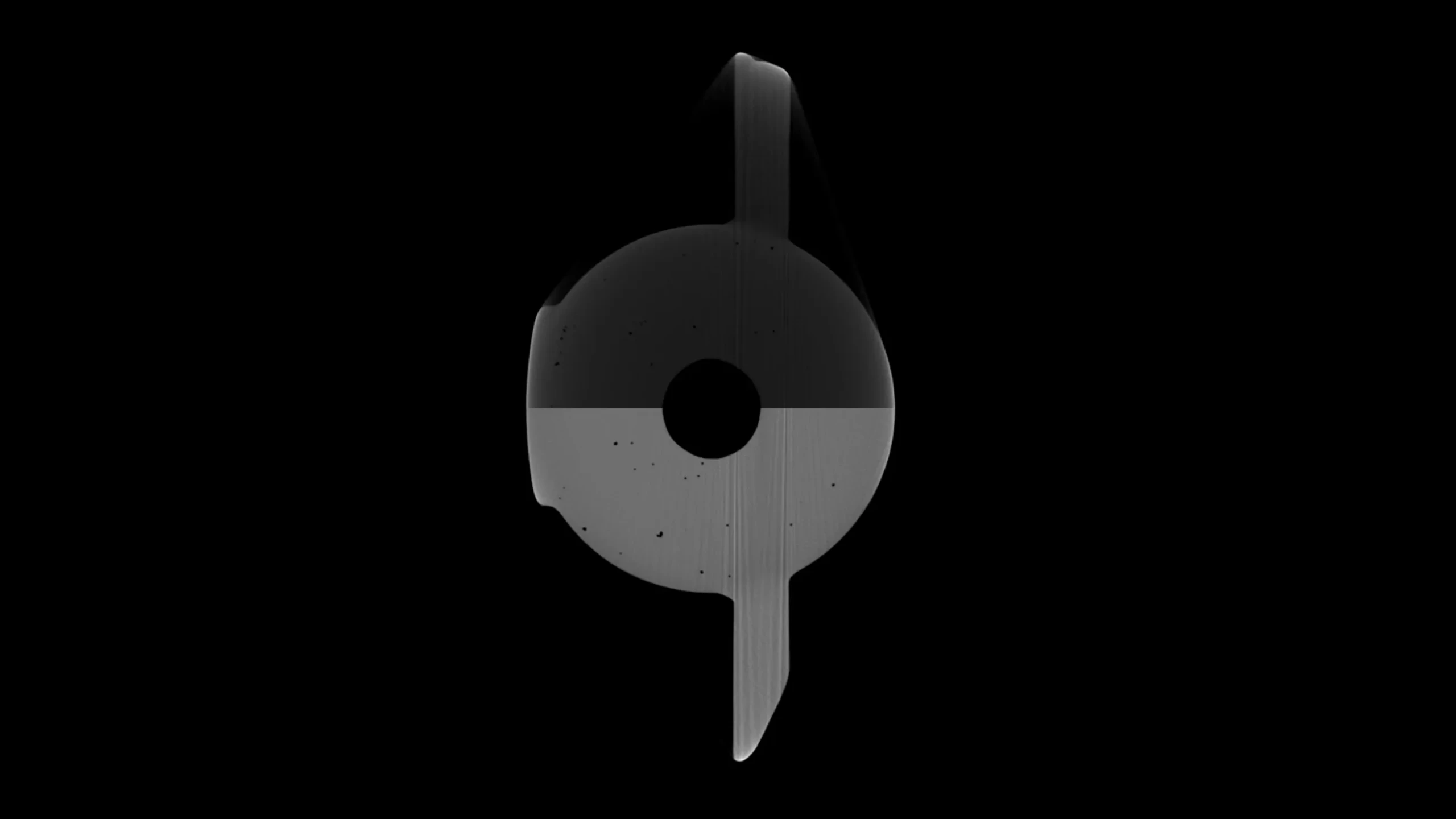

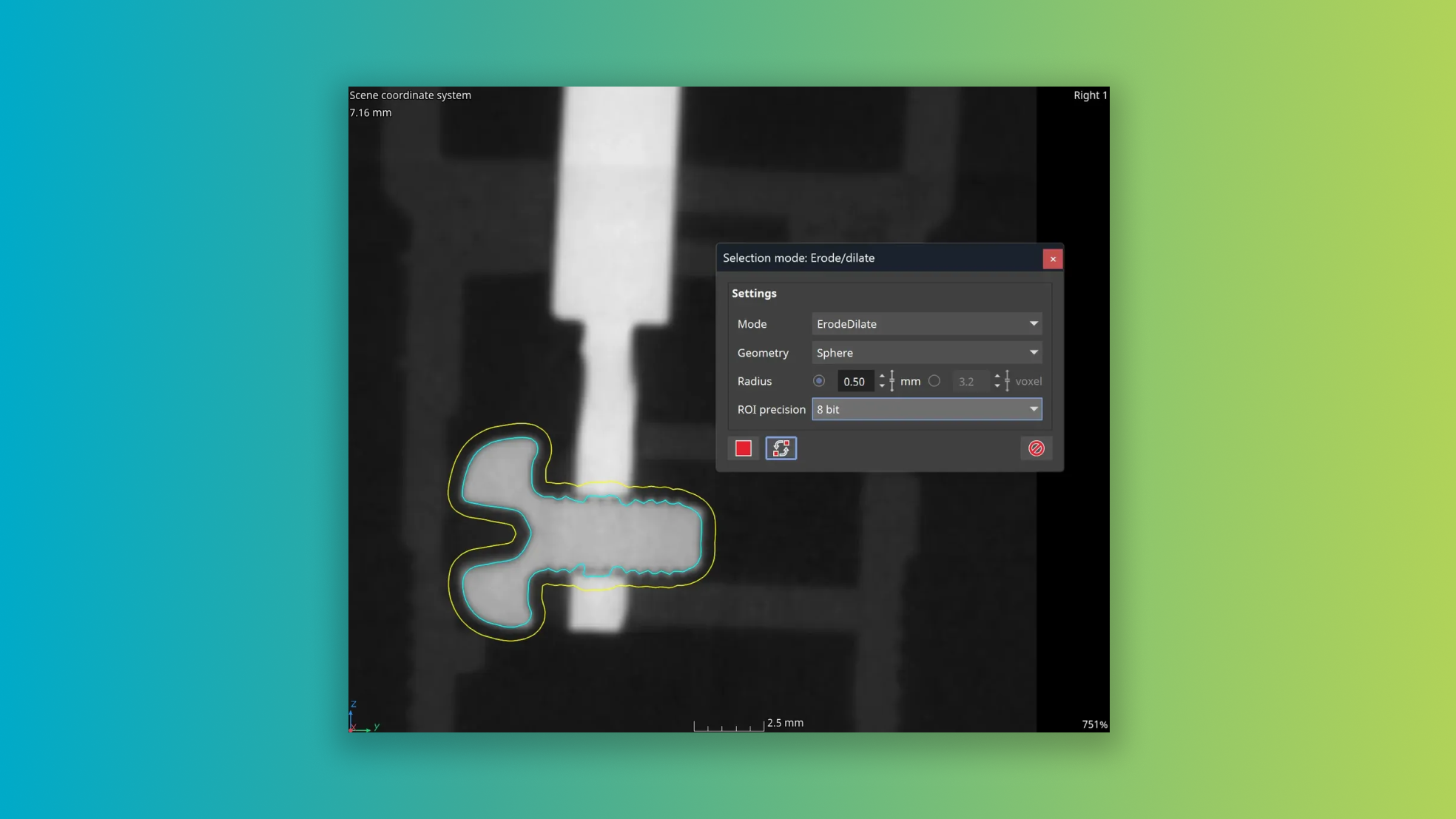

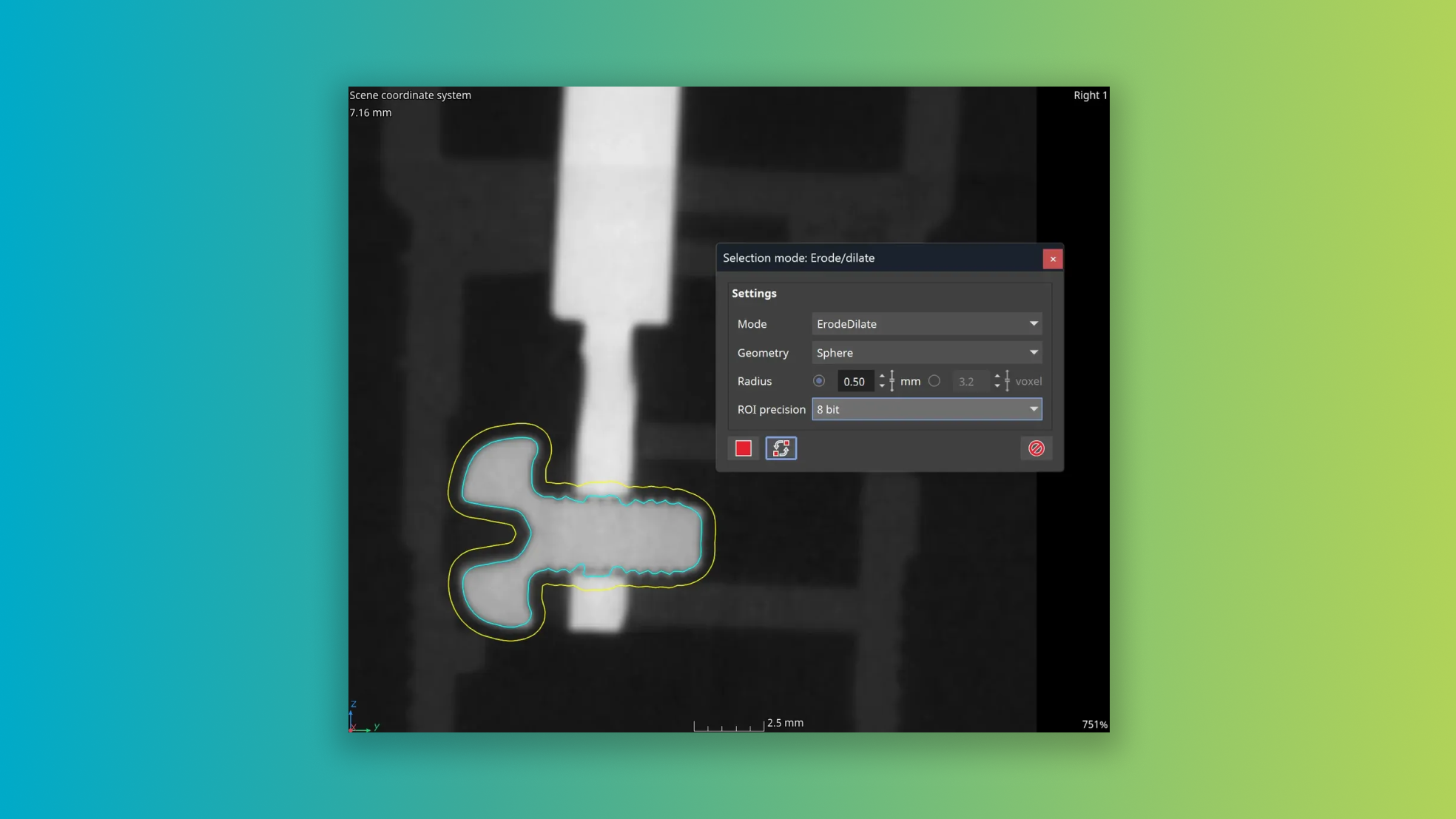

Separate data sets into individual regions of interest (ROIs) consisting of different components and materials using manual selection, drawing tools, and semi-automated tools.

Read more

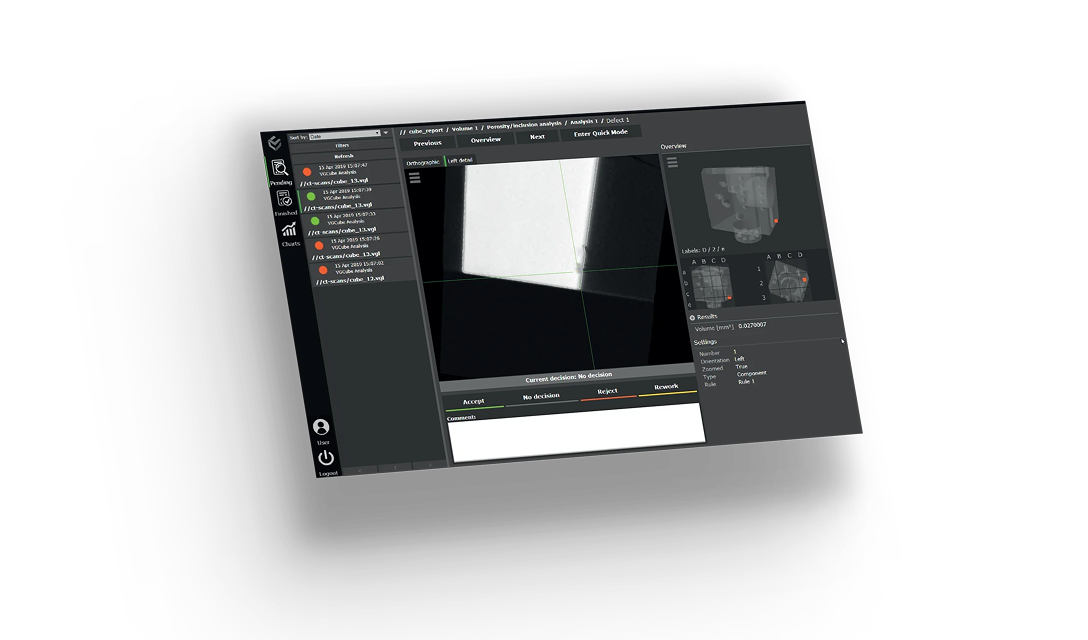

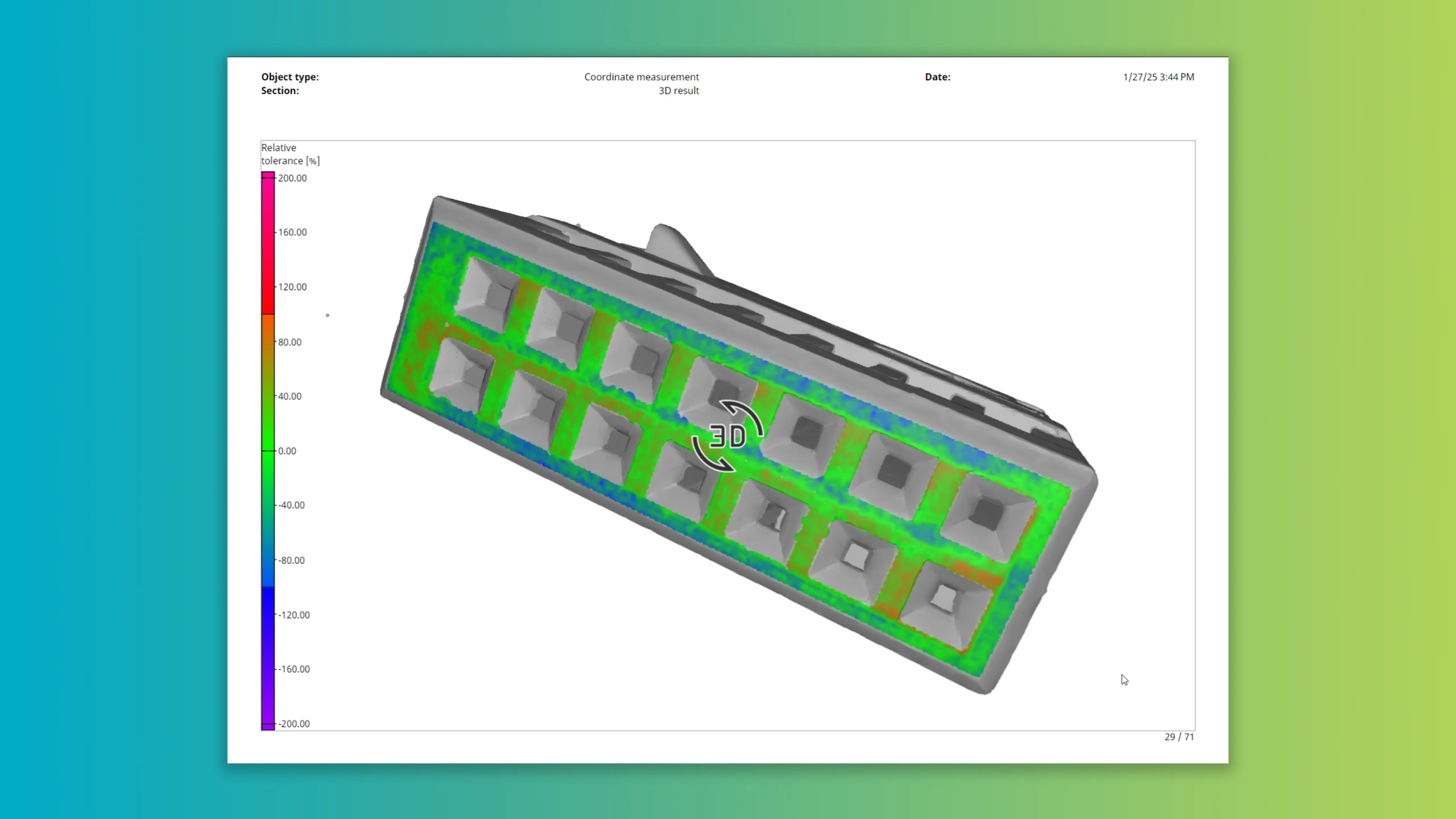

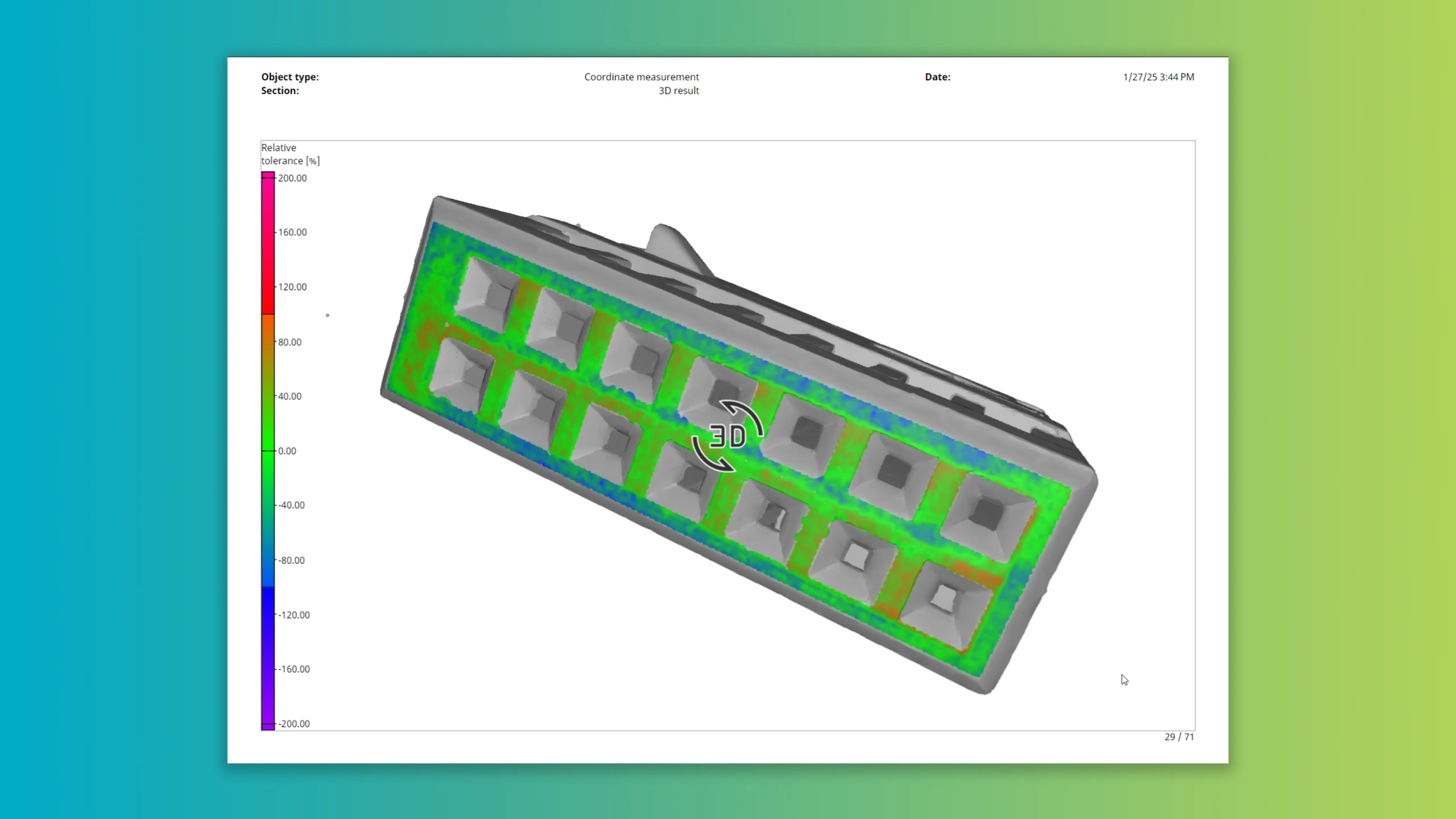

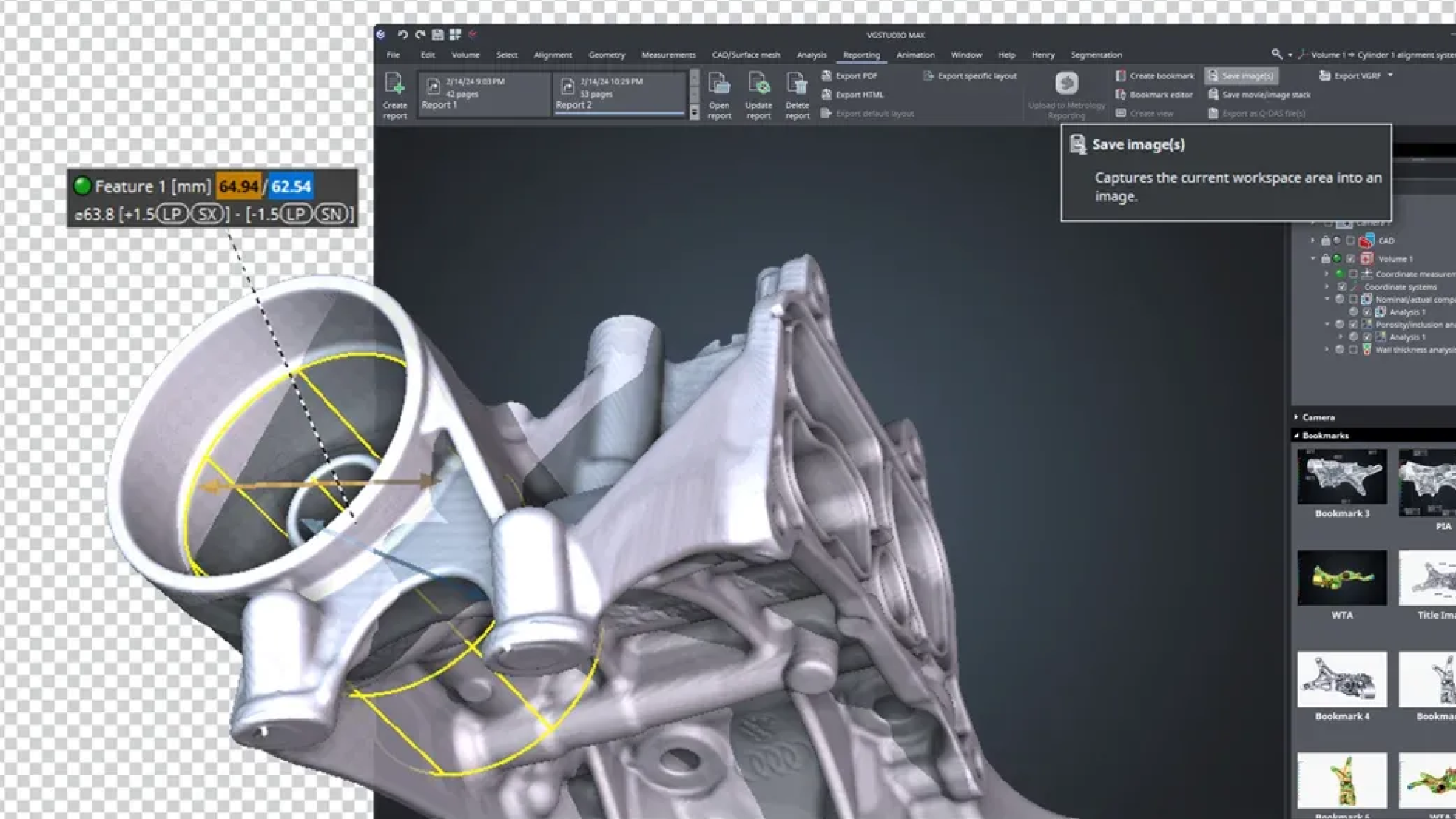

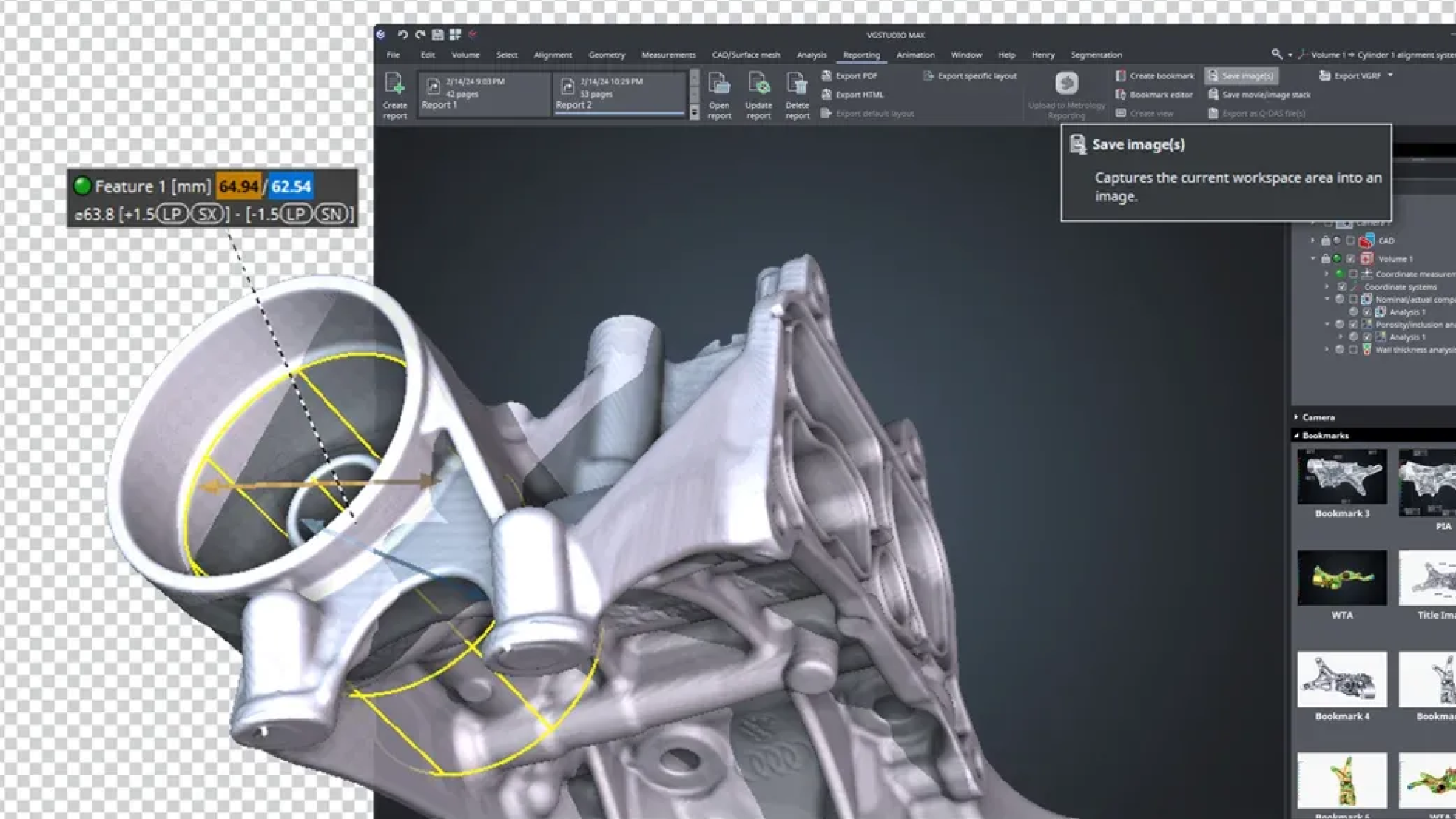

VG software delivers immediate, actionable results, including insightful graphics and detailed reports. Export images, histograms, and data tables in standard formats, create customisable inspection reports, and interface with third-party quality management or statistical process control software like Q-DAS or Metrology Reporting. These reporting features are an excellent way to share the extensive information VGSTUDIO MAX provides about your scanned parts.

Read more

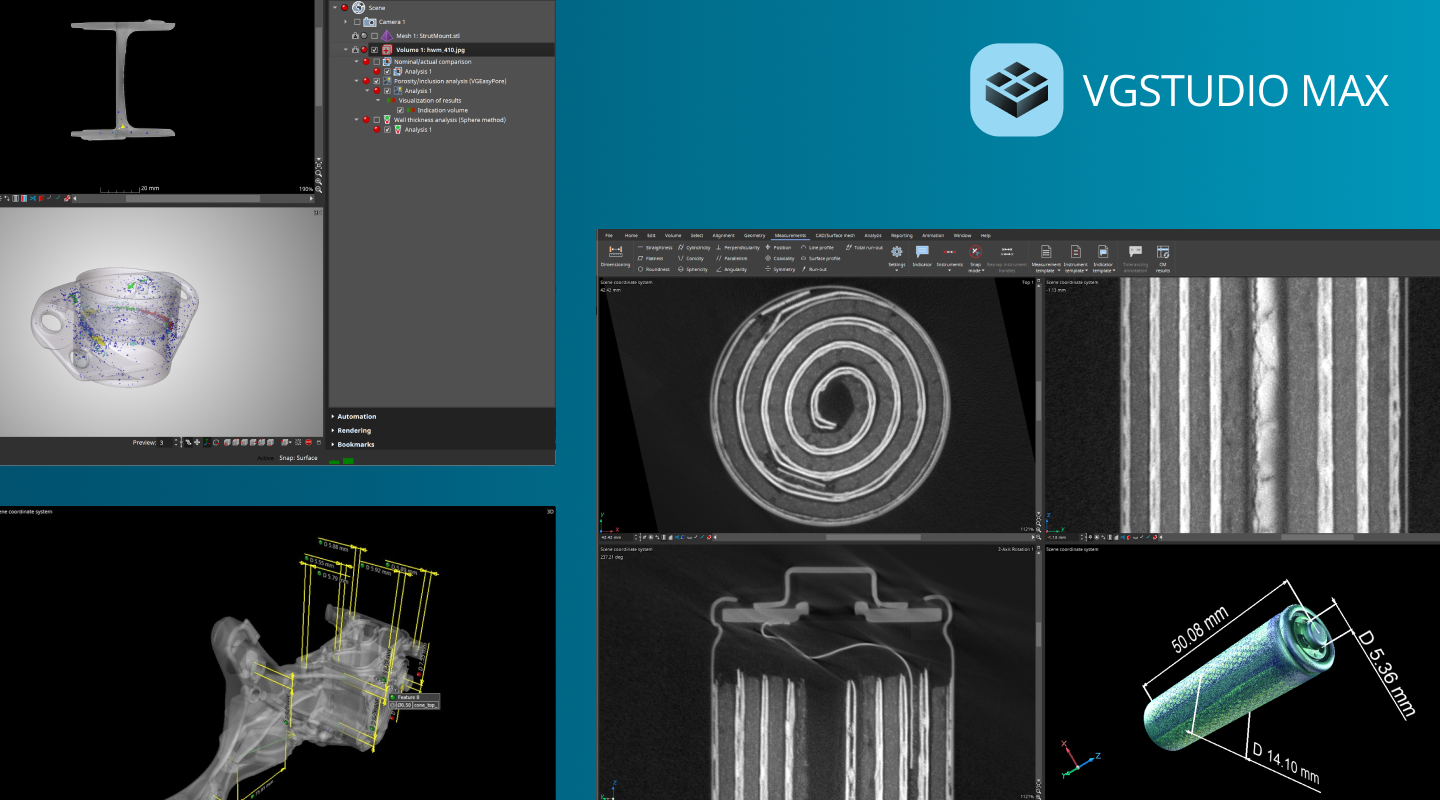

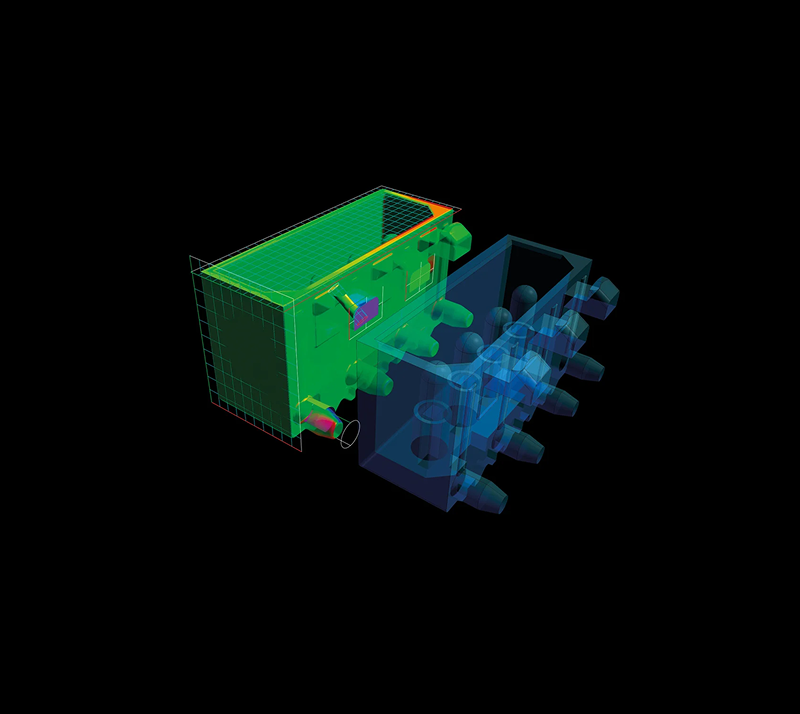

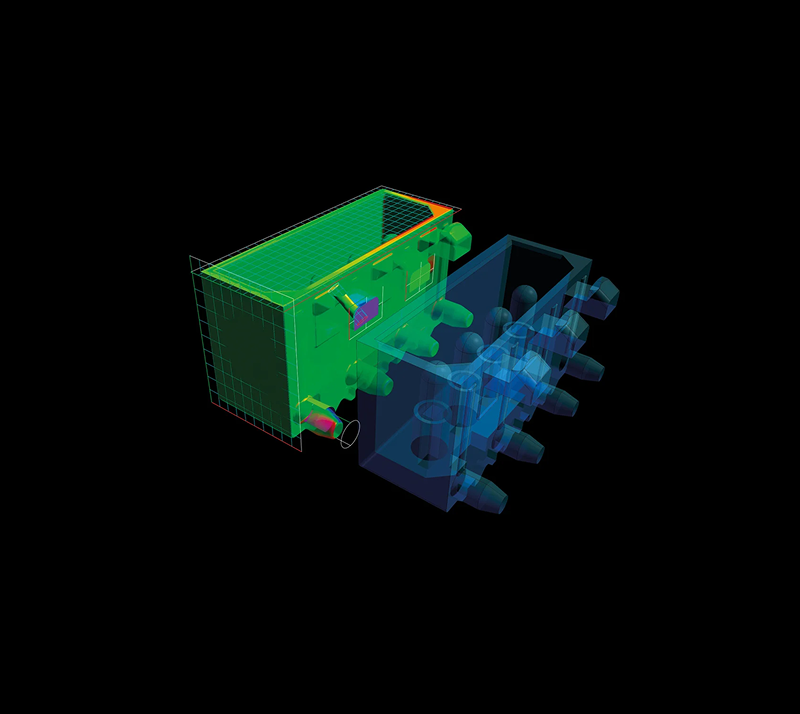

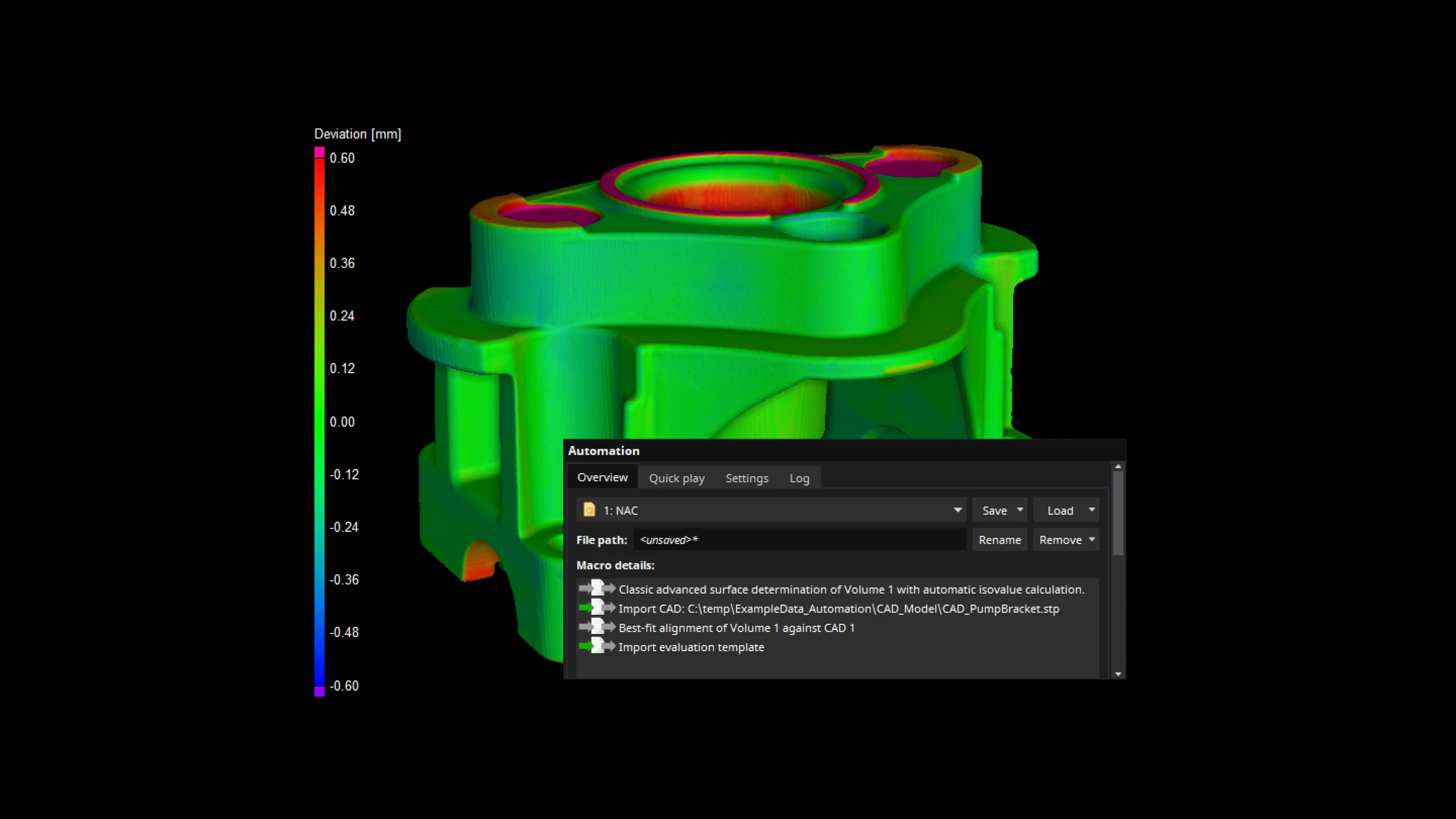

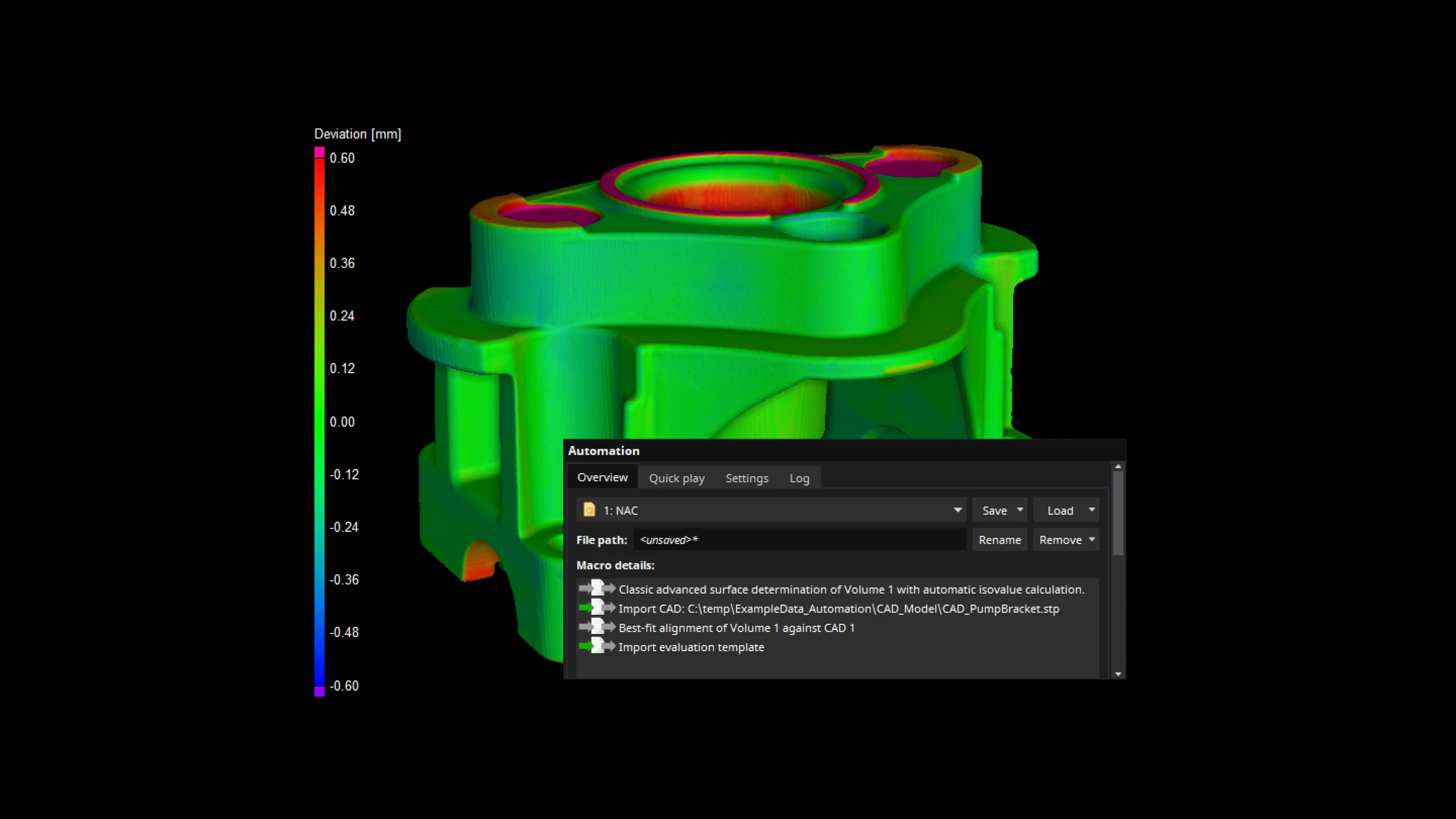

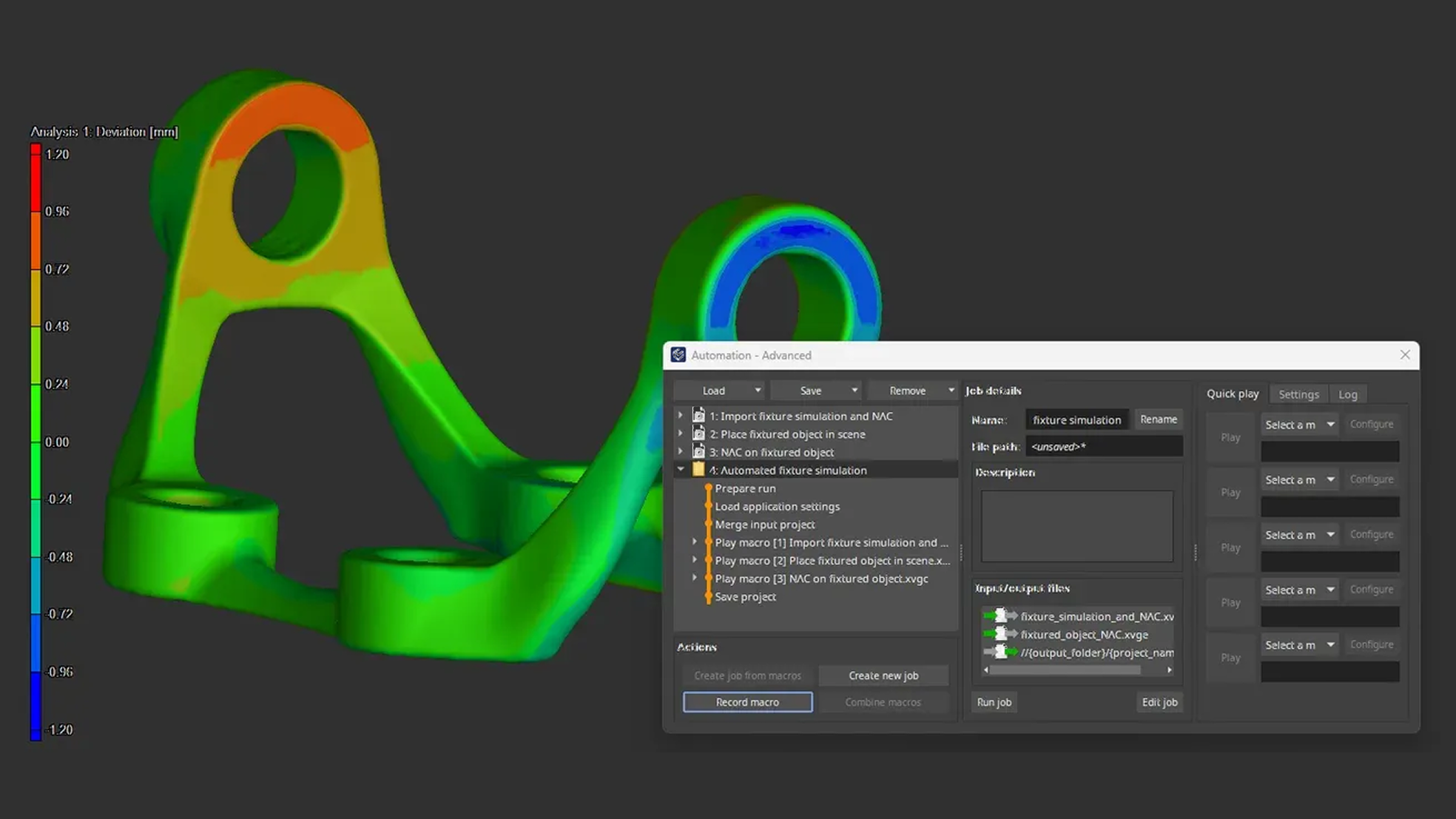

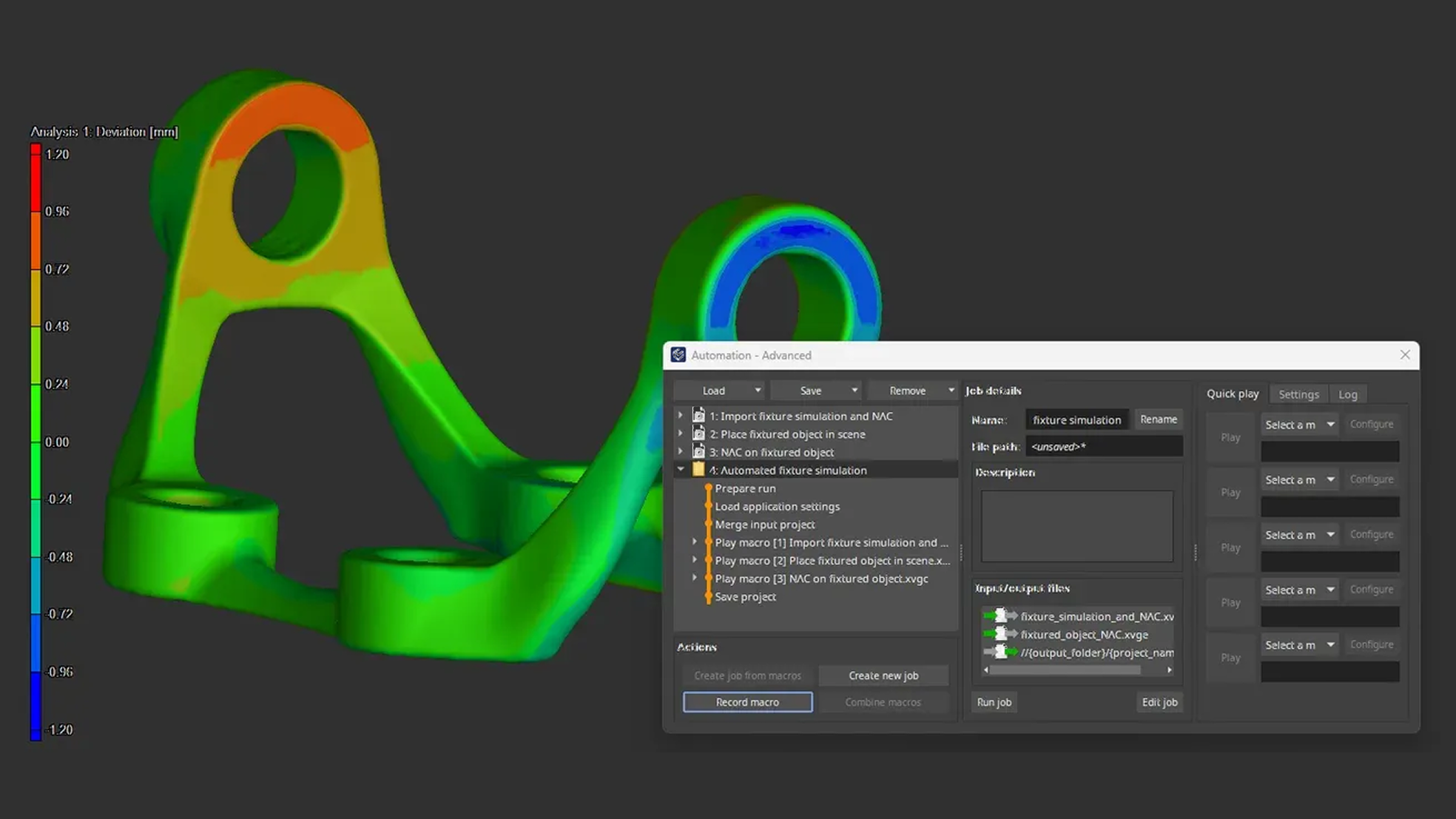

VGSTUDIO MAX offers easy-to-set-up automation compatible with nearly every CT system. This fast and flexible solution speeds up repetitive analyses with powerful automation functions. Automating recurring workflow elements can enhance efficiency across various tasks even for infrequently scanned objects.

Read more

Packages & bundles

VGSTUDIO MAX is available in pre-configured packages designed for the most common tasks across various industries, offering considerable savings compared to purchasing individual modules separately.

Each package includes a VGSTUDIO MAX license, selected add-on modules, and a one-year update/service agreement.

Existing VGSTUDIO MAX users can expand their capabilities with a pre-configured bundle, featuring add-on modules and a one-year update/service agreement.

For metrology and quality control across a broad range of industries

Includes these add-on modules:

- Coordinate Measurement

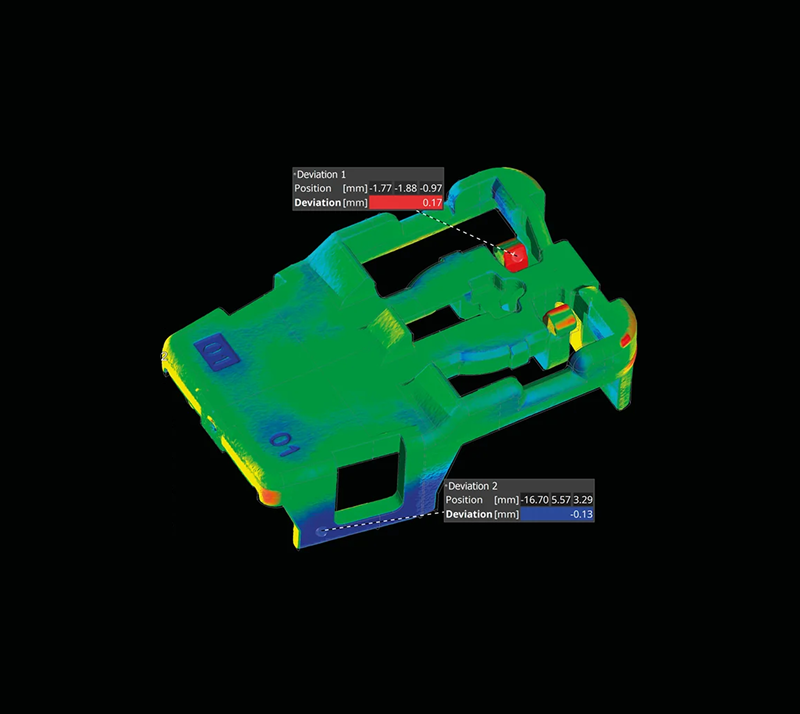

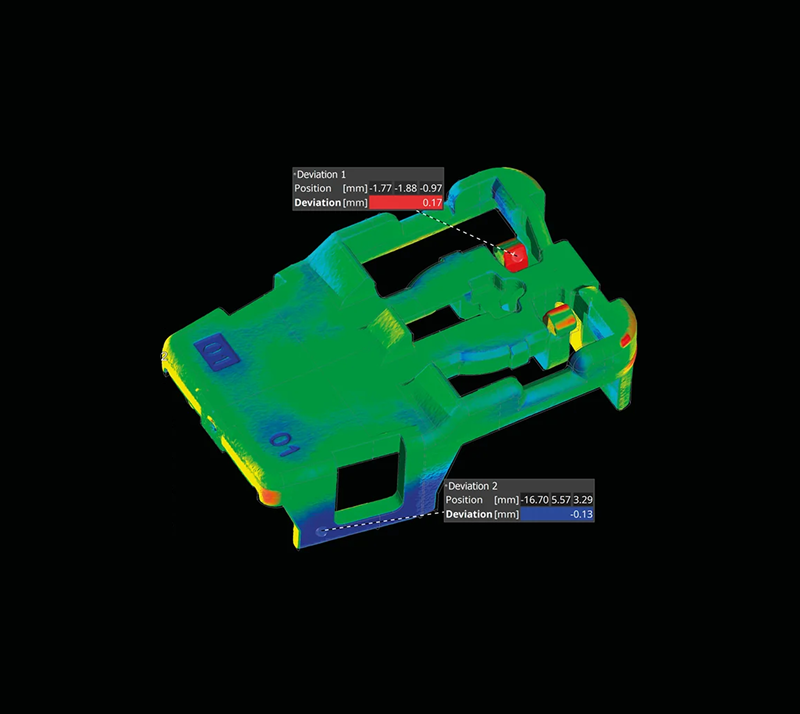

- Nominal/Actual Comparison

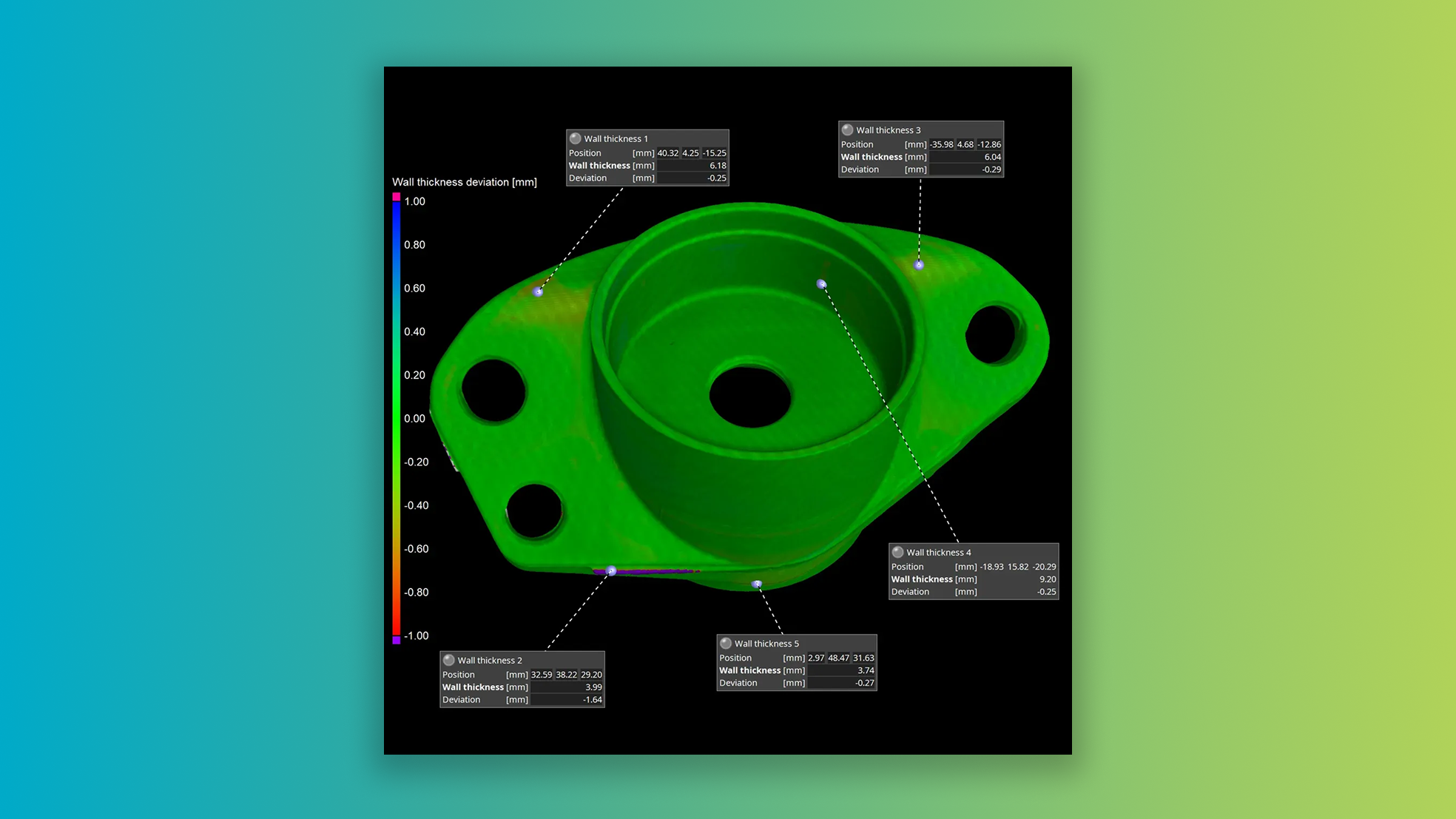

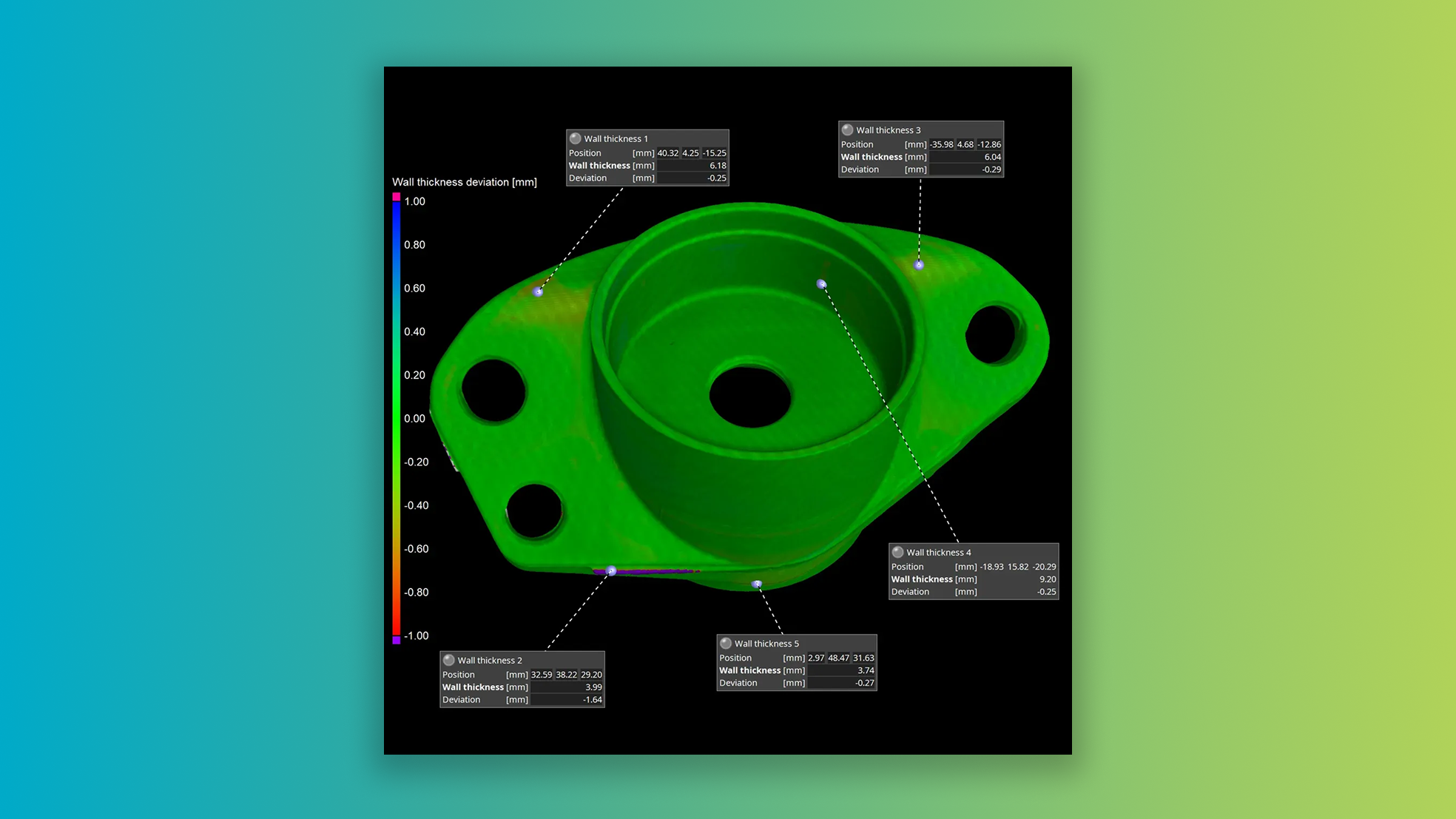

- Wall Thickness Analysis

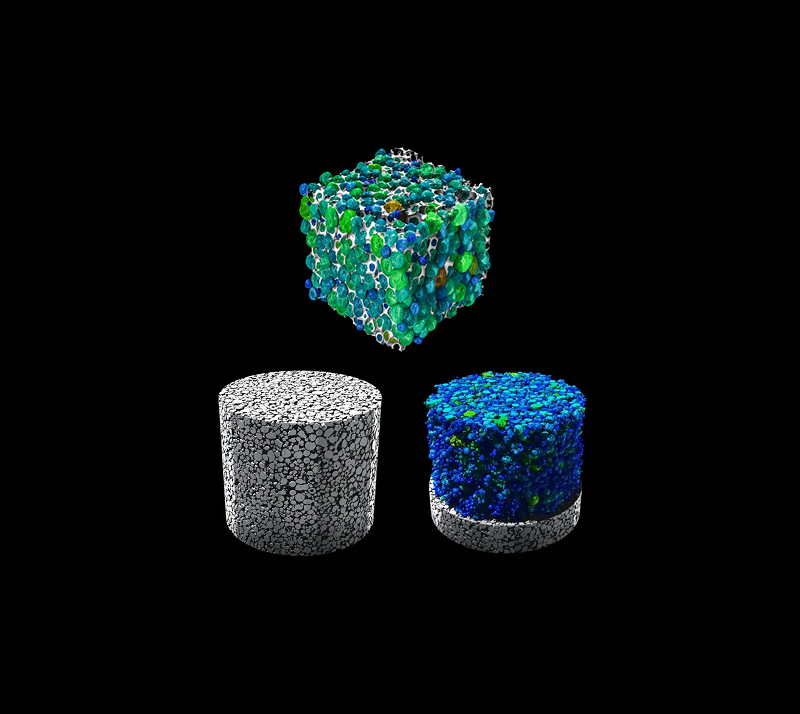

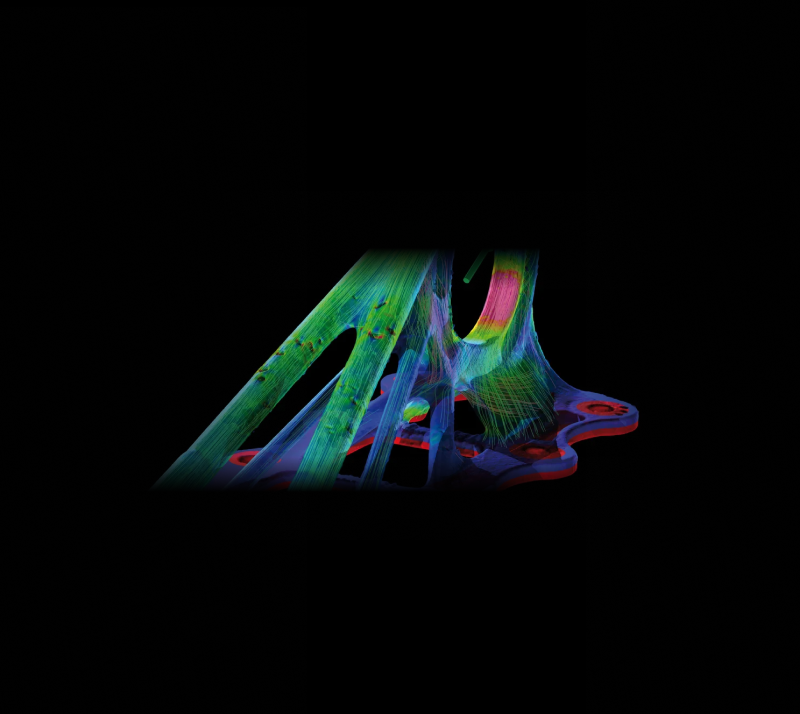

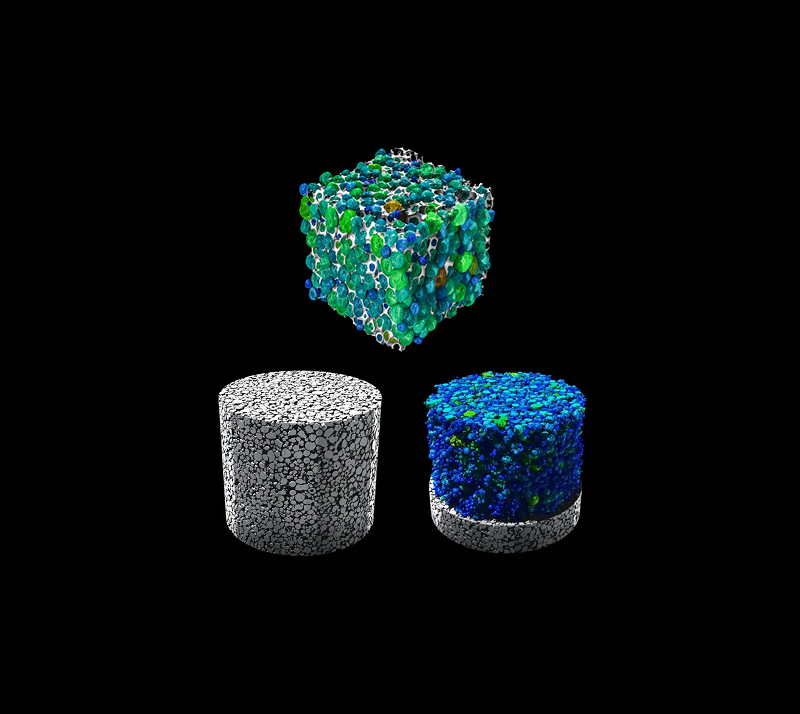

For lightweight construction and materials research

Includes these add-on modules:

- Coordinate Measurement

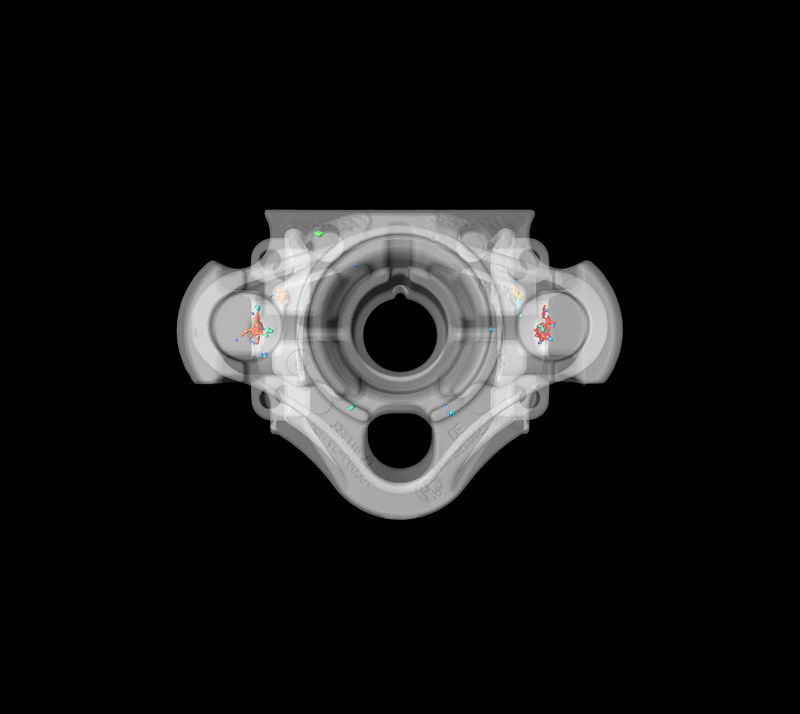

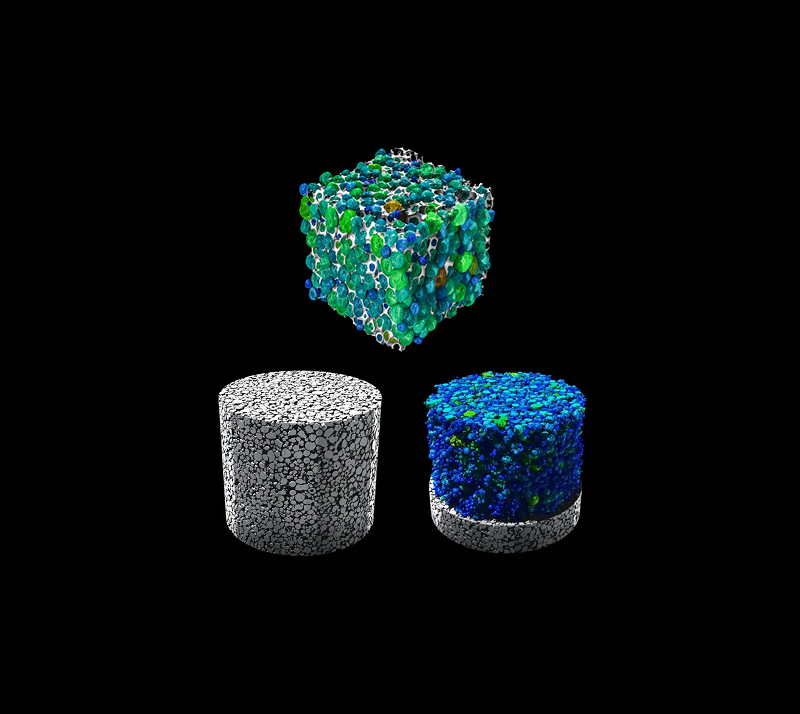

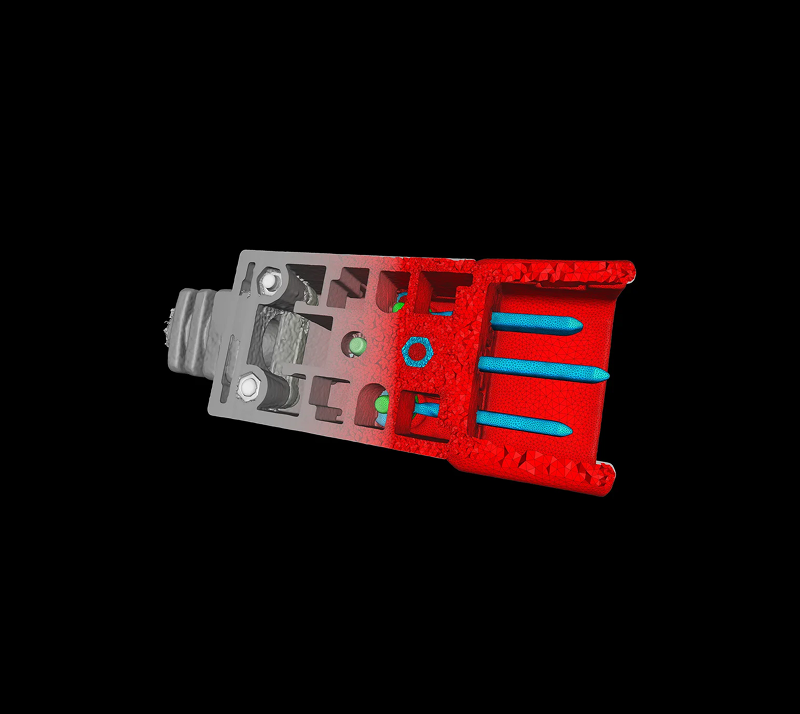

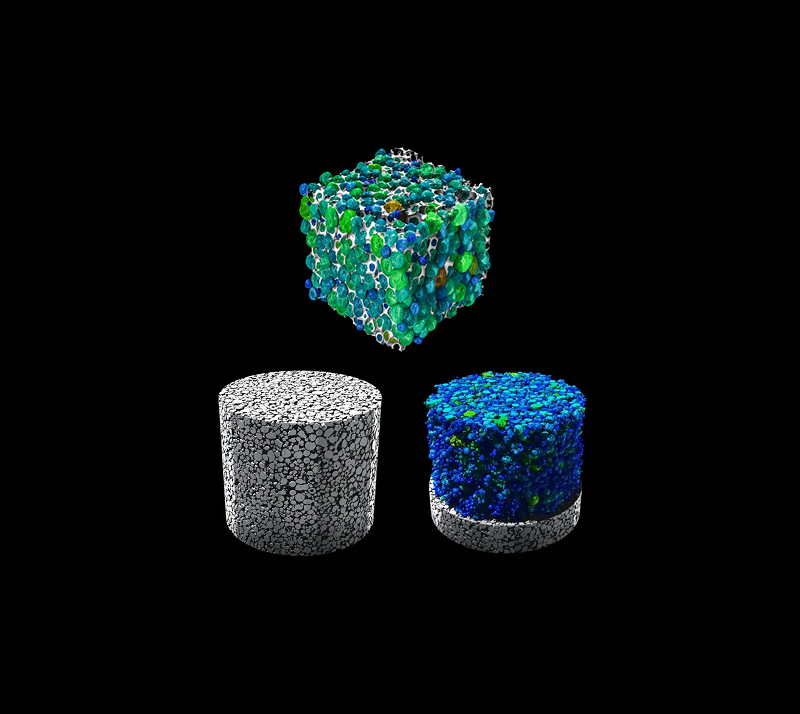

- Porosity/Inclusion Analysis

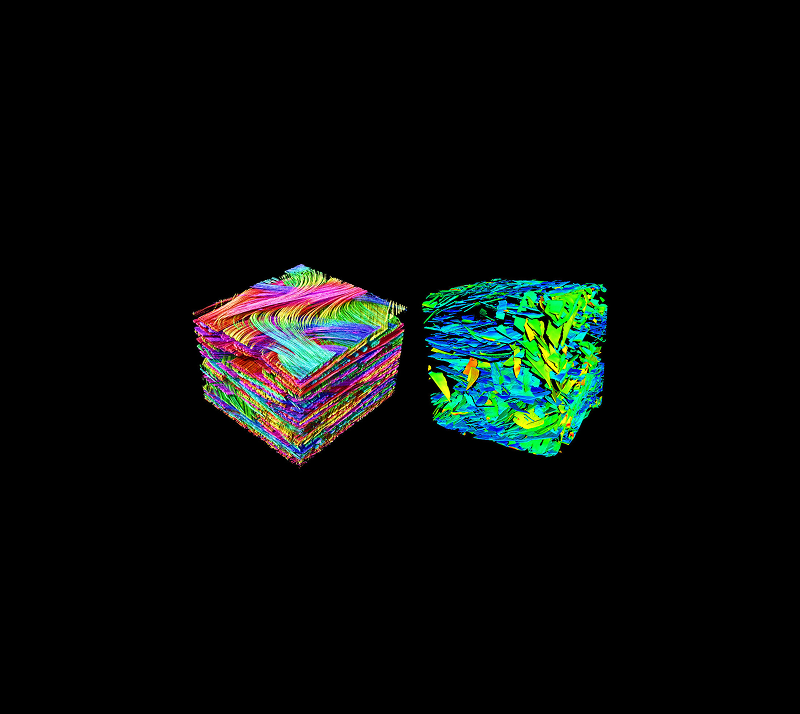

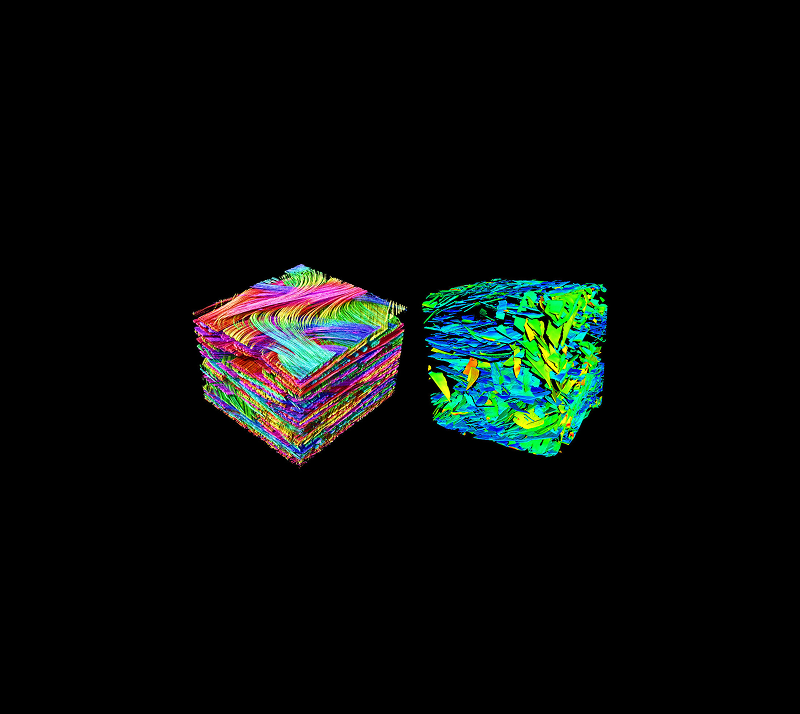

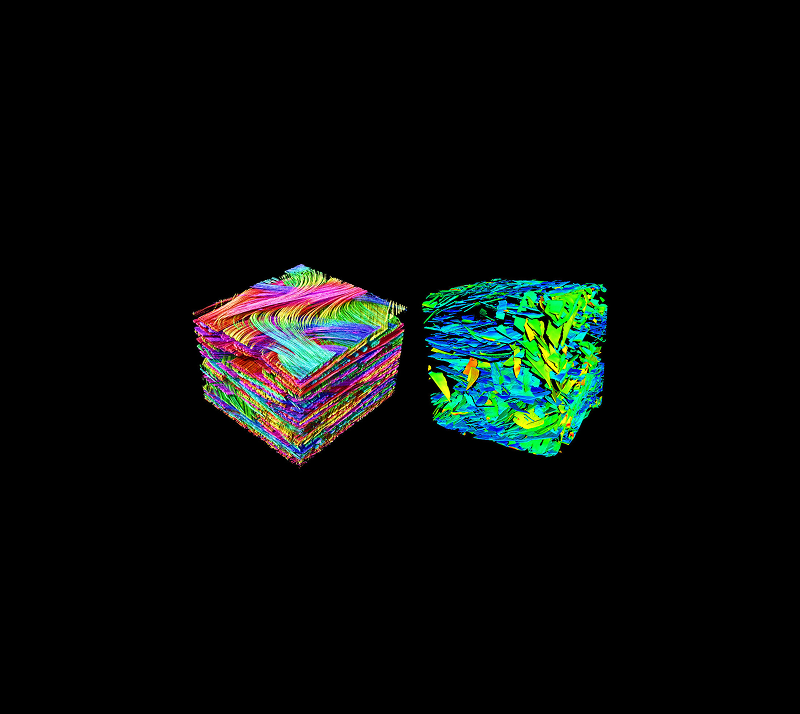

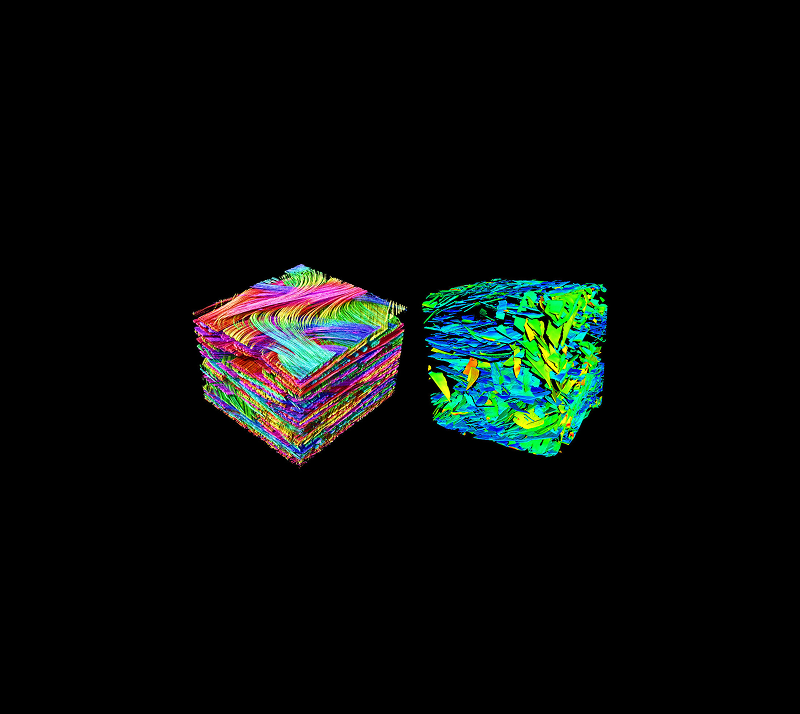

- Fiber Composite Material Analysis

- Foam/Powder Analysis

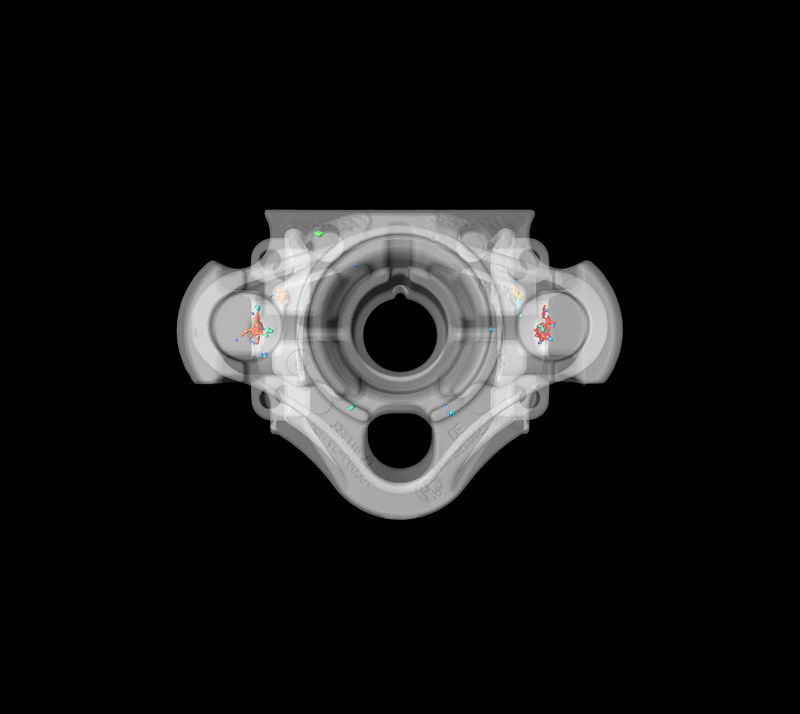

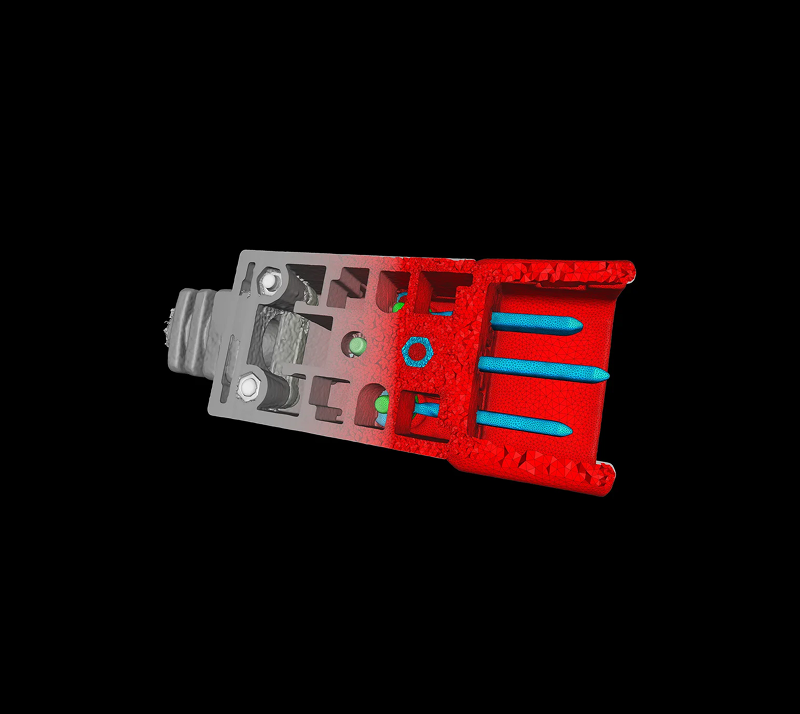

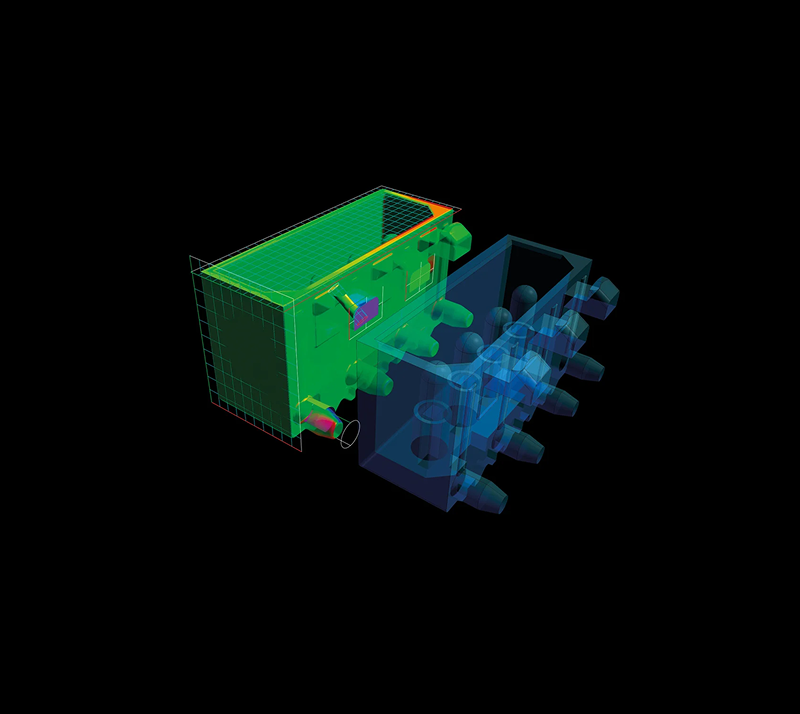

For casting and injection moulding (e.g., in the automotive and aerospace industry)

Includes these add-on modules:

- Coordinate Measurement

- Nominal/Actual Comparison

- Wall Thickness Analysis

- Porosity/Inclusion Analysis

For industries working with plastic injection molding and fiber composite materials

Includes these add-on modules:

- Coordinate Measurement

- Nominal/Actual Comparison

- Wall Thickness Analysis

- Porosity/Inclusion Analysis

- Fiber Composite Material Analysis

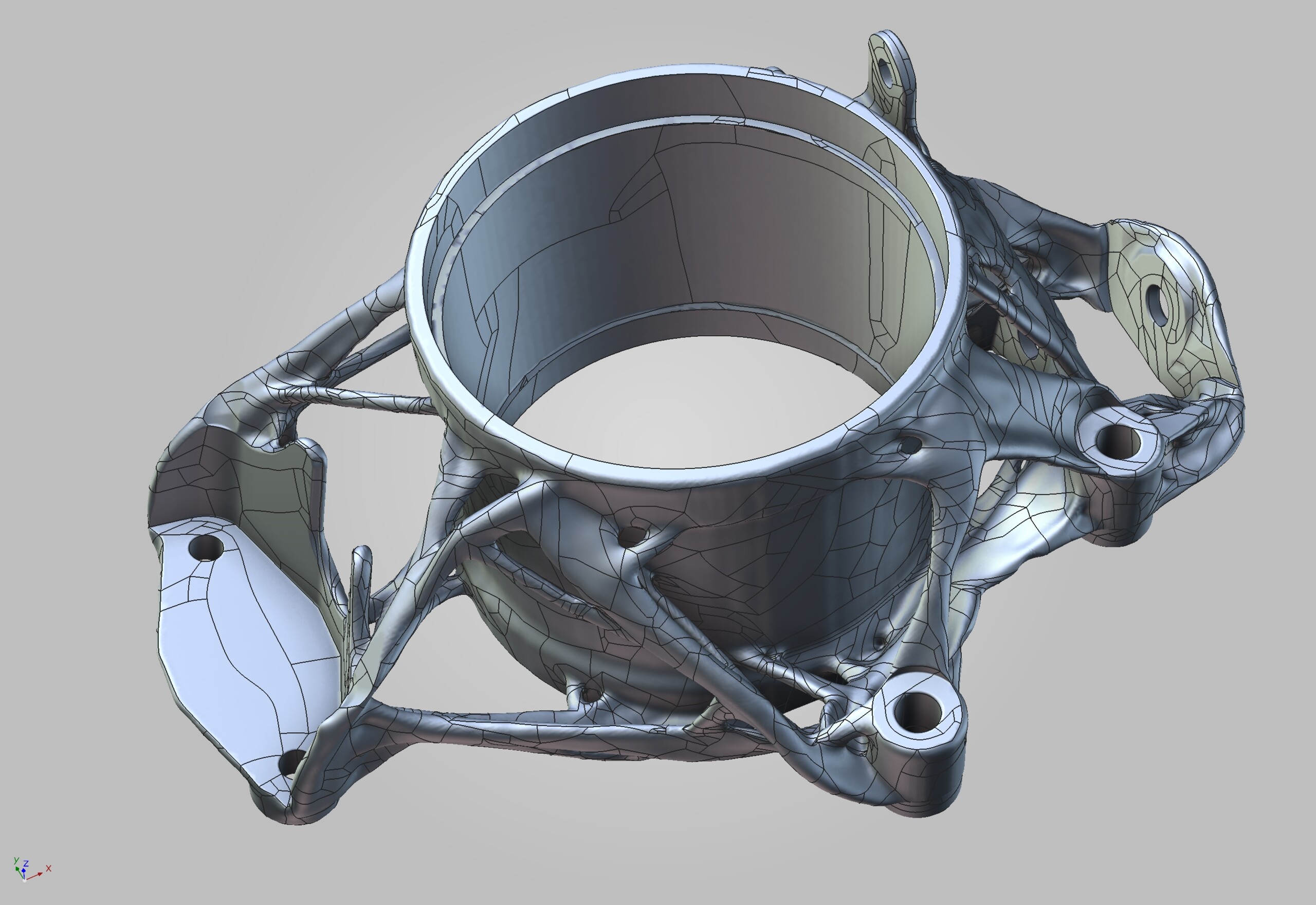

For the inspection of additively manufactured parts, including powders

Includes these add-on modules:

- Coordinate Measurement

- Nominal/Actual Comparison

- Wall Thickness Analysis

- Porosity/Inclusion Analysis

- Foam/Powder Analysis

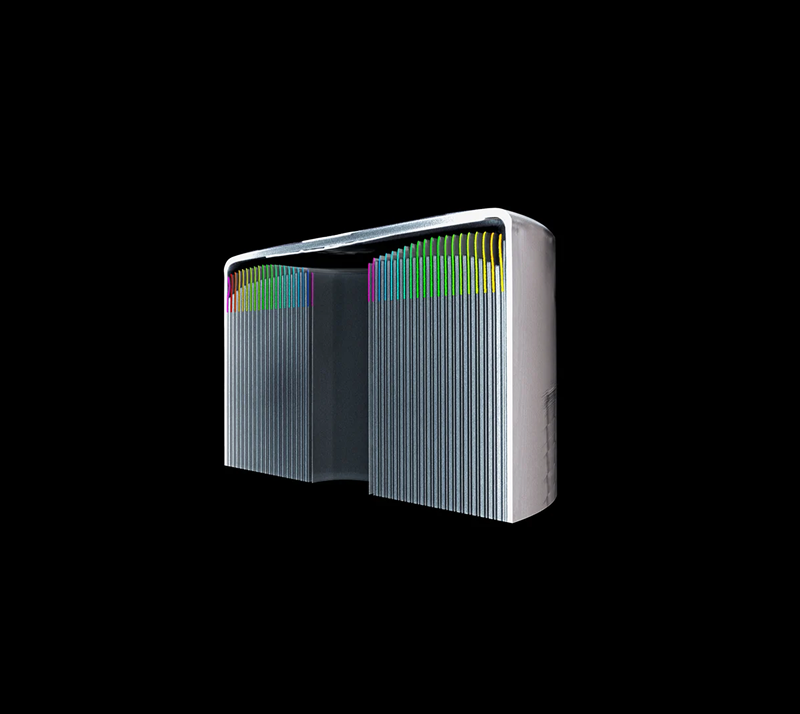

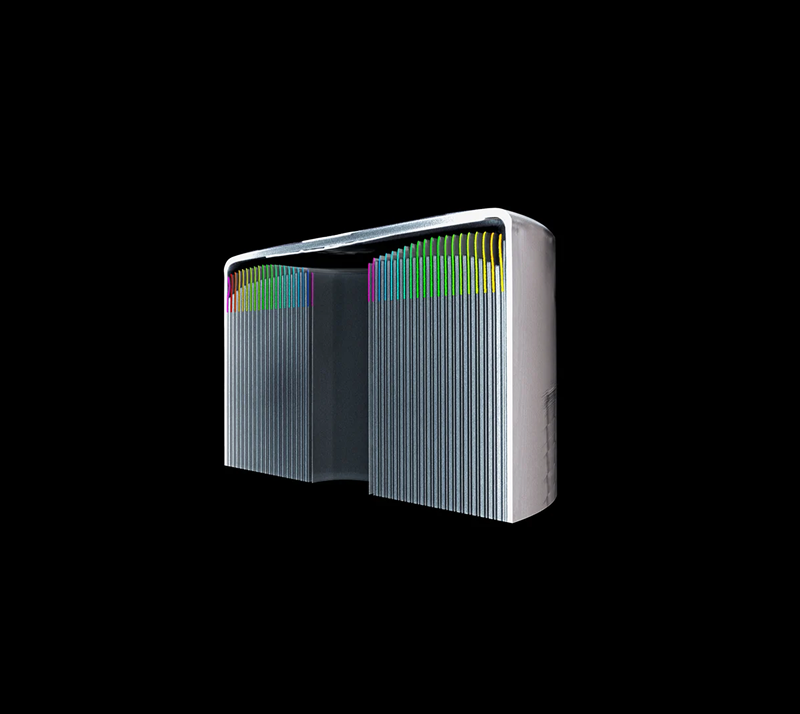

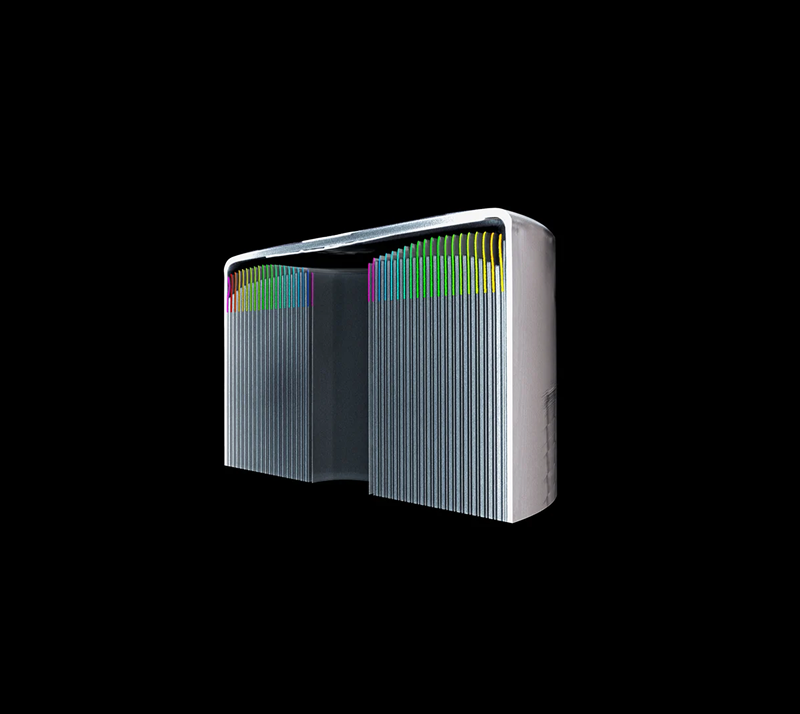

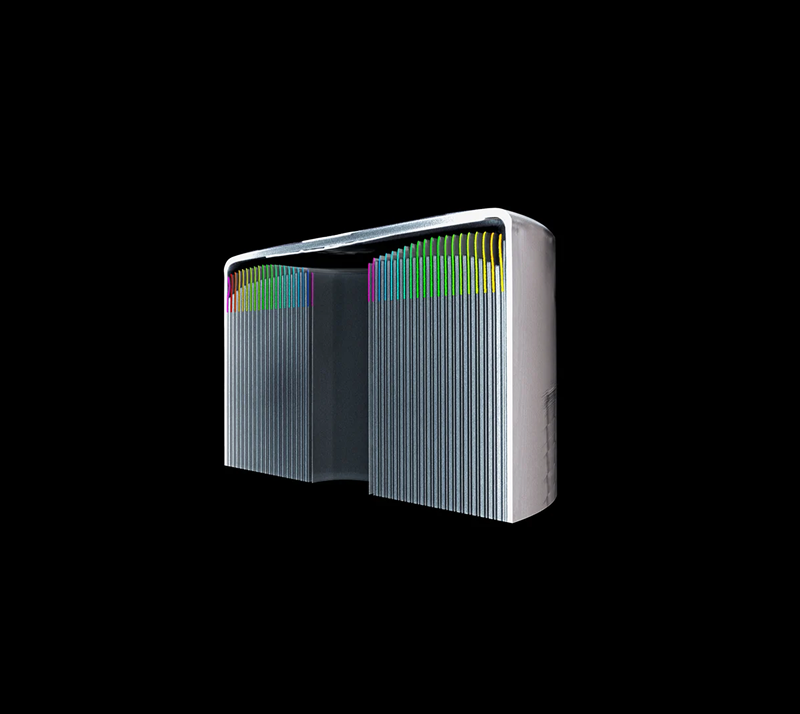

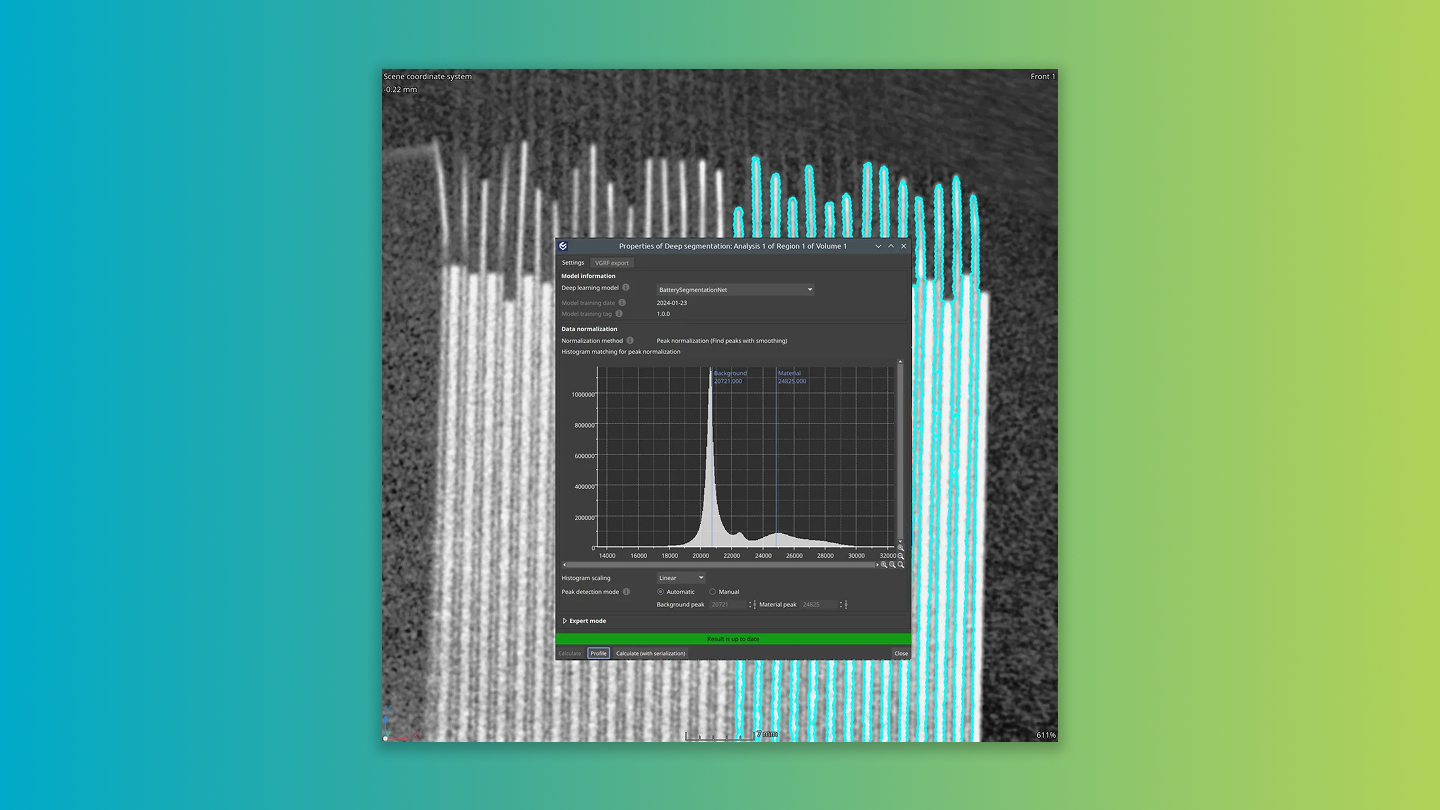

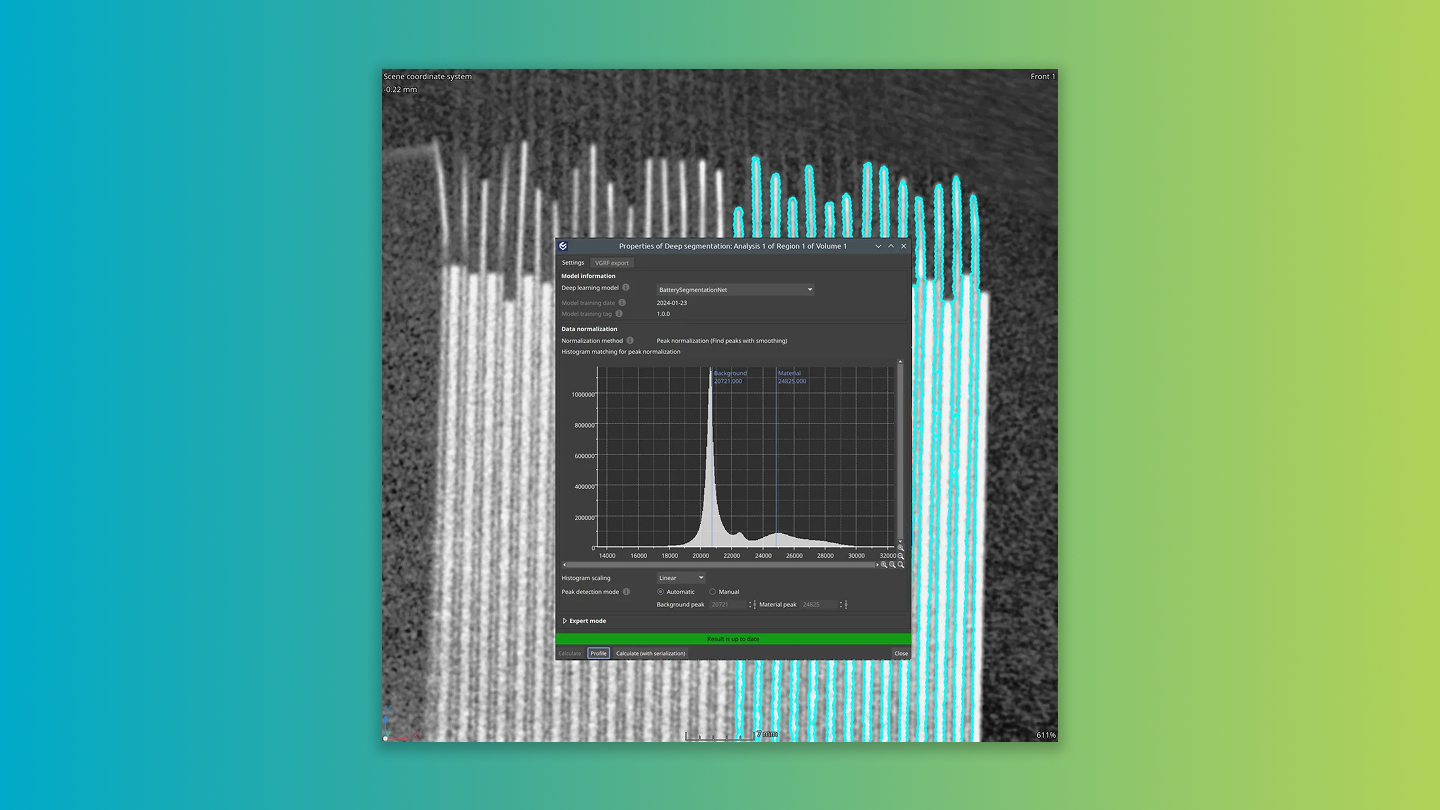

For the inspection of batteries, including finding and quantifying porosity, inclusions, anode overhang, and delamination

Includes these add-on modules:

- Coordinate Measurement

- Nominal/Actual Comparison

- Wall Thickness Analysis

- Porosity/Inclusion Analysis

- Battery Analysis

For advanced users in quality assurance labs who face different analysis and measurement tasks as part of their daily work

Includes these add-on modules:

- Coordinate Measurement

- Nominal/Actual Comparison

- Wall Thickness Analysis

- Porosity/Inclusion Analysis

- Manufacturing Geometry Correction

- Fiber Composite Material Analysis

- Foam/Powder Analysis

- Volume Meshing

- Structural Mechanics Simulation

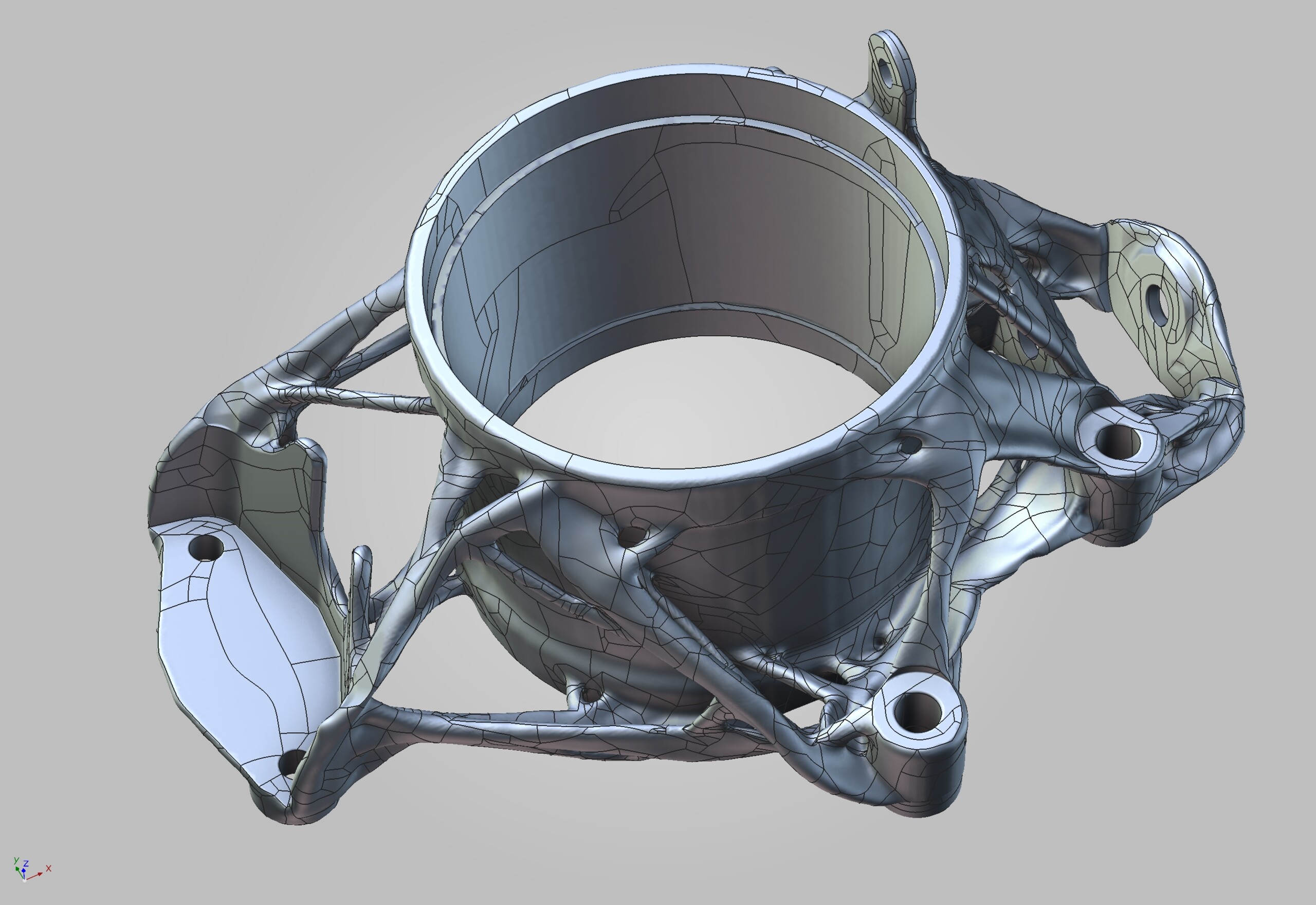

- Reverse Engineering

- Digital Volume Correlation

- CT Reconstruction (Cone/Fan/Parallel Beam, Special Algorithms (Helix, ART), and Planar)

- Deep Segmentation

For advanced users who need it all

Includes these add-on modules:

- Coordinate Measurement

- Nominal/Actual Comparison

- Wall Thickness Analysis

- Manufacturing Geometry Correction

- Reverse Engineering

- Fixture Simulation

- CAD Import*

- PMI Extension for CAD Import*

- Porosity/Inclusion Analysis

- Fiber Composite Material Analysis

- Foam/Powder Analysis

- Digital Volume Correlation

- Volume Meshing

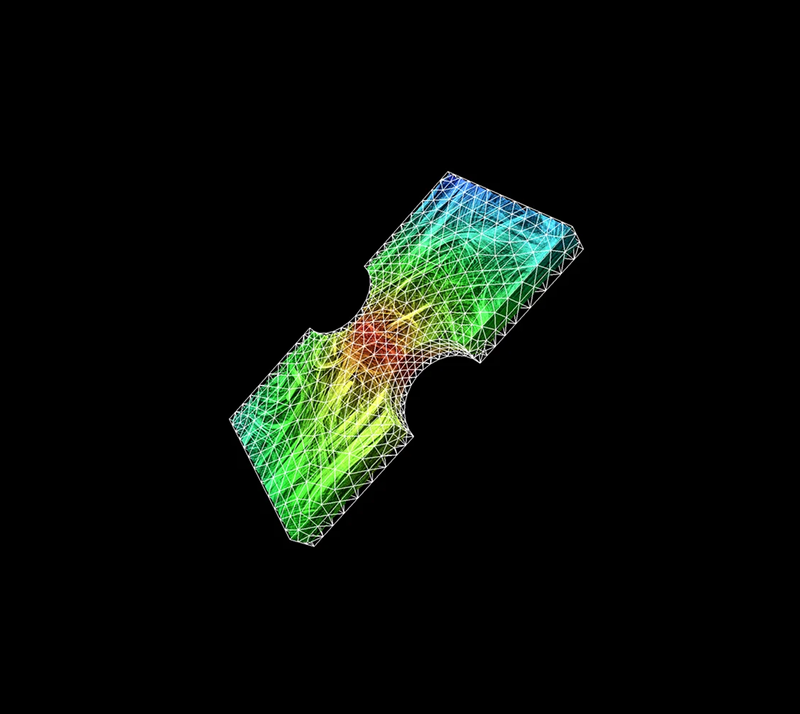

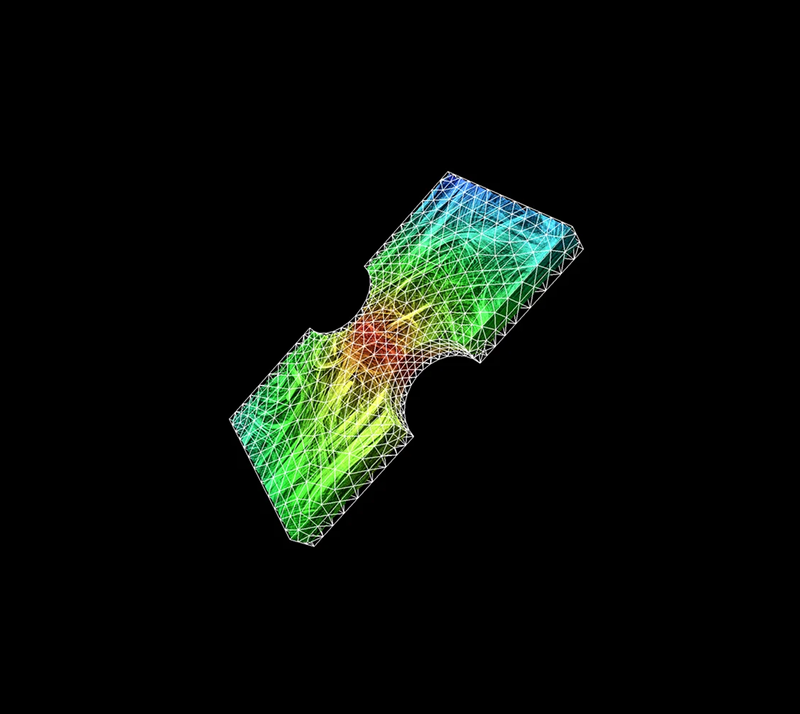

- Structural Mechanics Simulation

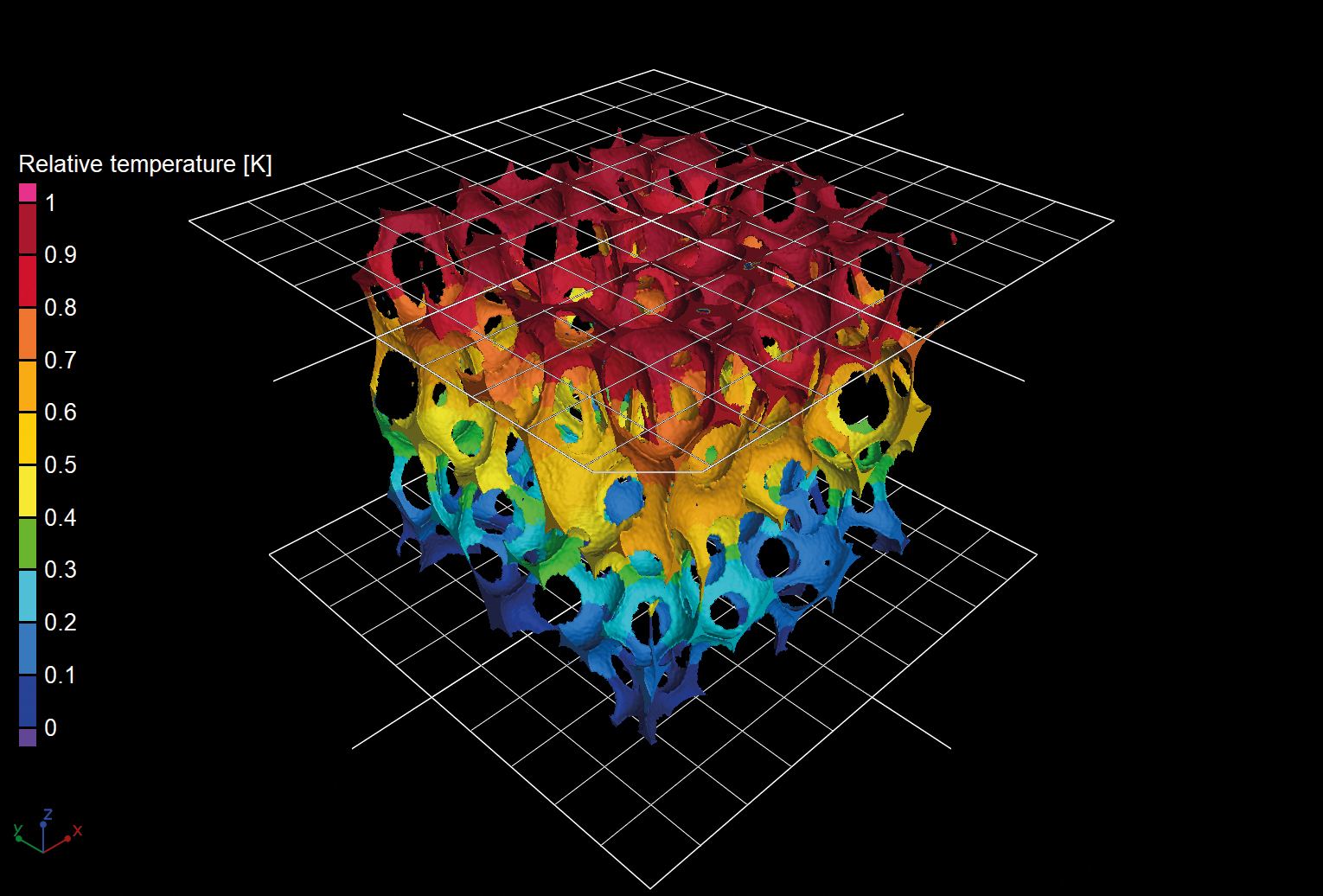

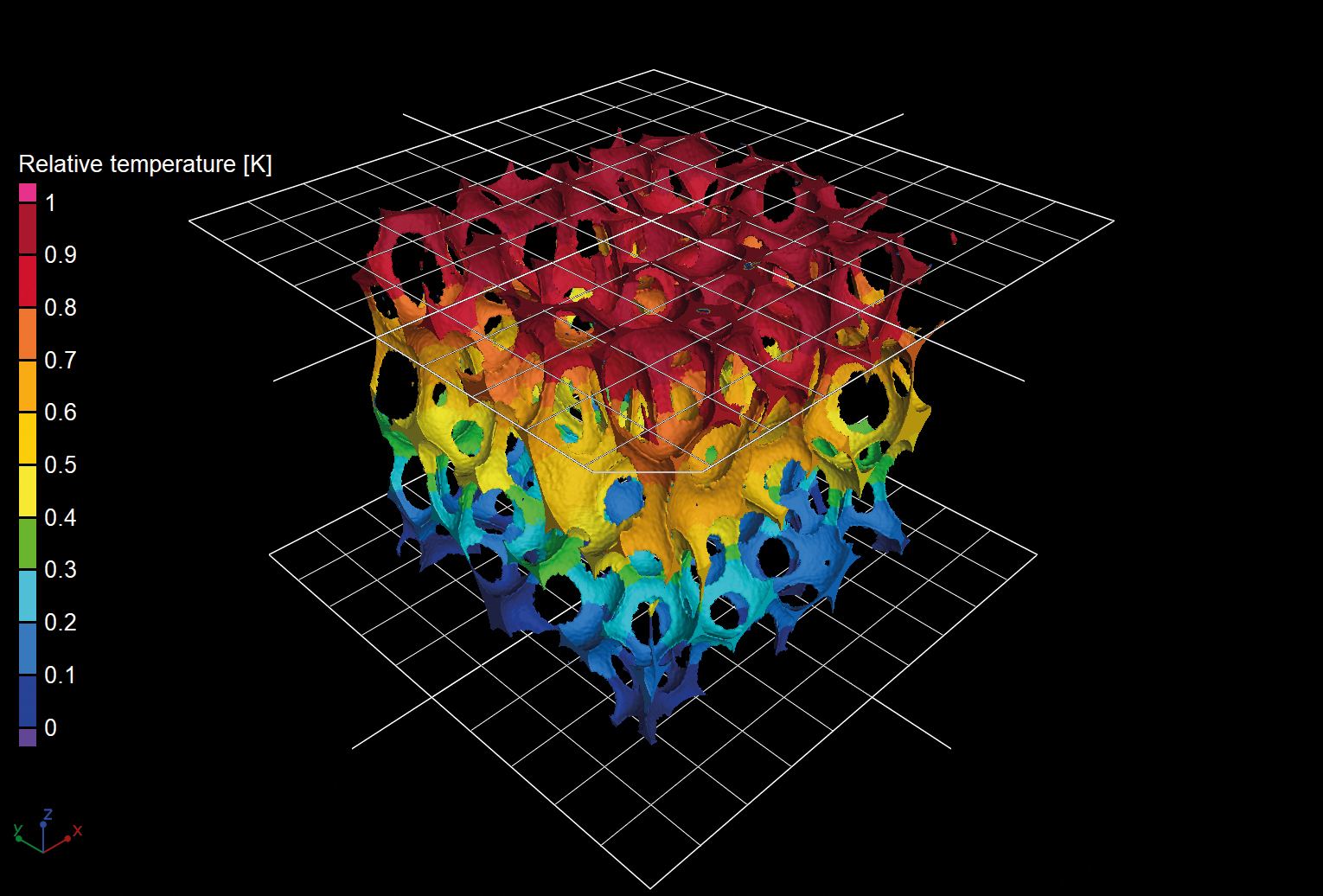

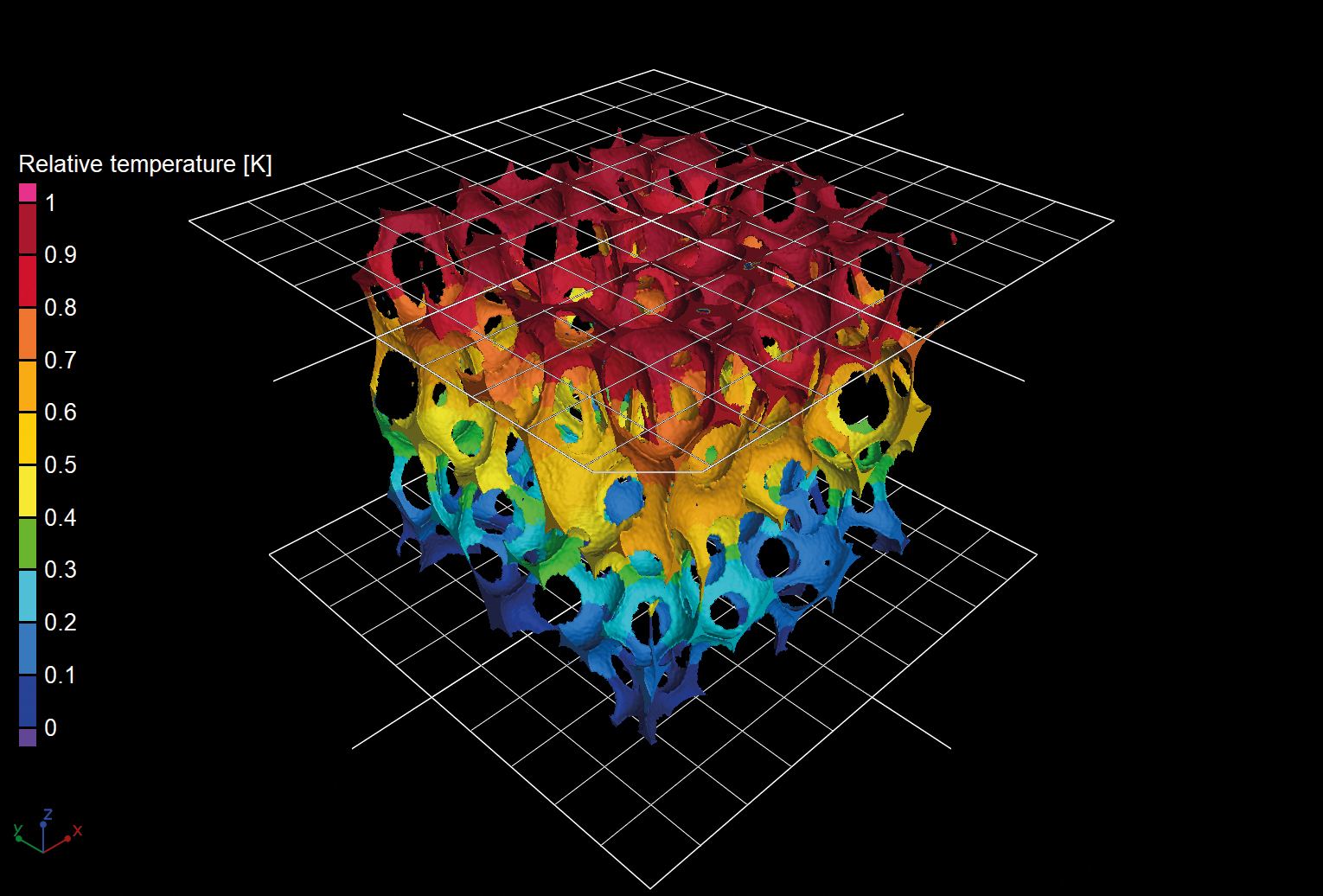

- Transport Phenomena Simulation

- Battery Analysis

- CT Reconstruction (Cone/Fan/Parallel Beam, Special Algorithms (Helix, ART), and Planar)

- Deep Segmentation

*CAD Translation Technology supplied by Tech Soft 3D

Get your free, 4-week trial license and see why we're the industry’s first and longest-trusted CT analysis software.

Request free trial

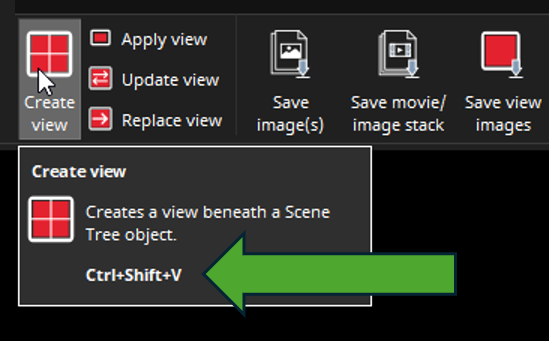

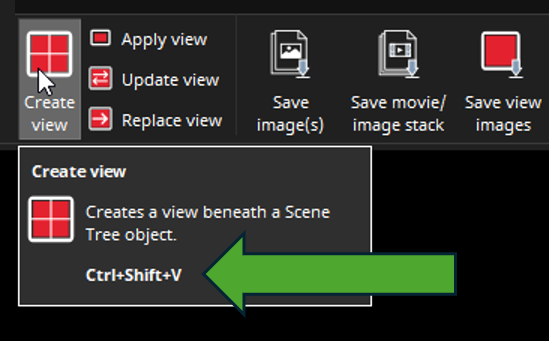

Define and apply visualization and workspace settings as "Views" for individual objects, enhancing project navigation and report generation. Easily transfer these views between objects and incorporate them into evaluation templates for streamlined automation.

Experience precision at its finest. Leverage our automatic and numerically validated method to counteract beam hardening artifacts. This isn't about making educated guesses — it's about employing precise calculations for accurate compensation results.

Enhance your reports with interactive 3D color overlays for geometric tolerances, facilitating a better understanding of numerical results.

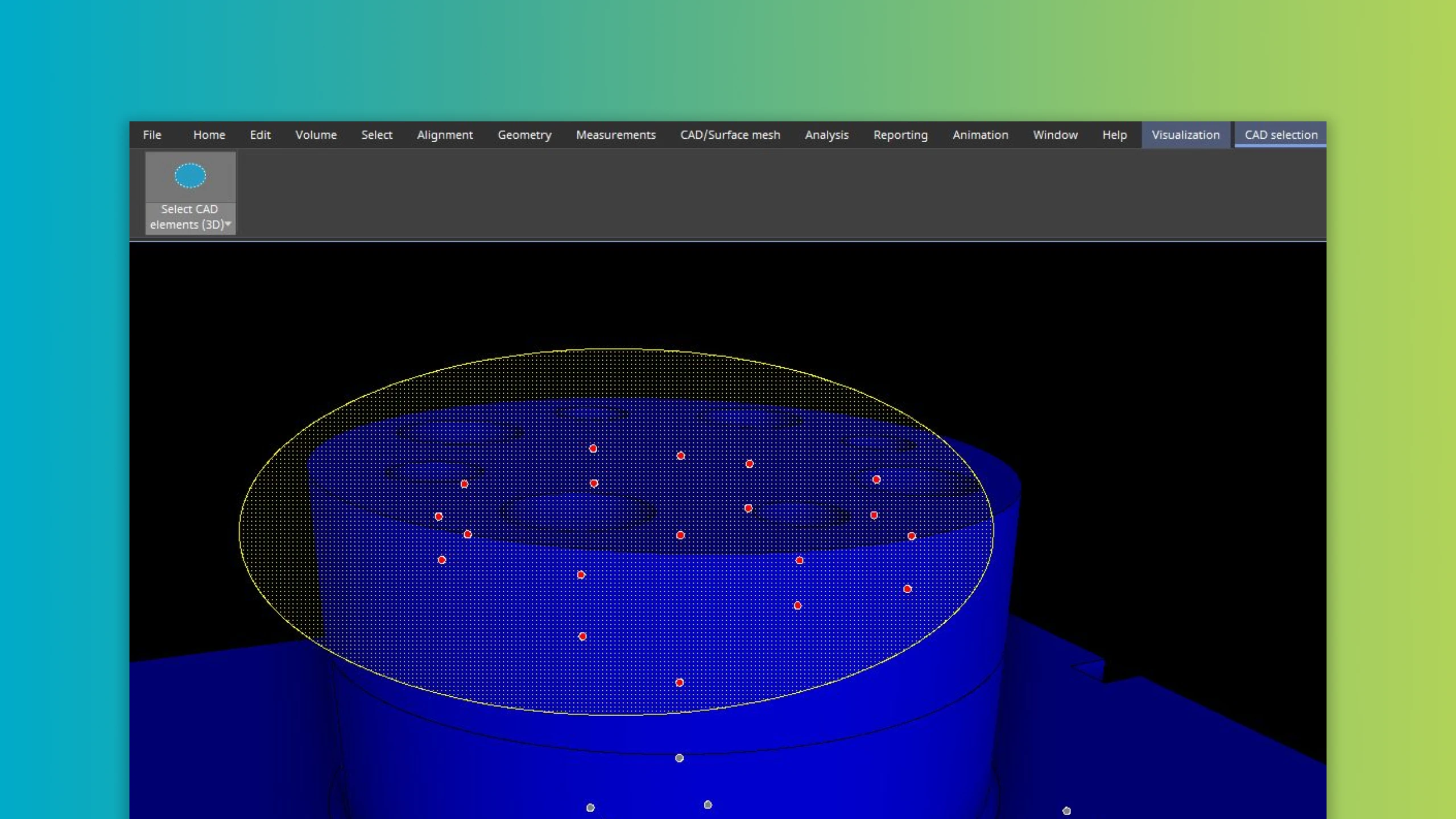

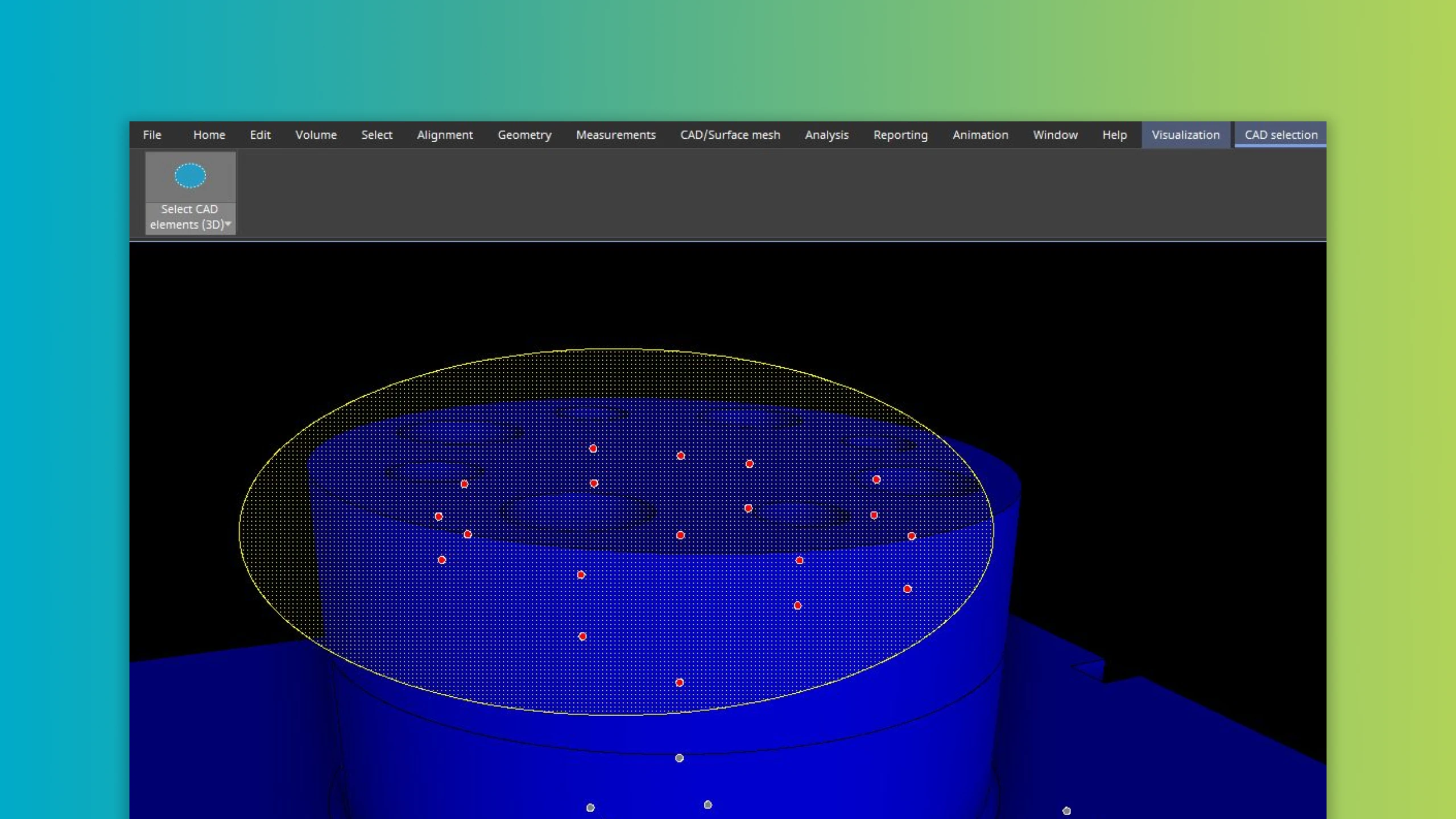

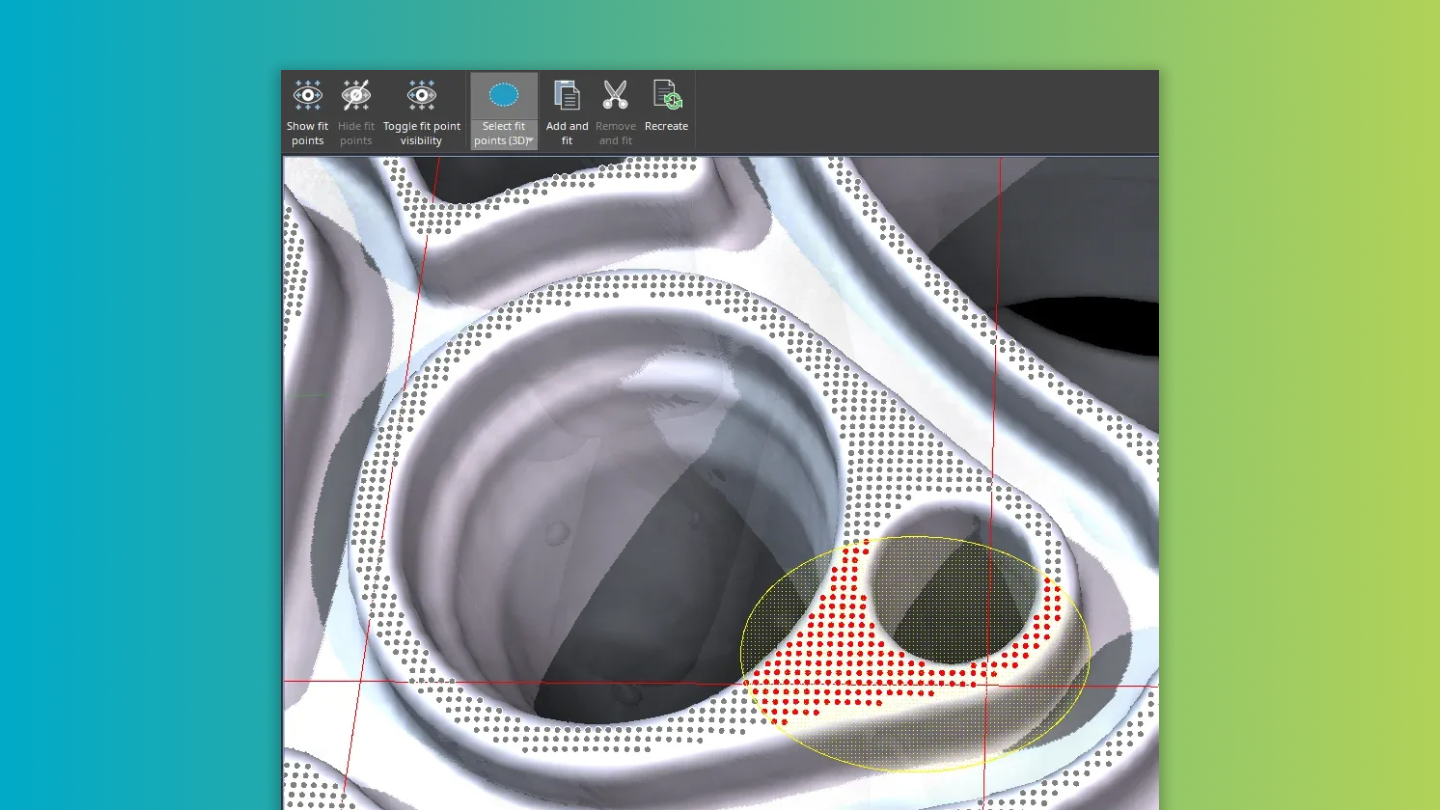

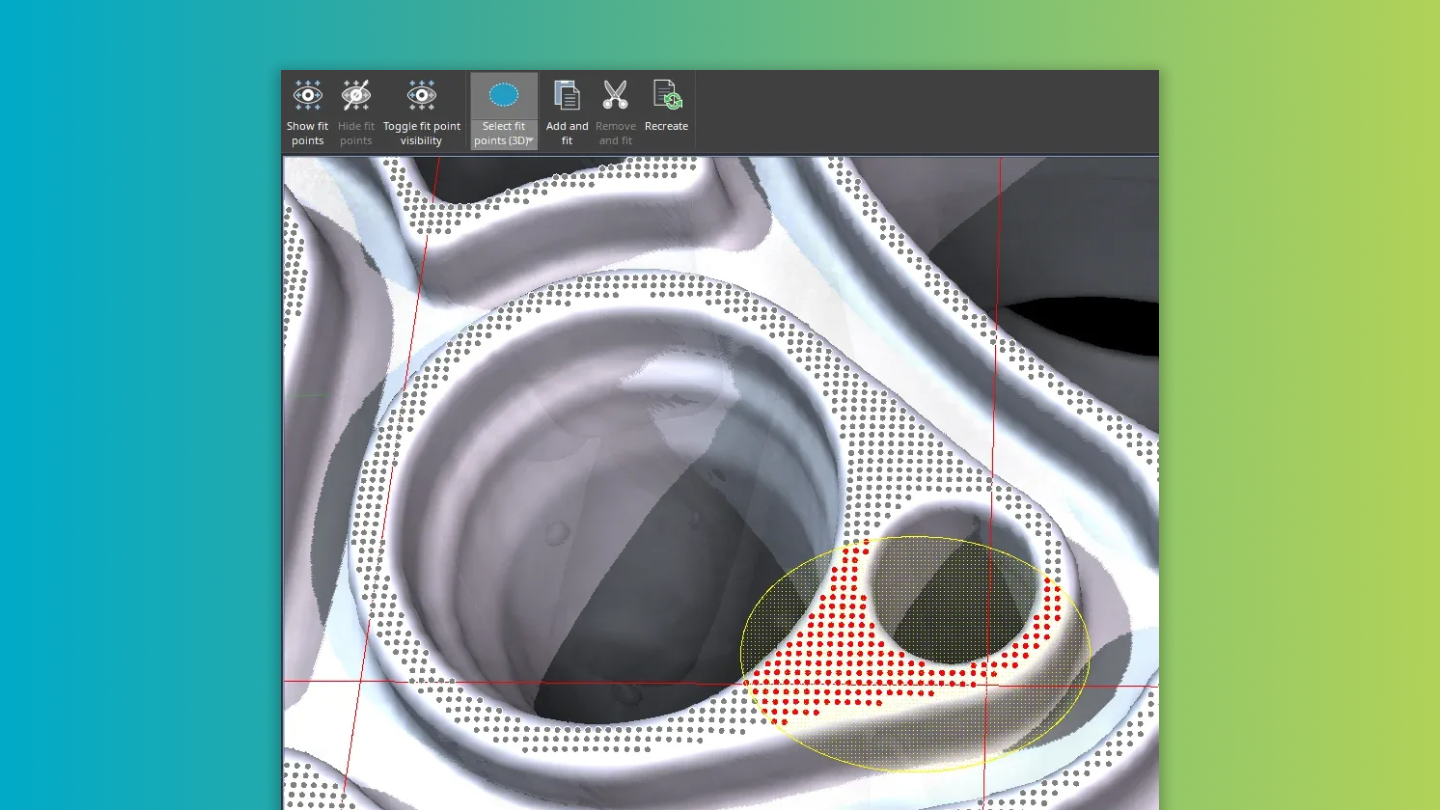

Select multiple CAD faces effortlessly using intuitive tools like rectangle, ellipse, and lasso in the 3D view. This feature simplifies working with complex components, aligning with object and fit point selections.

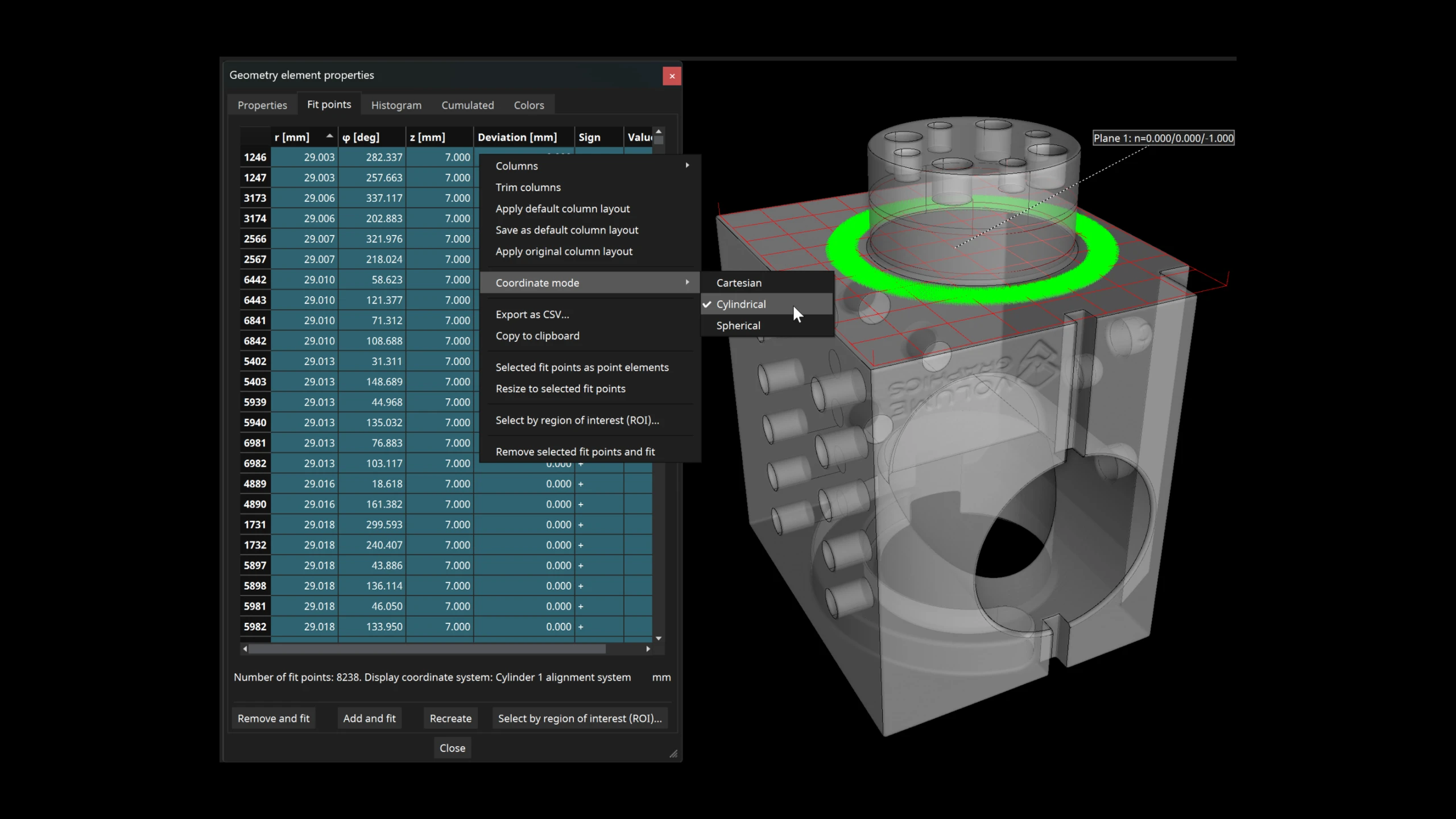

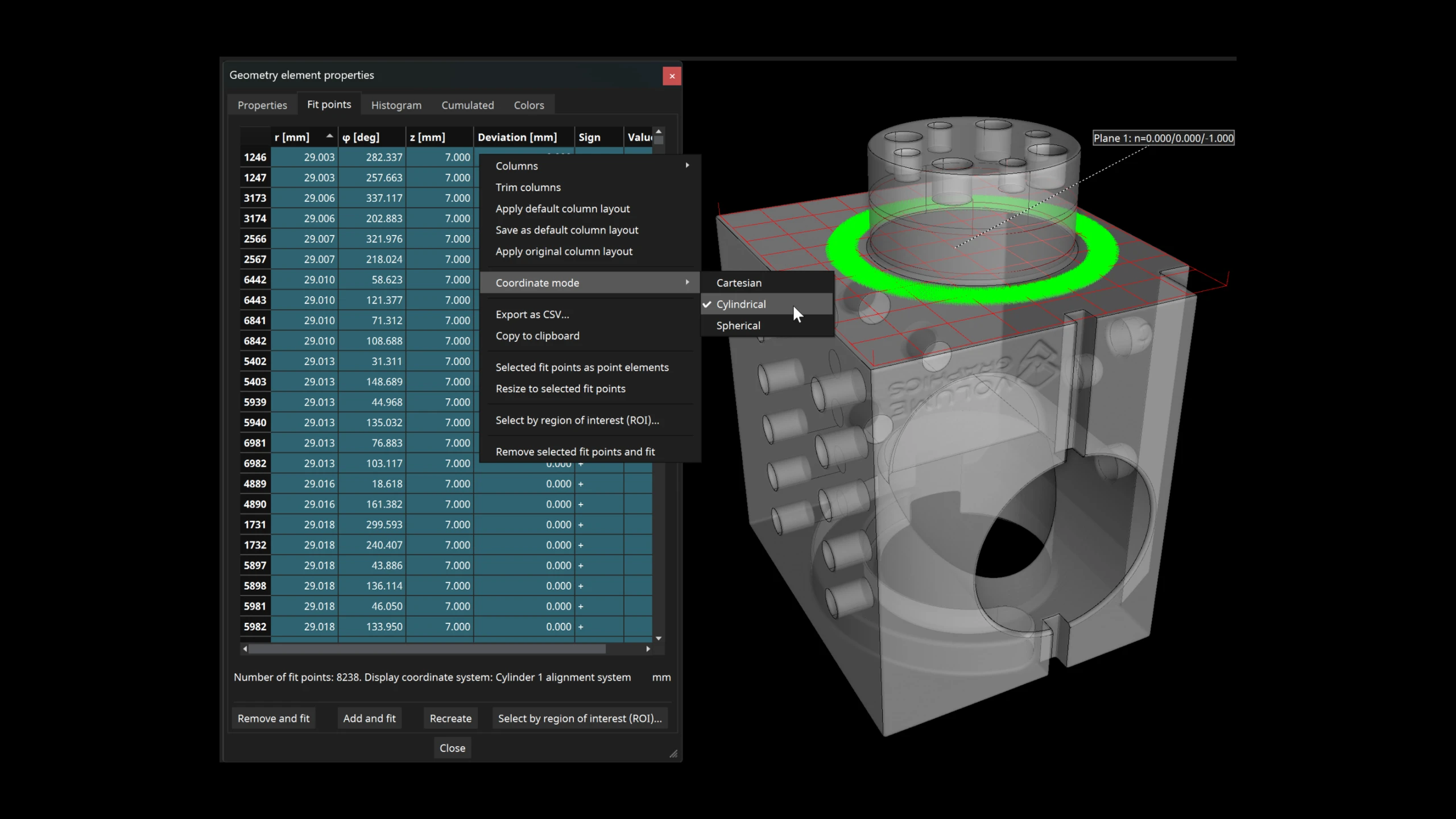

Switch fit point tables to cylindrical or spherical coordinates for rotational symmetric parts, enhancing import, export, and editing processes.

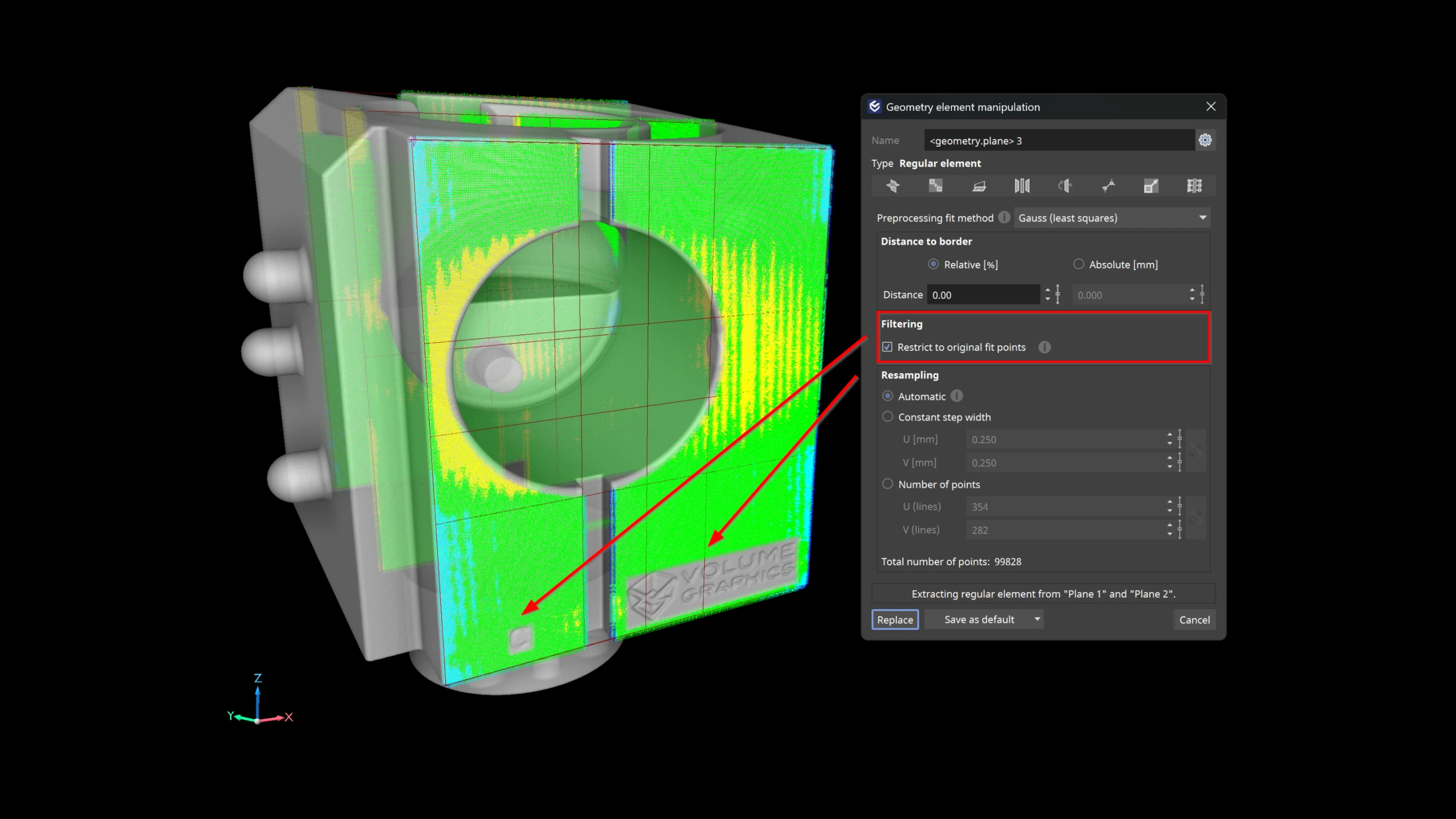

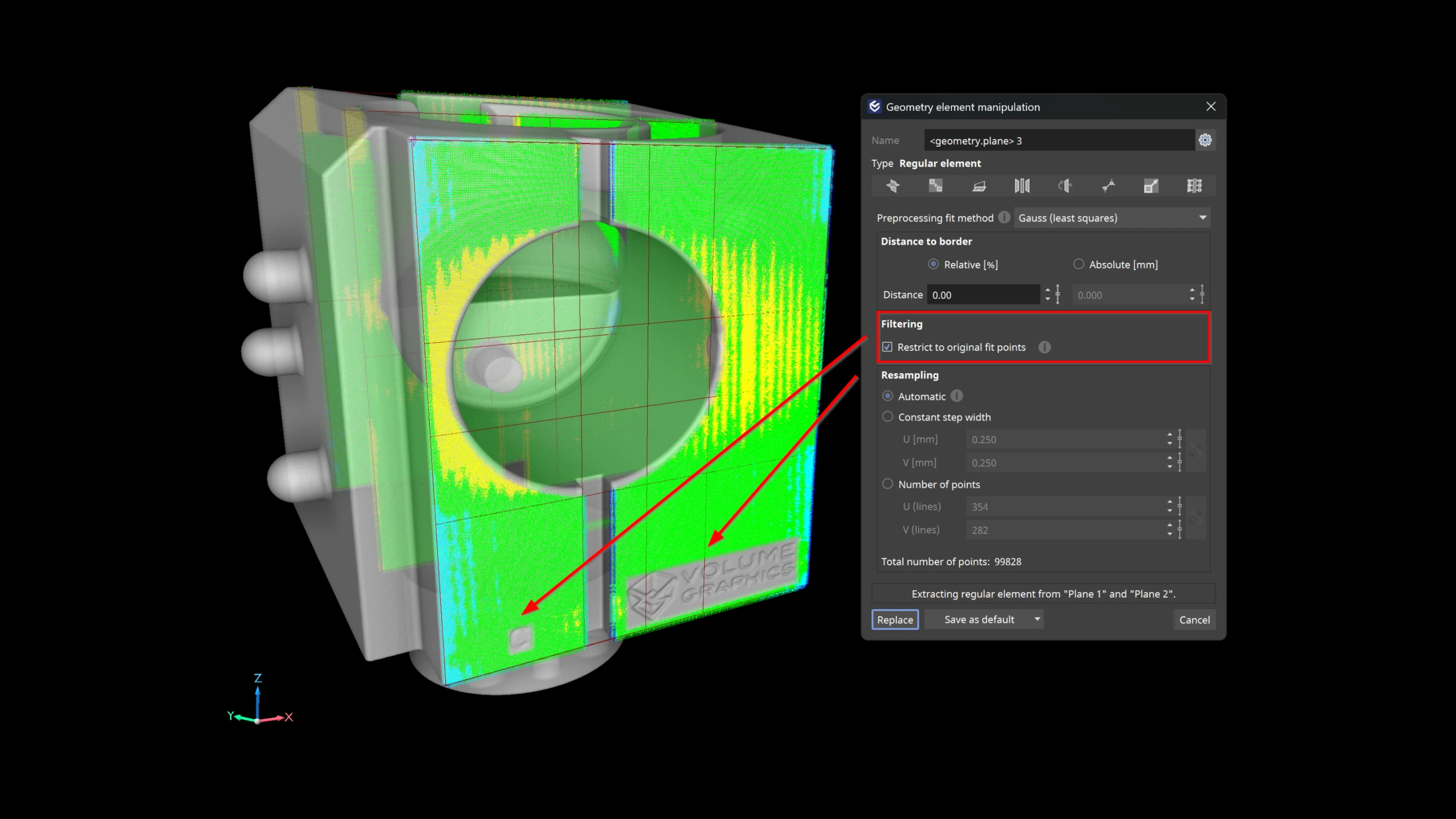

Ensure regular elements only sample fit points in desired areas with the "Restrict to original fit points" option. This avoids sampling in unwanted regions, maintaining accuracy in measurements.

Experience faster calculations for advanced surface determination on extracted ROIs and benefit from increased flexibility in workflow timing, either pre- or post-volume data split.

Shortcut display in ribbon tooltips

Streamline data processing with the new .xvgi file format, eliminating the need for manual data import. Utilize our Python reference implementation to automate VG software use, even without existing .vgl files.

Easily identify tags of interest in DICONDE metadata with the display of tag numbers in the object properties, enhancing data review processes.

Focus on actual deviations with auto-scaled color mapping that excludes outliers. This ensures color overlays provide valuable part evaluations without distortion.

The selected color overlay and "Show components only" checkbox are now stored and applied to all automated image generation functions including bookmarks, animations, and object-specific views. This enhances your options for reports and presentations.

VG software is now fully compatible with Ubuntu 22.04, ensuring support for modern Linux distributions.

Run VG software flexibly on virtual machines using floating licenses, expanding infrastructure options.

Learn how to speed up your workflows with the "Automation" tool in VGSTUDIO MAX or VGMETROLOGY. Automate part of your workflow by creating macros for single workflow steps, or create an inspection plan, a so-called job, and automate your entire inspection. The job file includes all necessary data for the inspection and can easily be shared with colleagues and customers for its use with other at-line- or in-line CT systems.

Designed especially for cases where multiple parts are scanned together, this intuitive feature allows users to easily divide the original volume data into individual volume objects. Beyond simplifying your workflow, this tool offers options for powerful segmentation, naming, and data reduction methods. Plus, automation has never been easier, with built-in features to detect missing parts and generate unique project files for each separated object.

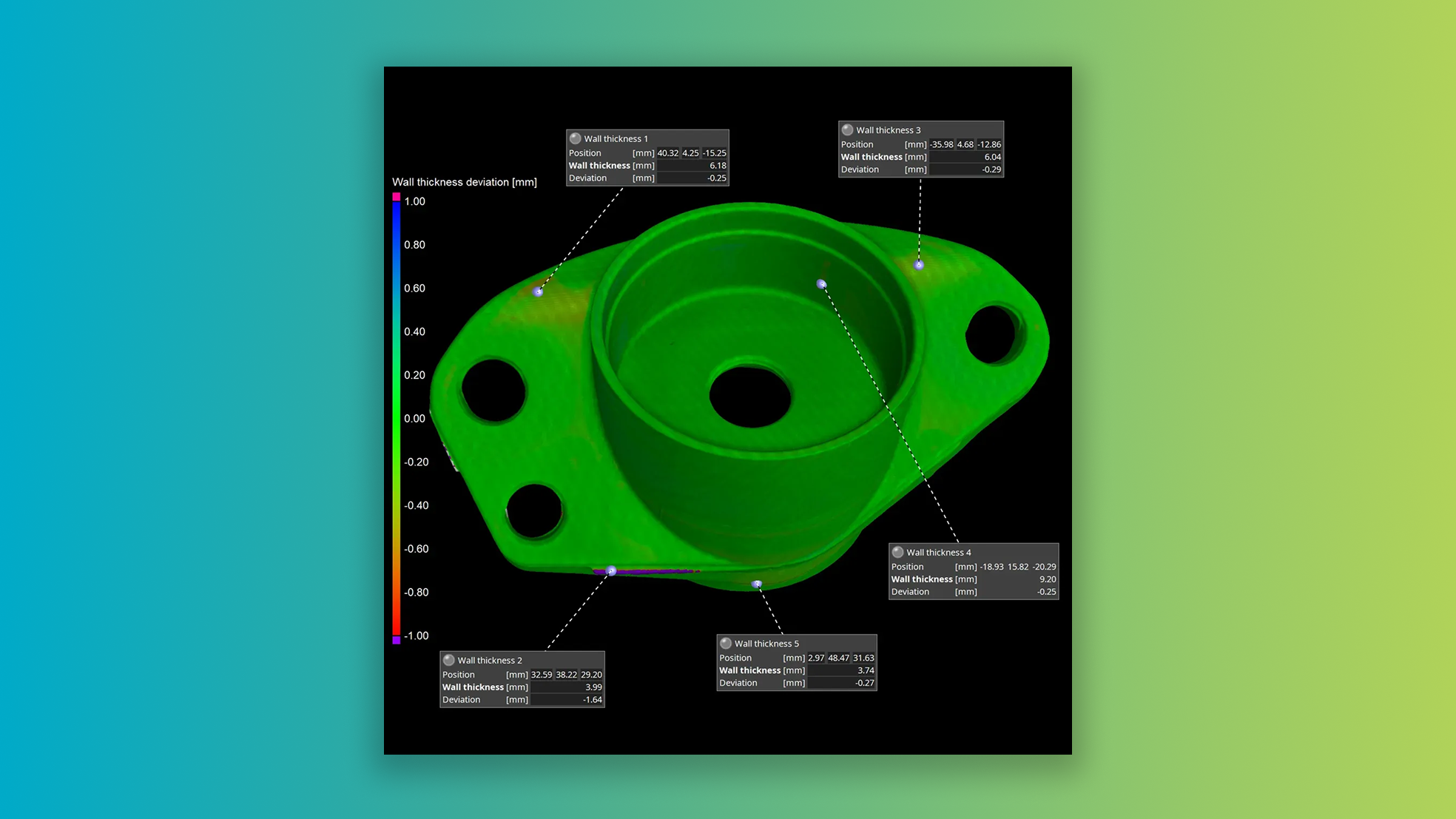

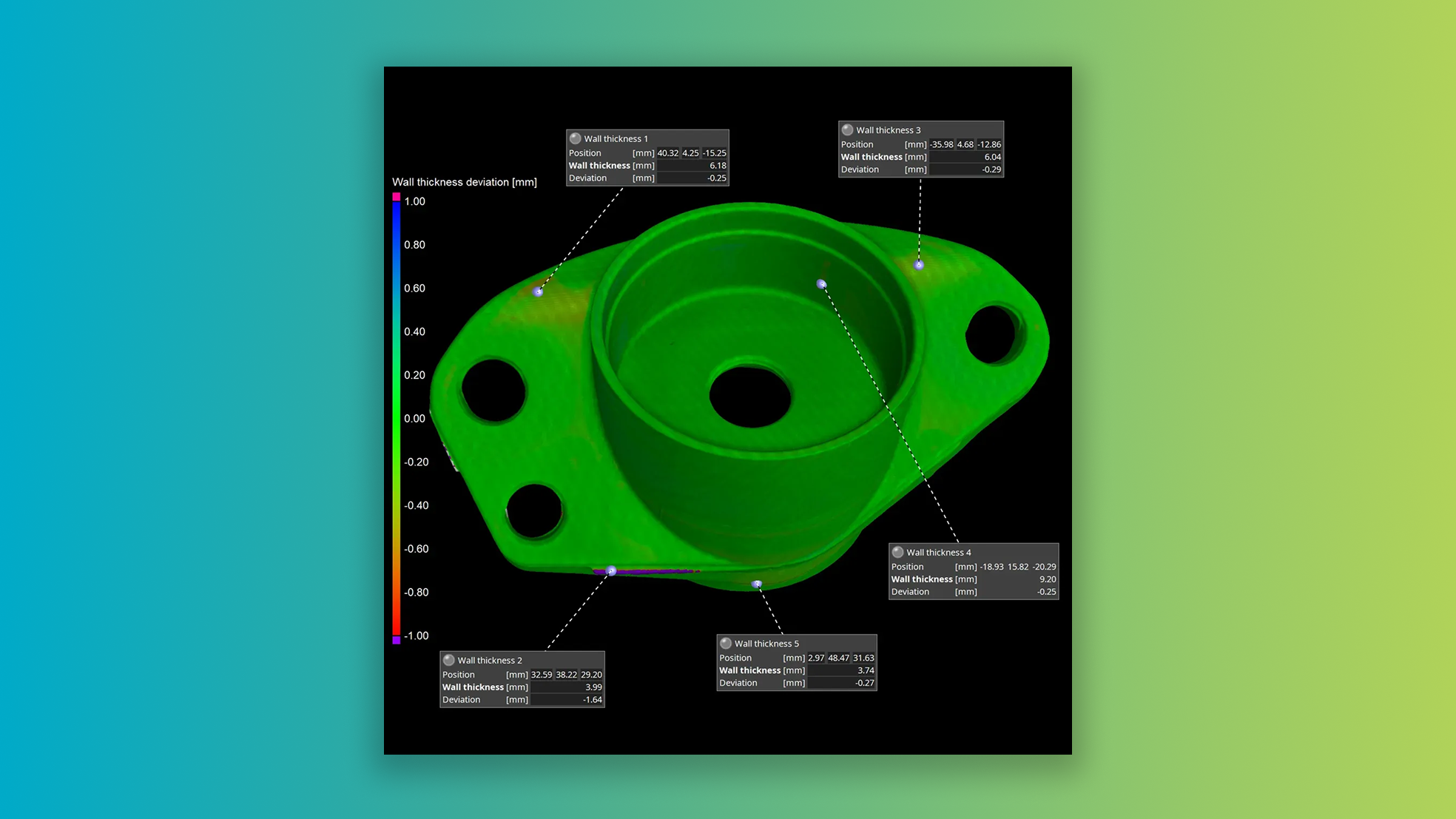

This innovative tool lets you evaluate deviations using percentual values, widening your analysis scope. Benefit from comprehensive insights into your component's stability over a full range of values, including absolute wall thickness, absolute deviation, and percentual deviation from the nominal value. Effortlessly analyze percentual deviations with features like color overlay, histogram, tolerances, and individual annotations.

Q-DAS export for relative wall thickness results

Elevate your data analytics with seamless exporting of toleranced relative wall thickness results in Q-DAS format. Enjoy superior compatibility and integration with the Q-DAS product family.

Easier navigation of PDF reports

PDF reports now also include a table of contents with direct links to the related section of the report. Enhance your user experience and swiftly peruse your reports with this clever addition.

Dive into a whole new interactive experience of creating regions of interest (ROIs) with the "Rectangle 3D" and "Ellipse 3D" ROI creation functions. Straightforward to use, these features let you use simple primitives (rectangle and ellipse) in the 3D view to create volumetric ROIs. Similar to polyline 3D, but without polyline complexity, just click and drag to get your ROI done.

When you move or rotate a region of interest (ROI) or copy it from another object, its mask may not be aligned with the voxel grid of the parent volume. This useful feature allows you to see this status at a glance in the Scene Tree or in the object properties. One click is enough to get the ROI aligned, an action that can also be recorded for automated scenarios.

Peer-to-peer collaboration is now easier than ever! Use the new link in the title bar to hop over to the VG Community on Nexus. Share your wins, get advice, and stay up to date on the latest and greatest in your products.

In this video, we will show you how to perform the analyses required for fixture simulation, record the necessary macros, and combine the macros to a job that you can eventually run in VGinLINE.

Click here to watch the video tutorial.

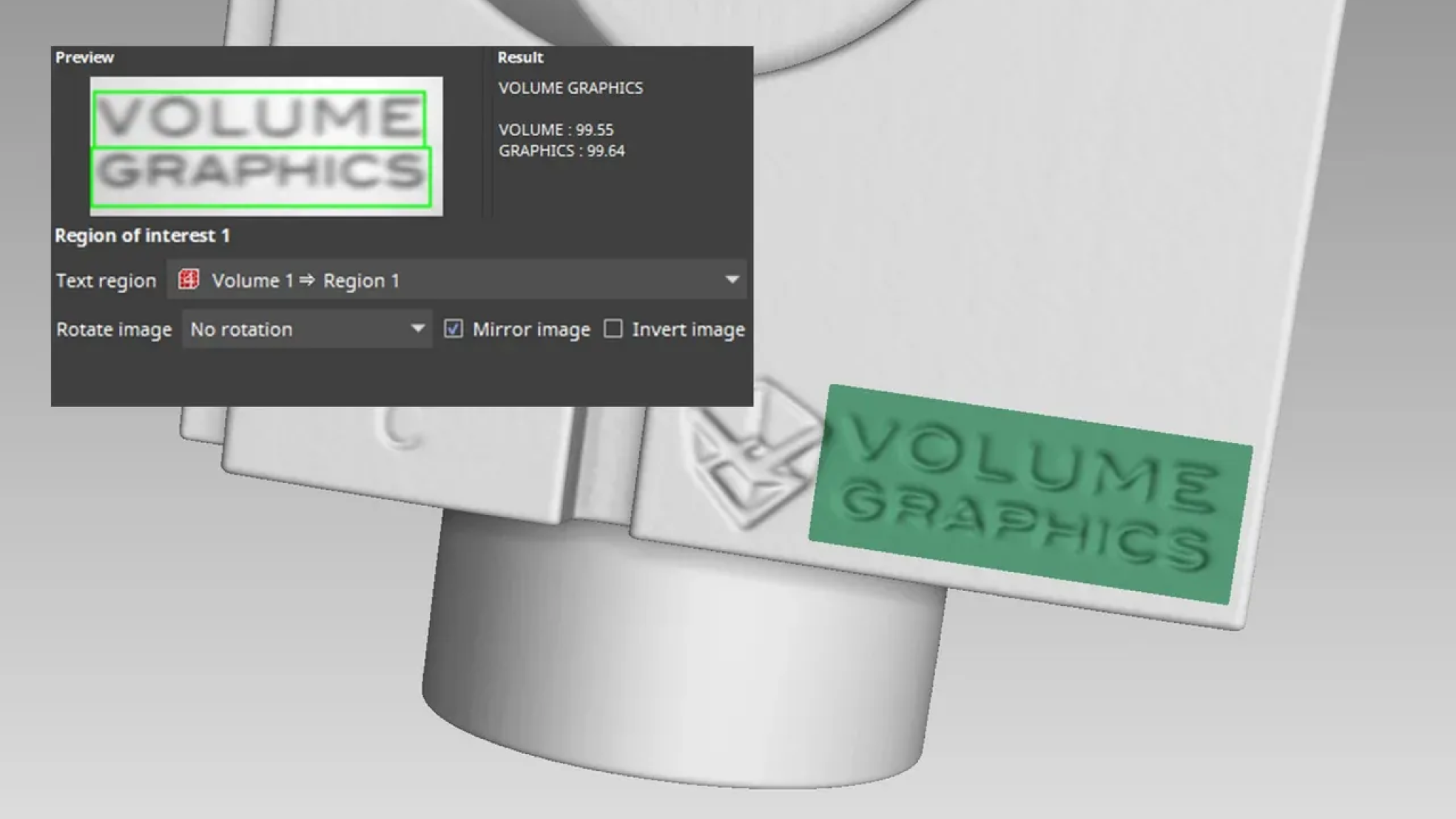

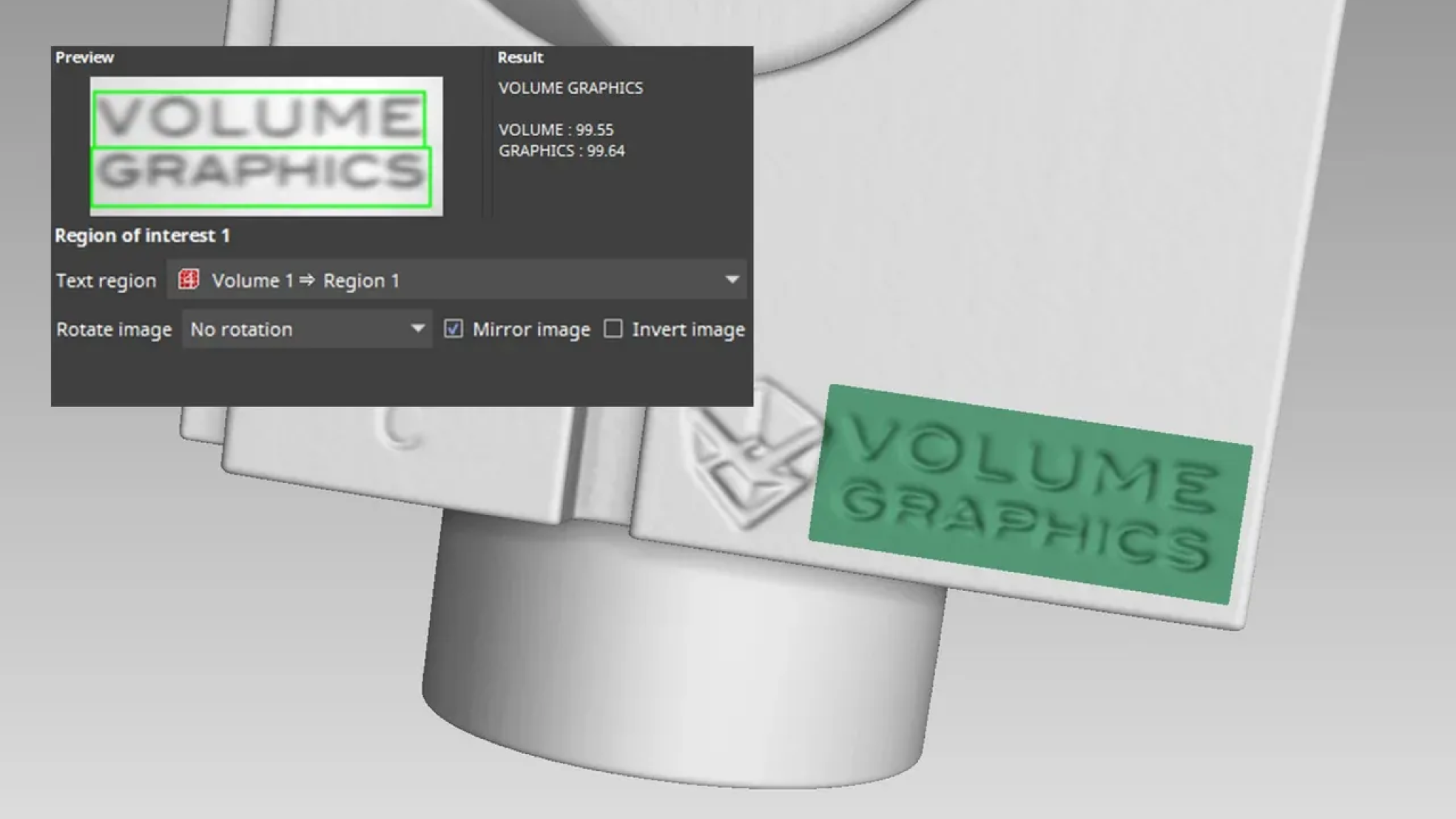

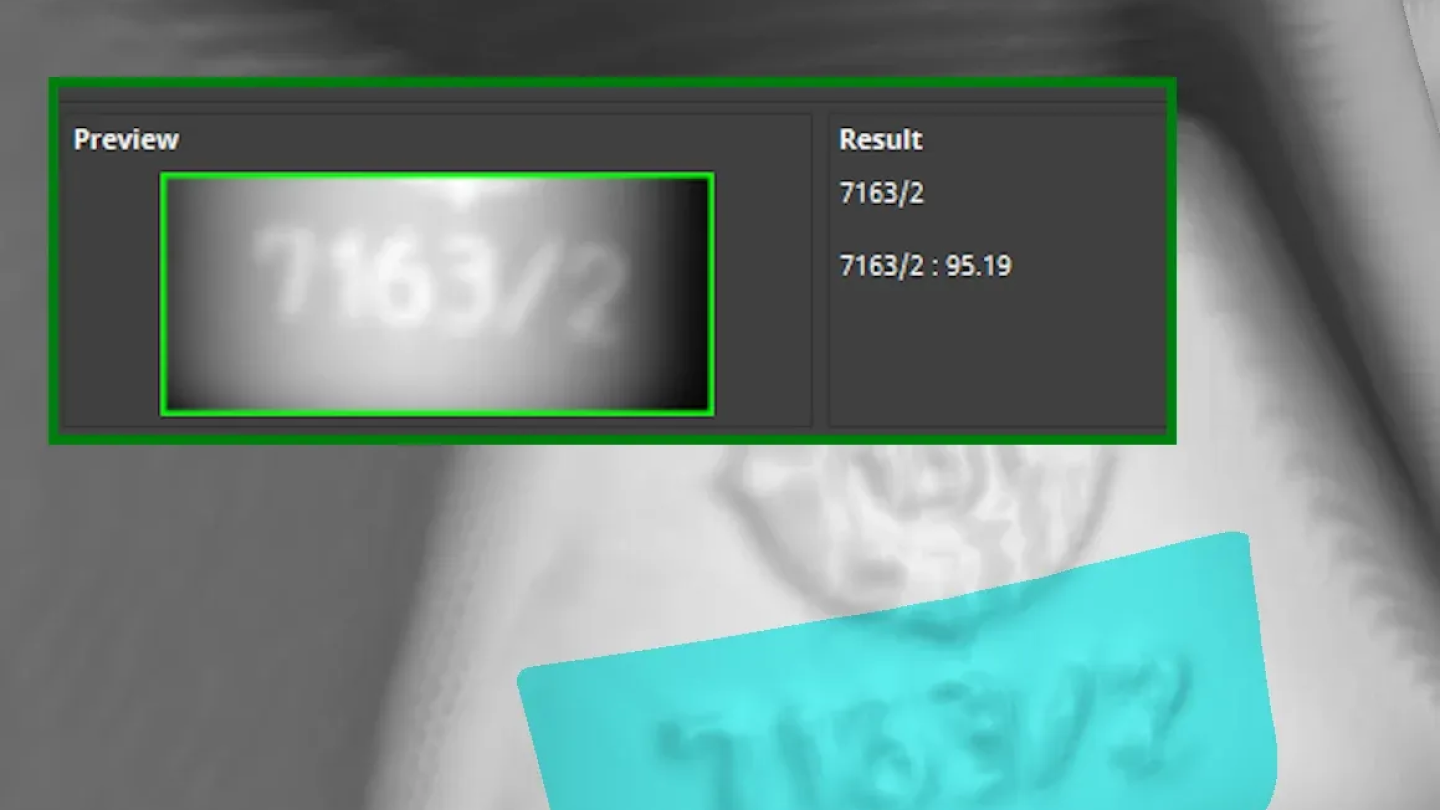

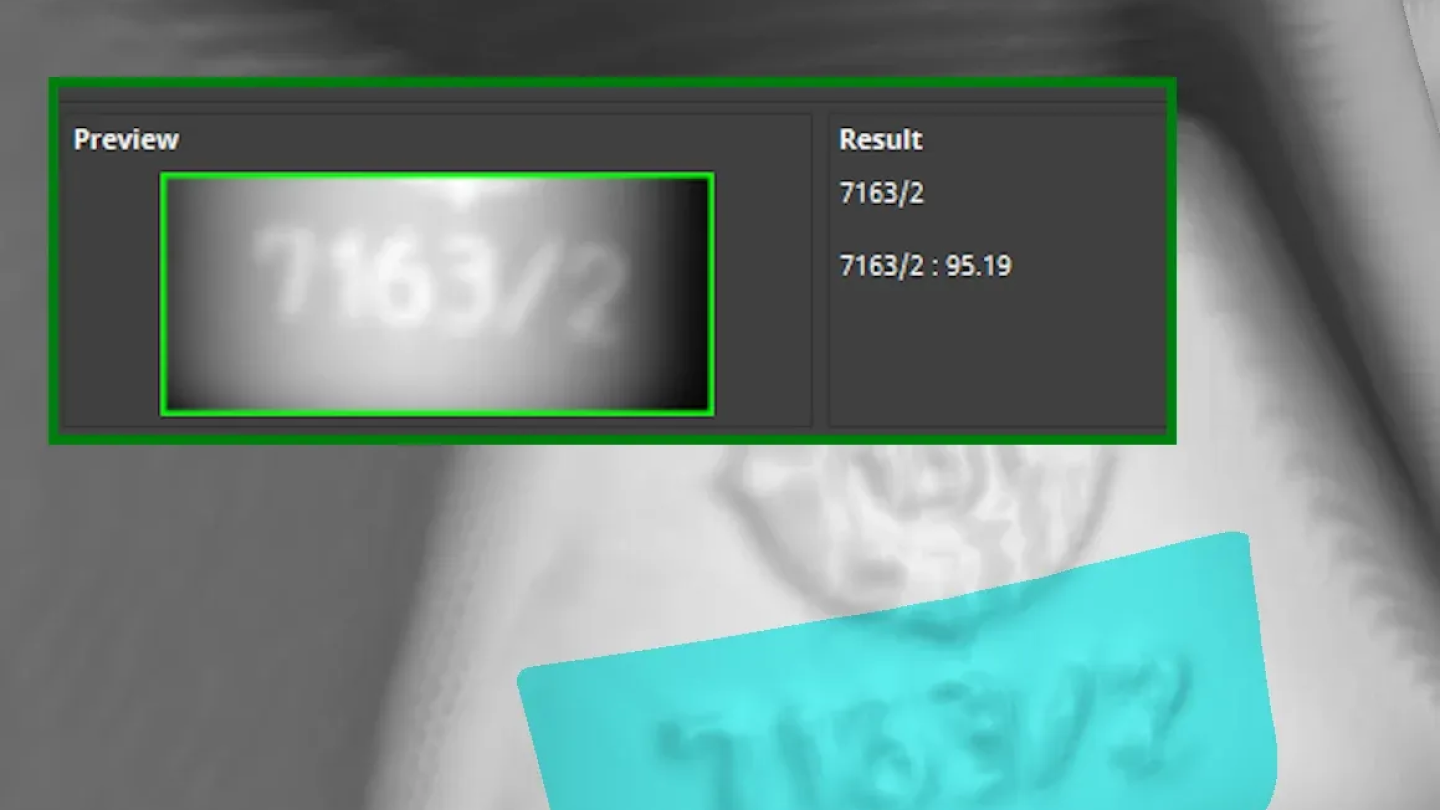

In our video tutorials on the OCR analysis, we will show you two different approaches of how to perform text recognition in VGSTUDIO MAX:

- Performing an OCR analysis using geometry element-based ROIs

- Performing an OCR analysis using manually defined ROIs

Click here to watch the video tutorials.

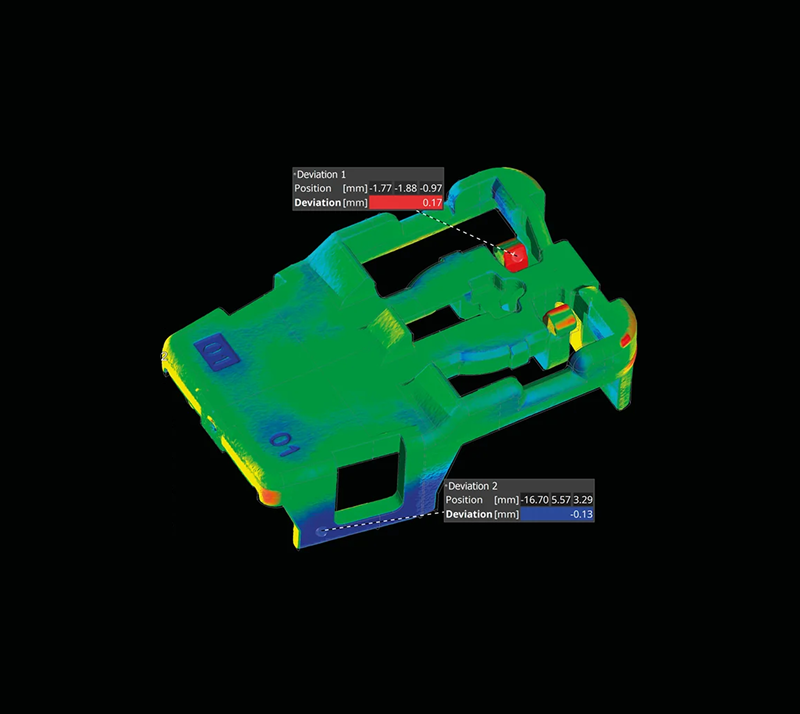

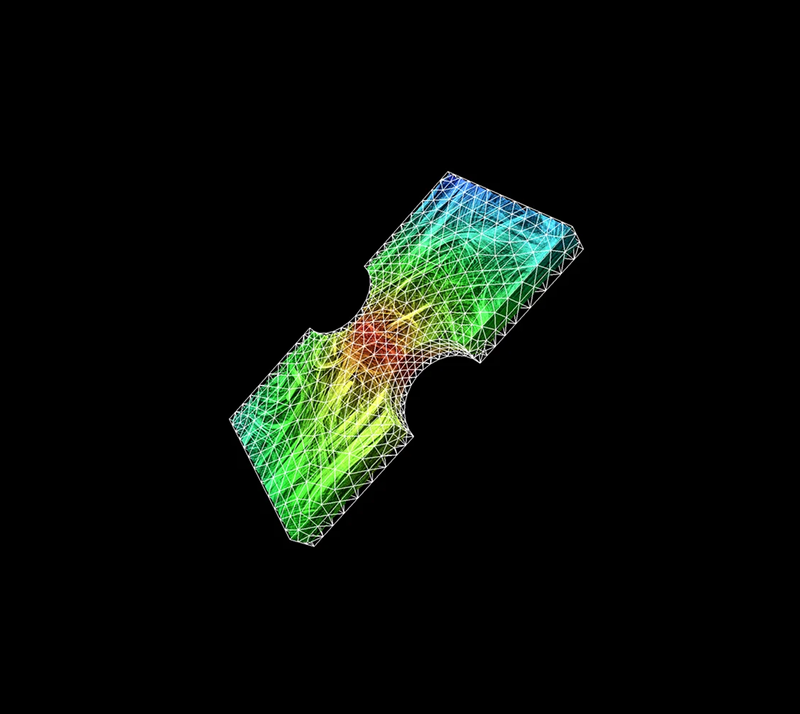

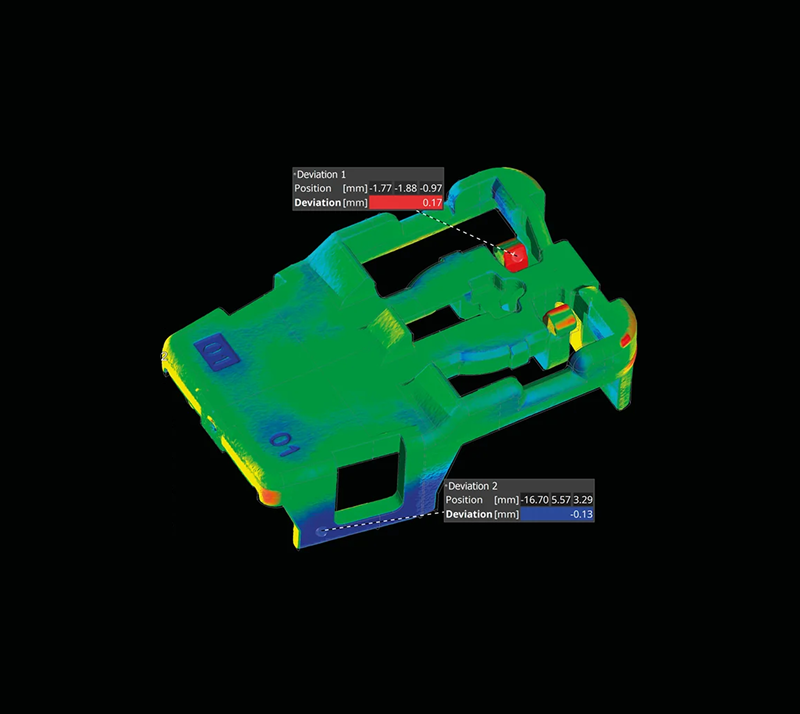

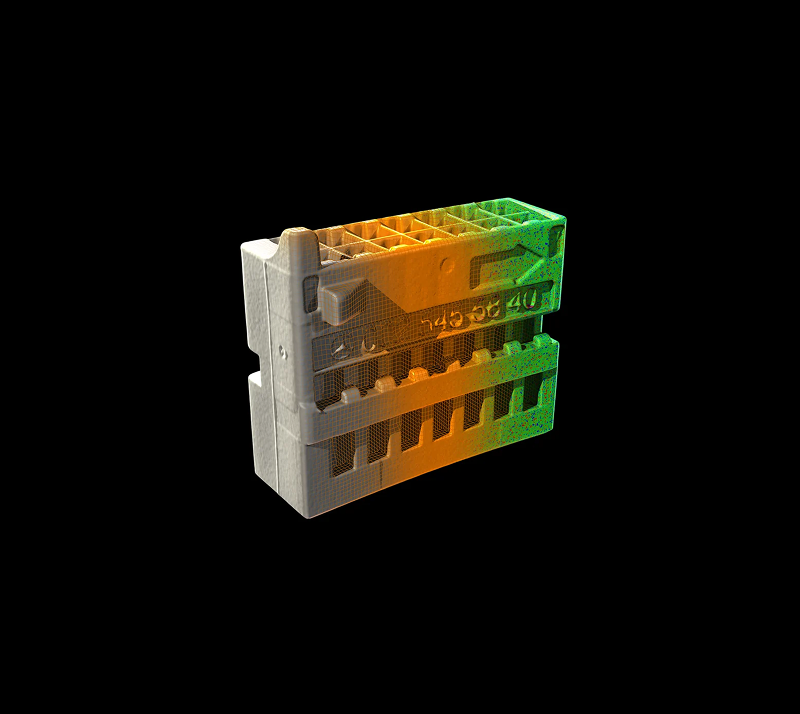

Introducing a game-changer in deviation analysis: Use your nominal part to tolerance wall thickness deviations on CT scans of the actual part. No more guessing games about wall thickness, no more relying on absolute values of the wall thickness sphere calculation.

Visualize, tolerance, report, and evaluate the real deviations between your nominal part and the actual scan. Leverage our unique adaptive transformation technology to ensure that calculated deviations correspond accurately to surface points on both your nominal and actual parts.

This innovative, machine-learning-based solution is tailored for noisy, low-quality data, and therefore can handle fast CT scans.

Saves time: Simplified processing lets you load data, select the model, calculate, and apply the resulting regions of interest for subsequent analyses – all in a few steps.

Ideal for automation: Designed with user convenience in mind, our Deep Segmentation tool fits seamlessly into automated inspection workflows.

Supports industry standards: The Deep Segmentation module is compatible with the industry-standard ONNX model format, empowering you to utilize problem-specific and data-specific deep learning models.

Our new intuitive ribbon tab puts all essential editing tools at your fingertips. You can adjust visibility, make selections, add, fit, remove, or recreate fit points – all from a single hub! No need to search through property dialogs or guess the location of desired fit points. Simply select a geometry element and the tab appears, streamlining your measurement plan adjustments.

Selecting objects is more intuitive than ever: Just pick your tool of choice — rectangle, ellipse, or lasso – and directly draw in the 3D window. As soon as an object’s center of mass is highlighted, the object will be selected in the Scene Tree. Add or remove objects directly in the 3D window – WYSIWYG.

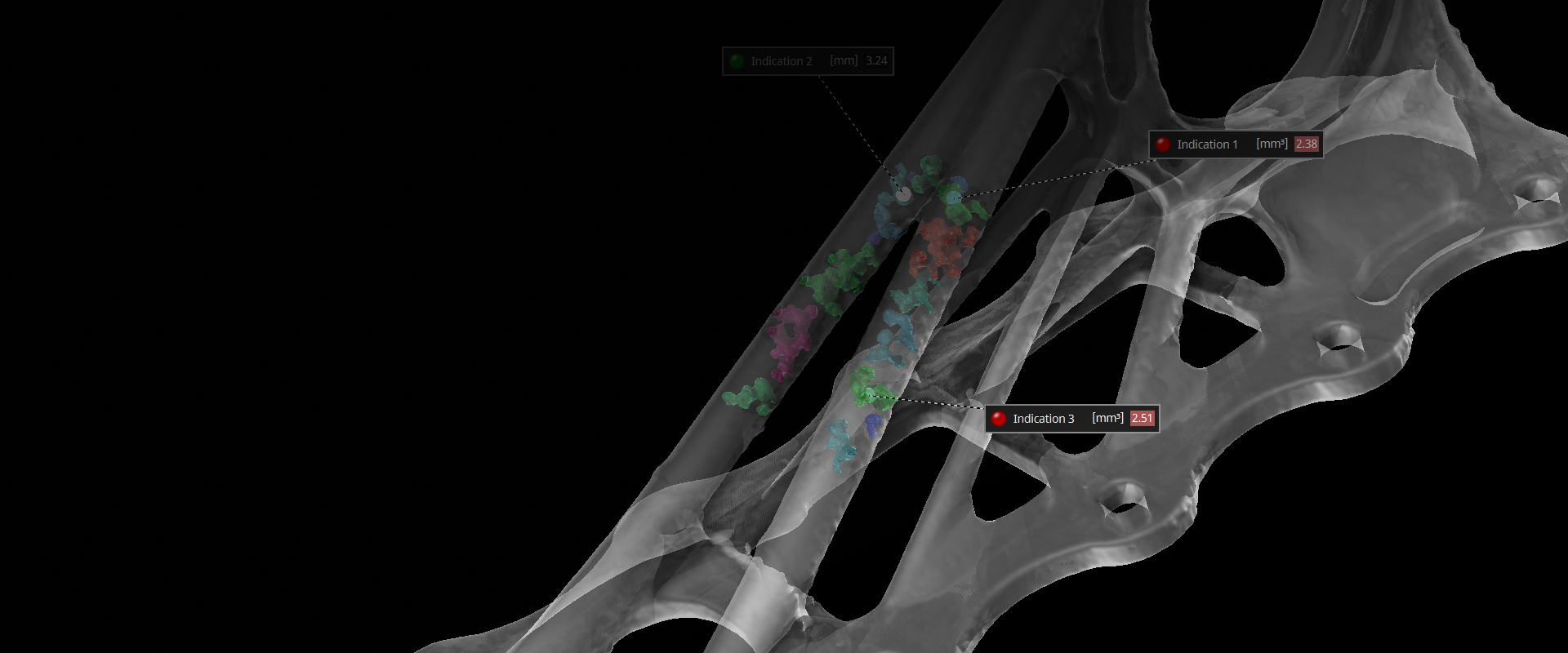

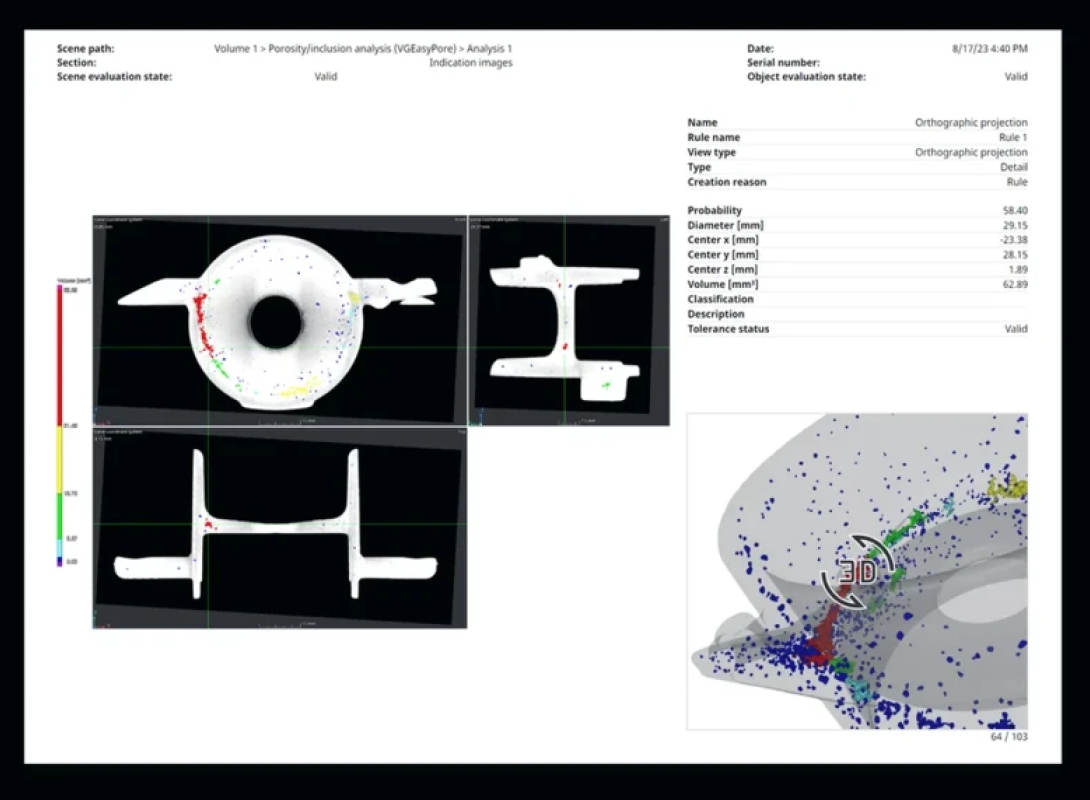

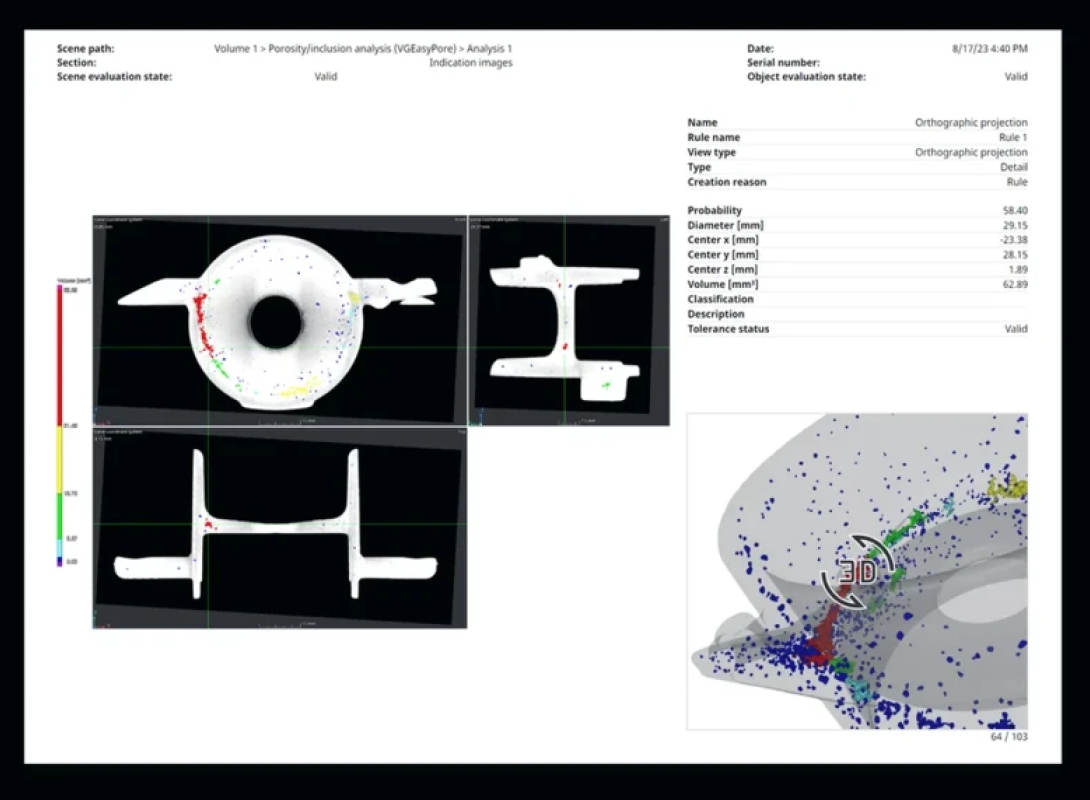

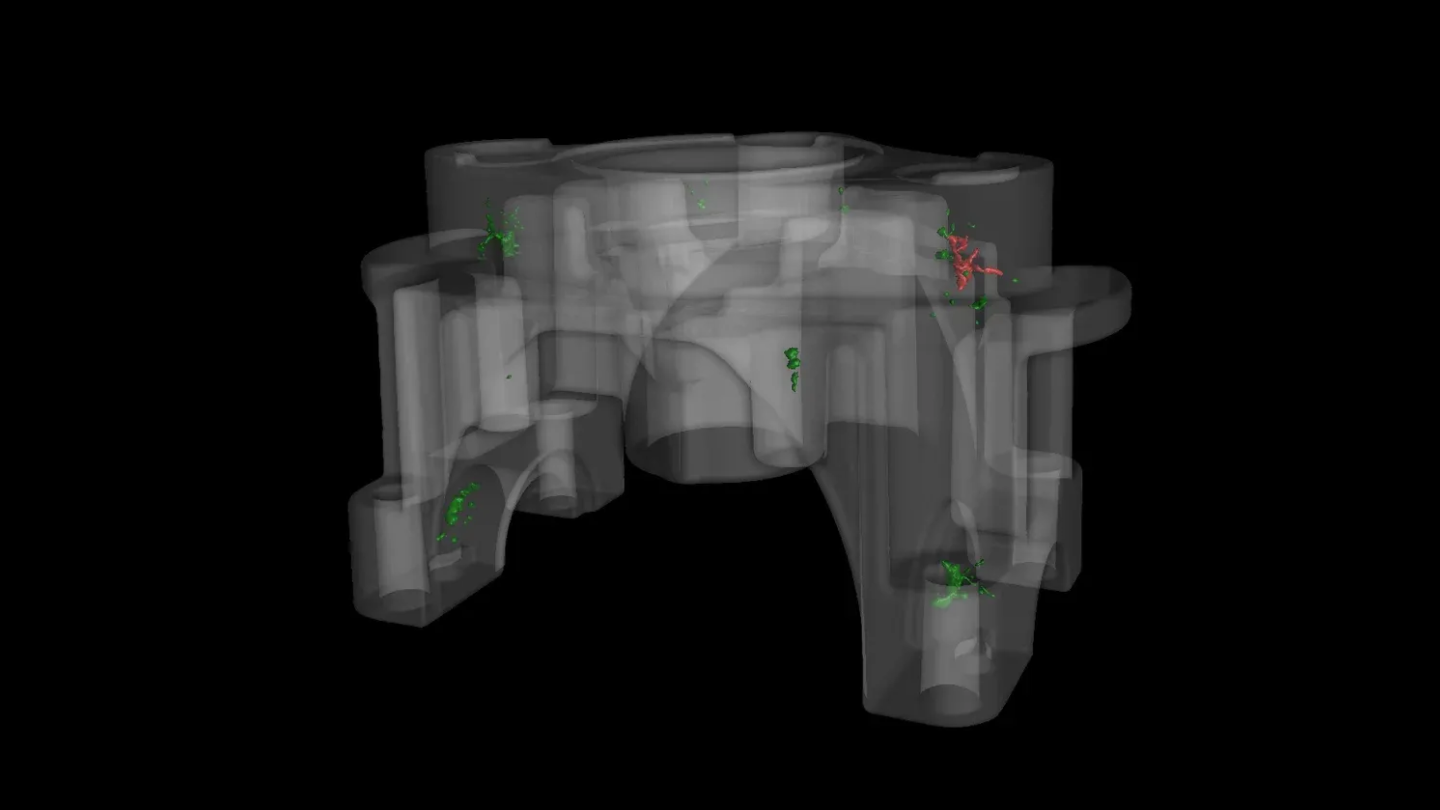

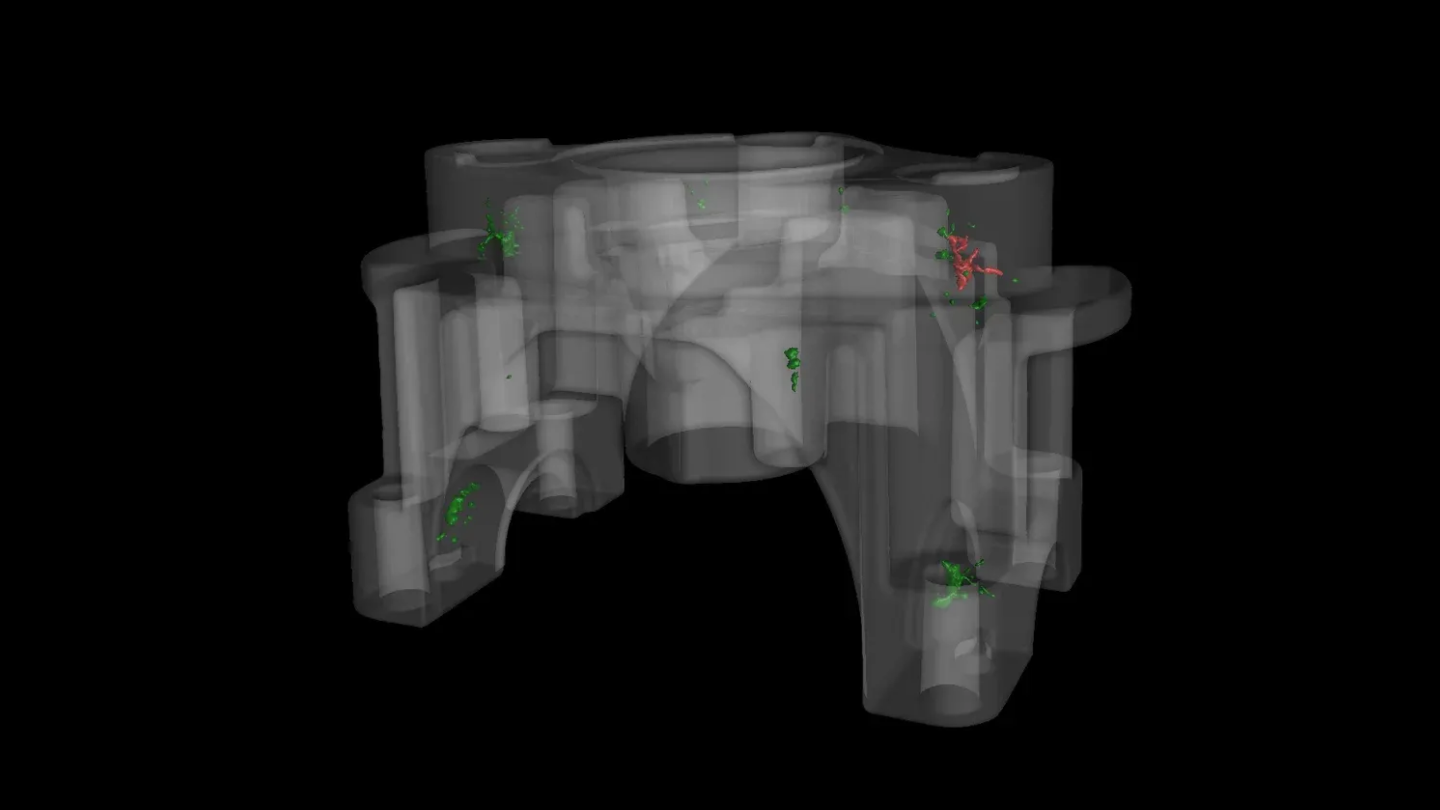

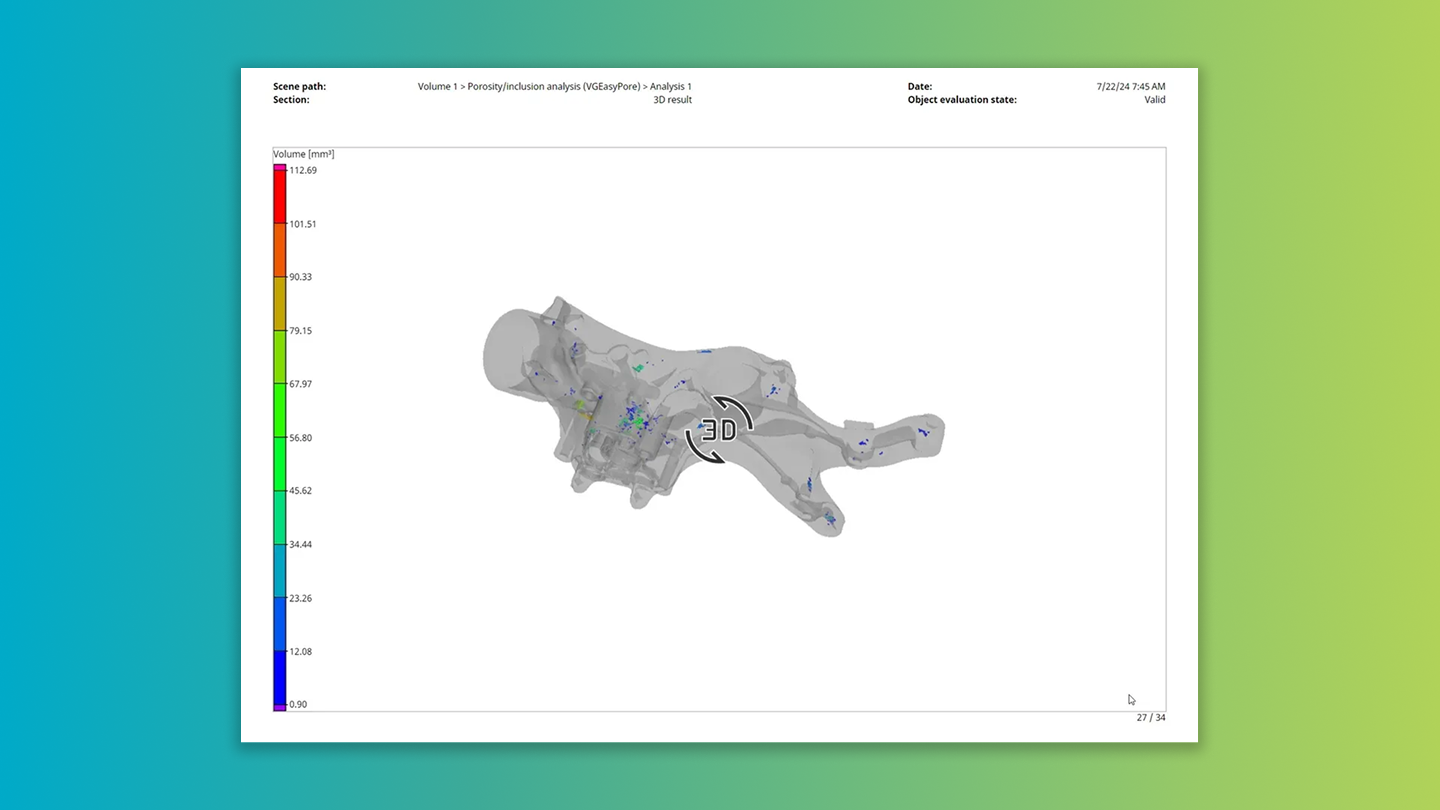

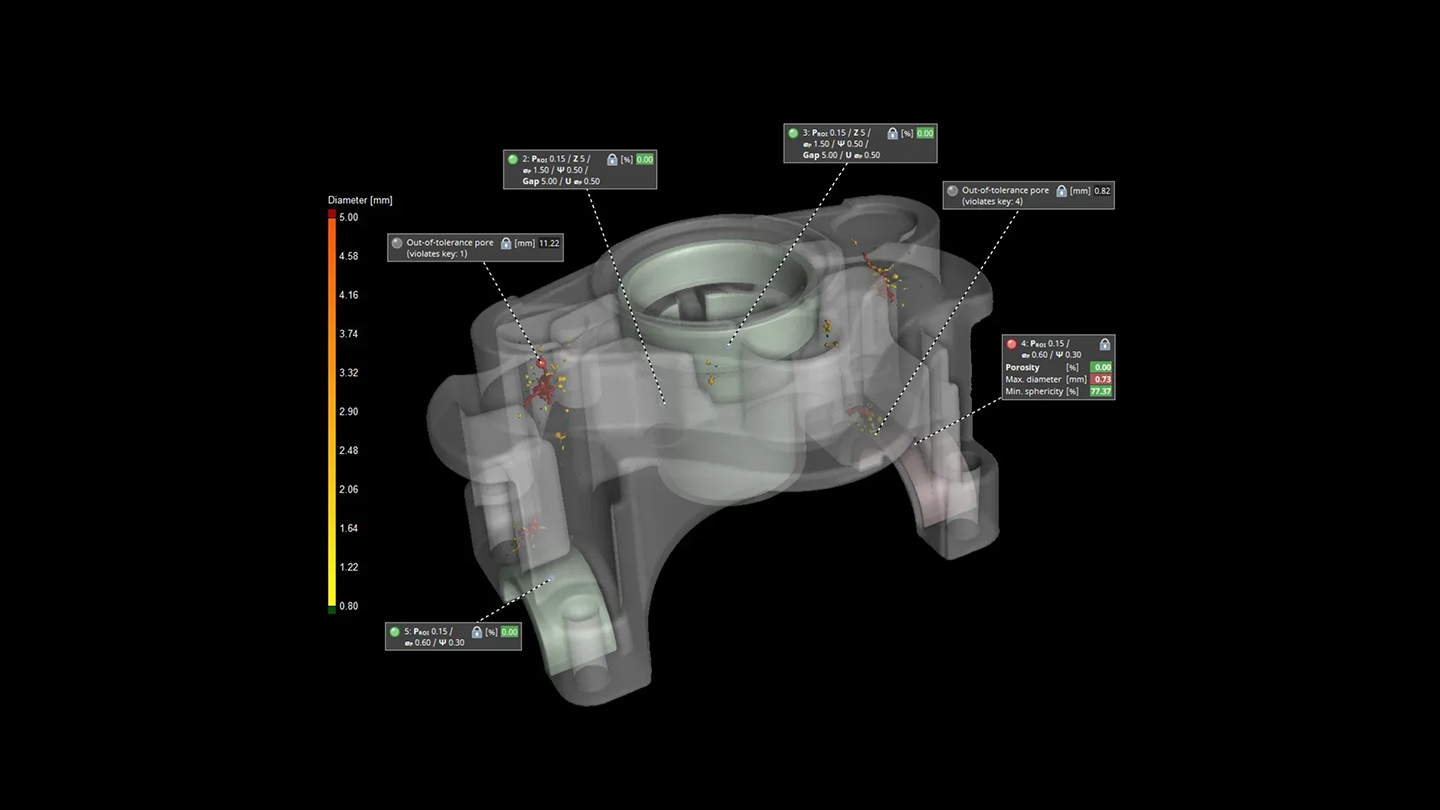

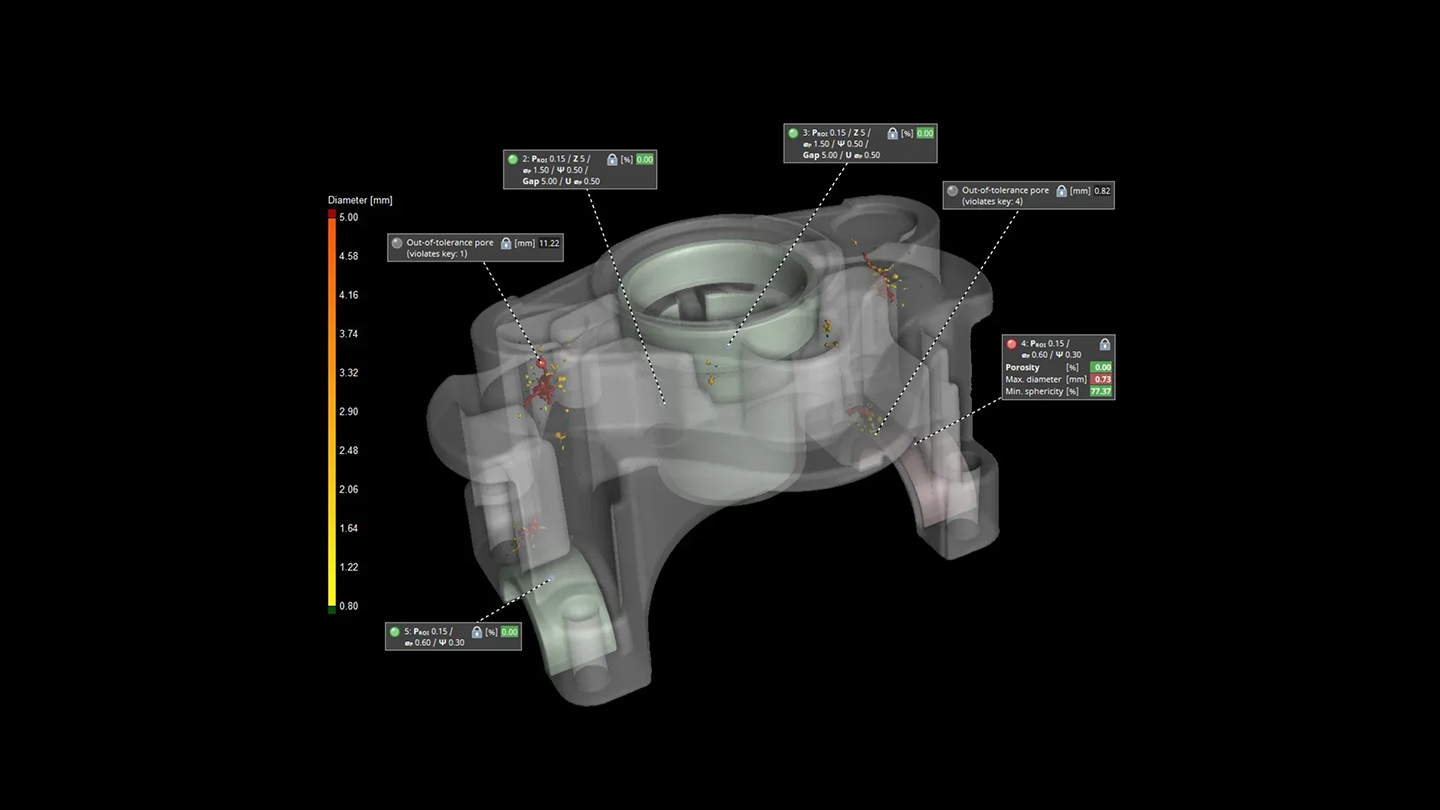

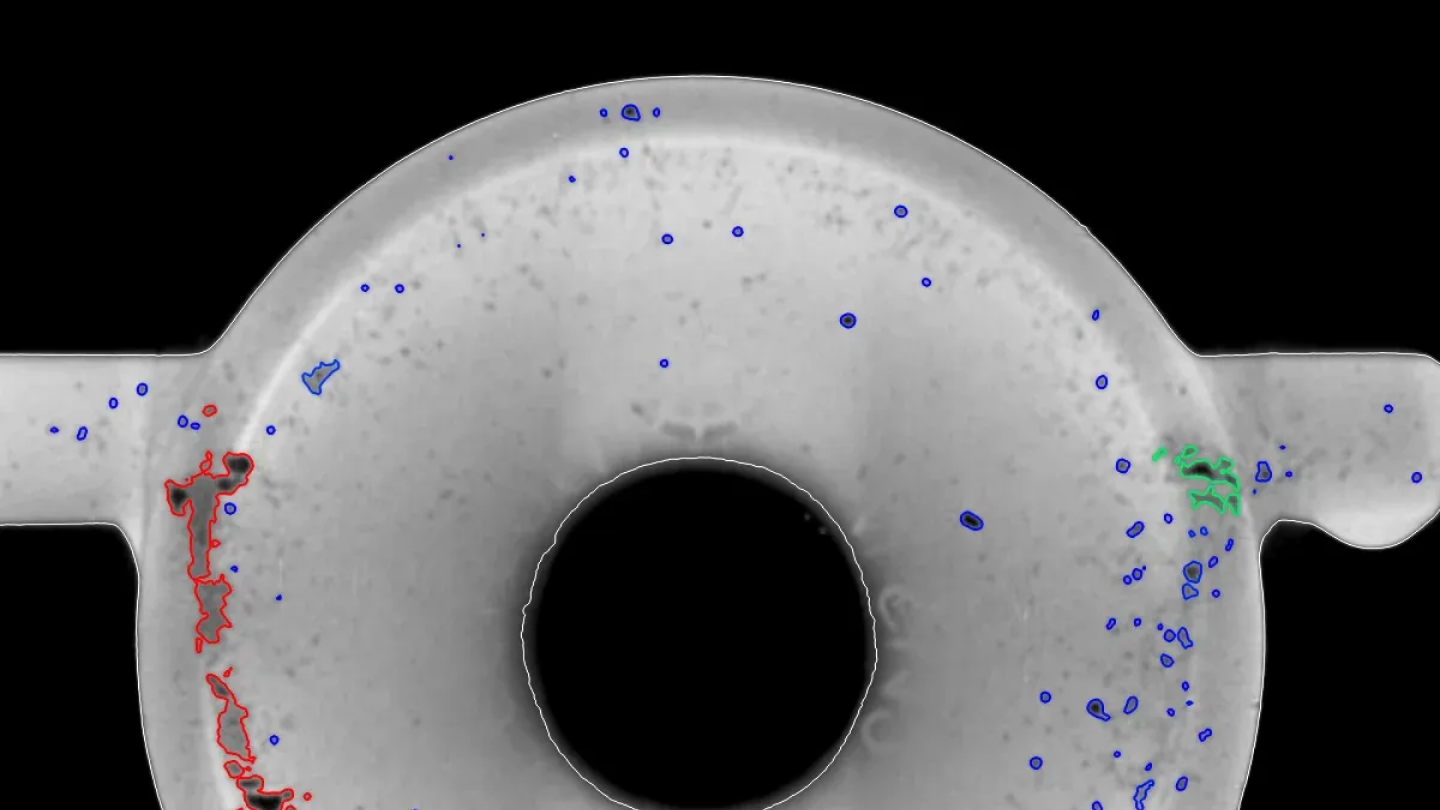

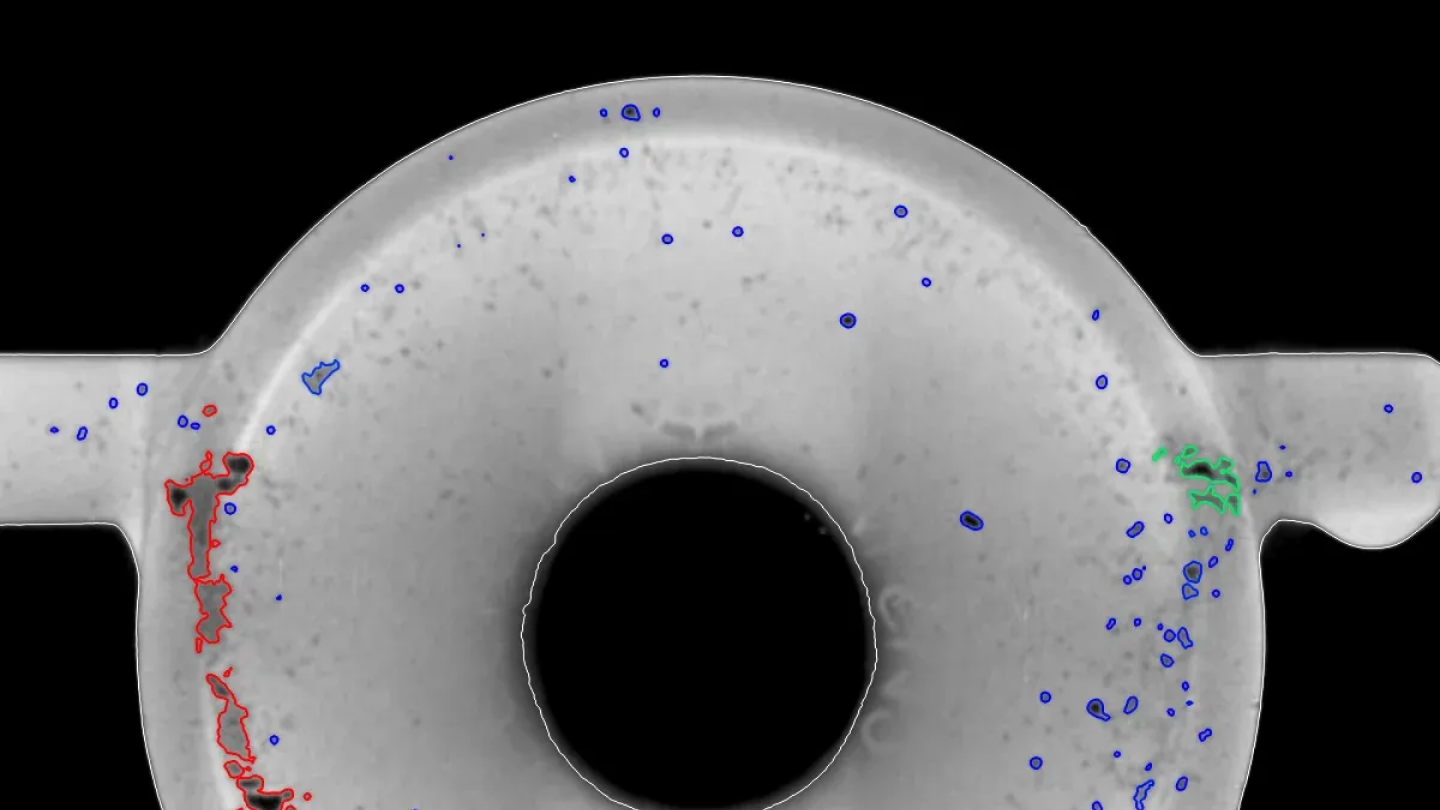

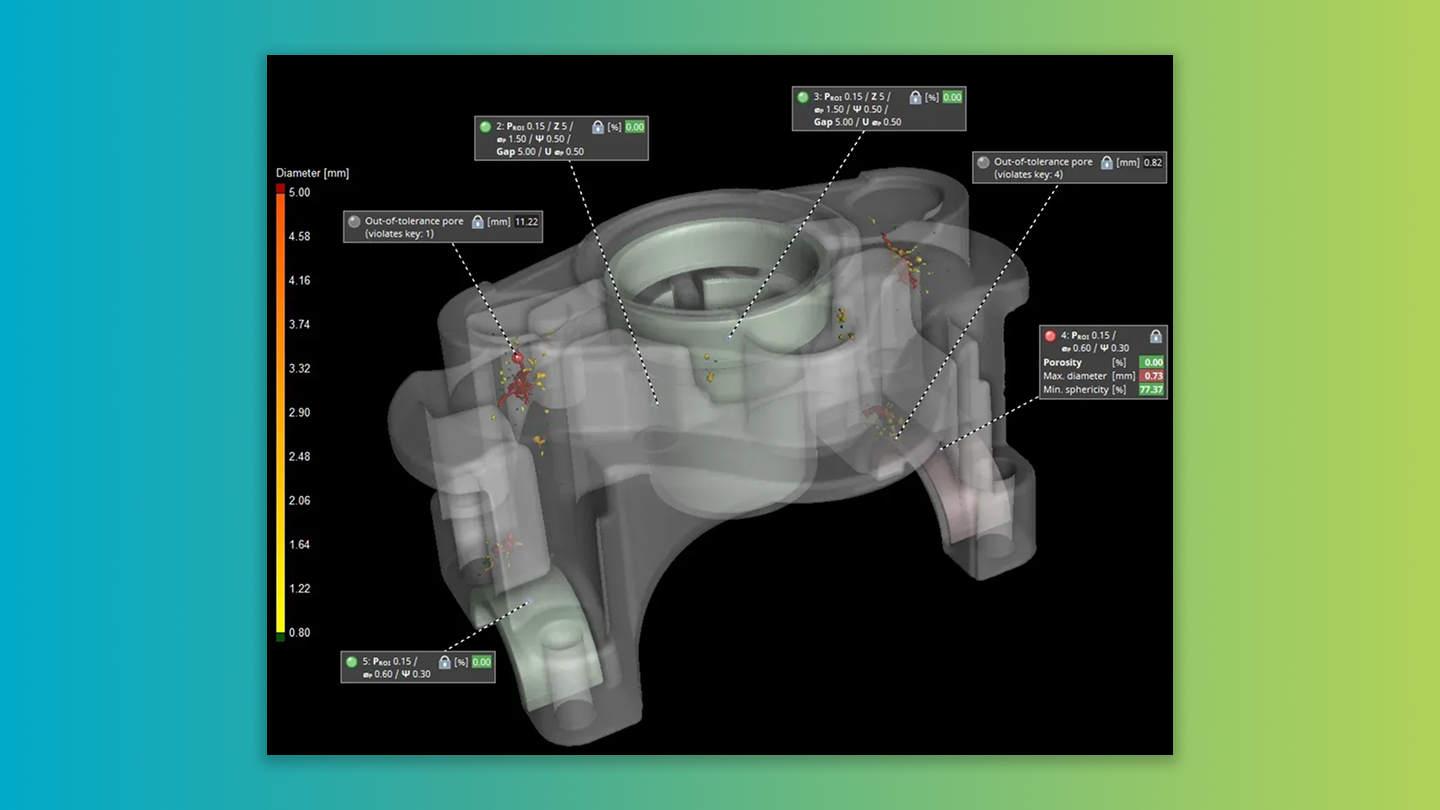

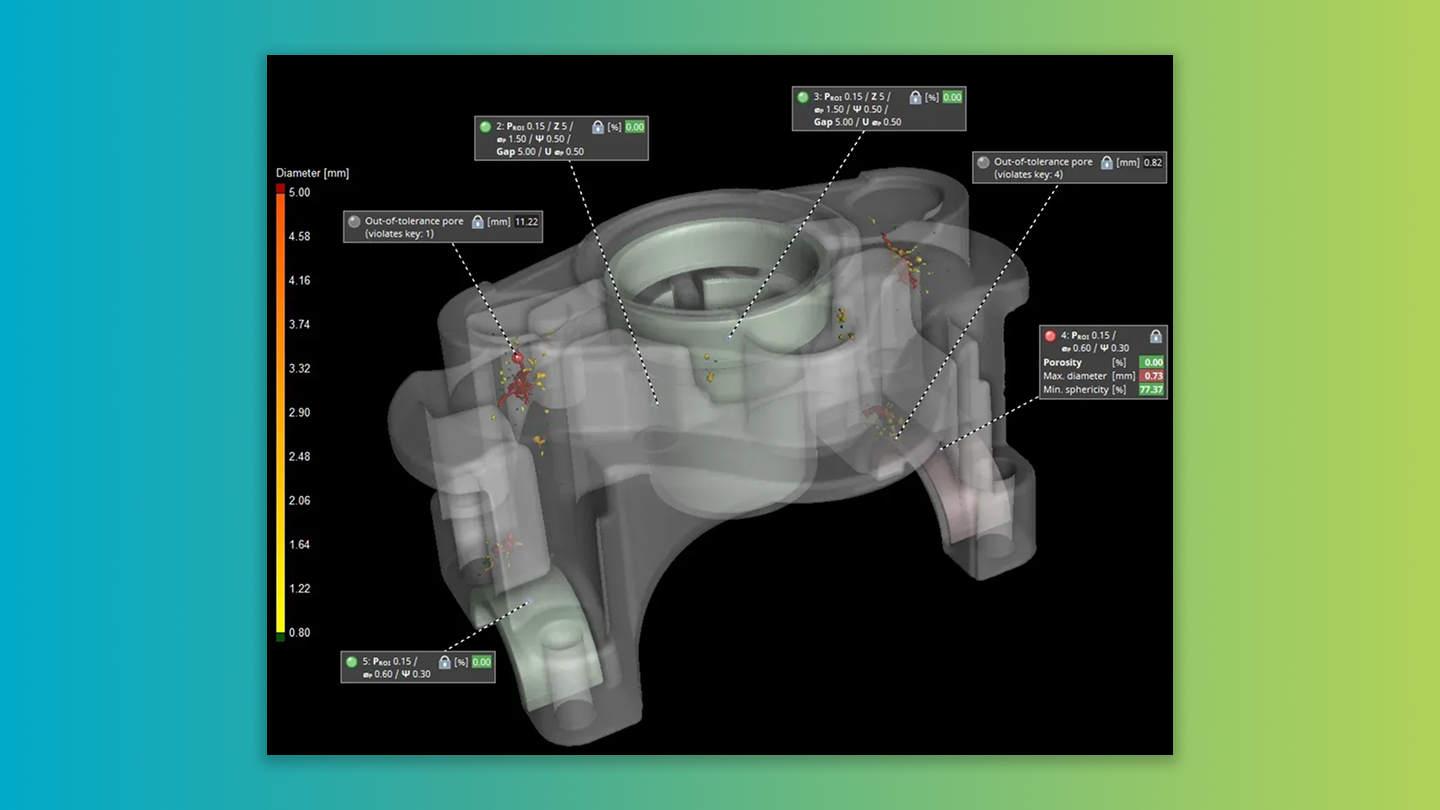

Instant tolerance status: Instantly view the tolerance status of each pore in an intuitive color-coded format. Simply select the tolerance status as "Active column" and identify the status visually using green (in-tolerance) and red (out-of-tolerance).

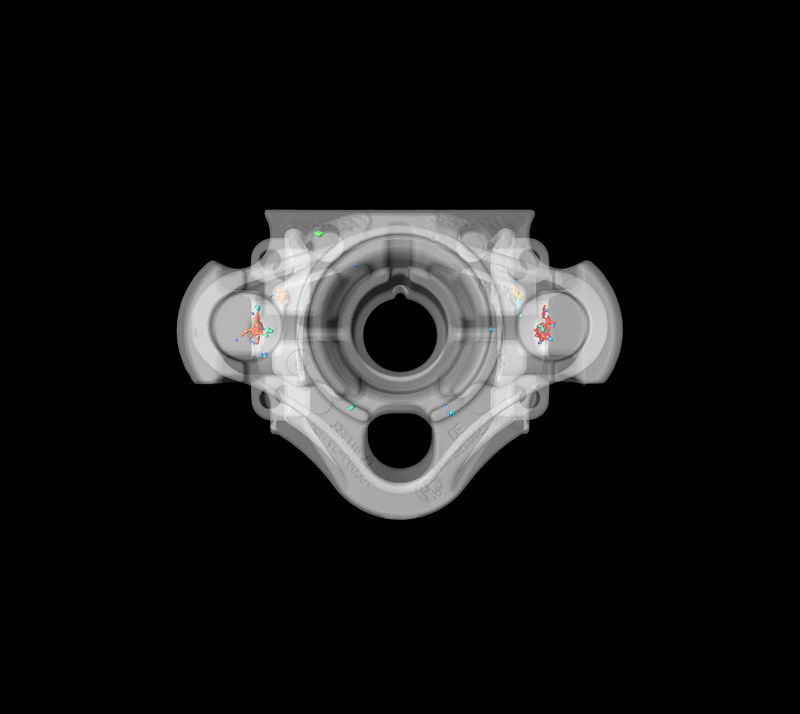

Quick surface determination: Forgot to execute a surface determination before starting your porosity analysis? No problem! Our new shortcut in the analysis window allows you to create a default surface determination suited specifically for porosity and inclusion analyses, ensuring a smoother, uninterrupted workflow.

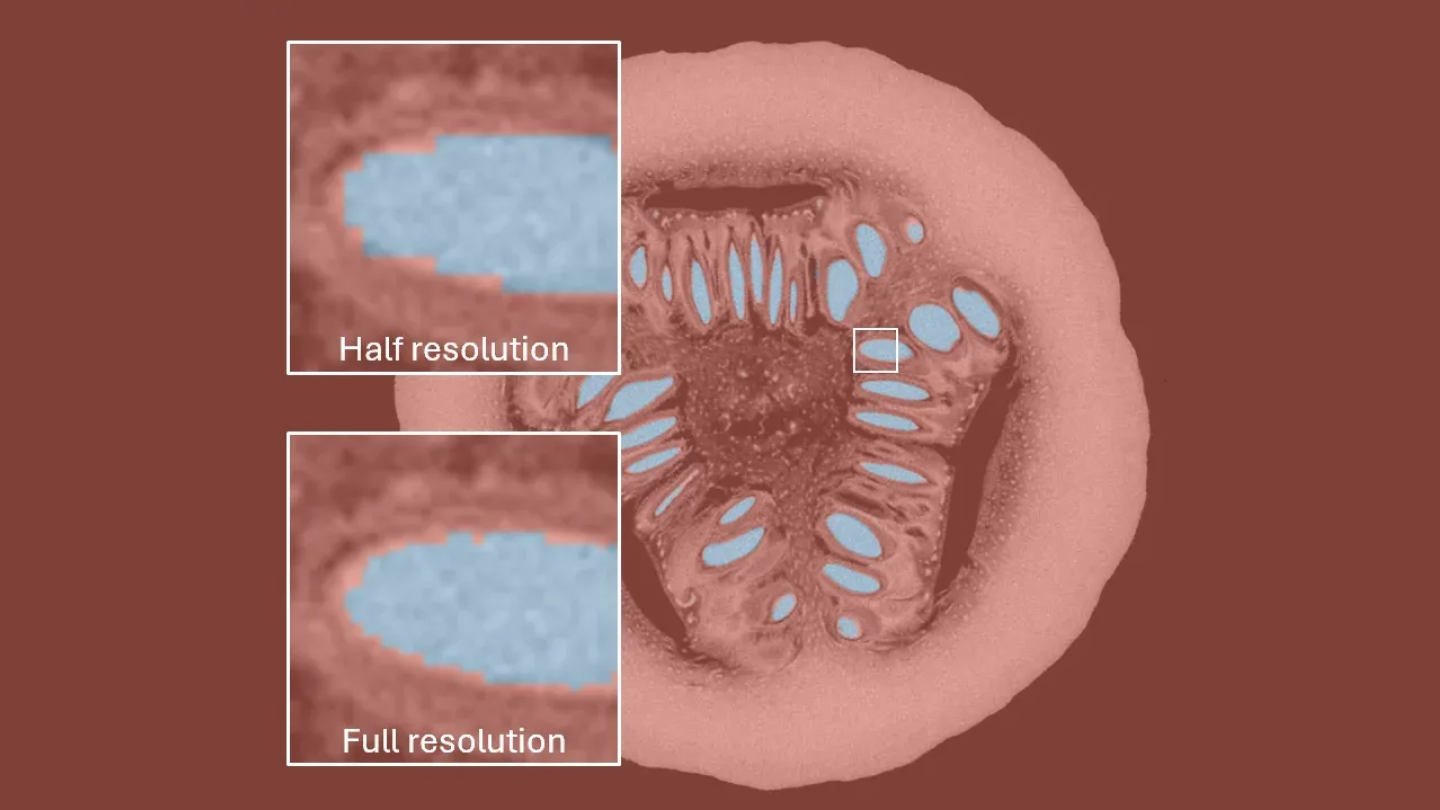

When speed is more important than exactness when using our Paint & Segment tool, reduce the resolution and get your segmentation much faster.

Opt for half resolution, and watch the segmentation run about 8x faster — freeing up valuable time for your other important tasks.

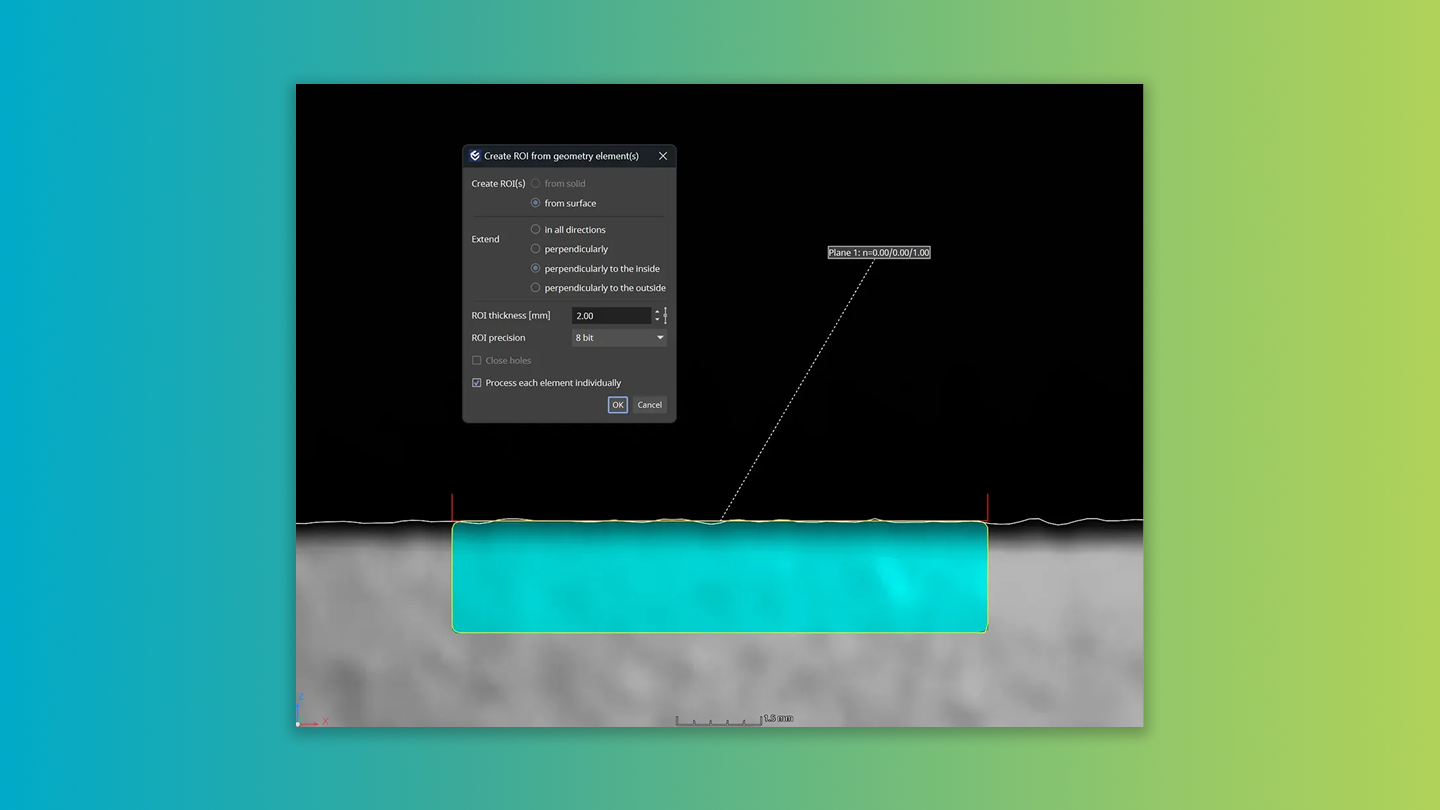

You can now create ROIs with a defined thickness from the surface of ideal geometries, making it simpler to streamline ROI creation for various analyses, including P 203. Choose from various expansion modes: in all directions, perpendicular to the surface, or exclusively to the inner or outer side based on the surface orientation.

Enable or disable ROI rendering for numerous objects simultaneously! Enjoy better automation scenarios, with the toggle macro step now distinctively separated into two clear steps: "Enable ROI rendering" and "Disable ROI rendering". This ensures better reproducibility of macro jobs for a more streamlined user experience.

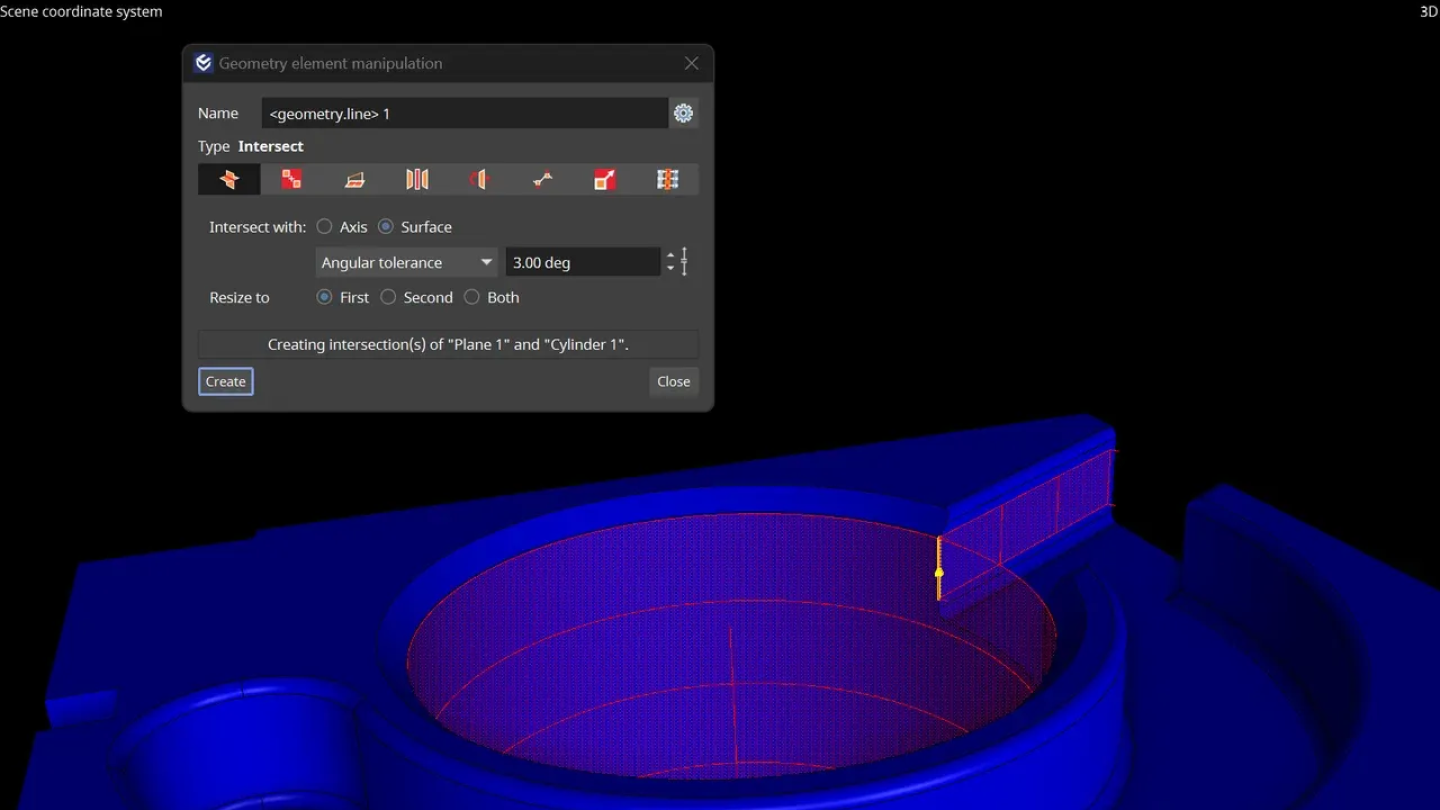

Say goodbye to those pesky workarounds! You’re now able to create an intersection line with the desired size directly between the shell of a cylinder and a parallel plane.

This dynamic feature utilizes the color bar settings configured directly in the analyses, offering an enriched context to interpret results in your reports. Elevate your reporting experience and data interpretation capacity with this unique update.

Color-code table cells in reports according to their tolerance state

You can now opt to color-code individual cells based on their tolerance status. This instant visual representation not only enhances the meaning of your result tables but also allows for quicker identification of specific indicators that caused a part to be out of tolerance. A more meaningful, intuitive understanding of your data is just a color away!

Hide info field names in reports

You can choose to hide the title of any info field in your report. This feature not only allows for seamless integration with any personalized text but also contributes to creating more succinct report pages. Enjoy more control and design freedom with our refined reporting settings.

Invalidation of bookmark images on analysis changes

Bookmark images are now tagged with an "out-of-sync" status if analysis results change. For automated scenarios, all "out-of-sync" images undergo an automatic update before saving, ensuring that the bookmark images reflect the current state of your project accurately. Experience improved visibility and control over your data with this dynamic update.

Rename objects using metainformation

You can now rename objects using one of their metainformation fields. Ideal for use in macros, this function can transfer text read from an object via OCR to its name in automation scenarios. Experience elevated control and efficiency in your data management with this latest feature enhancement.

Enhance your efficiency with our latest multi-threaded mesh simplification feature! Whether you're converting a volume to a mesh or preparing 3D data for reporting, this new implementation drastically reduces the number of triangles in a surface mesh and significantly accelerates calculation times. Step into a smoother, faster computation experience with this innovative update.

Our new upgrade allows for macro recording of placing the fixtured object within the scene, facilitating seamless fixture simulation in fully automated workflows.

This upgrade radically reduces the time spent browsing for macros in your file system. Enjoy a smoother, more efficient workflow and let us handle the heavy lifting. Work smarter, not harder!

In this video, we will show you how to automate your porosity inspection workflows. With the help of the "Automation" tool of VGSTUDIO MAX, you'll learn how to automate a once-defined porosity workflow by recording macros for each workflow step. In the end, you'll combine the macros to a job that you can run on as many data sets as you like. Let VGSTUDIO MAX help you reduce your inspection efforts to a few clicks — the ones that launch the automated process!

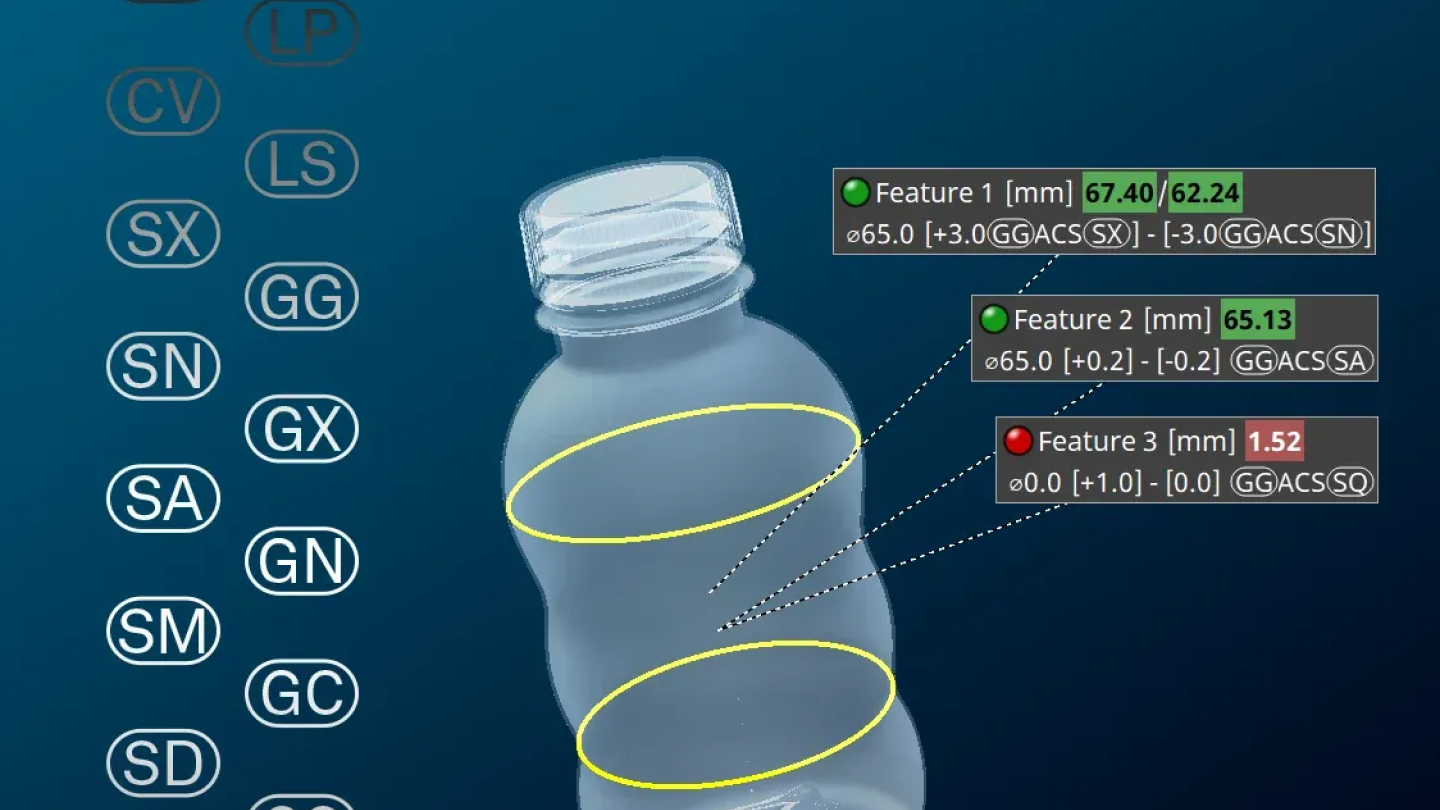

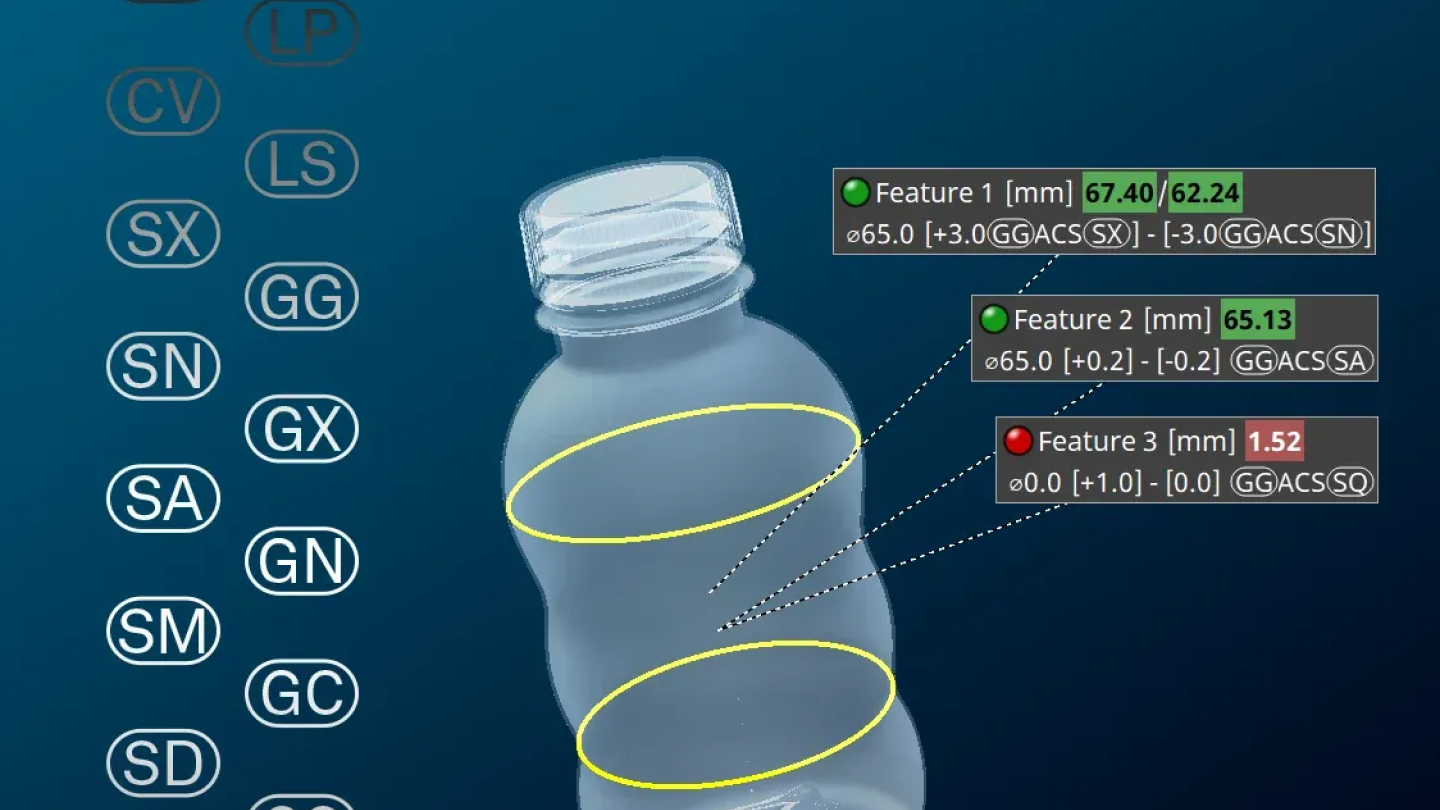

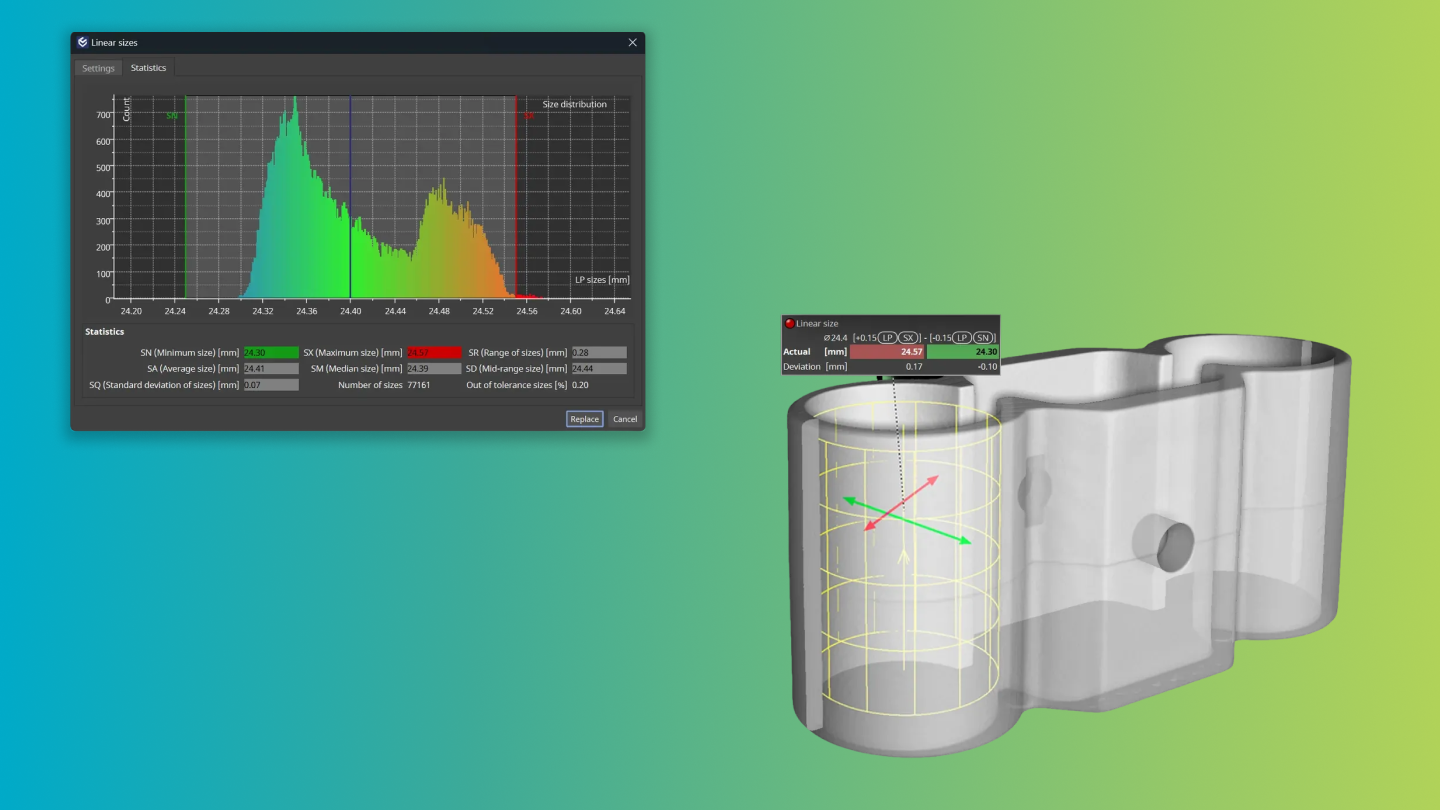

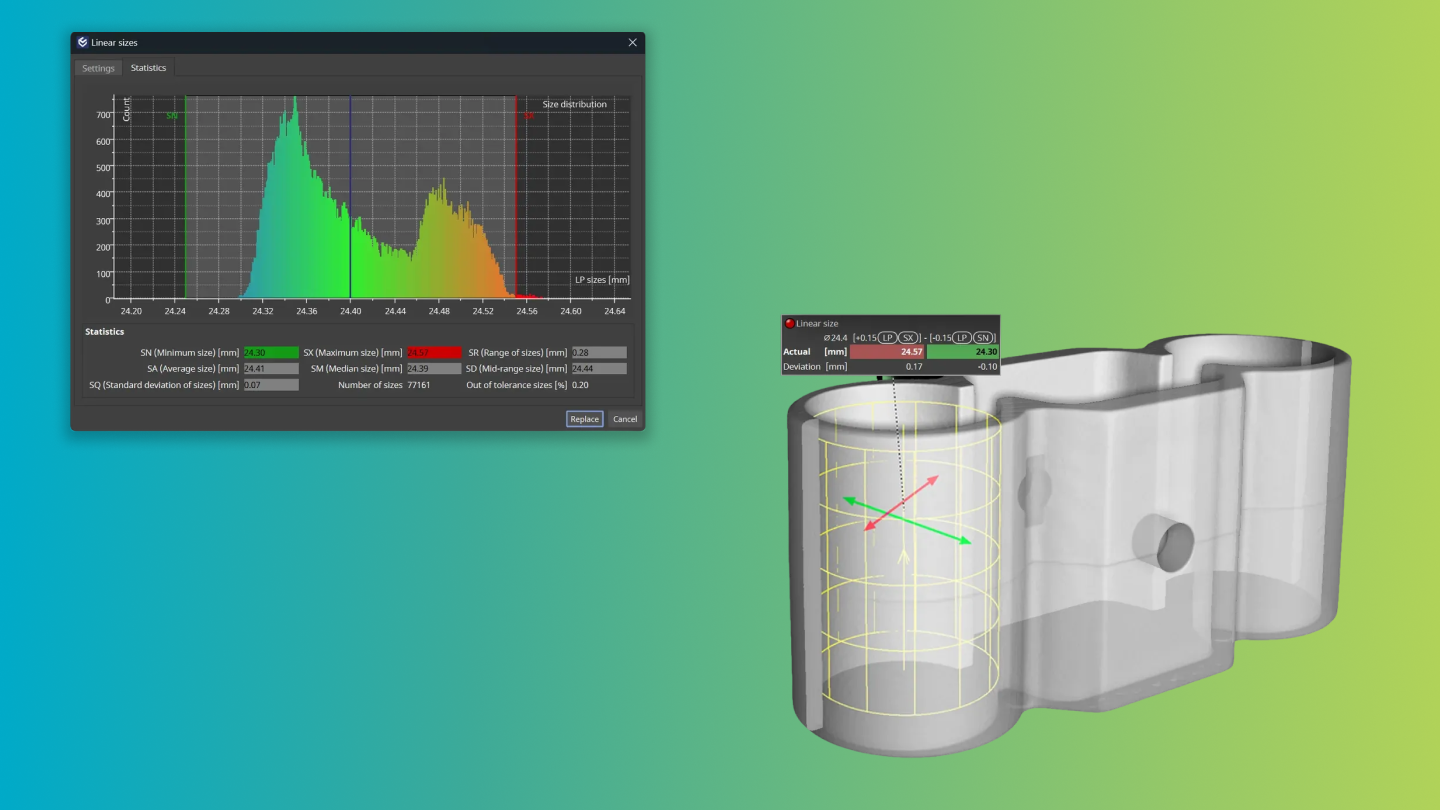

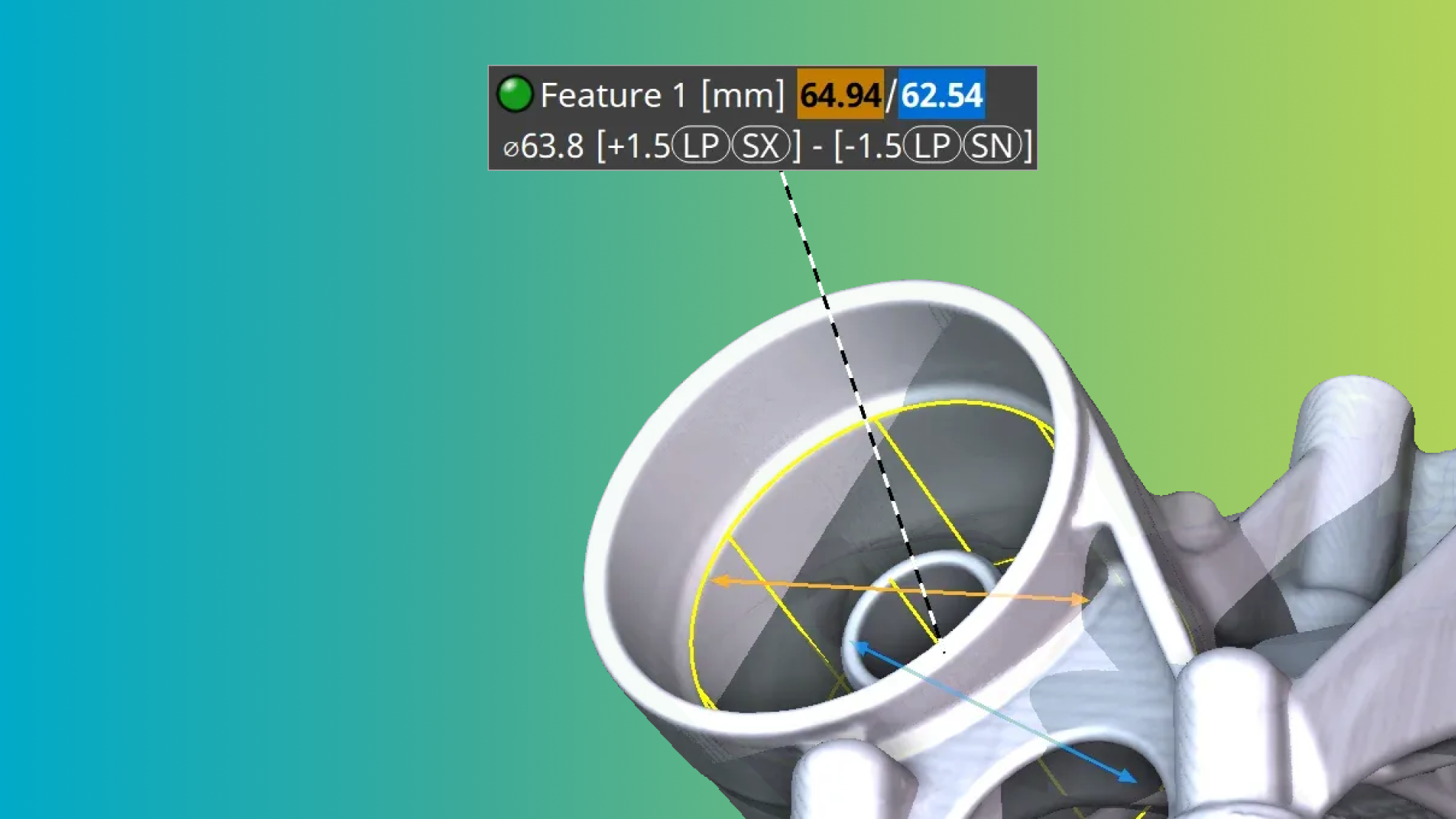

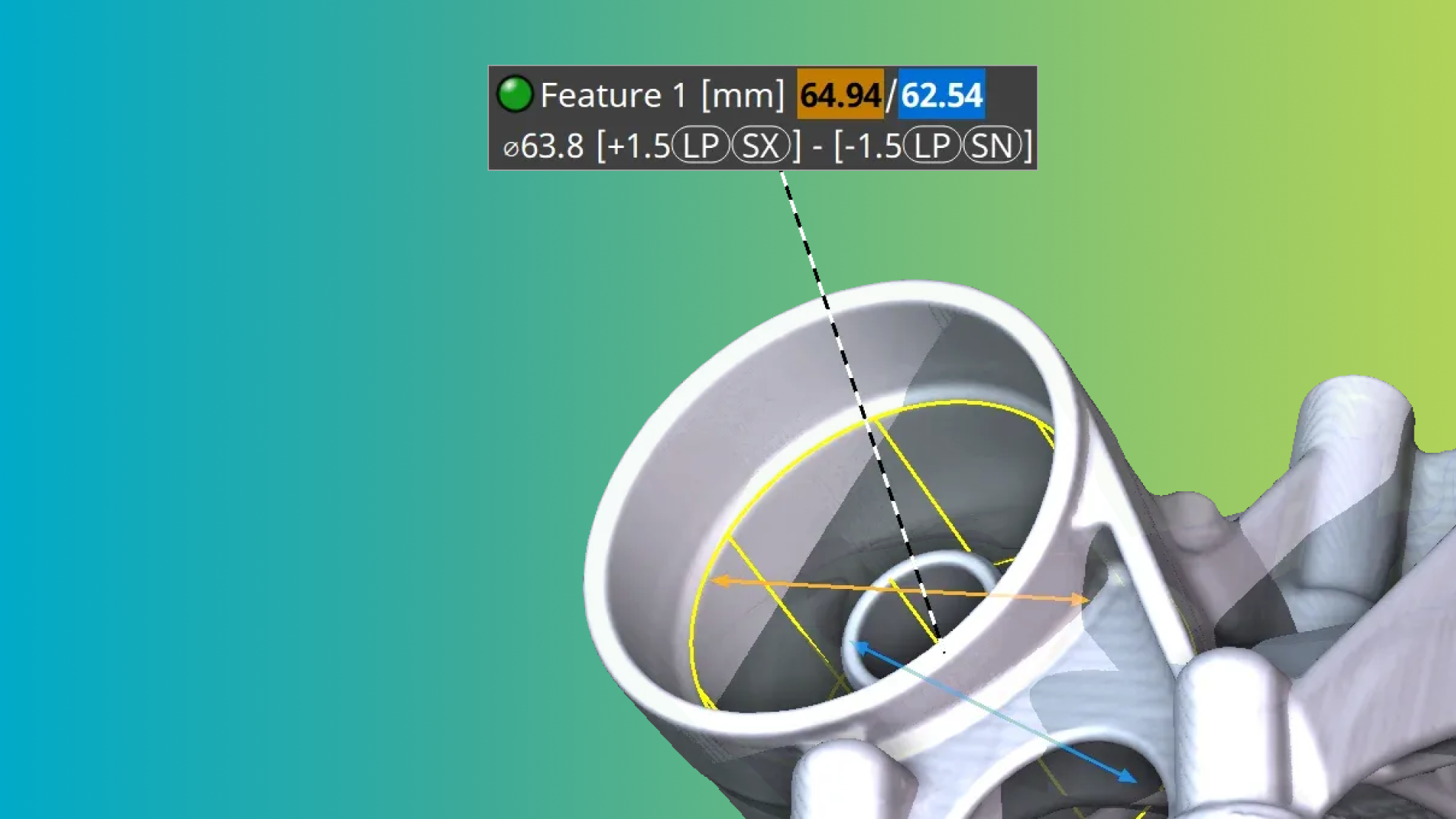

You can now measure linear sizes that require the use of rank order modifiers (for example, for the calculation of an average size) or the use of the ACS (arbitrary cross-section) modifier for the calculation of size measurements in any cross section.

Measurement tasks according to ISO 14405-1 that require the use of these modifiers can now be easily performed by choosing the appropriate modifier symbols in the "Linear sizes" dialog.

When you use linear size modifiers such as LP (local two-point size) or ACS (arbitrary cross-section), many sizes will be calculated at a time. While you will usually tolerance only a single size value (e.g., the maximum, SX, or the minimum, SN), much more information about the measurement itself is now available: A new tab in the "Linear sizes" dialog will show you a histogram of all calculated sizes as well as a number of statistical values, allowing for an intuitive overview of the size distribution and overall tolerance state of the measured element.

Our revamped OCR analysis significantly enhances the automatic text recognition capabilities of VGSTUDIO MAX and VGinLINE and comes with improved result customization options and reporting support. ASCII text on components will automatically be recognized and translated into the object's metainformation for use in inspection plans or reports.

While you will no longer be able to create new instances of the old OCR analysis, any inspection plans and evaluation templates that contain them will continue to work. We strongly recommend that you switch to the new OCR analysis as the outdated version will no longer be available with software release 2025.2.

The advanced CAD import with PMI is now capable of interpreting modifier symbols of linear sizes and automatically creating the appropriate linear size measurements during import.

Additional import options allow you to choose the default modifier symbols to be used when linear sizes without specific modifier symbols are found in the PMI data.

You can now create regular elements for circles and two parallel opposing lines in a 2D view and use them for linear size measurements and various geometric tolerances. This is especially useful when you have to measure linear sizes in a specific cross section (SCS) of an element.

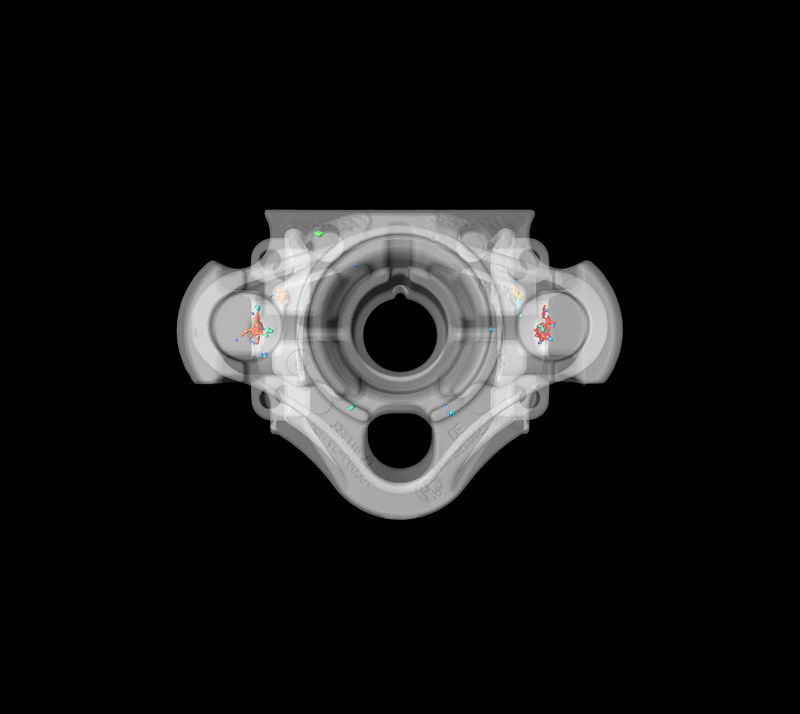

- The new "Automatic" mode for the "Analysis area" will consider the surface determination settings. This will make your daily work with the porosity/inclusion analysis faster and less error-prone.

- The visualization of pores is now by default set to "Render outline only" so you can still see the gray values of the detected pores.

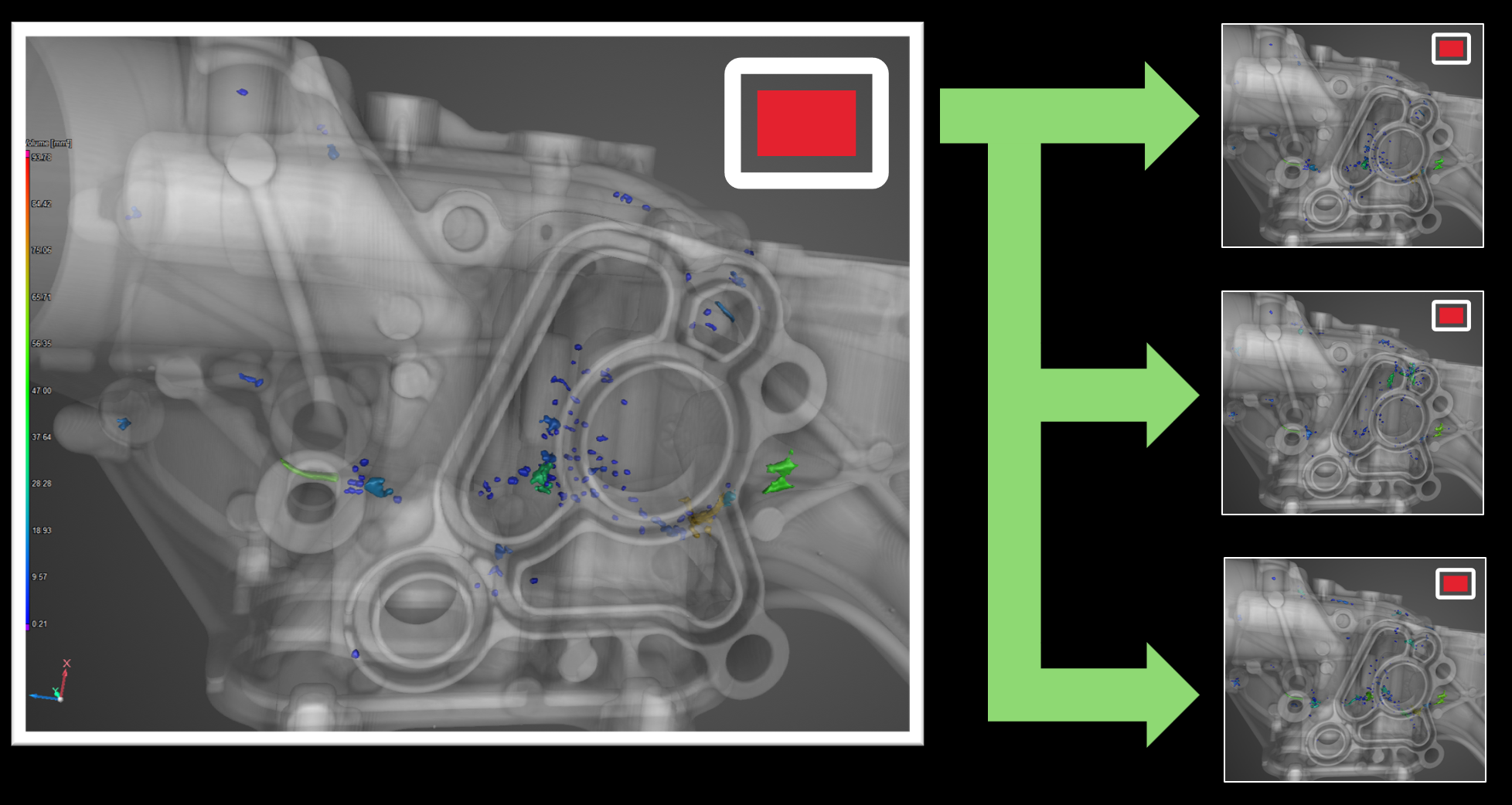

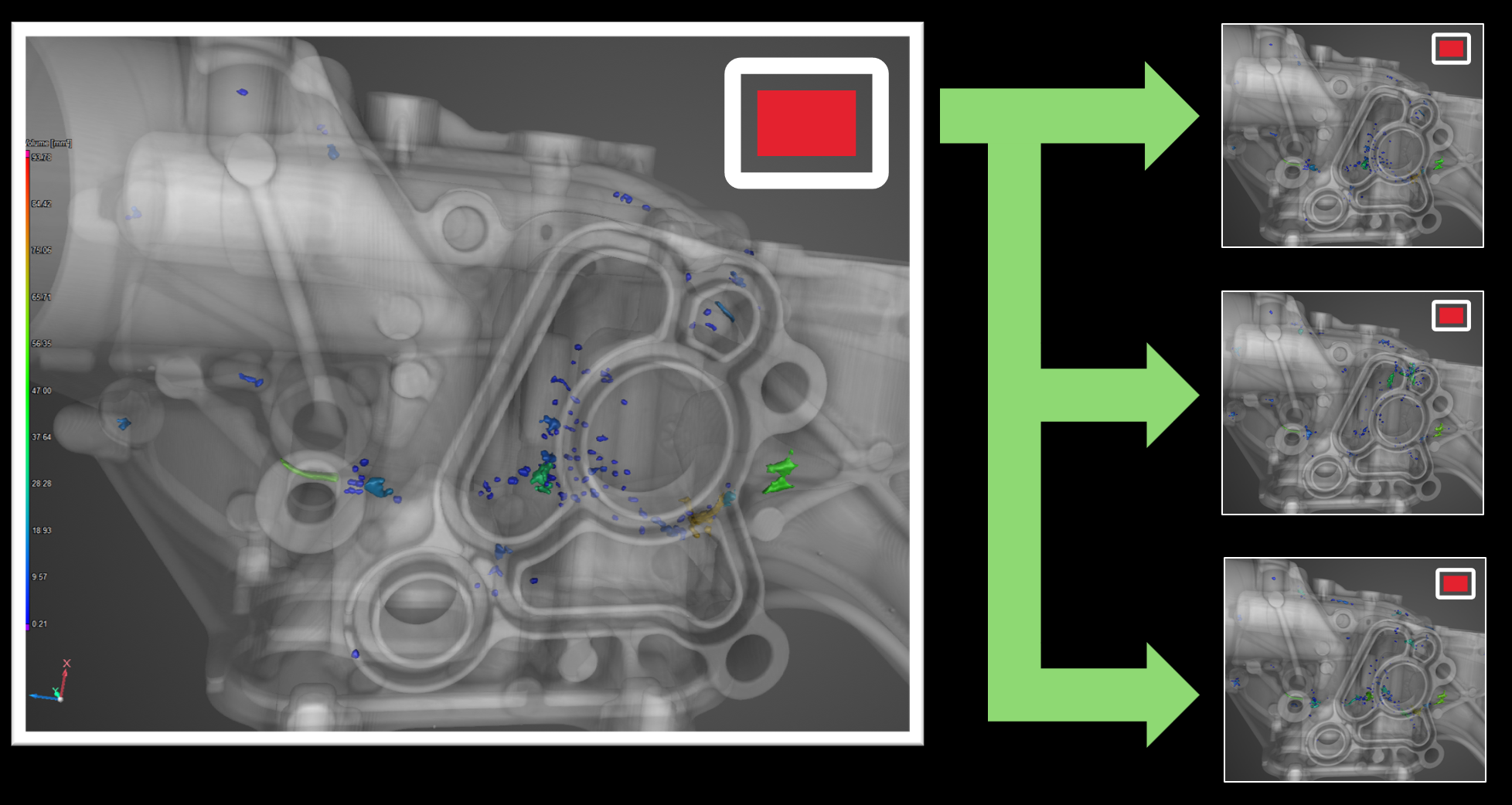

- With the new default report preset "Big five," you will get images of the five largest deviations in your standard report. If you want to have more, less, or just the deviations that exceed a certain value, you can simply customize the rule on the "Rules" tab of your porosity/inclusion analysis.

- To keep the dialog of your porosity/inclusion analysis tidy, only functionally relevant tabs will be shown.

- We extended the accurate voxel-based calculation of the "true gap" between pores: you can now tolerance the real distance between pores by setting a tolerance for the "Gap" parameter

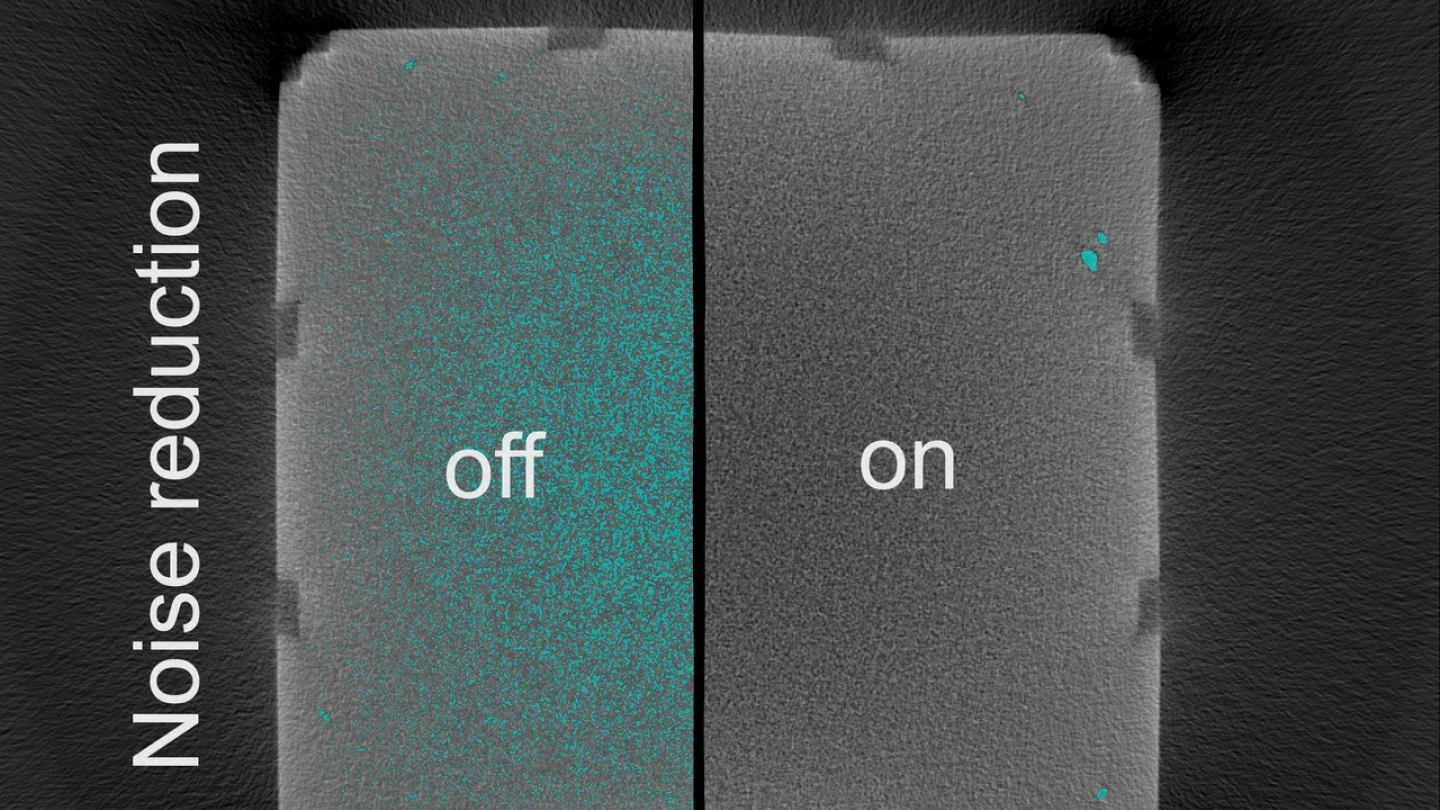

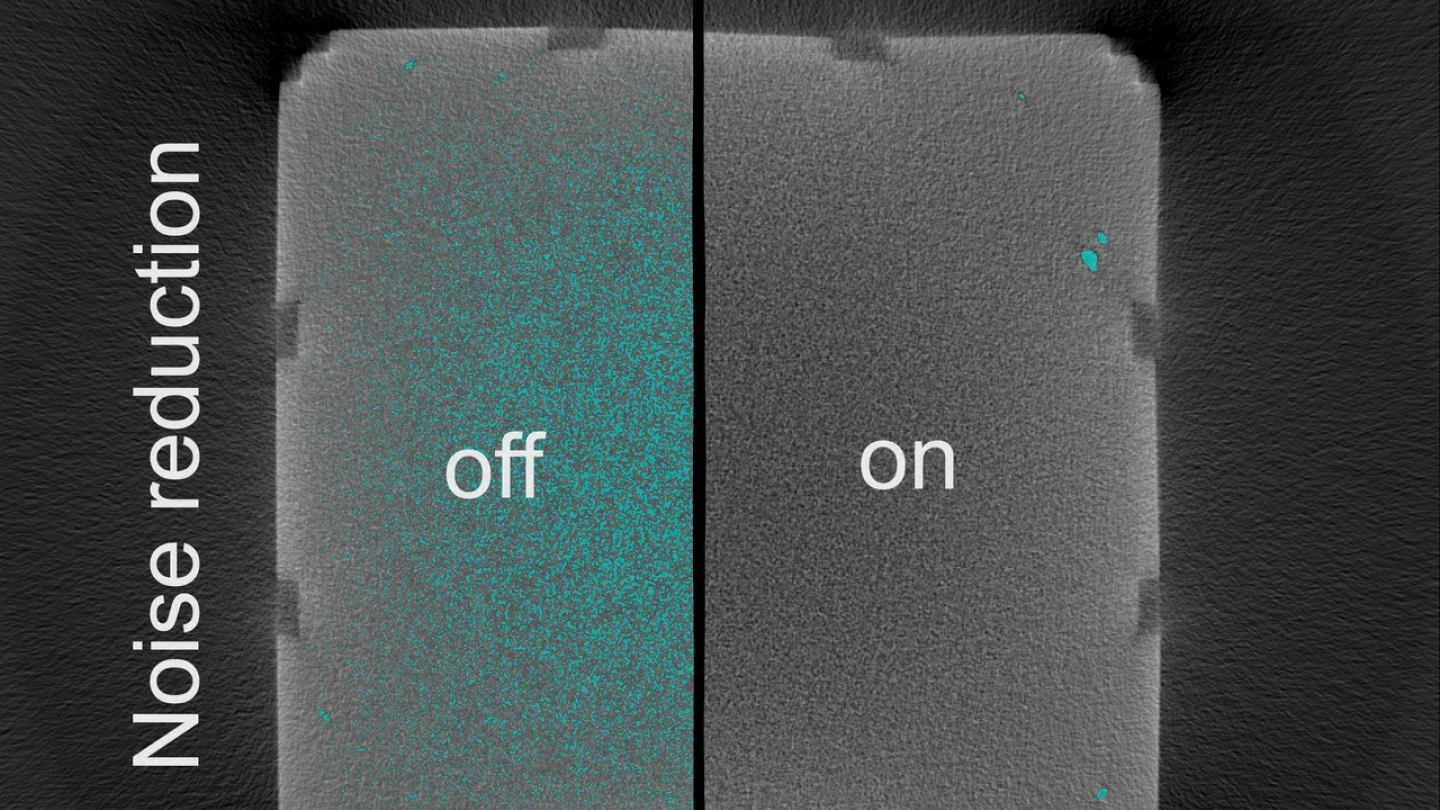

If your data is very noisy, VGEasyPore might detect plenty of noise particles. By activating the "Noise reduction" option in the VGEasyPore dialog, you can filter out noise from the very beginning. This makes it easier for you to adjust the parameters for successfully detecting porosity or inclusions.

And – unless you evaluate large amounts of tiny noise particles – the porosity/inclusion analysis can in many cases be much faster!

When you perform a VGEasyPore analysis on a small ROI (region of interest) – for example, when there are multiple components in the CT scan and you want to perform the analysis only on one of them – VGEasyPore will now run faster than before, depending on how much of the full scan data is covered by the selected single component.

You can now change the default settings of your analysis by setting one of your presets as default. For example, if you are not interested in pores smaller than 0.5 mm, just set the filter accordingly and save it as default preset. This will save you valuable time with each analysis.

The preset will apply until you save a new default preset or select another existing previously saved preset as default preset

Customizable text color in reports

We further enhanced the customizability of reports: you can now set arbitrary colors for all textual layout elements to highlight certain results or custom text.

Exporting multiple movies or image stacks of an inspected component at a time

The new queuing function of the "Save movie/image stack" dialog allows you to parameterize and queue multiple export jobs, and subsequently export all image stacks or movies at a time without further interaction.

This will streamline your export process considerably, as you will no longer have to wait for the completion of each individual export job before being able to parameterize and start the next one.

When series-testing the anode overhang in battery cells with the Battery Analysis module of VGSTUDIO MAX, you can now export the toleranced anode overhang properties in Q-DAS format. This allows you to use the analysis results in the Q-DAS software for statistical process control, for example, for process or machine capability analysis or for monitoring the results over time (trend analyses).

The new explanatory texts will make it easier for users to understand the purpose and functionality of both the "Bookmark" and the "Automation" tool and improve the accessibility of the software.

The computation of deformation fields can now be automated via macro. This way, you can save time in your daily work when using deformation fields for the “Morph mesh” or the "Compensation mesh" function, or for adaptive ROIs or coordinate measurement templates.

You can now directly import newer NSI formats, without the need for an extra tool. This makes working with newer NSI formats easier and more robust.

In this video, we will guide you through the various tabs of the reconstruction dialog so you can easily and quickly make the settings for a standard cone beam reconstruction.

Click here to watch the video.

In this video, we will guide you through the workflow of a P 203 porosity analysis on a typical die-cast workpiece. For this, we will examine and tolerance both the complete casting using a global porosity key and specific test regions using freeform ROI porosity keys.

Click here to watch the video.

Sharing comprehensive inspection results just became even easier. The new HTML format is an all-in-one solution that also supports interactive elements, like part or result 3D views. These self-contained documents eliminate the need for a separate viewer application and are easily accessible with any Chromium-based browser like Edge or Chrome.

Simplify standard conform measurements with direct support for modifier symbols. These include two-point measurements [LP], the envelope requirement (E), and global modifier symbols like [GG], empowering easy evaluations for many size features.

Now, projects loaded during batch processing won't automatically clutter your recent files list. This ensures your manually worked-on projects remain readily accessible. However, if you prefer the previous setup, don't worry — you can always change this setting in Preferences.

You can now specify the sphere radius in length units, even on anisotropic data sets. Enjoy significantly boosted performance, reaching computation speeds that are more than 50 times faster — specifically noticeable when utilizing larger radius values.

PNG format for streamlined image stack import and export

You can now bypass the need for additional file conversions when using PNG as a storage or data exchange format. Enjoy a faster workflow for importing and exporting your volume data.

New DICONDE export

Volume data can now also be exported in the DICONDE format, which includes the existing tags. For volumes that were not imported from DICONDE, the necessary tags are created on the fly.

Experience better image saving capabilities with native PNG format support, our new feature allowing lossless compression and 3D view images that include an alpha channel. Spice up your presentations with partially transparent images that pop!

In the past, transferring metainformation like DICONDE tags between different volumes in a scene was impossible. With this feature, you can now easily move this essential information, even when creating entirely new volumes from initial scan results. This enhancement ensures traceability is maintained throughout your process, keeping your work consistent and structured.

Fast toggle for Paint & Segment preview

You can now switch off the Paint & Segment preview temporarily by simply holding down the "O" key. This quick transition enables immediate comparison between gray values and segmentation preview, allowing you to evaluate the segmentation visually in real-time and paint the remaining voxels waiting for accurate classification.

Auto-color for ROIs

ROIs created by Paint & Segment are automatically colored based on their labels, facilitating an effortless differentiation after segmentation. This not only enhances visual clarity of segmented classes in your 2D view, but also renders them in 3D.

Equivalent diameter for P 202

We've listened to your needs and incorporated the commonly used parameter "equivalent diameter" from the P 202 standard into VGSTUDIO MAX. Now, you can further enhance your porosity analysis with the max equivalent diameter tolerance.

Visualize P 203 freeform ROI tolerance status

Managing multiple ROIs in P 203 just got easier. Instantly view the tolerance status of each ROI, color-coded in red or green. This ensures immediate recognition of out-of-tolerance ROIs and their corresponding location in the part, enabling smoother correlation and analysis.

Improved VGEasyPore relative mode

We've improved the relative mode in VGEasyPore to enable easier and more precise pore detection. This updated version* empowers precise pore identification with locally adaptive results, all by simply setting a contrast percentage without the need to manage absolute gray values. The default contrast value of 20% is suitable for most datasets, often eliminating the need for any further adjustments.

*The previous relative mode is still available, ensuring you can still seamlessly run existing analyses and VGinLINE jobs.

Faster VGEasyPore

VGEasyPore now runs up to three times faster on datasets with many small potential indications**. This significant performance boost will save your valuable time when working with noisy data, making your process more efficient than ever before.

**While the voxel count and number of smallest indications may differ to past results due to the new voxel-exact calculation, the volume and shape features of the detected indications in the results table is not affected and will not change.

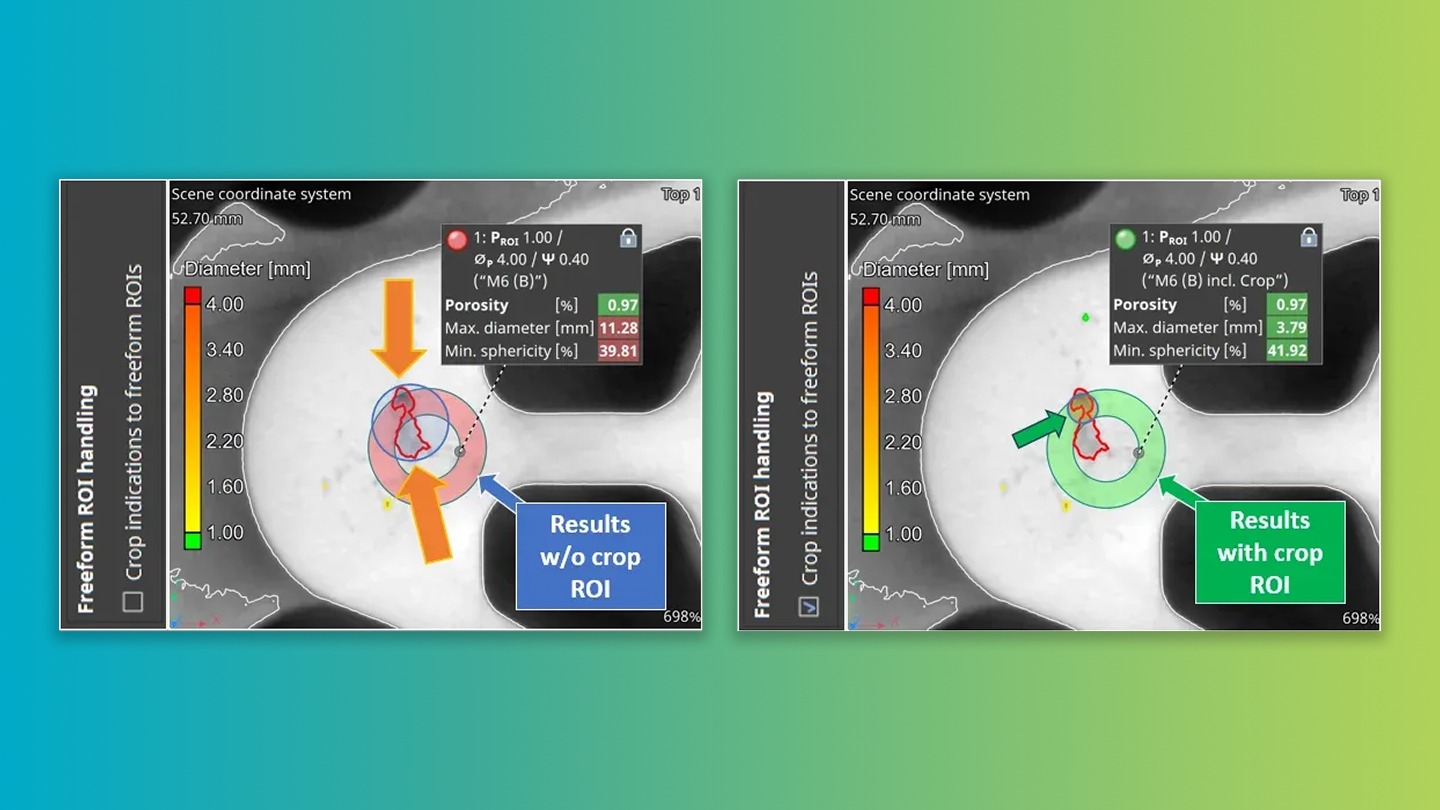

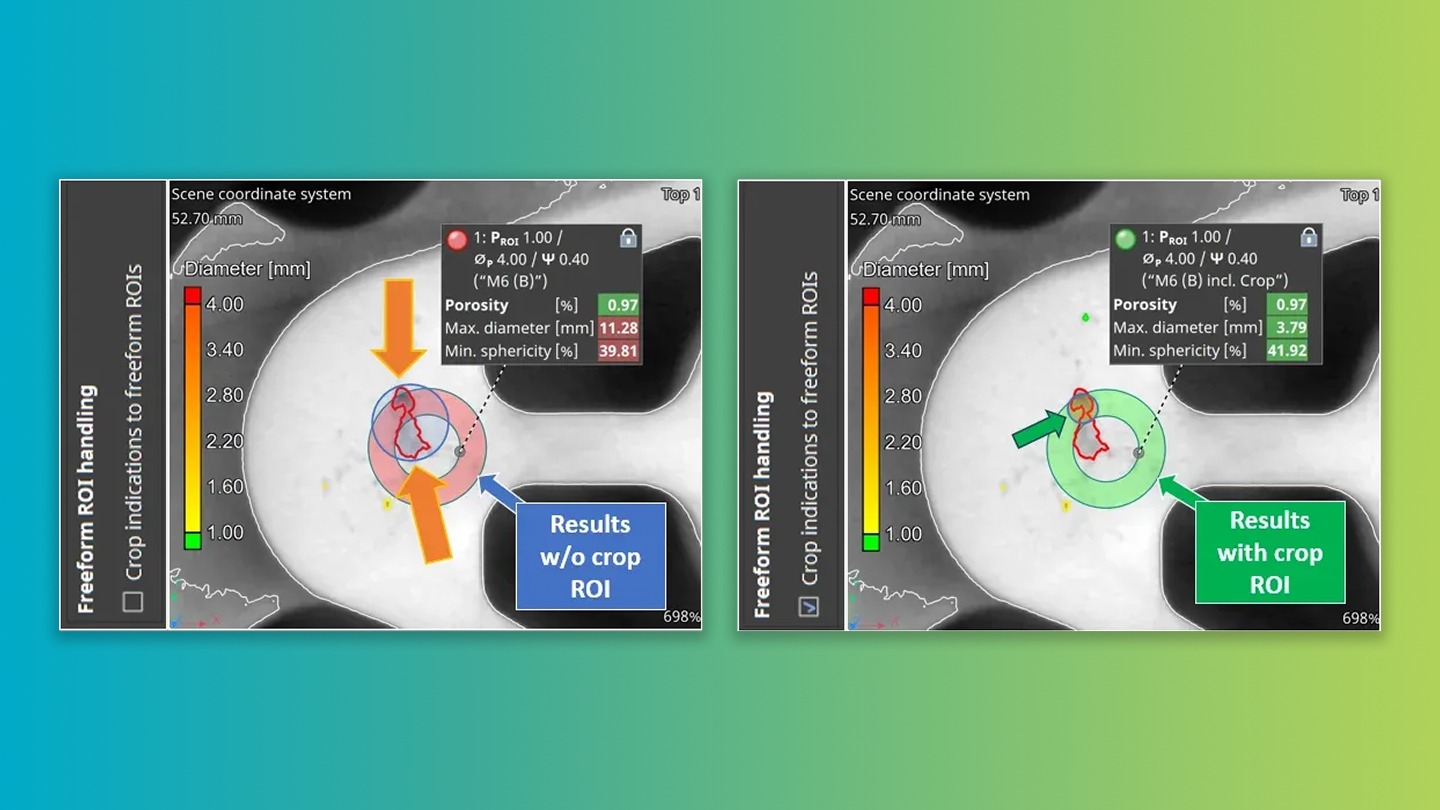

With the new function "Crop indications at freeform ROI edges", you can now decide whether pore feature parameters should only be evaluated within the ROI boundaries or, if desired, also within and beyond them. This applies in particular to detected pores that are intersected by the ROI boundaries and has a huge impact on the results of the porosity analysis on an ROI toleranced with a P 203 porosity key.

The new setting enables a foundry-related, application-specific customization of the porosity evaluation with regard to the application of the P 203 porosity key code to selected ROIs to avoid false-negative analysis results*.

*It is also the new default, but if you rely on the old behavior, you can disable it for newly created analyses. Existing analyses and evaluations will have it already disabled, to maintain consistency with previous versions.

Read the basic requirements below or download the PDF for the complete system requirements for VGSTUDIO MAX.

Windows 10* Enterprise 64-bit

Windows 10* Professional 64-bit

Windows 11 Enterprise 64-bit

Windows 11 Professional 64-bit

Ubuntu 22.04** LTS 64-bit

*VGSTUDIO MAX will no longer support Windows 10 as of version 2025.3

**The following add-on modules or functions are not available under Linux: “CAD Import,” “PMI Extension for CAD Import,” performing an OCR analysis, reporting via Excel, exporting AVI/ASF movies, and importing newer versions of the NSI format (*.nsihdr).

Minimum: x86-64 CPU with instruction set SSE 4.1. ARM processors are not supported.

Recommended: Performant Intel or AMD multi-core processors, e.g., Intel® Core™ i7 or i9 or Xeon® Gold processors with 3 GHz or higher.

Minimum:

VGSTUDIO MAX requires a minimum of 4 GB of free memory. However, the actual free main memory needed for creating or loading a complete project will usually be significantly higher, since it depends on the size of the data set and the analyses to be performed.

Recommended for professional use:

- 16-bit data set with 1024 slice images. Slice image with 1024 x 1024 pixels. 1024³ = 2 GB of data

=> Visualization only: minimum 4 GB free memory

=> Data analysis: 8–16 GB free memory - 16-bit data set with 2048 slice images. Slice image with 2048 x 2048 pixels. 2048³ = 16 GB of data

=> Visualization only: minimum 32 GB free memory

=> Data analysis: 64–96 GB free memory - For performing advanced analyses, such as transport phenomena or structural mechanics simulations, a free memory of 50 GB or more is recommended.

- Typical for industrial use with data set sizes as in the examples above (2 to 16 GB) is a PC with at least 64 (for one data set) to 512 GB RAM (for multiple data sets). Higher RAM clock speeds are recommended.